Silicone Leather Fabric Material Manufacturer

Silicone leather is a silicone coated fabric recycle leather, referred to silicone skin, is a kind of innovative synthetic leather. Silicone faux leather can redefine high-performance fabrics through the best combination of leather textures and the superior advantages of silicone making a high-end alternative to PU/PVC.

ZSR silicone Leather

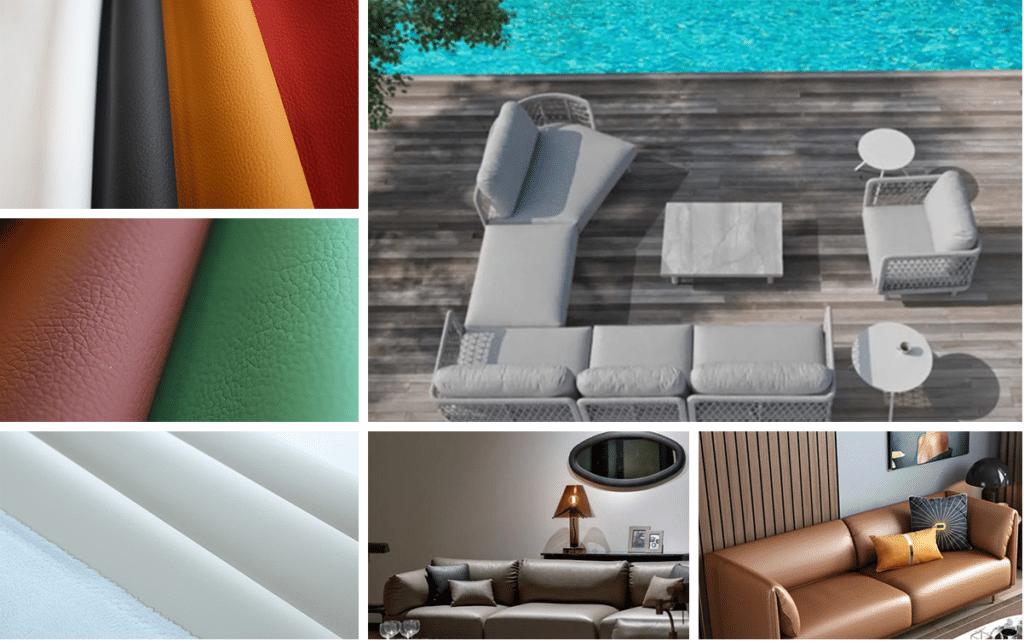

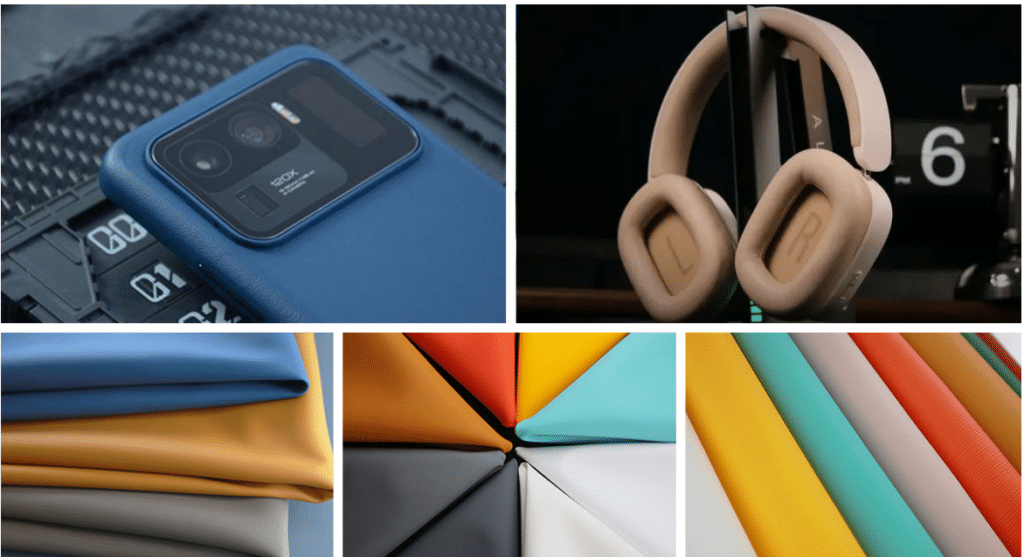

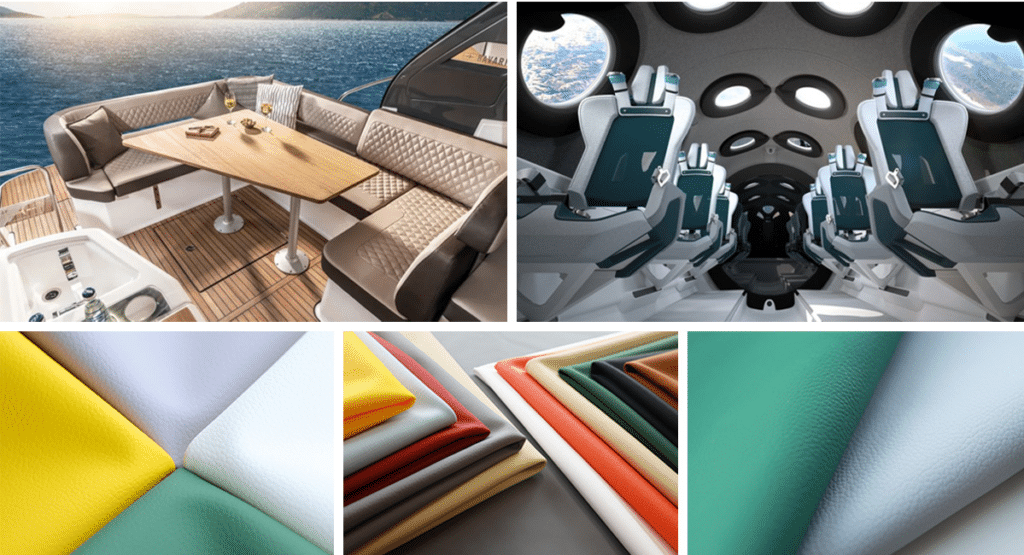

Z.S.R’s silicone leather has good wear resistance, high and low temperature resistance, UV resistance, waterproof, anti-fouling, oil and corrosion resistance. The surface texture of silicone leather is soft, comfortable to the touch, with good elasticity and flexibly, which can provide designers with a variety of product design options.

Z.S.R team work with the different industries product fabric selection designers, product developers, R&D engineer, product manager together designs and manufactures the Silicone leather fabric in design and functional requirements to empower their product’s project success.

Request A Quote

Custom Silicone leathers service

Z.S.R Silicone leathers are non-toxic and more durable than other materials like vegan PU leather or vegan faux leather due to the features of silicone, including weather resistance, temperature resistance, waterproofing, UV/Ozone resistance, durability, and easy to clean.

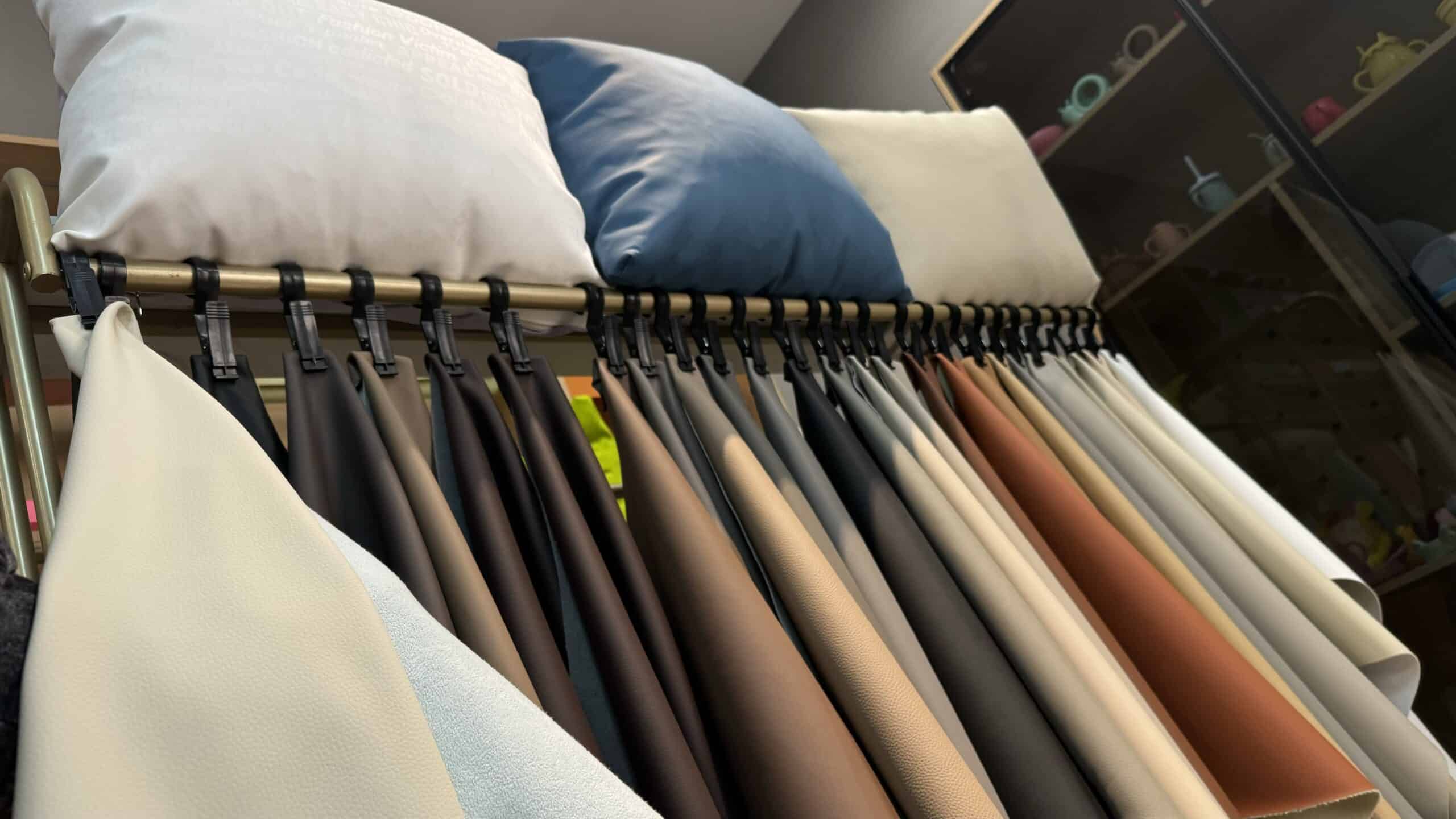

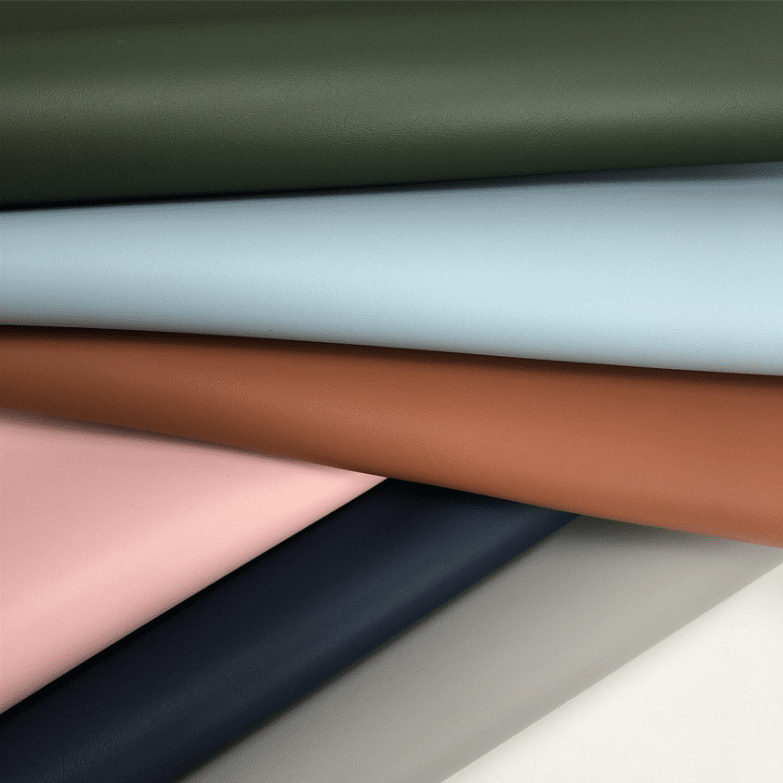

Z.S.R aims to provide the designers with more flexibility in design and respond to customers’ requirements by offering a wide range of customized options, including color,base fabric layer and surface textures. What’s more, we support the roll-to-roll (R2R) process. The lamination of our Silicone Vegan Leather with other textiles is easily achieved by using existing R2R processes without changing the current production lines or supply chain.

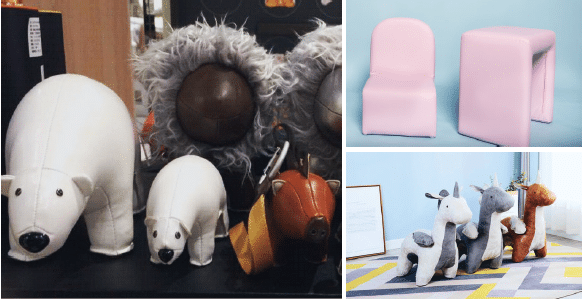

As a leading silicone leather manufacturer in China. Z.S.R Group also offer the Custom silicone leather service with the custom silicone leather Base fabric layer, color, texture,application, Function,sizes, logo, printing, pattern, package to the leather/Fabric wholesalers,Fabric store,Fabric products manufacturer for them to serve the local baby, Pets,Furnitures, Vehicles, Healthcare, Sports, 3C Electronic, Upholstery Manufacturers industry.

Our Factory is certified by SA8000(SGS), ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, and Disney.

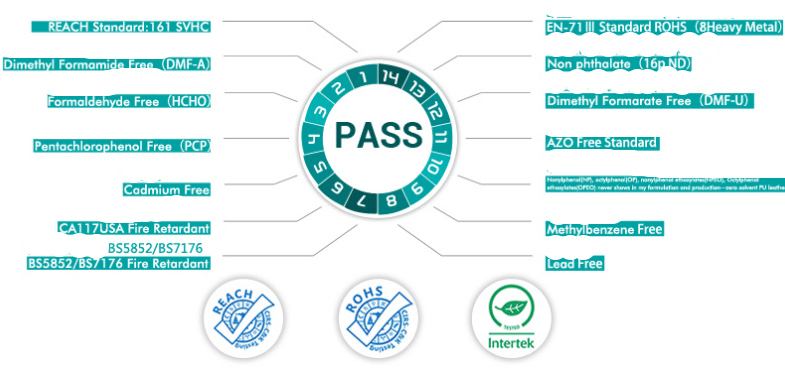

All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, and Phthalate all tested by SGS., etc.

All the silicone leather can pass: GRS,FDA,LFGB,CA-65,ROHS,REACH or Others your needed.

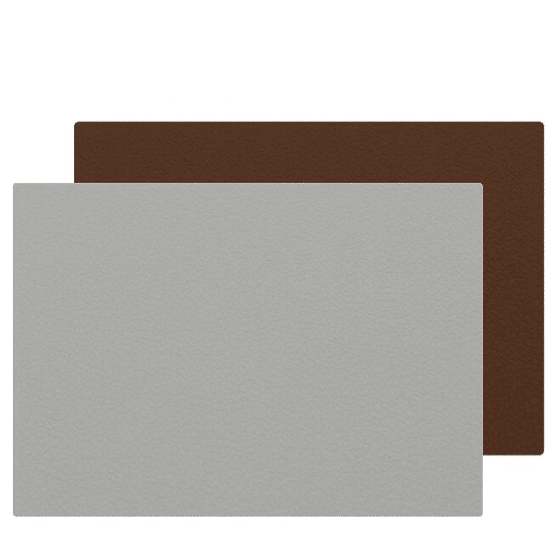

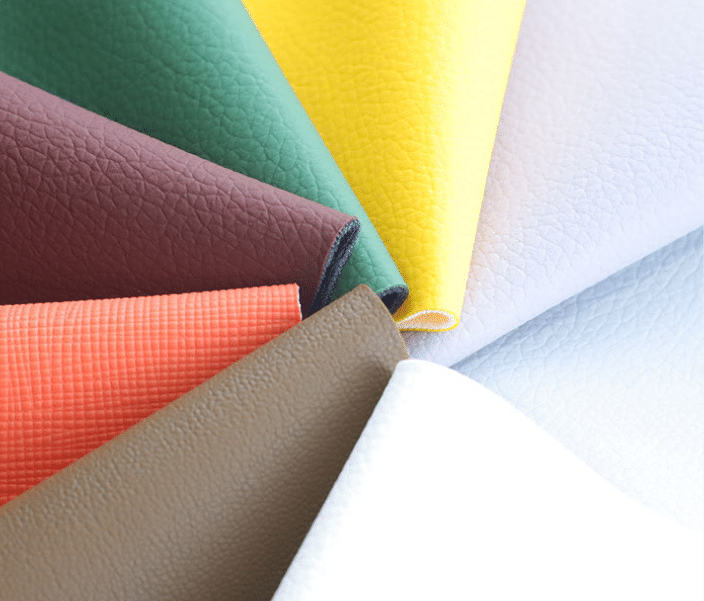

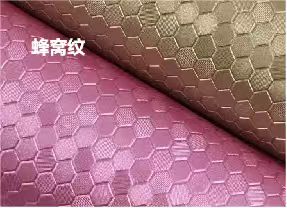

Z.S.R produce and supply wide range of customized options, including color and surface textures. You can choose the following texture silicone leather to fit your projects.

Bark Texture silicone leather

Bark Texture silicone leather Honeycomb pattern silicone leather

Honeycomb pattern silicone leather Crocodile pattern silicone leather

Crocodile pattern silicone leather Carbon fiber pattern silicone leather

Carbon fiber pattern silicone leather Weaving pattern silicone leather

Weaving pattern silicone leather Pinhole Grain Pattern silicone leather

Pinhole Grain Pattern silicone leather Snake texture silicone leather

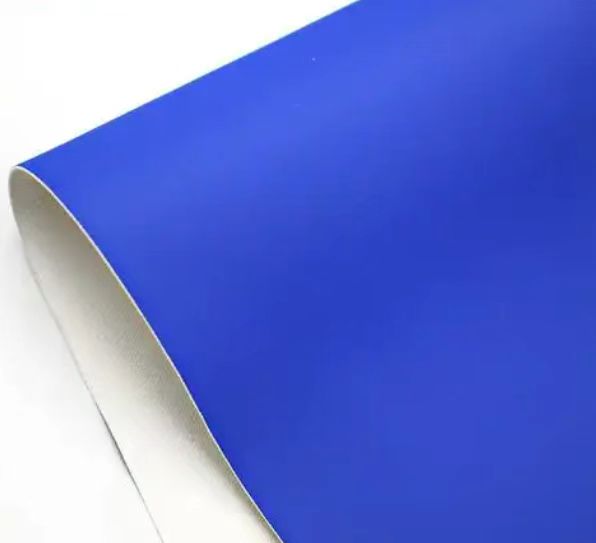

Snake texture silicone leather Plain silicone leather

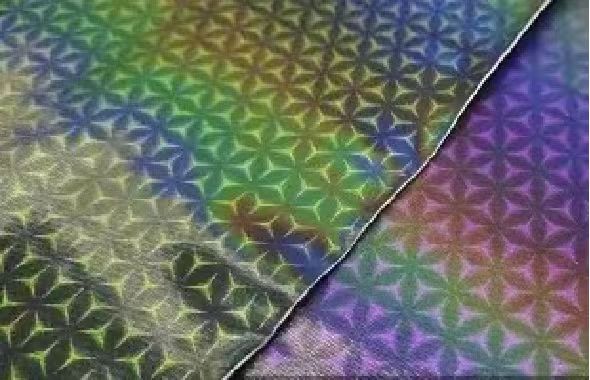

Plain silicone leather Optical iridescent texture

Optical iridescent texture Gravel Texture silicone leather

Gravel Texture silicone leather lamb pattern silicone leather (2)

lamb pattern silicone leather (2) Cloth pattern silicone leather

Cloth pattern silicone leather Diamond pattern silicone leather

Diamond pattern silicone leather Nappa silicone leather

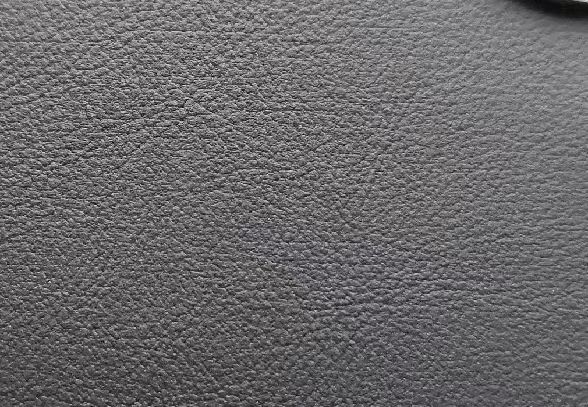

Nappa silicone leather Lychee texture silicone leather

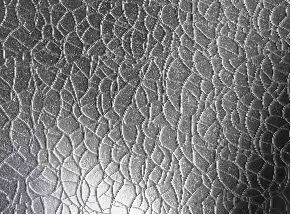

Lychee texture silicone leather Oil wax pattern silicone leather

Oil wax pattern silicone leather kidskin silicone leather

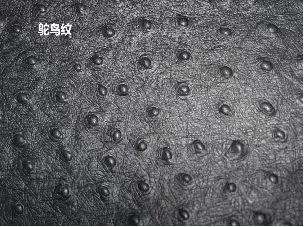

kidskin silicone leather Ostrich pattern silicone leather

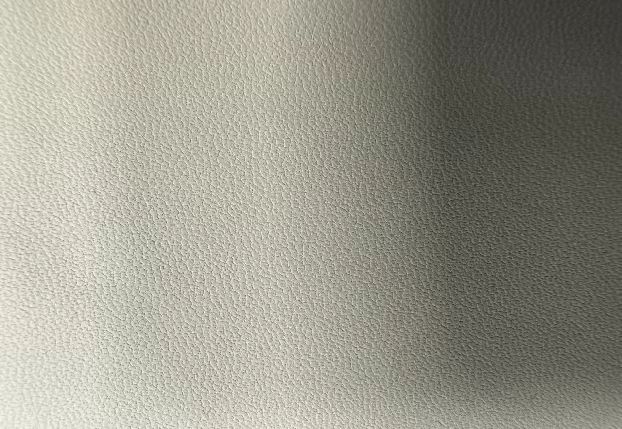

Ostrich pattern silicone leather Napa silicone leather

Napa silicone leather Hami Melon pattern silicone leather

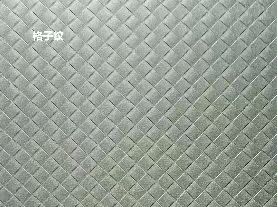

Hami Melon pattern silicone leather Plaid silicone leather

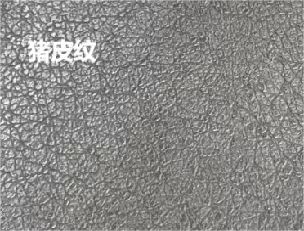

Plaid silicone leather Pigskin silicone leather

Pigskin silicone leather

Z.S.R offer the variety following base backing fabric layer to fit your project’s different usage, function, application needs.

Silicone leather fabric layer- air layer

Silicone leather fabric layer- air layer silicone leather backing fabric layer -glass fiber

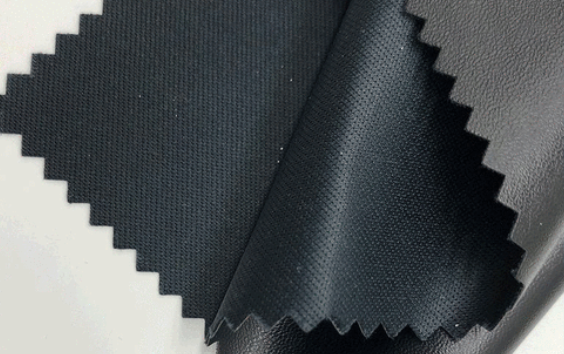

silicone leather backing fabric layer -glass fiber silicone leather backing fabric layer-Back coating

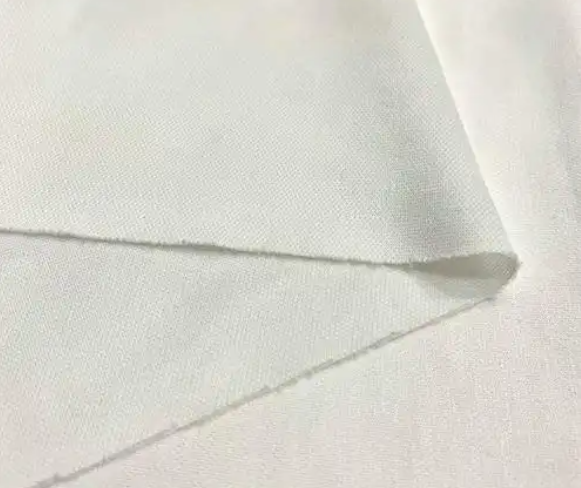

silicone leather backing fabric layer-Back coating Silicone leather backing fabric layer-Cotton

Silicone leather backing fabric layer-Cotton Silicone leather backing fabric layer-Four-sided stretch

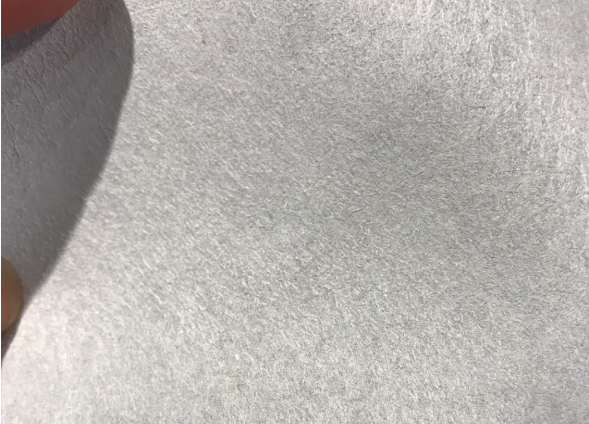

Silicone leather backing fabric layer-Four-sided stretch silicone leather backing fabric layer-healthy cloth

silicone leather backing fabric layer-healthy cloth silicone leather backing fabric layer-PET

silicone leather backing fabric layer-PET silicone leather backing fabric layer-PK cloth

silicone leather backing fabric layer-PK cloth silicone leather backing fabric layer-stretchy fabric

silicone leather backing fabric layer-stretchy fabric silicone leather backing fabric layer-Suede

silicone leather backing fabric layer-Suede silicone leather backing fabric layer-TPU

silicone leather backing fabric layer-TPU Silicone leather Backing Fabric Micro Fabric

Silicone leather Backing Fabric Micro Fabric silicone leather backing fabric-cow fiber

silicone leather backing fabric-cow fiber silicone leather backing fabric-Lycra

silicone leather backing fabric-Lycra

Contact Z.S.R to custom your own Silicone Synthetic leather.

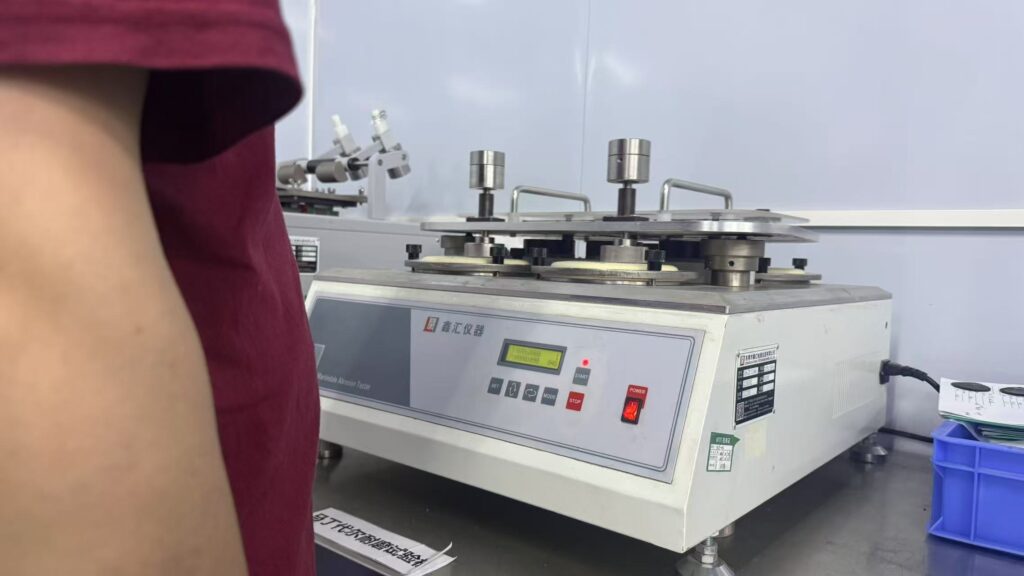

Quality lab Test

In order to ensure that our customers receive high quality silicone leather, Z.S.R silicone leather is strictly tested from incoming material inspection to laboratory testing.

Silicone leather Taber Wear test

Silicone leather Taber Wear test Silicone leather thickness test

Silicone leather thickness test Silicone leather UV resistance test

Silicone leather UV resistance test Abrasion wear test

Abrasion wear test Silicone leather color match

Silicone leather color match Silicone leather Flexure resistance test

Silicone leather Flexure resistance test silicone leather Hydrolysis resistance test

silicone leather Hydrolysis resistance test silicone leather Martindale Wear test

silicone leather Martindale Wear test

Download

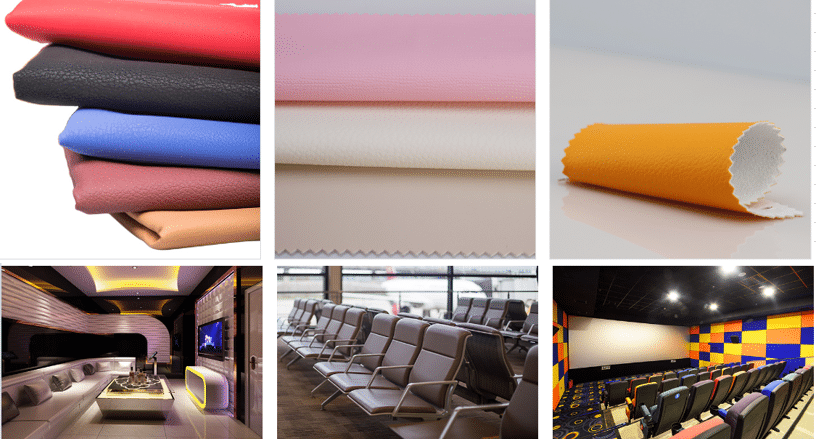

Common silicone leather products

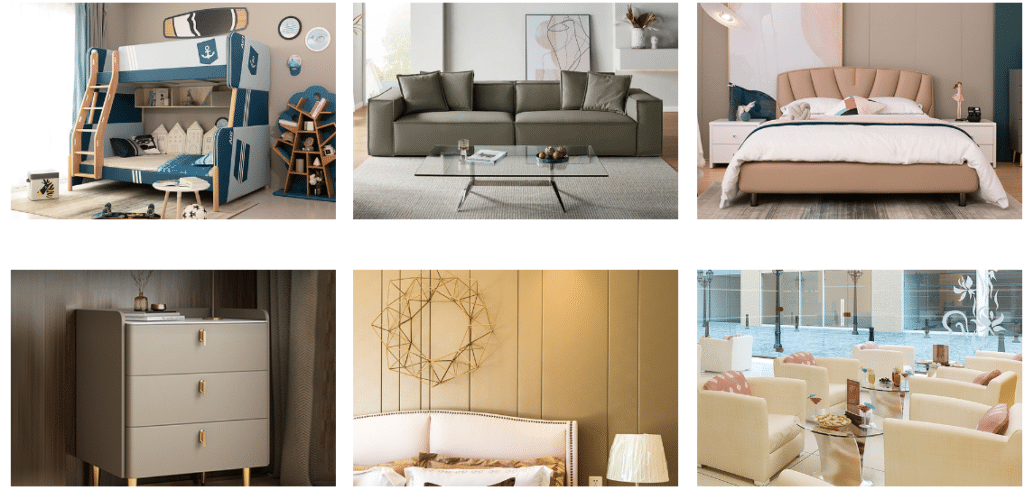

As a leading silicone leather fabrication factory,Z.S.R produce and supply variety pattern, thickness, base backing fabric layer of silicone leather including : silicone armchairs leather /office chair leather /bedding leather /headboard lether / ottomans and pours leather/ sofa leather /car leather /Vehicle leather/ seating leather,silicone credentials leather/ cushion leather / electronic case leather /garment leather /gloves leather /Hat leather/shoes leather /label leather /waist belt leather,silicone floor leather/ ball leather/ luggage and handbag leather / notebook leather /packing leather/Iphone 16 case leather.You can choice the fitted silicone leathers by your usage.

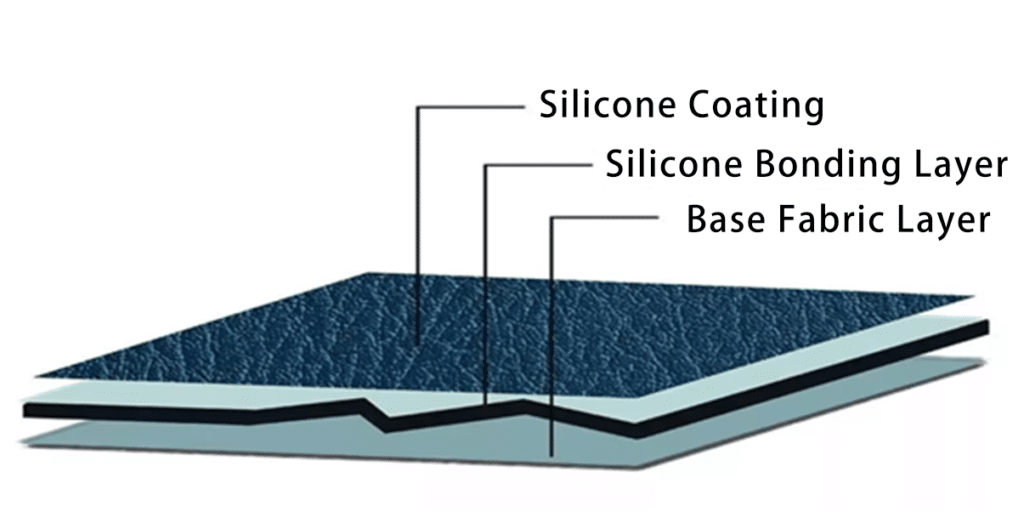

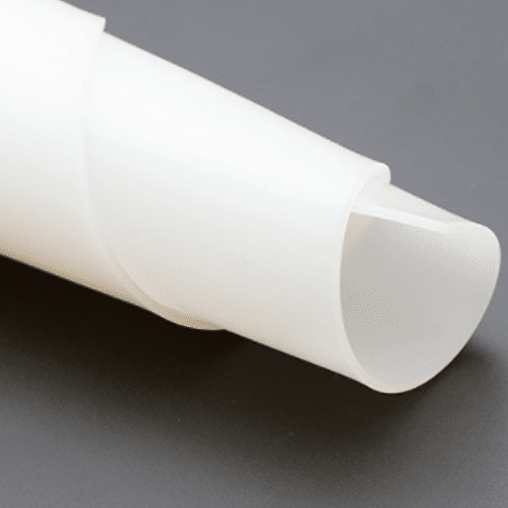

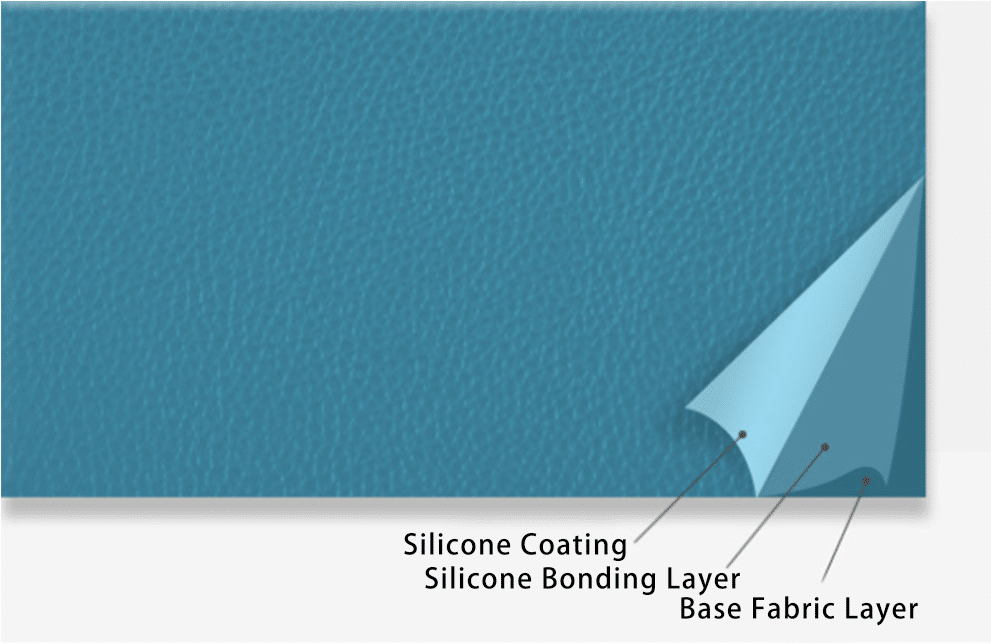

The surface layer of Z.S.R Silicone vegan leather is 100% LSR material with Platinum, and the middle layer is bonded with a 100% silicone bonding layer to bond the silicone material and the base fabric. The base fabric and surface leather texture and thickness can be freely selected to achieve different uses and application scenarios of leather.

Our existing color silicone leather is white, green, orange, grey and milk white ect. You can choice our existing color silicone leather directly and contact our expert to get the free samples.

Our existing fabric base and texture silicone leather is Microfiber cloth/imitation lint cloth/flannelette cloth base and Lychee/plain/carbon fiber/crocodile/star/kid skin.

They are widely used in Fashion accessories, Auto Upholstery, Medical and Healthcare, Sports, 3C Electronic, Upholstery, Commercial interior covering, Baby Toys and education, Marine, Pets, handbag, Special package, Furniture etc industry.

Contact Z.S.R to custom your own silicone Faux leather.

silicone leather Specification

|

PROPERTIES |

VALUES |

|---|---|

|

Item |

Silicone Vegan leather |

|

Material |

100% Silicone + Backing Fabric |

|

Width |

54/55” 1370mm+100mm fabric margin |

|

Thickness |

0.4 MM-3.5 MM |

|

Color |

Brown, black, white or customization color as clients’ request |

|

Surface layer |

100% silicone material with Platinum for baby pacifier |

|

Backing fabric |

Micro Fabric, Cotton, Lycra, Pique, micro suede, stretchy fabric, Knitted fabric, non-woven fabric, flannelette, PET, PC, TPU, PI FILM 3M adhesive tape etc |

|

Texture |

Lychee/plain/carbon fiber/crocodile/star/kid skin |

|

Weight |

600-2600 gsm |

|

Finish |

Available in matte, glossy, and textured finishes |

|

Pattern |

Lichi Grain, Plain grain, Lambskin Grain, Pigskin Grain, Pin Grain, Crocodile Grain, Giant Pebble, Hami melon Grain, Bark Grain etc |

|

Tensile Strength |

Warp >400 N/200mm, Weft>400 N/200mm (ISO 3376) |

|

Elongation at Break |

Warp >15% , Weft > 20% (ISO 3376)) |

|

Tear Strength |

>60N (ISO 3377-2) |

|

Peeling Strength |

>30 N/30mm (ISO11644) |

|

Anti-mildew |

Excellent (ASTM G21) or can added as the client’s request |

|

Abrasion Resistance |

> 50,000-200,000 (Martindale Wear ISO 12947) depends on the backing fabric |

|

Color Fastness to Rubbing |

Dry Rubs 5000 cycles, Wet Rubs 500 cycles, Ethanol ≥ (10 times) Neutral soap solution ≥ (100 times) Grade 4/5 (AATCC-8) |

|

Odor |

No odor |

|

Color Migration |

Temperature 50±2℃, press with 5KG weight for 18 hours no color migration |

|

Heat aging resistance |

1. (80±2)℃, relative humidity <10%, 2. Put in the oven for 24 hours, take out, cool at room temperature for (120±15) minutes, No stickiness, shininess, brittleness or other degradation phenomena on the surface Grade 4 |

|

High temperature resistance |

Oven 120℃, 168H No obvious cracks on the surface |

|

Cold temperature resistance |

-30℃, 24 hours, no obvious cracks on the surface |

|

Light fastness |

≥ 4 (ISO 105 B02) |

|

Anti-adhesion |

The sample coating is bonded to the coating, placed in a constant temperature of 80 (±2)℃ and pressed with a load of 10N, kept at the constant temperature for 3 hours, taken out, and the bonded sample can be peeled off by hand |

|

Bursting strength |

Müller Bursting Strength Tester ≥ 1MPA |

|

Hydrolysis Resistance |

70℃95%RH*10W, 15,000 cycles, no cracking, no color change (ASTM-D3690) |

|

Flame Resistance |

≤100 mm/min (FMVSS302, CA117) |

|

Anti-yellow |

Grade 4, QUV*200hours (HG/T3689) |

|

Bending Resistance |

Normal temperature, 200,000-700,000 cycles, no cracking ,-10℃,70,000 – 200,000 cycles, no cracking depend on the backing fabric |

|

Anti-Stain |

Italian dressing/Lipstick/Mustard/Suntan Oil/ Instant coffee/ketchup/blue or black ballpoint pen/cola/soy sauce/chocolate milk/saturated sodium chloride solution ≥ level 4 |

|

Waterproof |

Excellent |

|

Chemical Resistance |

High resistance to chemicals, stains, and UV exposure, Eco-Friendly Aspects Non-toxic, PVC-free, phthalate-free, recyclable |

|

Feature |

Durability, waterproof, antifouling, easy cleaning, environmental friendliness, and good touch and visual effects |

|

Applications |

Marine, Furniture, Automotive, Healthcare and Medical, Sports, 3C Electronic, Handbag, Interior Upholstery, Baby product. Pets, Fashion, package |

|

Usage |

Manufacturing and Upholstery |

|

Storage Conditions |

Store in a cool, dry place away from direct sunlight |

|

Cleaning Instructions |

Easily cleaned with mild soap and water; stain-resistant |

|

Certifications |

REACH, RoHS, and OEKO-TEX Standard 100 compliant |

|

Customization Options |

Texture, color, and backing fabric customization available |

|

Place of Origin |

China |

|

MOQ |

300 Meters |

Custom Silicone leather solution

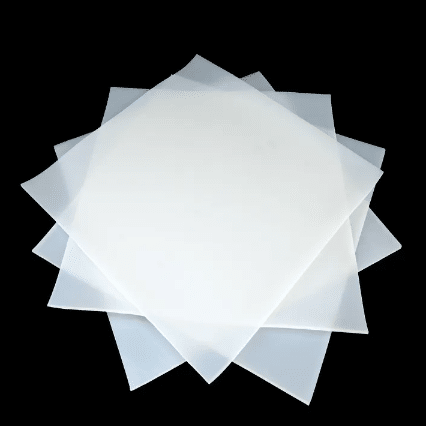

Composition of silicone leather Fabric

The raw material of silicone leather Fabric coating is Platinum liquid silicone, the same material as baby pacifiers. It is taken from natural sand. Its production process is low in VOC, with no wastewater, waste gas, or waste emissions, and the product is highly environmentally friendly and recyclable.

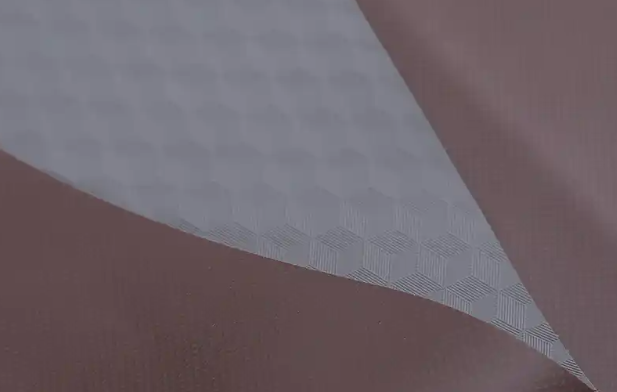

Silicone leather fabric is mainly composed of four parts:

- Silicone feel layer,

- Silicone coating,

- Silicone bonding layer,

- Backing fabric layer.

Related information: It is a kind of silicone material based on green environmental protection, which is made of special coating process. it does not contain DMF, phthalates, lead. The silicone leather can pass Reach, ROHS(Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

100% Silicone Vegan Leather is eco-friendly, sustainable, easy to clean, weatherproof, and highly durable performance fabrics that can be applied in various applications, even in extreme environment. Silicone coated fabrics are for use as a textile in the manufacture of furniture upholstery, furnishings, trim, decorative features.

Contact Z.S.R to custom your own silicone leather fabric.

The advantage of silicone leathers

All the silicone leathers made in Z.S.R is Solvent Free,Food-grade,Non-toxic,Formaldehyde-Free,No VOC,No DMF, UV Resistance,Weather Resistance,Hydrolysis Resistance 10 Years, Anti-Stain, CA117 Fire Resistance,Meet Reach Standard,High Abrasion Reistance,Water Resistant & Sweat Proof,Resistant to medical alcohol Wipes,Cold Resistance ,High-temperature Tolerance, Anti Yellow.

Low-temperature resistance

Leather maintains its original softness in the harsh climate of -40℃

Waterproof and anti-fouling

pen stains juice, sauce oil easy to clean

UV resistance

UV resistance fusion of excellent weather and light resistance

Anti-flaming

Silicone has strong flame-resistantgrade testing

High-temperature resistance

Not deformation, shrink, or burn athigh temperatures of +200℃

ECO-friendly

baby nipple material non-toxic no smell and anti-allergic

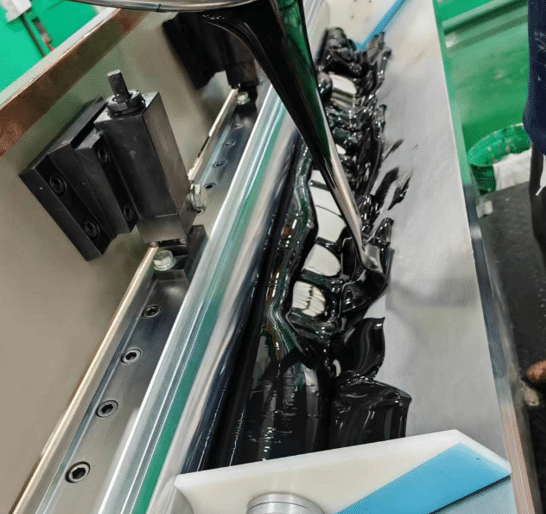

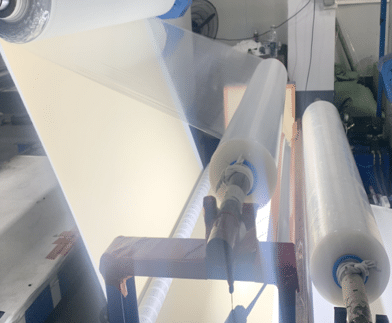

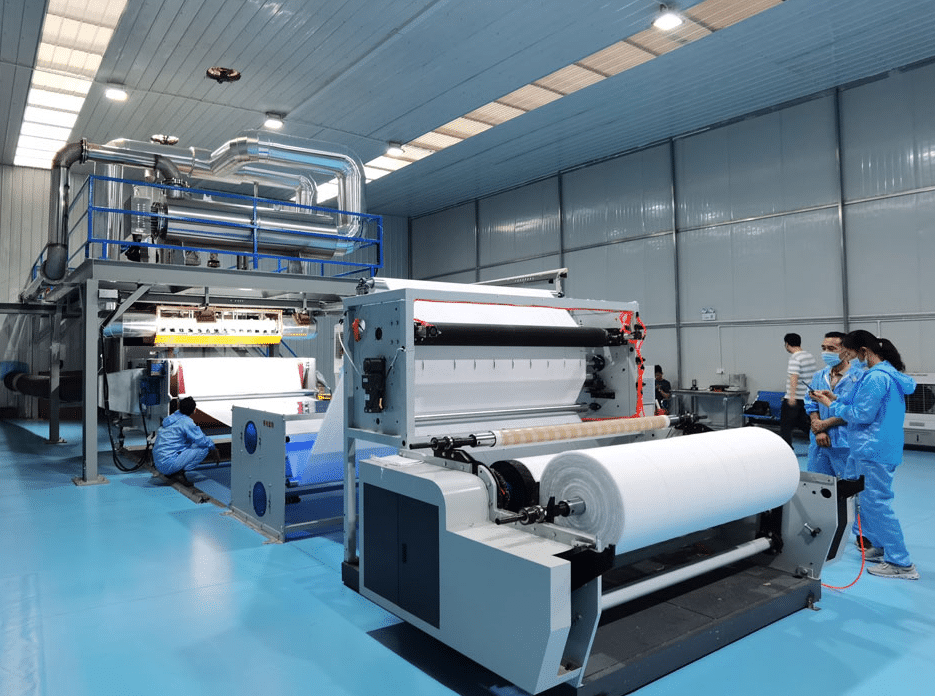

Silicone leathers Manufacturing Process

1. Prepared Material: Mixed the Liquid silicone rubber material color according to the confirmed samples ‘color. Prepare the confirmed base fabric layer.

2. Set up and coating:Put mixed LSR on the machine, then coating the liquid silicone rubber. lt is the First coating with the liquid silicone rubber on the surface. Embossed for the silicone leather texture in this process.

3. Heat the first coating silicone leather in the oven to dry.

4. Second coating: Second coating the liquid silicone rubber in bottom and then sticker with the base fabric layer

5. Lamination: Collection the half-finished silicone leather with plastic film in order to keep the surface clean

6. Painting Dusty Free oil: Painting the different oil to get different surface (gloss or matt) and different touch feeling silicone leather. (Skin, dry, smooth) and let the silicone leather keep dusty free and easy to clean.

Contact Z.S.R to custom your own Silicone Synthetic leather.

The Application of Silicone Leathers

Silicone leather is becoming popular for all upholstery projects as it is a recycle leather. They are widely used in Marine upholstery, Furnishing and Furniture, Automotive upholstery, Medical Healthcare, Sports, 3C Electronics, Handbags, Baby products, Pets,Commercial Upholstery etc. Z.S.R have established long-term strategic partnerships with industry-leading home brands, real estate developers, architectural design institutes, as well as ship, RV and automobile brand customers.

Silicone leather VS other leathers

Silicone leather is different with traditional PU leather or PVC leather. Silicone leather does not use plasticizers, which are often found in PVC products.

| Item | silicone Leather | Nature Leather | PVC | Microfiber |

|---|---|---|---|---|

| “Raw Materials ECO* | No pollution | The pollution of ingredients is serious | Some pollution | Medium |

| Production Pollution | No pollution | Larger | Medium | Benzene reduction process is polluted |

| Product Safety | Safe | Medium | Some harm | |

| “Product ECO-Friendly’ | Recyclable | Degradable | Hard to degrade | Degradable |

| Waste disposal | Medium | Difficult | Difficult | Medium |

| “Energy Consumption Analysis | Very Low | Medium | Medium | Very high |

| Item | Silicone Leather | Nature Leather | PVC | PU | Microfiber |

|---|---|---|---|---|---|

| Raw material | Silicon coating +fabric | “Pigskin, cowhide, Lambskin, etc.” | PVC resin, fabric. | PUresin, fabric | PU resin, fabric |

| Touch feel | Excellent | Excellent | Bad | Medium | Excellent |

| Elasticity | Excellent | Excellent | Bad | Bad | Good |

| Color, Pattern, Thickness | Good | Medium | Medium | Good | Medium |

| Production Process | Dry process | Tanning and nitration | Dry process | Wet and dry process | Microfiber weaving Wet reduction, dry proc |

| Service life | 5-10years | 5-10years | 2-5years | 2-5years | 2-10years |

| Price | 14-23USD/m | 15-50USD/m | 1-3USD/m | 1.5-5USD/m | 8-16USD/m |

Silicone has many advantages over PU and PVC as it does not break down under UV light, deteriorate in cold temperatures, has no odors, and maintains consistency and shape over time. Silicone leather is a pioneer in performance leather made of 100% silicone.

| Item | Silicone Leather | Nature Leather | PVC | PU | Microfiber |

|---|---|---|---|---|---|

| Breathability | Excellent | Good | Bad | Medium | Good |

| Fire Resistance | Excellent | Good | Good | Bad | Medium |

| Solvent/chemical resistance | Excellent | Bad | Good | Medium | Medium |

| Acid resistant | Excellent | Bad | Good | Medium | Good |

| Alkali resistance | Excellent | Bad | Good | Medium | Good |

| Hydrolysis resistance | Excellent | Medium | Good | Medium | Good |

| Durability | Excellent | Good | Medium | Bad | Good |

| Color fastness | Excellent | Bad | Medium | Better than PVC | Medium |

| Antibacterial and mildew resistance | Excellent | Bad | Medium | Medium | Medium |

| Normal Fixture | Excellent | Good | Bad | Medium | Medium |

| Low temperature Fixture | Excellent | Medium | Bad | Medium | Good |

| Tear intensity | Excellent | Good | Medium | Medium | Medium |

| Peel intensity | Excellent | Excellent | Medium | Medium | Good |

| break intensity | Excellent | Good | Medium | Medium | Medium |

| Stitch intensity | Excellent | Excellent | Bad | Medium | Good |

| High temperature resistance | Excellent | Good | Medium | Good | Good |

| Abrasion resistance | Excellent | Medium | Good | Medium | Medium |

| Anti-Wrinkle | Excellent | Good | Bad | Medium | Medium |

| Quality uniform | Excellent | Bad | Medium | Excellent | Medium |

| Tailorability | Excellent | Bad | Excellent | Excellent | Excellent |

| Post Processing | Easy | Bad | Easy | Easy | Easy |

Z.S.R Silicone leather products are non-toxic and more durable than other materials like vegan PU leather or vegan faux leather due to the features of silicone, including weather resistance, temperature resistance, waterproofing, UV/Ozone resistance, durability, and easy to clean.

Z.S.R aims to provide the designers with more flexibility in design and respond to customers’ requirements by offering a wide range of customized options, including color and surface textures. What’s more, we support the roll-to-roll (R2R) process. The lamination of our Silicone Vegan Leather with other textiles is easily achieved by using existing R2R processes without changing the current production lines or supply chain.

Contact Z.S.R to custom your own silicone leather.

10 Problems that silicone leather can be a solution

- Solve the problems of PU hydrolyzing, peeling, peeling, cracking, and can not stand temperature.

- Solve the hidden danger that PVC cannot be degraded and recycled, and harmful substances will be released under high temperatures.

- Natural material, no allergies when in contact with the body, and can pass medical biocompatibility testing.

- Cold-resistant to minus 40℃ without cracking, heat-resistant and hot-resistant to 220℃ above zero without coking or shrinking.

- Silicone leather items can be washed and dried at high temperatures than other leather.

- It can avoid the problem of chemical solvent treatment and heavy metal problems in dermal slaughter of animals and post-processing.

- Common stains in life such as coffee, juice, snacks, oil stains, handwriting, etc. are easy to clean

- No skin peeling, no fading, no yellowing, and excellent anti-aging properties when exposed to the sun for a long time.

- The natural flame retardancy of silicone makes it not flammable and will self-extinguish after being removed from the fire for 10 seconds.

- Permanent and excellent skin smoothness and natural cooling feeling.

Why Choose Z.S.R silicone leather?

Z.S.R is a leading silicone leather manufacturer in China with many years experience. The monthly production capacity is 3 million meters, and it is exported to 50 different country.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.