About Z.S.R

Z.S.R International Group(HONG KONG)CO., LIMITED,is a one-stop Custom molded silicone products manufacturer and silicone molding solution provider founded in 2007.It is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX 4P, BRC, FCCA, NBCU, and Disney FAC-020760. We support our partner silicone products from idea to market. We are the partner of choice for leading silicone products brands and retailers. The silicone products what we made suitable for various industries, including consumer,industrial,medical.Recognized for delivering innovative custom-molded silicone products, manufacturing expertise, and technical solutions to them.

Z.S.R Custom Silicone Products service

Good business comes from a focus on

- Quality Management

- Customer Satisfaction

- Continuous Improvement

At Z.S.R we make these 3 items the core of our business and spirit. We work with products development companies, supply chain management, brands, chain store, retails to offer customized, private label molded silicone products. We are honored to provide high-quality silicone products and molding services to more than 500 clients from 30+ countries in the world, they are active in the:

To ensure that customers can enjoy a steady supply, quality assurance, and punctual delivery.

Are you looking for a molded silicone products manufacturer? Please contact us today to get your design quote. From 3D CAD modeling to prototyping to Mass Silicone production molding, we will help you along the way!

How to work with ZSR?

From initial silicone product design to final delivery, we provide comprehensive one stop services. You do not need deal with multiple suppliers or coordinate different aspects of the project yourself. Simplify the entire process and save your valuable time.

Confirm requirement

Choose the existing style or Design 3D Drawing(stp) according to you needs and get our Engineer Support

Cost Evaluation

Z.S.R offer the quote according to your design, quantity, color and other specific requirements.

Prototype and Tooling

Once you approve the quote and make the payment, production will begin from prototype, tooling.

Mass production

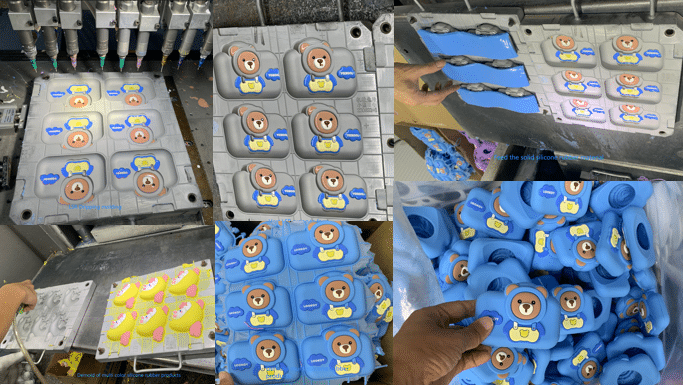

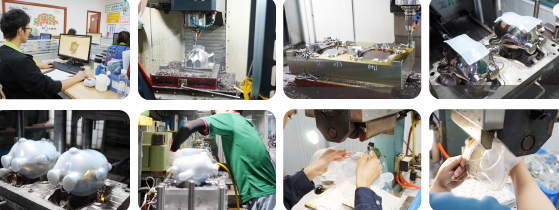

Prepared Silicone Material according to your material selection and mixed, molding, Demold And First Quality Inspection, Deflash, Trimming, Secondary vulcanization And Branding Packaging.

Quality inspection

Z.S.R perform multiple rigorous tests throughout the manufacturing process to ensure that the quality of the product meets expectations when it leaves the factory.

Afterservice

Z.S.R established and improved the after-sales system, timely and comprehensive grasp of customer information, and achieved timely service contact and coordination to slove the aftersevice problem your ocured.

Z.S.R perform multiple rigorous tests throughout the silicone products manufacturing process to ensure that the quality of the silicone product meets expectations when it leaves the factory.

Why Choose Z.S.R as Silicone products Supplier

16 years’ experience

Rich market experience makes us familiar with the products and market requirements of different wholesale customers

Safety Factory

Z.S.R is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney

The third parties and the world’s Fortune 500 companies have helped you verify Jution silicone’s factory strength and reliable for you.

100% safe raw material

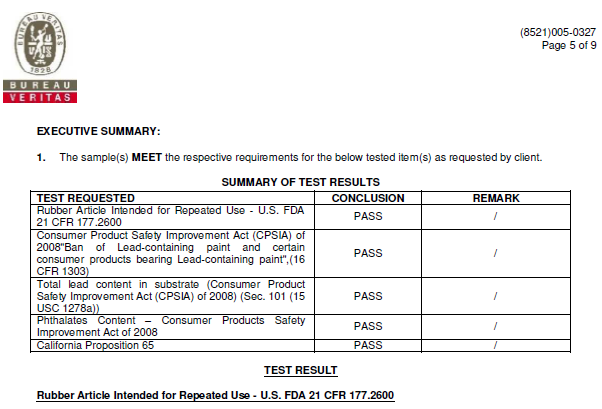

Food-grade high-quality silicone materials, 100% high-purity food-grade platinum silicone which are safe and environmentally friendly, non-toxic and harmless. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

One Stop Service from design to whole process manufacturing

Z.S.R have the own mold workshop and mold design engineer, Complete post-processing workshop own Secondary Vulcanization workshop, Laser engraving workshop, pad printing, screen printing, painting workshop, package workshop. All the silicone products cycle under one roof- from designing products & building tooling to launching into full-blown production.

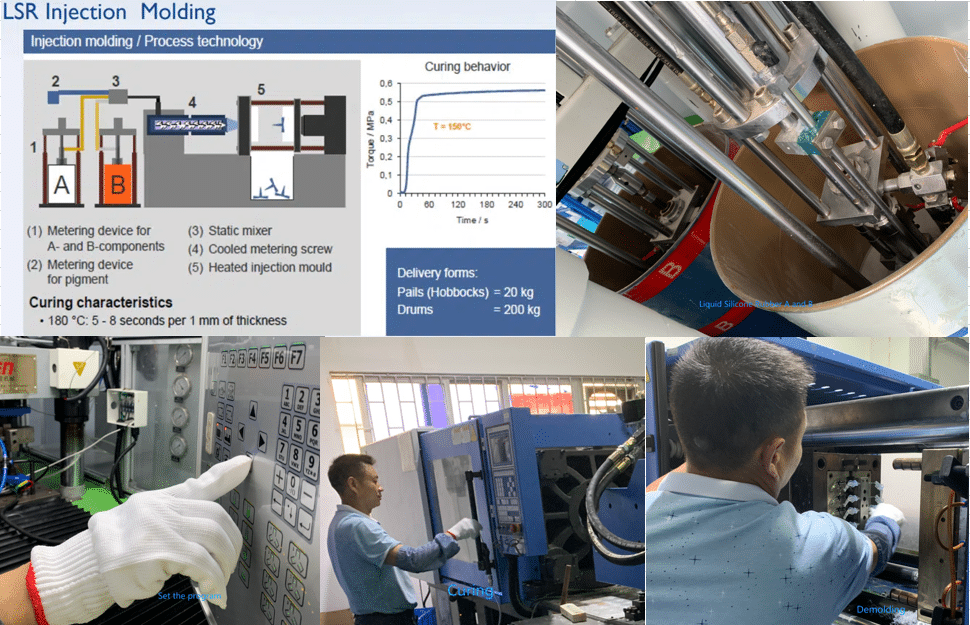

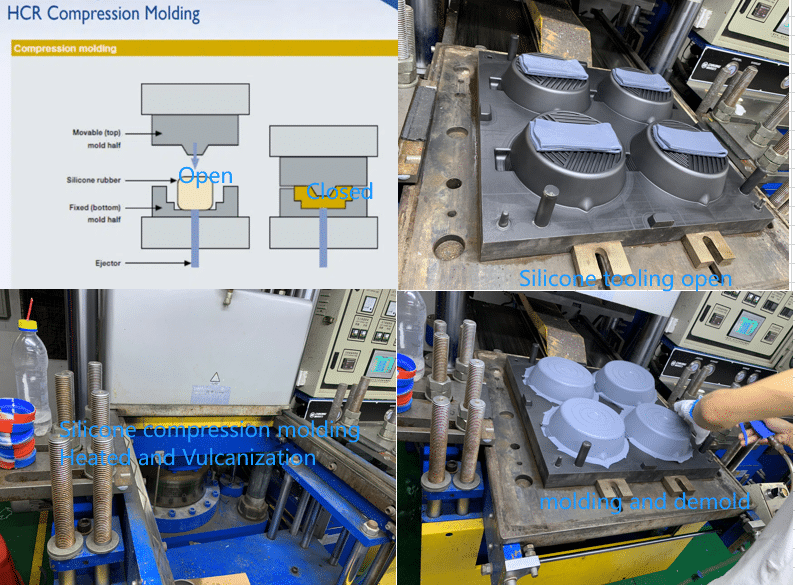

You will reduce the risks of working with multiple vendors, save your time to market & lower costs.32 sets of silicone compression molding machines, 6 sets of liquid silicone rubber molding machines, with 8 sets of co-injection silicone molding machines with Manufacturing 100,000-150,000 pcs daily and export to 40+ countries.

Z.S.R complete OEM/ODM Services provides a variety of wholesale customization services to suit customers’ different designs and product needs. Customized service for design, color, packaging.

Strict Quality Control

Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the qualified Silicone products as the prototype they approved before mass production.

Safety products

The cups what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV

Trade Show and Customer Visit Gallery

As the Consumer Silicone Products OEM Manufacturing Brand Behind The Brands. We specialize in OEM & ODM manufacturing to create customized silicone products for our customers around the world.We attend different fairs from Domestic to Oversea. The Fair what we attend from Baby products shows such as CBME to gifts show in HK. We also attend the home and houseware show in USA in 2019. In addition, as a OEM Manufacturing brand. We welcome our partner to visit us in our factory.