Silicone Medical Parts solution

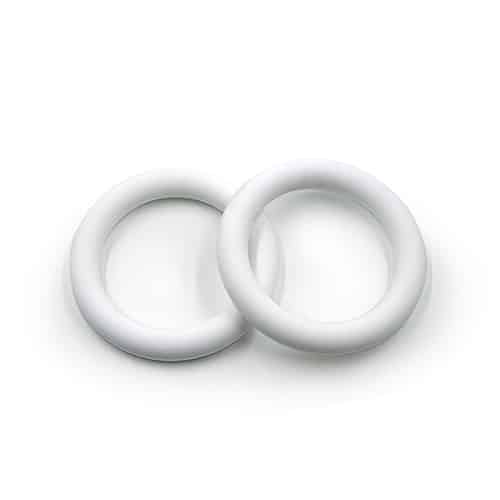

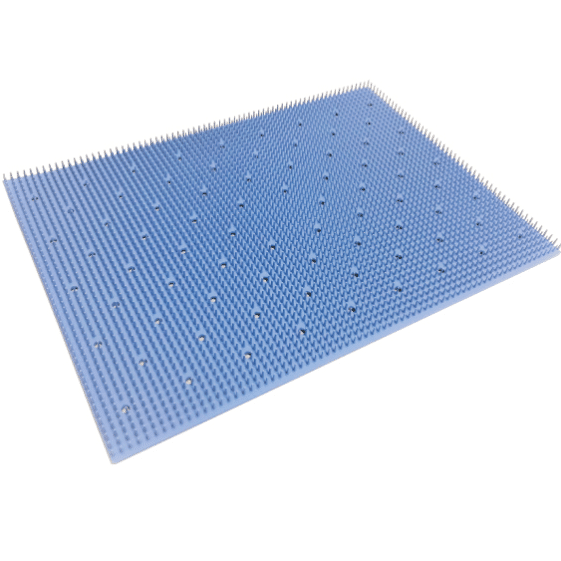

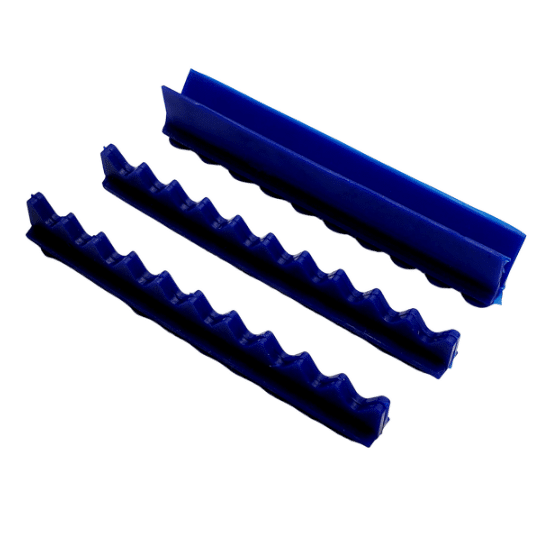

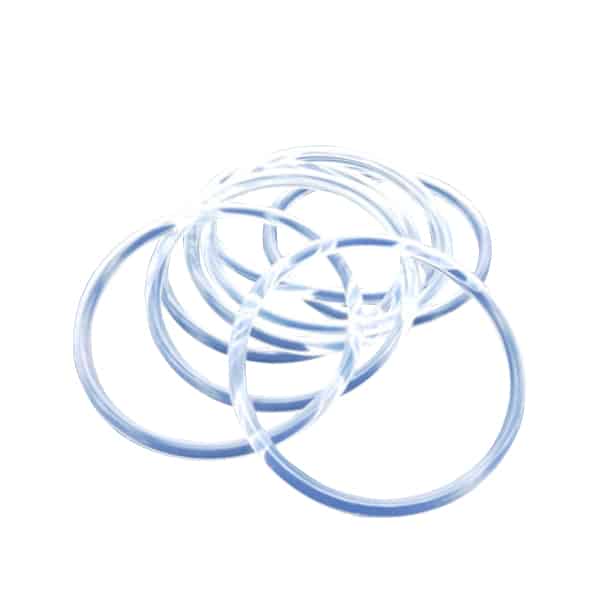

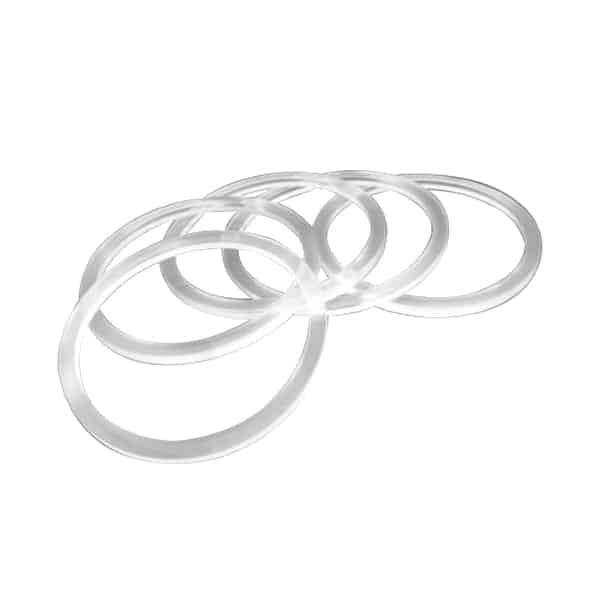

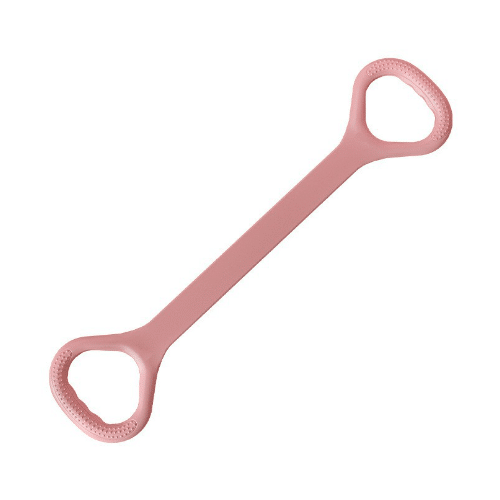

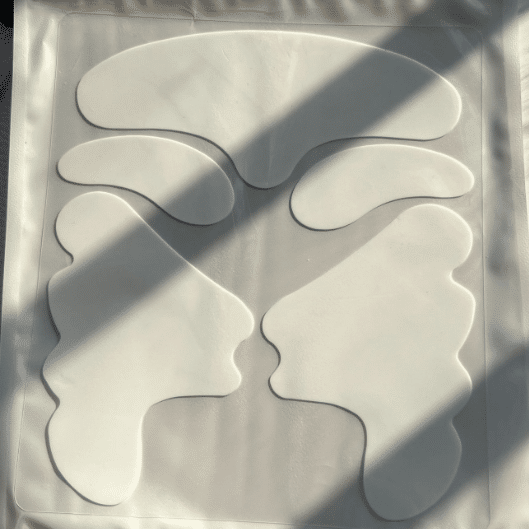

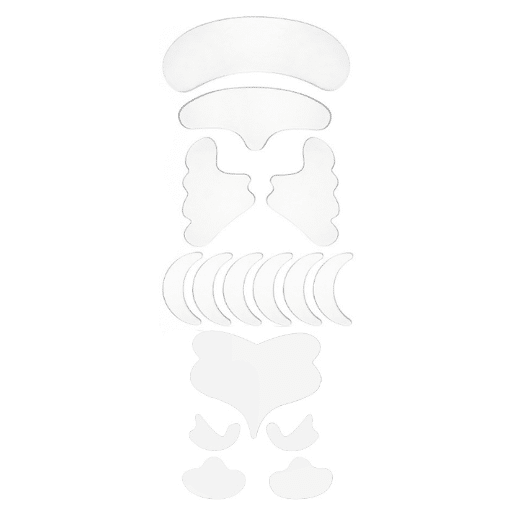

As One-Stop Supplier silicone medical components manufacturer And medical-grade Silicone Molding Solution From Idea To Market.Our facility meets ISO and FDA standards, ensuring safe, clean, and scalable OEM/ODM solutions.We work with Owner, product development manager,product manger, product designer or engineer together custom silicone Medical parts material,structure,shape, size, function, logo, color, packaging and label for their medical devices project.Our precision silicone medical molded parts include:

At Z.S.R, we respect the confidentiality of our clients, which is why we don’t display all product details due to NDAs.

Silicone Medical Products

Our commitment to quality is unwavering.

Contact Z.S.R OEM silicone medical parts supplier with years to the global healthcare industry.

100% FDA or LFGB standard

All our silicone medical parts are made using 100% LFGB and medical standard silicone material (Liquid silicone rubber or solid silicone rubber) ensuring they are Medical-grade silicone (USP Class VI, FDA, ISO 10993),Non-toxic, hypoallergenic, and latex-free,Sterilizable (autoclave, EO, gamma),Heat and chemical resistance,Tight-tolerance, cleanroom production available.

Innovation and collaboration are at the heart of what we do. Our team of engineers and chemists work closely with your team to meet your medical device’s unique requirements.

Let Z.S.R be your go-to partner for all your silicone molded medical parts needs to Empowering Your Medical Device Project Success.

Contact us today and let’s create something amazing together!

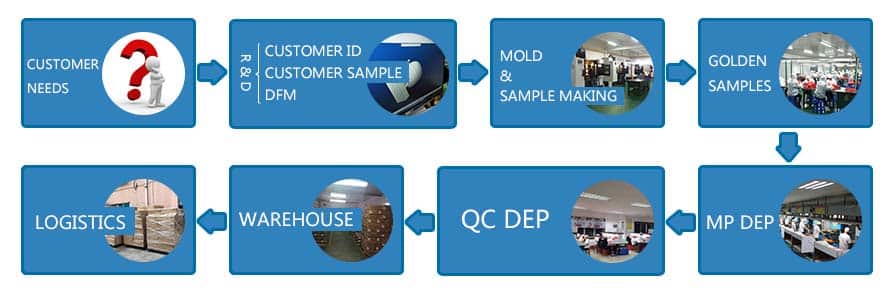

Custom Silicone Medical Products process

Z.S.R Group Makes Custom Silicone Medical Parts to empowering their project’s success.

As the OEM Brand behind the brands, we collaborate with various industries to create custom silicone medical molds and other silicone medical products.

As a silicone products fabrication factory.We work with brands, wholesalers, retail chains, and product development companies, offering silicone medical products OEM and ODM solutions worldwide for over 10 years. With extensive experience in silicone product technicalities, we’ve customized more than 10,000 silicone product projects for our partners.

Such as silicone molds, silicone brushes, silicone sleeves, silicone mats,silicone cups,silicone bowls,etc.

How To Order Custom Silicone Medical Products

Z.S.R Group: As a silicone molding company specializing in Silicone Medical Parts, we provide you with high-quality, custom-made products tailored to your project requirements.

We assist you throughout the entire process, from part and tool designing, mold manufacturing, silicone medical part production, to final delivery as per your specifications.

Here’s the path to customized silicone medical parts for our customers:

Step 1: Custom Needs And Budget

Determine your company’s needs and budget for an order. This will help you decide on the type of silicone medical parts to purchase and their level of personalization. Once your budget is finalized, contact Z.S.R Group. We can guide you in the right direction to create the perfect silicone medical parts.

Step 2: Customer Idea, Design, Sample

Provide us with a CAD file containing your Silicone Medical Parts project’s specifications, and we’ll handle the rest. If you don’t have a CAD file, we can create a design from a hand-sketch, drawing, picture, or samples, and develop a silicone medical part prototype mold based on that.

Step 3: Prototype Tooling To Get The Silicone Parts Samples

For new silicone medical parts development, we can create a prototype to check fitment, functionality, and aesthetics before investing in mass production tooling. Once satisfied with the prototype, proceed with silicone medical part mold development. This minimizes risk and allows for market testing with low investment. Additionally, it’s easier to make design changes at the prototype stage than after completing mass production tooling.

Step 4: Mass Production Tooling

After approving the silicone medical parts samples, we’ll develop mass production tooling based on sample communication in our in-house tooling workshop.

Step 5: Silicone Molds And Mass Production

You can start with a small order (low MOQ of 3000 pcs) to test the market before proceeding with larger quantities. We also create cost-effective silicone medical parts molds (AL Material) based on your project requirements.

Once the silicone medical parts are approved, we start processing and producing the merchandise. All silicone medical parts undergo trimming and QC in our dust-free workshop, with 100% QC performed before packaging. We guarantee well-organized operations and timely delivery of custom-made silicone parts per your specifications.

Step 6: Storage And Delivery

We offer an independent warehouse for medical parts storage before shipment, if needed. The final stage—delivery—is always exciting for us as we strive to serve our customers. After completing production, we can arrange pickup, shipping, or delivery based on your location and preference.

Certification

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.