silicone dripping Molding Services

Z.S.R International Group(HONG KONG)CO., LIMITED own 12 sets of silicone dripping molding machines for multi color silicone products Manufacturing or offer the custom multi-color dripping molding service.

silicone dripping Molding Services

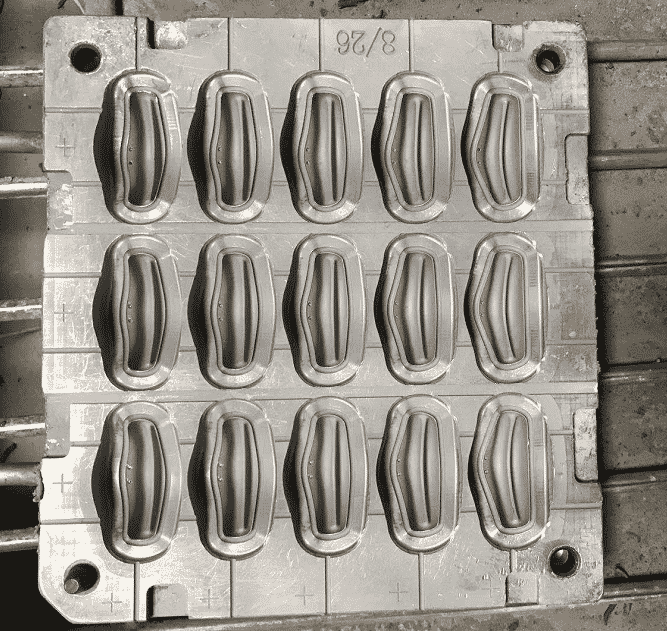

- Silicone Dripping molding, Insert Molding

- Single, multi-cavity, and family molds

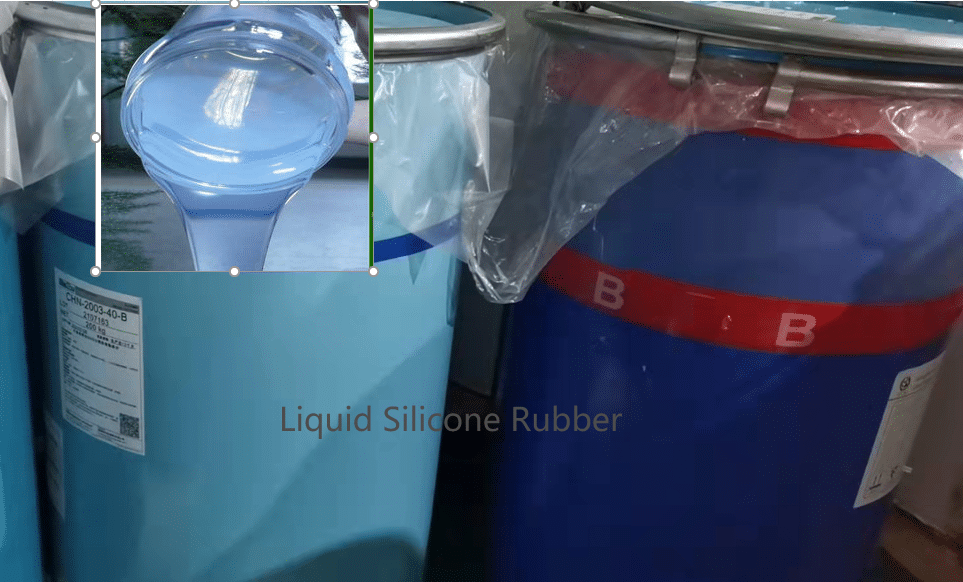

- Liquid silicone rubber, Solid silicone

- Ideal for serial production of silicone products

- Rapid tool production in up to 2 weeks

Start A New Molding Quote

STEP | STP | CAD | PDF

Please upload your technical drawings here for a quote.

Z.S.R Silicone Dripping Molding Capacities

The multi-color dripping molding widely used in promotinal and baby products except for Medical, daily necessities (such as silicone housewares, kitchenware, silicone gifts, etc.), and other fields that require high levels of safety and environmental protection. They are in :

After the silicone multi-color dripping molding, our Post-processing department do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, Secondary vulcanization, LOGO or Pattern printing if needed, Final Quality control and testing, Package and Warehouse. If you would like to know more information:

what is Multi-color dripping molding

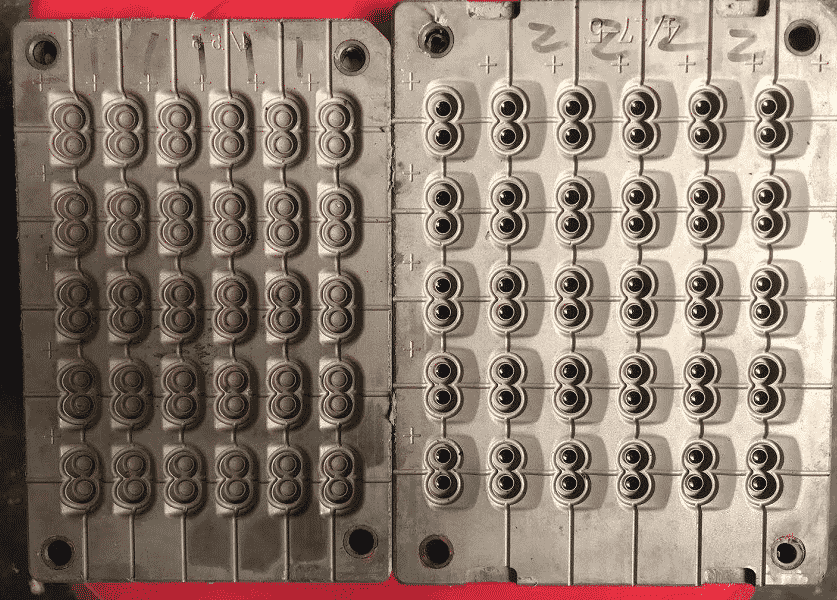

Multi-color dripping molding(Epoxy molding) allows two different silicone material(solid silicone rubber and liquid silicone rubber) to be combined into a single products stream. Liquid silicone’s colors can be adjusted according to different customers, and the colors will do nothing to the qualities of rockery liquid silicone.

When in use, we need to mix the two parts evenly according to a certain proportion first , and then carry on the vacuum processing.This specialized process can be used to enhance products color performance and reduce cost without any penalty to cycle time or production volume. It is perfect customize solutions for difficult complex multi-colors silicone products. Depending on the materials selected and the application, Multi-color dripping molding can be used to improve production efficiency and allow for greater design flexibility.

Multi-color dripping molding can be used for a wide range of applications across any industry including Consumer Electronic(Cute iPhone12 silicone case, air pod case, iPad case), Beauty products(cosmetic bag, brush ). Promotional gifts(Colorful products include: Key chain, purse bag, fashion accessories and gifts), baby products(colorful baby teether, colorful baby toys)

As the pioneer and industry leader in Multi-color dripping molding Technology, We has extensive Multi-color dripping molding science knowledge and the most application experience.

Characteristics Of Multi-color dripping molding

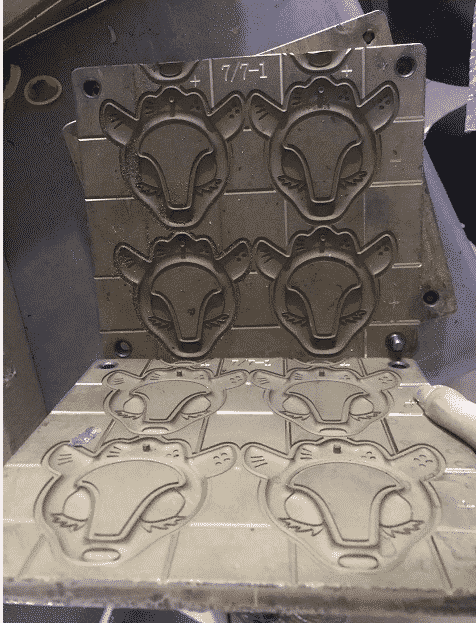

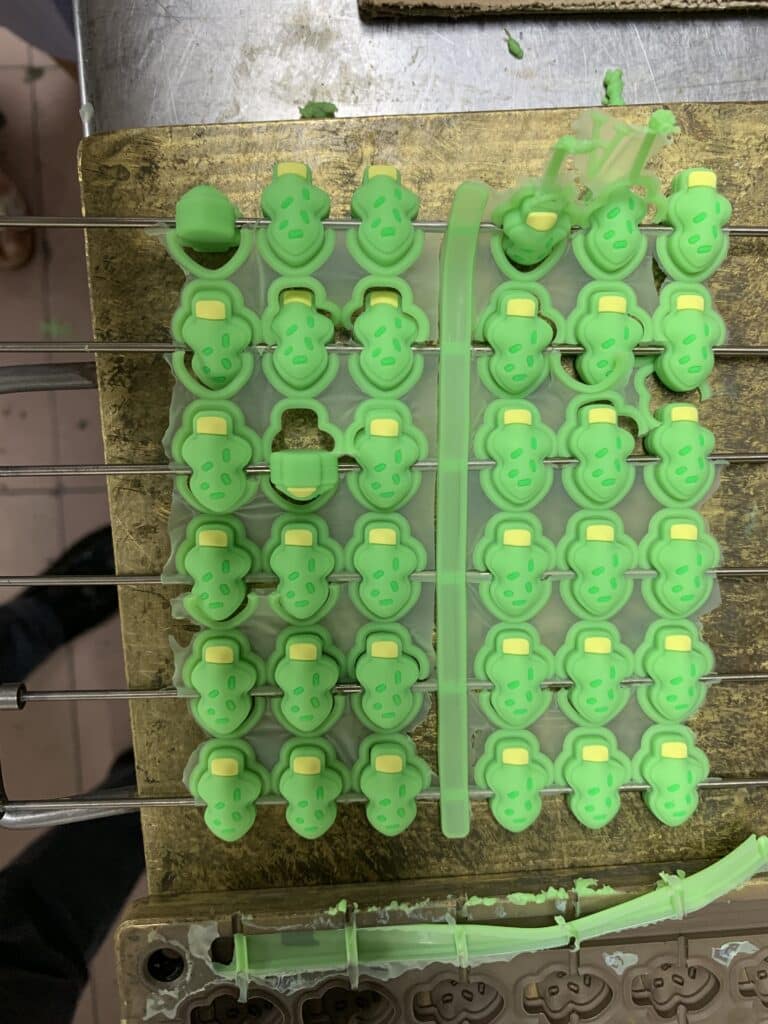

Multi-color dripping molding(Epoxy molding) will use two different silicone material(solid silicone rubber and liquid silicone rubber) to be combined into a single products stream. Liquid silicone’s colors can be adjusted according to different customers, and the colors will do nothing to the qualities of rockery liquid silicone. It is widely application to the more multicolored silicone products. The colors and pattern can be get from 2-12 colors and with different pattern. It will be widely use for the licensed products with the character’s. Especially for the games,Ip’s/Movie’s/ Animation’s/ Character’s peripheral cute products and promotional gifts.

Multi-color dripping molding products Design And Materials

Multicolored silicone products will use the co-injection dripping molding process. When we have the Multicolored silicone products. We have to consider the products designed from the beginning to be manufacturable. By making the right material, color, durometer, dimension, and tolerance choices. To avoid the liquid silicone peel off . Also the OEMs can develop molded Multicolored silicone products that can be reliably manufactured in large volume — while minimizing scrap rates and their losses.So, There are a few things to consider when deciding on a silicone to use for manufacturing. These include type of silicone (liquid silicone rubber or high consistency rubber), durometer (hardness or shore ), and even colors,gaps for the colors. Each of these can have an impact on manufacturability. Z.S.R group we have the experienced Engineer, we will offer our professional select and suggestion from material form,design that fits with the Multicolored silicone products made.

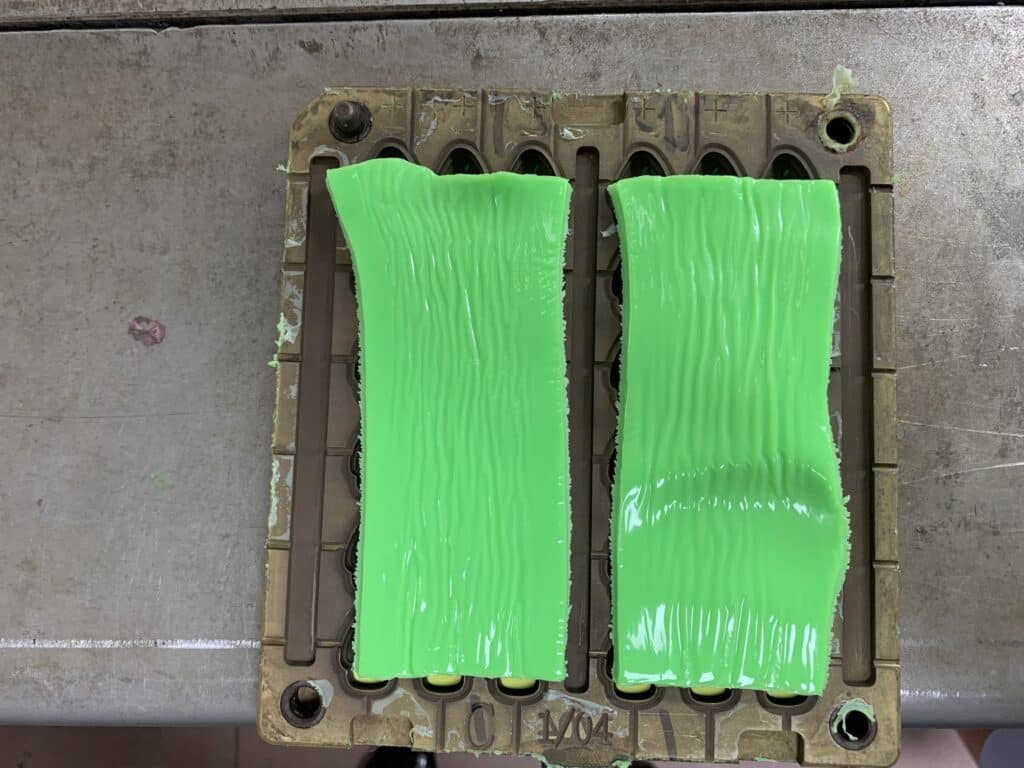

The process of Multi-color dripping molding

Multi-color dripping molding Silicone Rubber Products Production

More than 10 years, Z.S.R Group offer co-injection dripping (epoxy) molding to the Brands/Wholesalers/Retailers for consumer goods. As we own 6 sets of the co-injection dripping (epoxy) molding lines.

As the pioneer and industry leader in Co-injection dripping molding Technology, We has extensive co-injection science knowledge and the most application experience.

The world’s leading brands(we can not show here because of the NDA)and Licensee (such as Line Friends, Kakao Friends, Disney, Universal Studio (NBC Universal), Hasbro, Mcdonald’s, Hello Kitty, Pokemon, Winnie the Pooh, Mickey mouse, Star wars, Anpanman/アンパンマン, Jump, Mario, Marvel, ASTRO BOY, Miffy, Snoopy, Rilakkuma, Doraemon, Minions, Starbucks, P&G, Cocacola, SpongeBob, Warner Bros., MGA Entertainment, Olympic, Forbidden City Culture, etc) rely on our Co-injection dripping molding Technology to deliver solutions that outperform.We have help these licensee, Entertainment Culture,licensed,Advertising and Marketing companies make more than 1000 models Ip’s/Movie’s/ Animation’s/ Character’s peripheral cute products and promotional gifts. Please Contact us with your application today.

we’ve been manufacturing a wide range of silicone products, mainly focused on customized silicone consumer products. Our one-stop silicone products manufacturing factory operates at a high capacity and is focused on producing your personalized silicone products to meet your scalability requirements。

Cooperate with LineFriends: Pencil case, Hand Mirror,Cup Coaster,Bags,Lids, 3D keyring, Name tags,Silicone pouch, airpod pro case, phone case,mobile phone stand, phone holder, Silicone cup and cover, Silicone purse bag,Silicone multi-colored pouch etc.

Cooperate with KakaoFriends:Pencil case, Bags,Lids,night light, Airpod case, phone cases, luggage tag, 3D Models etc.

Benefits Of Multi-color Dripping Molding

Design: Multi-colored. You can get 12 colors in one product without any printed.

Flexibility: Can make the 3D show with the products.

Attraction: More attraction and cute as gifts for the kids and Women

Industries And Applications

- Home & housewares & Appliances ( Kitchen & dinning&table & Drink ware &household.etc.)

- Baby & Toys ( Baby care & Baby Feeding & Baby Toy & kids learning toy etc)

- Health & Beauty & Personal Care (Oral care & Beauty tools/Accessories & hair care ,etc.)

- Stationery & Office Products(Arts & Crafts& School products & Office products etc. )

- Sports & Outdoor & Garden ( Sports and fitness & Travelling & Outdoor portable etc. )

- Pets Supplies

- Electronic & Cell Phones Accessories ( Protective cover& Case, holder etc.)

- Smoking products

- Promotional products (Licensed products & Mascot & Gifts & Blind box products)

Multi-color dripping molding Silicone products Quality Standards

Material Standard: FDA and LFGB

Size and Tolerances:+/- 0.15 mm Tolerances or according to the 2D drawing request

Surface and Color:Check the surface to see if there is any damage, lack of glue, deformation, different color.Material overflow… and other UN-quality

Custom Multi-color dripping molding Solutions For Your Business

Z.S.R is a silicone products fabrication factory. In Z.S.R Group, we work with your timeline and budgets for your multicolored silicone products. Our cost-effective prototypes can be populated in small production runs that align with your schedule. We work closely for achieving high-quality custom colorful silicone products for your company. Get in touch to learn more and order your custom multicolored silicone rubber products.