PROJECT OVERVIEW

Customize a full set of silicone feeding products for baby brands

The baby products brand was sold on the target. Z.S.R Group established a preliminary contact with this brand in September 2019. After we discussed several quotations, and did silicone products samples and sent. The cooperation plan was initially established in December 2019.

The client wants to develop 5-7 items, including silicone reusable bags, silicone milk powder bags, silicone collapsible cups, silicone lunch bowls, silicone snack bowls, silicone baby bibs, silicone folding place-mats, etc.

The Spring Festival of 2020 is on 24th Jan. We receive customer emails on 23rd Jan. They would like to confirm the plan as soon as possible. They informed the first batch of large shipments must be sent to the US retailer Target before the 31st of May, otherwise, Need to bear Target’s fine.

1. At that time, the COVID-19 outbreak had just broken out, and the entire country was under quarantine in China. We made an appointment with the customer to start an online meeting on 2-1 to discuss project drawings, prototype arrangements and timeline arrangements. The customer sent us a 2D drawing of the desired product before 2-1. Our team, business, engineering, and project management meet the customer online in the 1st Feb, 3 rd Feb, and 7th Feb. respectively. Then we make a decision we will give the customer the 3D product drawings in 10th Feb. The 10th of Feb was the first day that Dongguan could start work at that time. On the first day of workday, we sent the 3D drawings of the project and the 2D drawings with size standards to the customer.

2. After getting the customer’s confirmation, we made the prototype molds of all projects within 10 days and make samples according to the customer’s requirements. Then we send the samples to the customer. And according to the customer’s request, the samples mold and samples improved. Finally the all the project samples confirm by the customer in 15th March.

3. After receiving the customer’s sample confirmation, we quickly run up the production of the mass production mold according to the latest samples and drawings. The mass production silicone tooling was produced within 15 days, and the small quantity bulk goods with printing and packaging were re-arranged for the clients for confirmation.

4. After getting the mass production PO from the customer in early April, we try our best to arrange mass production. In less than a month, we completed mass production of all projects and arranged all the products of 2 containers before 30 th April. So the customer can get the goods at the end of May, and delivery them to Target smoothly.

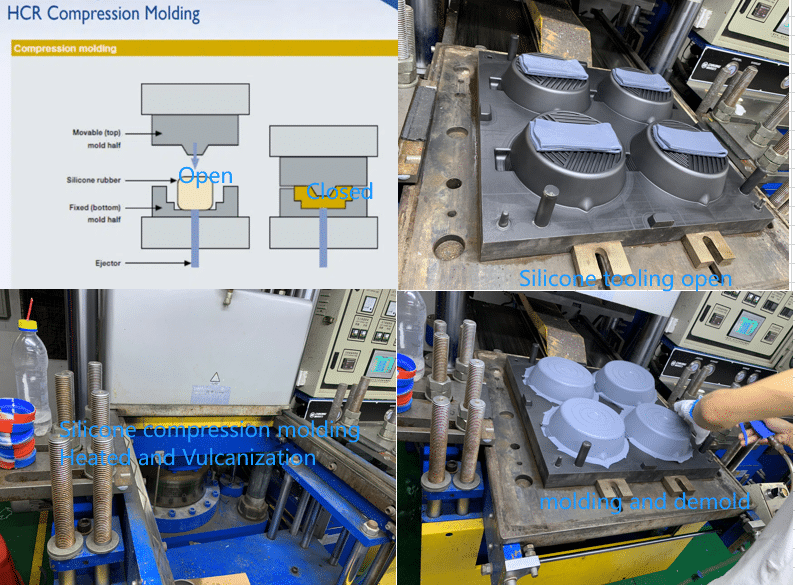

5. The process used in this batch of projects includes silicone compression molding, liquid silicone rubber molding, liquid silicone over-molding, screen printing, heat transfer printing and other processes. Under the complex process and the epidemic situation, we have made our customers’ products from dreams to reality in less than half a year, and have entered the marketing and selling.

Until now, these projects are still in mass production in Z.S.R Group, and all projects have been produced smoothly. Our team has won great praise from customers.

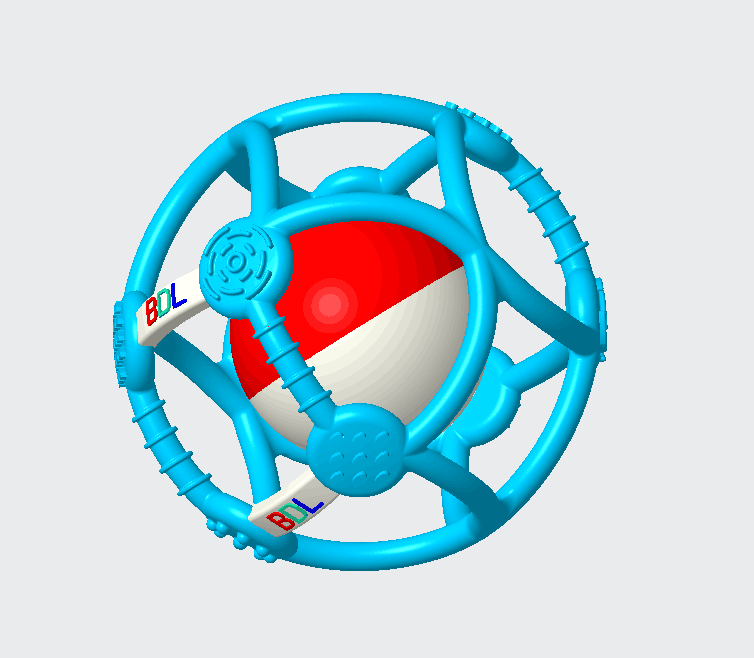

Related Product

TECHNICAL CAPABILITIES

Customer comments: Whether it is from the design, the prototype, or the mass production, thanks to the rapid cooperation of the Z.S.R team, our products have gotten from a dream to a reality and entered the market in less than half a year.