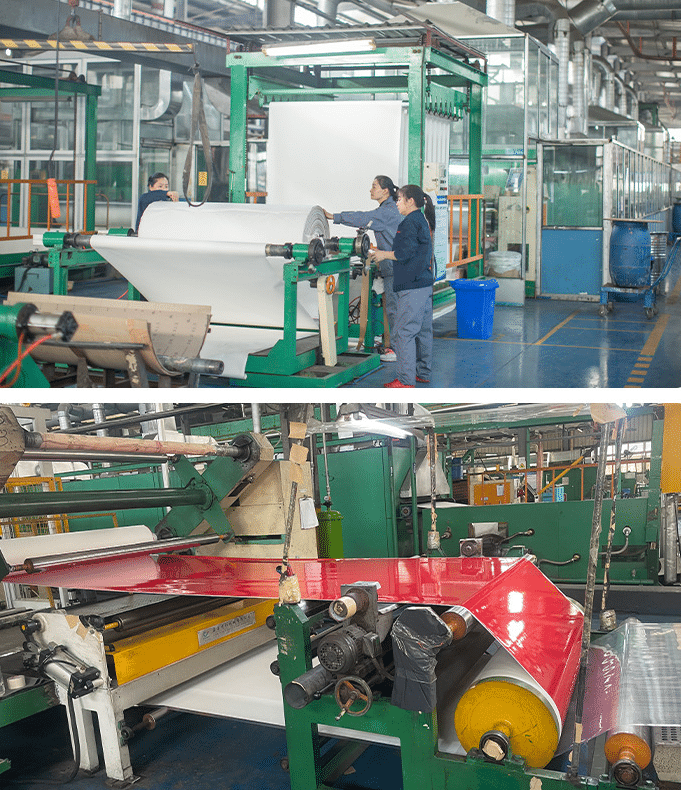

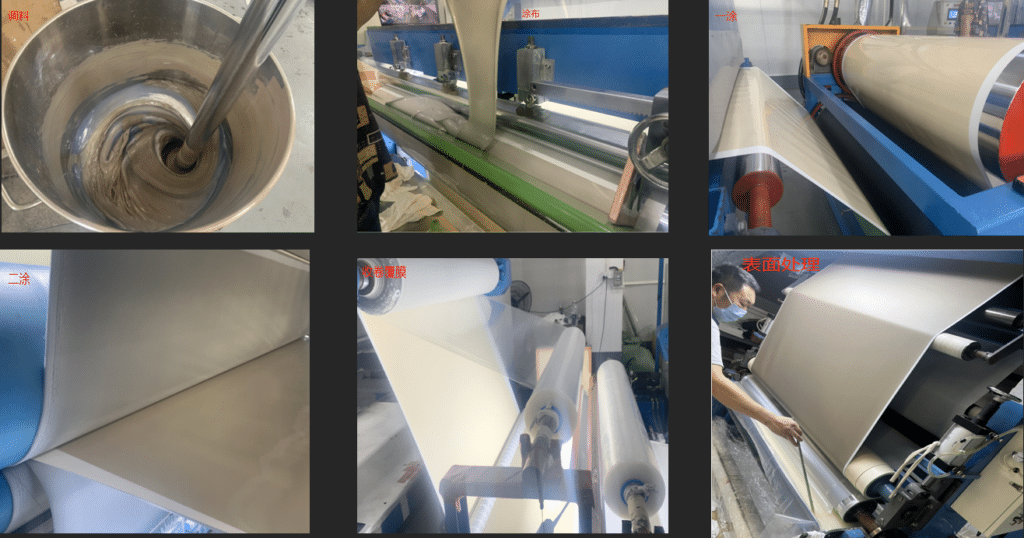

silicone fabric coating and curing

Silicone fabric Coating and curing – Uncured silicon is made into a film of a certain thickness with a roller. coated on the fabric, and then completely hardened by pressing the silicon surface with a heat roller having a specific pattern, And a step of coating with a surface treating agent after the above-mentioned process. Then to get the silicone leather to various desirable properties, such as water resistance, heat resistance, and hydrolysis resistance qualities. ZSR Silicone leather is made of organic silicone coated and bonded to various substrates utilizing a solvent free technology.

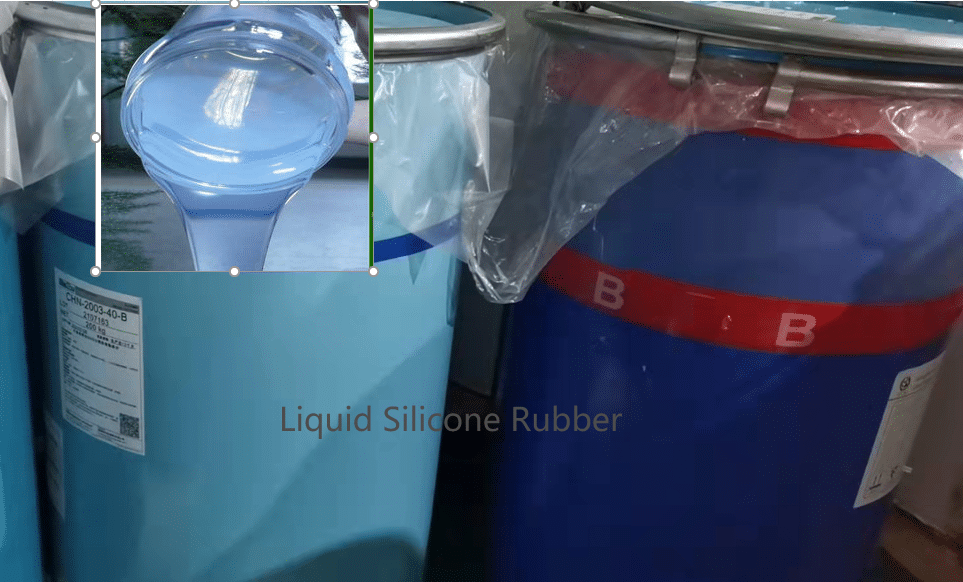

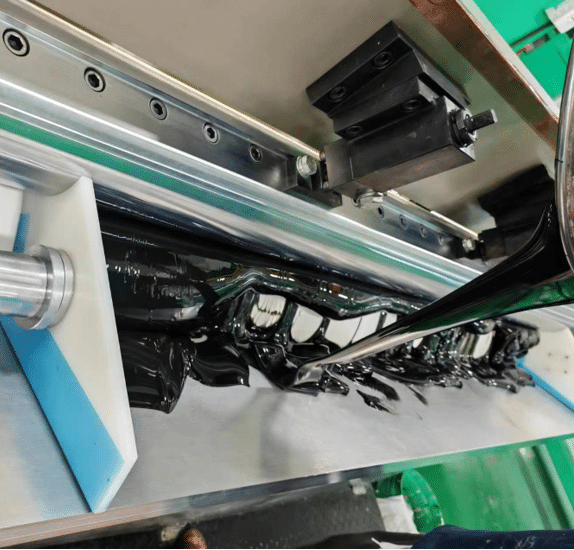

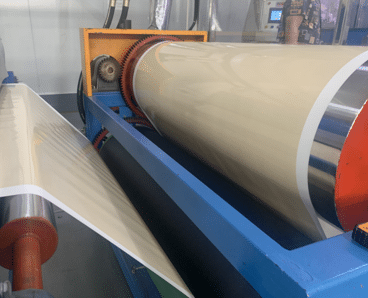

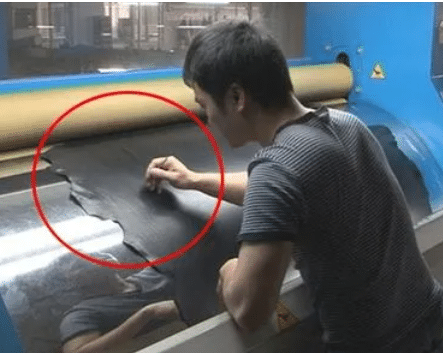

In this process, Z.S.R worker will mix liquid silicone rubber, color paste, and platinum vulcanizer evenly and coated once. The uncured silicone is made into a film of a certain thickness by a roller, and then the surface of the silicone is completely cured by a hot roller with a specific pattern to obtain a silicone sheet with a textured film;

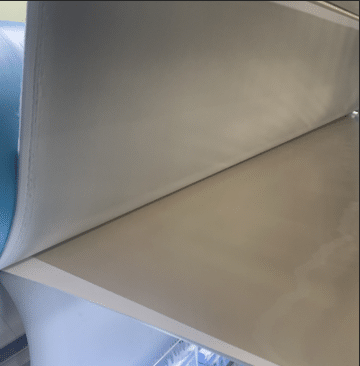

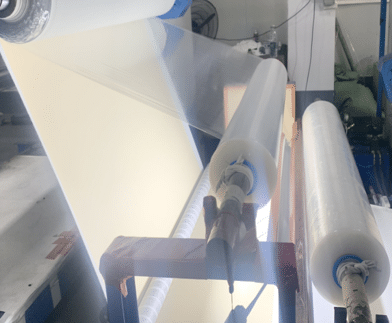

The silicone sheet with a textured film is pressed with the base layer, initially vulcanized, and the textured film is peeled off to obtain a silicone leather semi-finished product with a texture;

Hand-feel oil is applied on the texture surface of the silicone leather semi-finished product with a texture, and finally vulcanized.

Silicone Leather Fabric Material Manufacturer

Fiberglass Reinforced Silicone Rubber Sheet For Sale

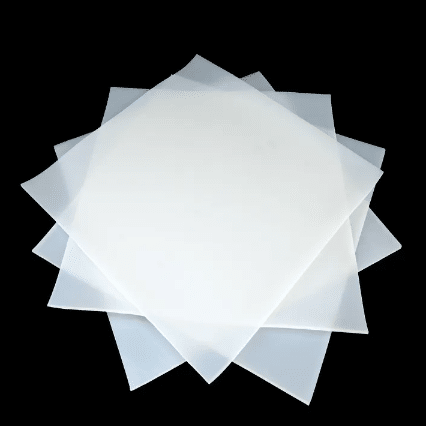

Platinum Cured Silicone Sheet For Sale

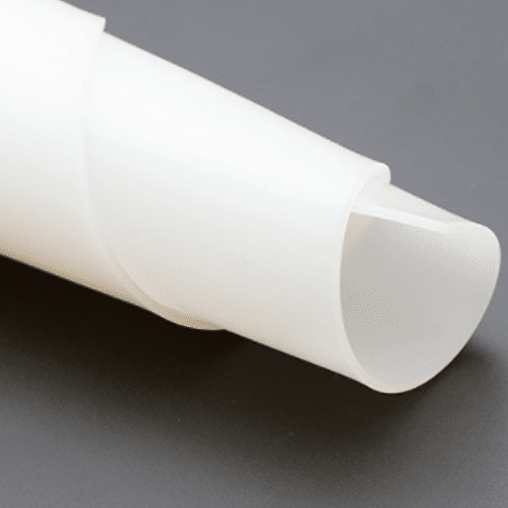

White Silicone Rubber Sheet/Roll For Sale

Translucent Silicone rubber Sheet For Sale

Clear Silicone Rubber Sheet For Sale

The 10 process of silicone fabric coating and curing

Z.S.R team have the experienced Engineer, we will offer our professional selection and suggestion from the silicone raw material, Fabric layer base to make the custom silicone leather to ensure your project success.

Silicone leather production

More than 10 years, Z.S.R Group offer the Custom silicone leather service with the custom silicone leather Base fabric layer, custom silicone leather color, custom silicone leather texture, custom silicone leather application, custom silicone leather sizes, custom silicone leather logo, custom silicone leather printing, custom silicone leather pattern, brand, package and other silicone products technical support to the baby, Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronic, Upholstery industry.

The advantage of Silicone fabric coating curing

Industries And Applications

Z.S.R Group use the silicone fabric coating and curing process make the silicone leather. Z.S.R Silicone leather is becoming popular in Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronics, Handbags, Baby products, upholstery etc.

Z.S.R is a silicone leather fabrication factory. Z.S.R team work with the Brand owner, products development manager, product designer, product manager together to customized the silicone leather according to the needs of customers, with fabric layer base, textures, thicknesses and colors to fit their project needs and ensure their project success. Our engineers provide sample analysis, which can quickly match customer needs and 100% match sample to meet the customized of different customers’ request.

Contact Z.S.R silicone to get your own needed silicone leather to ensure your project success!