Custom Silicone Leathers manufacturer/ eco-friendly leathers alternative Solution factory

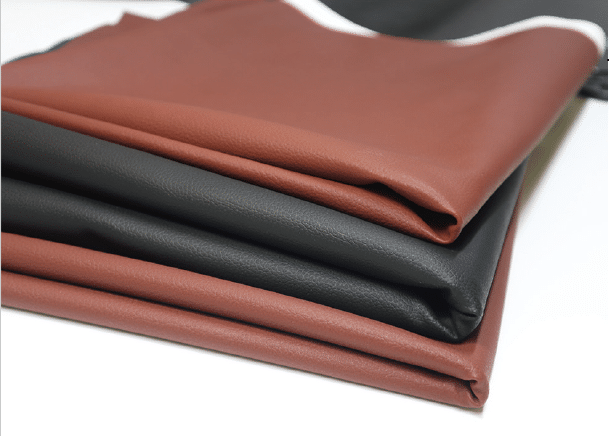

Z.S.R Group is a leading silicone leathers manufacturer and custom silicone leathers molding solution provider in China help more than 10.500 silicone projects success in the past 16 years.Z.S.R team work with product fabric selection designers, product developers, R&D engineers, product managers,Brand owners together design and make the custom silicone leathers in an assortment of performance,base backing fabrics ,colors,texture,thickness to empower their project’s success.

Z.S.R Group customized silicone leather services, including customization of base backing fabric layer, color, texture, application, thickness,size, logo, pattern printing, branding, packaging, and technical support related silicone leathers to fit your unique project needs. These silicone leathers are suitable for industries such as Garment textile,Upholstery,building material, Vehicle,Seating,Packing, baby , marine, furniture fabric, automotive,Aviation medical and healthcare, sports, 3C electronics , interior decoration,industrial manufacturing, and Vegan fashion.

Silicone leather customization details

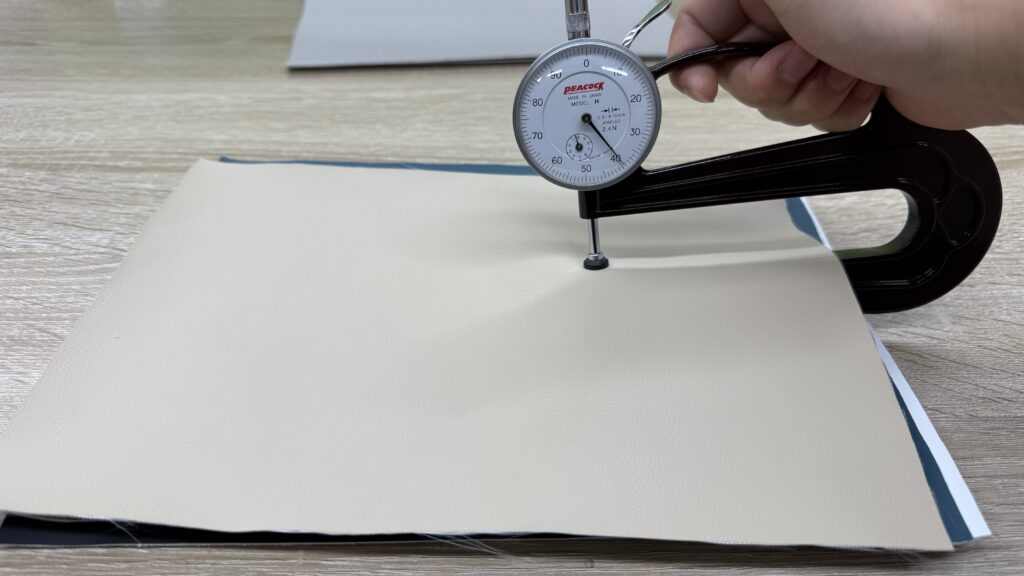

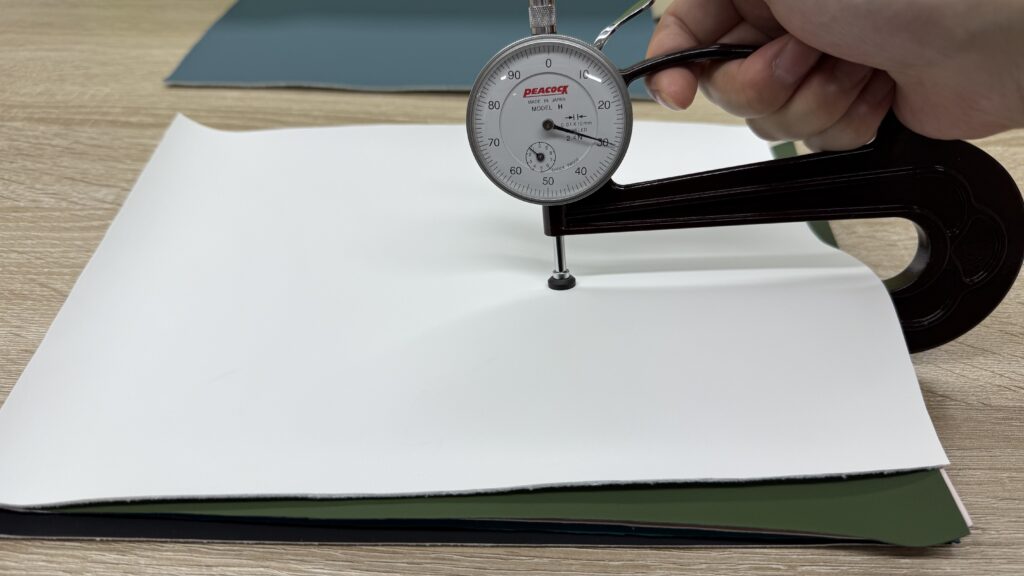

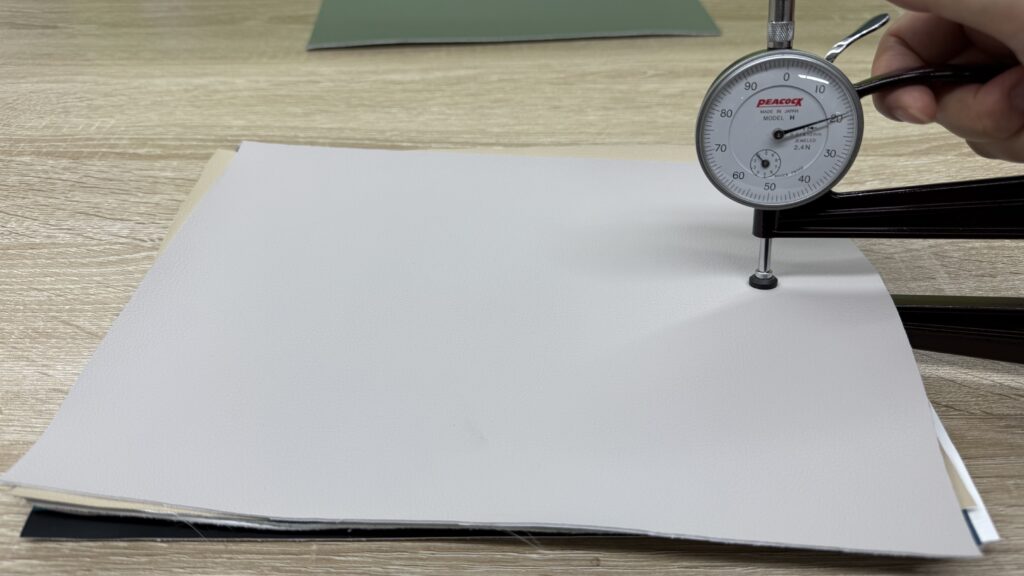

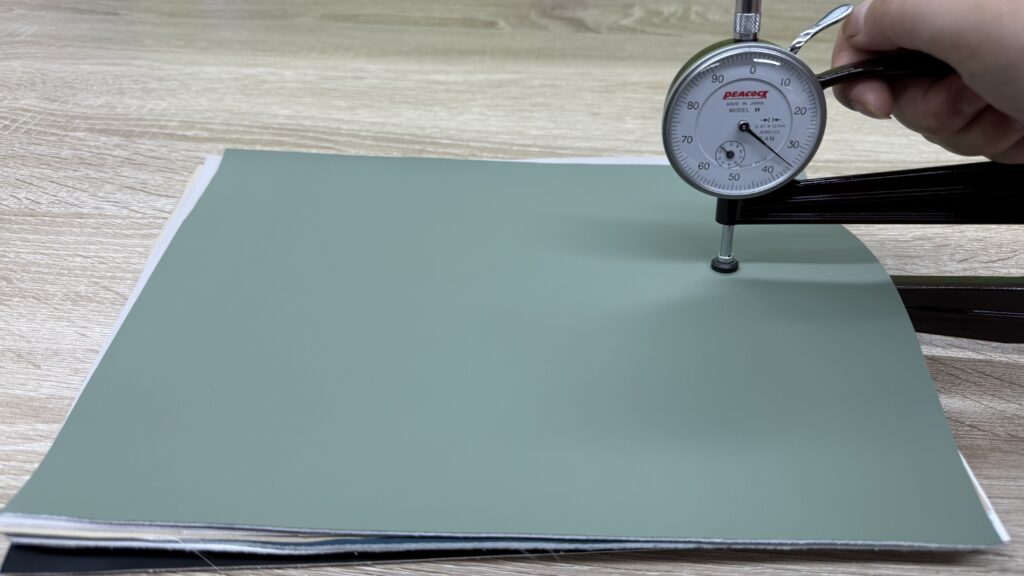

silicone leathers thickness

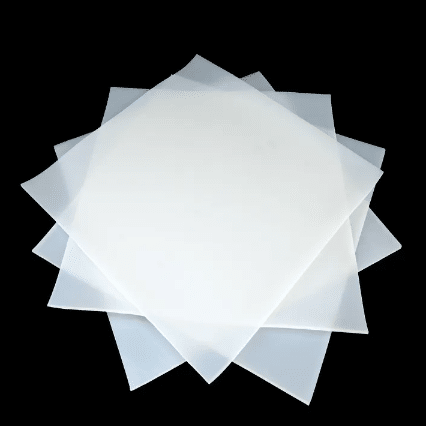

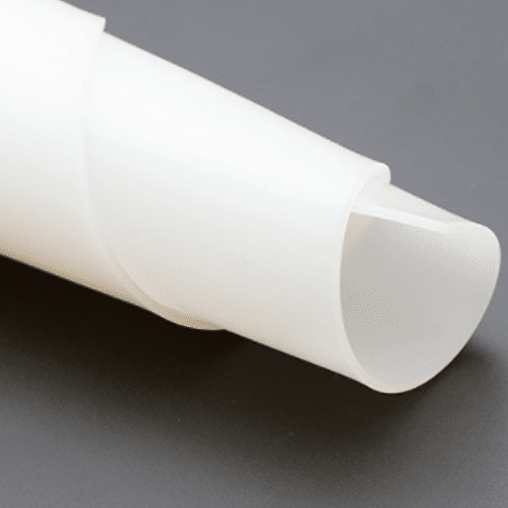

You can custom the silicone leathers thickness and embossed and debossed logo, texture by use the different tooling. The custom silicone leathers texture :Grains – smooth, leather,or other styles ,Textures – smooth or tacky (grip) texture . You can make is Lychee/plain/carbon fiber/crocodile/star/kid skin etc.

All the silicone leathers that your custom is Food Grade Silicone, BPA-free, Eco-friendly, and Heat-resistant.

The custom silicone leathers width can design from 1370MM-1470MM, the thickness that we can make is from 0.4-4.2 mm.

thickness 1.65MM

thickness 1.65MM thickness 0.39MM

thickness 0.39MM thickness 0.44MM

thickness 0.44MM thickness 0.54MM

thickness 0.54MM thickness 1.3MM

thickness 1.3MM thickness 1.19MM

thickness 1.19MM thickness 1.35MM

thickness 1.35MM

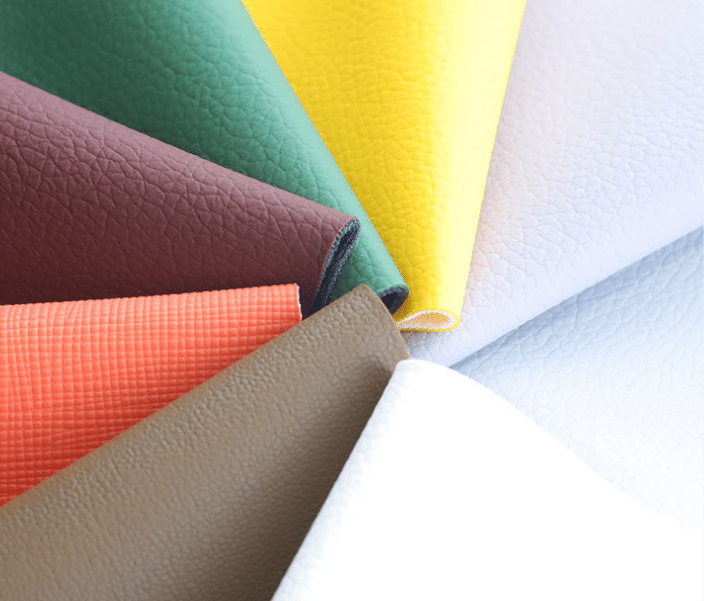

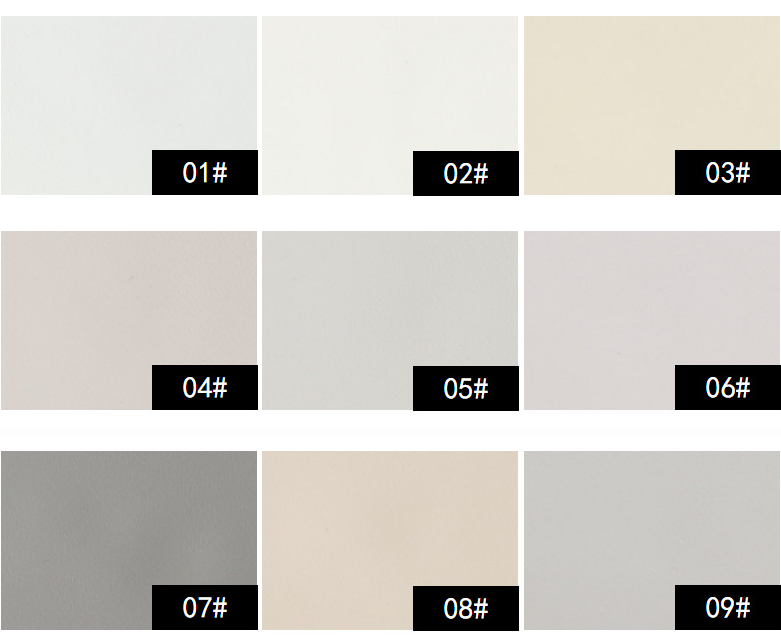

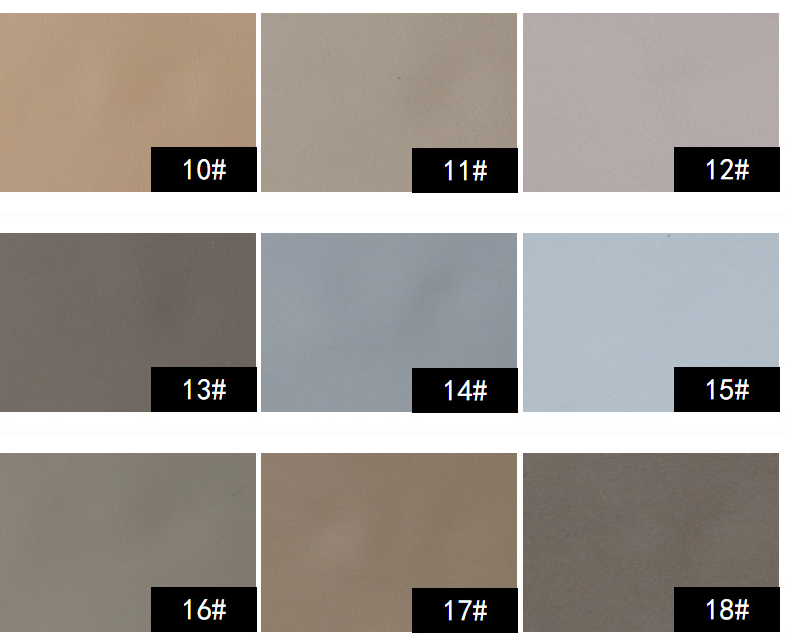

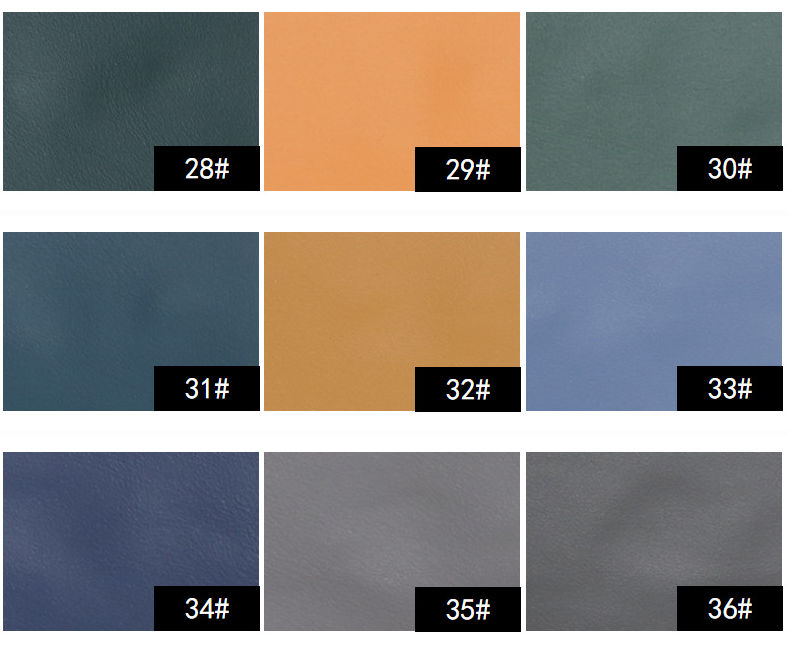

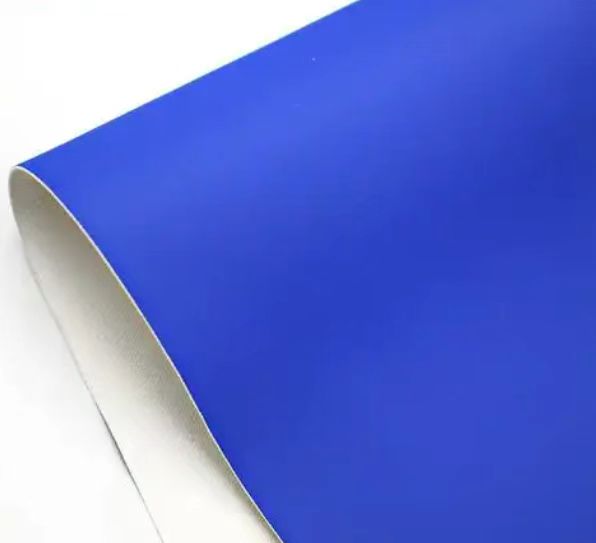

Custom silicone leathers Color

You can customize the size color according to the Pantone book. Our usual colors are white, green, orange, grey and milk white ect.

ZSR own the printing workshop for printing your pattern,design and logo by Laser Engraving, Silk Screen printing, UV printing with flexibility design for your artwork printing.

See the blog to know more about it: Silicone Printing Guide

Custom silicone leathers brands, labels and package

Z.S.R also provide customized packaging solutions for manufactured silicone leathers. We offer one-stop services such as helping customers to design, develop, assemble and inspect the packaging, ensuring the appearance of finished products and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished products can delivery to the clients with the highest quality.

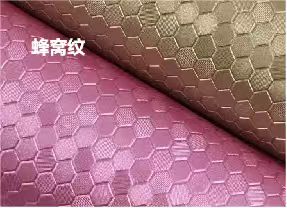

Custom silicone leathers texture

Z.S.R produce and supply wide range of customized options, including color and surface textures. You can choose the following texture silicone leathers to fit your projects.

Bark Texture silicone leather

Bark Texture silicone leather Honeycomb pattern silicone leather

Honeycomb pattern silicone leather Crocodile pattern silicone leather

Crocodile pattern silicone leather Carbon fiber pattern silicone leather

Carbon fiber pattern silicone leather Weaving pattern silicone leather

Weaving pattern silicone leather Pinhole Grain Pattern silicone leather

Pinhole Grain Pattern silicone leather Snake texture silicone leather

Snake texture silicone leather Plain silicone leather

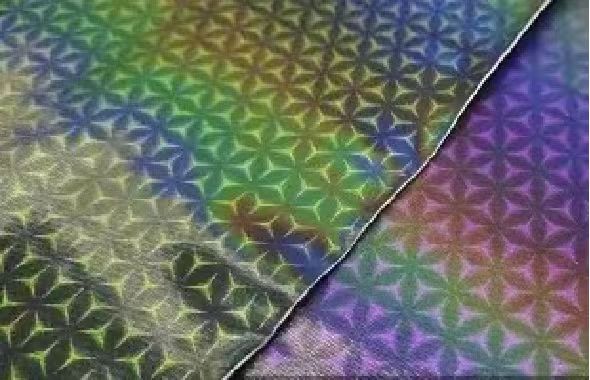

Plain silicone leather Optical iridescent texture

Optical iridescent texture Gravel Texture silicone leather

Gravel Texture silicone leather lamb pattern silicone leather (2)

lamb pattern silicone leather (2) Cloth pattern silicone leather

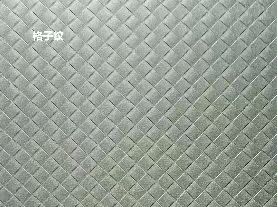

Cloth pattern silicone leather Diamond pattern silicone leather

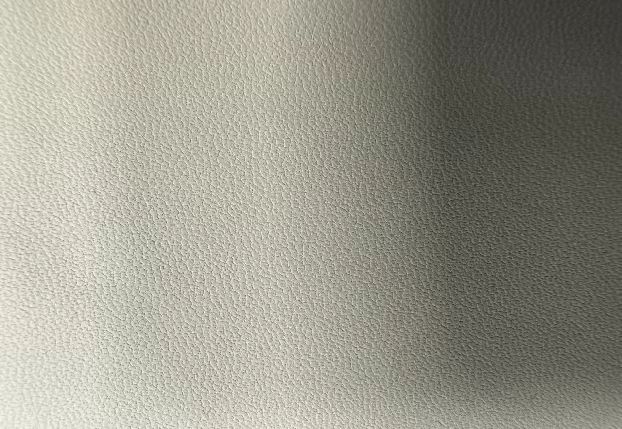

Diamond pattern silicone leather Nappa silicone leather

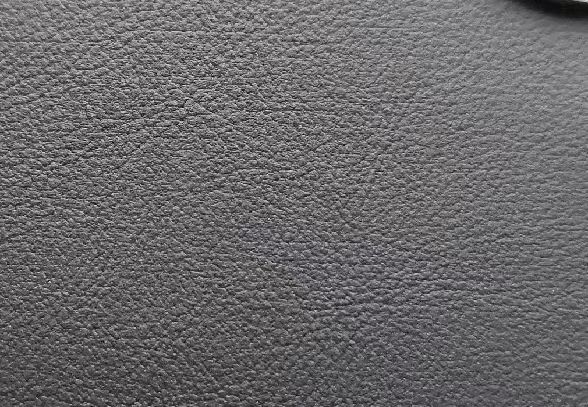

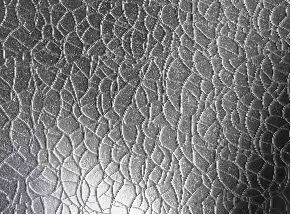

Nappa silicone leather Lychee texture silicone leather

Lychee texture silicone leather Oil wax pattern silicone leather

Oil wax pattern silicone leather kidskin silicone leather

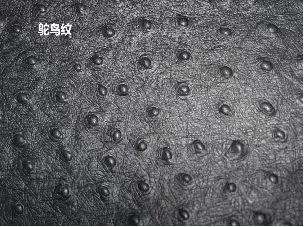

kidskin silicone leather Ostrich pattern silicone leather

Ostrich pattern silicone leather Napa silicone leather

Napa silicone leather Hami Melon pattern silicone leather

Hami Melon pattern silicone leather Plaid silicone leather

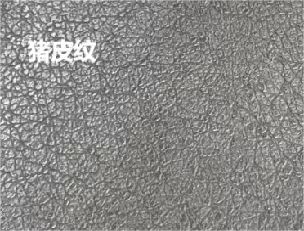

Plaid silicone leather Pigskin silicone leather

Pigskin silicone leather

silicone material and base backing fabric layer

Z.S.R offer Custom silicone leather service from Custom the silicone raw Material and base backing fabric layer:

Our expert Engineer will recommend the most suitable raw materials according to your requirements (e.g. Platinum Liquid silicone rubber and base fabric layer, tensile strength, tearing strength, etc.; different standards such as FDA and LFGB or medical grade or different Brands. Different base baking fabric layer such as Microfiber cloth/imitation lint cloth/flannelette cloth according to your application). The fabric can directional stretching or no elasticity. Flame resistance standards,Durability other specific characteristics. Also it is feasible to add an antimicrobial agent to the raw materials for the product to reach the sterility standard.

Silicone leathers Fabric Applications

As a silicone leathers fabrication factory in China. Z.S.R’s team cooperates with the leathers /Fabric wholesalers,Fabric stores,Fabric products manufacturers in hot sales,support for the following products manufacturing:

Car interior

Car Seats, steering wheel, instrument panel, Dashboard and center console, Car door panels and armrest interiors, ceilings and carpets

Features: Safety, No VOC, Flame-retardant ,Soft-touch, UV-stable, Excellent durability, High and low temperature resistance: -40℃~200℃ stable performance.

Case: BYD looks up to U8’s silicone seats, HiPhi X , Wenjie M9, Leapmotor C10, Smart Elf #1 all use silicone leather for car interior.

Outdoor & Recreational

Outdoor furniture such as outdoor sofas, outdoor tables and chairs. Tents, folding chairs, mountaineering bags, Yoga mats, fitness gloves, cycling seats. Diving suit accessories, life jackets, Baby carriers, picnic mats, Yacht interiors, golf bags

Features: Anti-UV aging, anti-slip and shock absorption, easy to clean sweat stains, anti-salt spray, quick drying, non-toxic and chewable, dirt-resistant, lightweight, waterproof and wear-resistant, luxurious touch

Case:

The North Face: Use silicone leather for wear-resistant parts of mountaineering bags to replace PVC-coated fabrics.

Nike, Under Armour, Adidas use them for their shoes and bags from 2022.

Yeti: Use silicone leather for sealing strips of high-end cooling boxes to improve resistance to freezing and cracking.

Lululemon: Develop silicone yoga mats that are both non-slip and easy to clean.

Vegan Fashion

100% zero animal ingredients, environmentally friendly production, Extreme durability tear strength ≥40N/mm², Weather resistance: stable at -30℃~150℃, Self-cleaning surface

Case:

Stella McCartney: Silicone Leather Alter Series Handbag

Piñatex (Collaboration): Pineapple Fiber + Silicone Composite Leather Sneakers Adidas

Bolt Threads Mylo™: Silicone Mushroom Leather Wallet

Matt & Nat’s: Children’s Schoolbag

Industrial

Silicone mass production mats for High temperature production lining. Reactor gaskets and acid delivery pipes are resistant to hydrofluoric acid corrosion, Transformer insulation sleeves and cable protective layers are arc-resistant.Aseptic production line conveyor belts and filling valve diaphragms. Ships and oceans submarine cable sheaths, anti-biological attachment covers, ship seat covers, anti-salt spray + anti-barnacle attachment.

Features: Extreme environment tolerance, working temperature -60℃~250℃ (short-term resistance to 300℃),Anti-aging, Suitable for outdoor industrial equipment (such as wind turbine blade protective cover).Chemical inertness & corrosion resistance, Can resist corrosive media such as 98% sulfuric acid and 40% sodium hydroxide. High tear resistance, Long wear life.

Case: STO use Silicone baking mat as the drying of antique wall tiles.

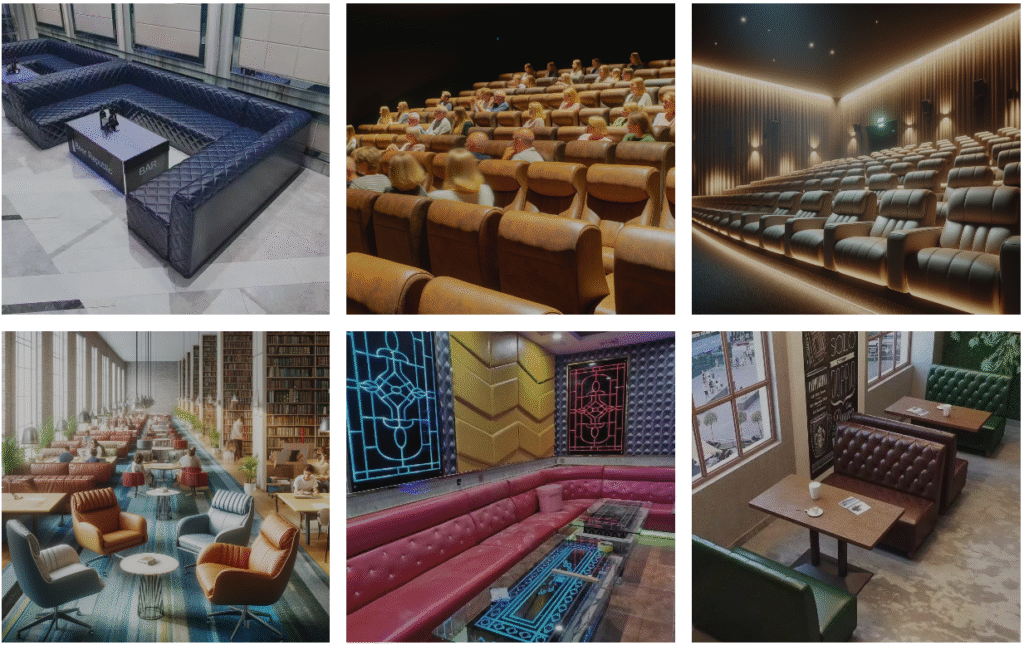

Commercial and Office

- Office space Office chairs, conference tables, reception desks Wear-resistant, stain-resistant, easy to clean, reducing maintenance costs

- Hotel/catering Restaurant booths, bar counters, guest room sofas Waterproof and mildew-proof, alcohol-resistant, suitable for high-traffic areas

- Retail space Luxury display cabinets, fitting room chairs High-end touch, enhance brand image

- Medical/education Hospital waiting chairs, school desks and chairs Antibacterial, easy to disinfect, meet hygiene standards

- Public transportation Airport seats, subway car interiors Flame retardant (EN45545-2), scratch-resistant, suitable for public facilities

Features: Strong durability: wear and scratch resistance: Martindale test ≥100,000 times, anti-UV aging, Anti-fouling and anti-seepage, easy to clean and maintain, suitable for high-traffic areas: stains such as oily pens and coffee can be easily wiped off, reducing cleaning costs. Environmentally friendly and healthy: zero VOC emissions meet WELL building standards and LEED certification. 100% vegan. The touch is close to genuine leather, and can imitate crocodile patterns, lychee patterns, etc., or customize corporate LOGO embossing (such as brand flagship store display wall). Color stability.

Case: WeWork: Some shared office spaces use silicone leather seats, reducing cleaning costs by 30%.

Hilton Hotel: Suite sofas use silicone leather, which is highly stain-resistant and increases customer satisfaction by 20%.

Tesla Showroom: The display stand uses customized silicone leather, reflecting the brand tone of technology + environmental protection.

Medical and Healthcare

Hospitals bed pads, wheelchair cushions Operating table covers, instrument tray pads Orthotic linings, prosthetic sockets Neonatal thermal mattresses, nursing pillows Anti-bedsore mattresses, walker handles

Features:

Biocompatibility & medical-grade safety, certified by ISO 10993-5 (cytotoxicity test) and USP Class VI, suitable for long-term contact with skin (such as wheelchair cushions, medical mattresses). Antibacterial and mildew-proof, reducing the risk of infection, resistant to chemical and biological disinfection, suitable for medical environments

Resistant to strong disinfectants: can be in long-term contact with alcohol, sodium hypochlorite (84 disinfectant), hydrogen peroxide (H₂O₂), etc., without degradation or discoloration. High-temperature sterilization: supports 121℃ high-pressure steam sterilization (EPDM rubber is only resistant to 100℃), suitable for reusable instrument coverings.

Comfortable and durable, improve patient experience, soft touch: Shore hardness is adjustable (20A-60A), mimicking the touch of human skin (prosthetic covers, baby monitoring equipment).

Case

Antibacterial operating table cover: developed in cooperation with Stryker of the United States

Smart pressure sensing mattress: Permobil of the Netherlands, silicone leather + piezoelectric sensor, real-time monitoring of the position of bedridden patients to prevent bedsores.

Sports

Mountaineering bags, ski boot bindings, weightlifting belts, battle rope grips, basketball/football surface coverings, wetsuit accessories, surfboard foot pads, bicycle seats, motorcycle gloves

Features:

Super durable, wear-resistant and tear-resistant, Martindale test ≥100,000 times (twice that of ordinary PU leather. Excellent weather resistance, UV resistance (QUV test 1000 hours without cracks), suitable for long-term outdoor use (golf bags, cycling seat cushions). Lightweight and high rebound, 30% weight reduction, good dynamic rebound, waterproof and breathable, non-slip and stable, antibacterial and mildew-proof, Staphylococcus aureus inhibition rate >99% (ISO 22196), avoid cross-infection in the gym. Zero harmful substances, passed REACH/ROHS certification, suitable for children’s sports protective gear.

Case:

Nike ACG Series: 2024 outdoor hiking shoes use silicone leather uppers, which are 25% lighter and completely waterproof.

Specialized Cycling Saddle: Honeycomb silicone leather surface, 50% more breathable.

Interior Construction

Background wall, cabinet door panel, elevator car, guest room headboard, conference room partition, front desk countertop

Nursing bed fence, barrier-free handrail, kindergarten wall, library chair

Features:

- Environmentally friendly and healthy, zero pollution: zero VOC release: GREENGUARD Gold certified, formaldehyde content <0.01mg/m³ (1/10 of the national standard), suitable for sensitive spaces such as maternal and child rooms, hospital wards, etc. Super durable and easy to maintain

- Long wear life: Martindale test ≥150,000 times (3 times that of high-end PU), suitable for high friction areas such as hotel corridor walls. One-click cleaning.

- Anti-aging: UV irradiation for 2000 hours, color difference ΔE <1, floor-to-ceiling window furniture does not fade.

- Outstanding design expression: 3D embossing technology reproduces the Hermès leather texture.

Case:

The luminous silicone leather curtain wall of Italian brand DKTN is only 2mm thick but achieves IP67 waterproof. The entire guest room of Aman Tokyo Hotel uses matte silicone leather ceiling, which has passed the highest level of JIS L 1096 mildew resistance certification.

Clothing and Accessories

Silicone leather jacket, leather coat, leather skirt, leather pants, belt, silicone leather gloves, silicone leather upper

Features:

Innovative and avant-garde technology, extreme functionality, 85% resilience in extreme cold (-50℃), no obvious fading after 1000 hours of desert exposure (80℃+UV), 100% structural integrity under deep sea pressure, no swelling after 48 hours of acid and alkali corrosion (pH1-13).

Environmental breakthrough: zero slaughter alternative, recyclable production system, 100% recyclable.

Case:

South Korea’s SKINX is developing a silicone leather jacket that monitors heart rate. South Korea’s clients made silicone leather upper Labor protection shoes for chemical and fiber factories.

Marine

Sofa/mattress covering and wall panels in luxury cabins, operating tables and seats in cockpits

Bar counters and chairs in cruise ship dining areas, waterproof roller blinds and anti-slip mats in bathrooms, wall panels and handrails in cruise ship public corridors

Features:

- Super corrosion resistance: passed 5000 hours salt spray test (ASTM B117): no blistering or fading on the surface

- Anti-mold and anti-bacterial guarantee

- Class 0 mildew resistance (ISO 22196): no mildew spots in humid cabins (humidity>80%) for 3 years

- Inhibition of Escherichia coli/Staphylococcus aureus>99.9%

- Fire safety

- IMO FTPC Part 8 certification: low smoke and non-toxic (smoke density <5), droplet distance is 0

- Self-extinguishing properties: oxygen index ≥32% (ordinary leather is only 21%)

Case:

Sunseeker 100Yacht: Silicone leather is used throughout the cabin and is certified by Lloyd’s Register (LR) as a “zero maintenance interior”

Royal Caribbean Icon-class cruise ship: Water Park seats have been used for 2 million times without wear and tear.

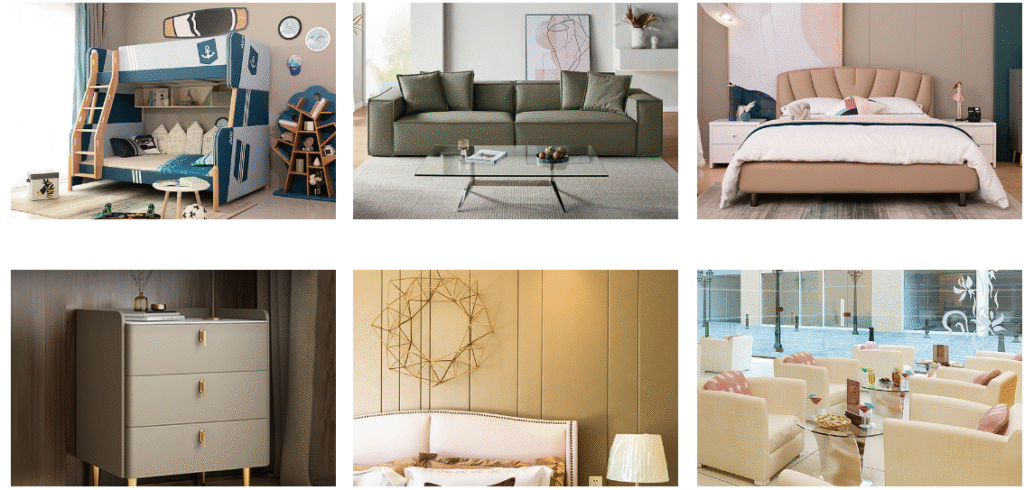

Furniture

Sofa, dining chair, office chair, children’s furniture, outdoor furniture

Features:

Eco-friendly and healthy, formaldehyde/VOC emission is close to zero, super durable, wear test: Martindale 200,000 times without damage, tear resistance, weather resistance: -40℃~150℃ stable. Easy to clean. New possibilities for design aesthetics, texture upgrade: 3D embossing technology: imitation crocodile pattern/lychee pattern, flame retardant, non-slip.

Case:

Poltrona Frau: New sofas for 2024 use self-healing silicone leather

Herman Miller: Upgraded version of Aeron chair.

Baby and Children products

Diaper changing mats, wash pads, stroller seat cushions, safety basket linings, dining chair seat cushions, crawling mats, cloth book covers, crib surrounds, pillowcases

Features:

FDA 21 CFR 177.2600 food contact material certification, No phthalates/BPA,antibacterial and mildew-proof, hydrophobic and oleophobic surface is easy to clean, milk stains and baby food stains can be wiped off .Upgraded durability, tear resistance: strength reaches 35N/mm², wear resistance test: Martindale 100,000 times friction without damage, comfortable experience, skin-like touch.

Case:

Stokke: The new Tripp Trapp dining chair features a silicone leather seat.

BabyBjörn: The portable changing table is ultra-light at 1kg.

Aviation

Cabin interior, business class seat covering, side wall panels, joystick cover, instrument panel anti-glare layer, escape slide connection, life jacket accessories, container anti-collision strip, pet cabin lining, easy to clean, avionics system insulation cover.

Features:

Perfect balance between ultralightness and toughness. Extreme environmental adaptability, -70℃~260℃ stable, UV anti-aging,10,000 hours of sunlight test, Safety compliance.

Case:

Airbus A350 cabin, with silicone leather side panels throughout the cabin

SpaceX manned Dragon spacecraft.

Electronic

Folding screen protective case, gaming phone case, TWS earphone case, laptop case, smart watch strap, TWS earphone, game controller case

Features:

The ultimate impact protection performance, 5 meters drop protection, 1.2mm thickness can resist key/nail scratches, environmental tolerance – 40℃~150℃ stable, thin and light (0.3mm-0.4MM), fashionable, environmentally friendly, and carbon footprint reduced by 52%. Security and function are optimized and integrated

Case:

Apple Vision Pro headset, DJI Avata 2, Sony PS5 silicone leather Controller Cover, iPhone 16 Leather Case

Fireproof

Building curtain walls-Class A fireproof insulation board coverings, high-speed rail compartment partitions, subway seats, substation cable sheaths, electrical cabinet insulation layers, petrochemical tank fire blankets, pipeline insulation layers, aerospace cabin fire curtains, engine compartment insulation.

Features:

Silicone leather is inherently flame retardant, with an ultra-high fire rating and the highest flame retardant standard of UL94 V-0. Low smoke and non-toxic smoke density Ds <5, which is 1/20 of PVC, zero release of toxic gases and extreme high temperature resistance, short-term temperature resistance of 1200°C.

Case:

Tesla Energy Storage Power Station: Megapack battery pack is wrapped in silicone fireproof leather, blocking the spread of thermal runaway in 5 minutes

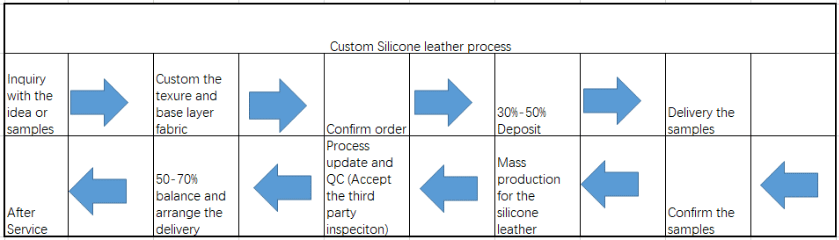

Silicone leather customization process

Create your business line of silicone leathers

100% FDA or LFGB standard

All the silicone leather that we made use of 100% FDA (USA Food Grade) or LFGB(EU Food Grade) Platinum liquid silicone material, BPA-free, environmentally friendly. Sustainable & Recyclable. All the silicone leather are easy-clean, quick-dry, waterproof, Antibacterial. Reduce stress and pollution on the environment.