Custom Silicone Mats Manufacturer

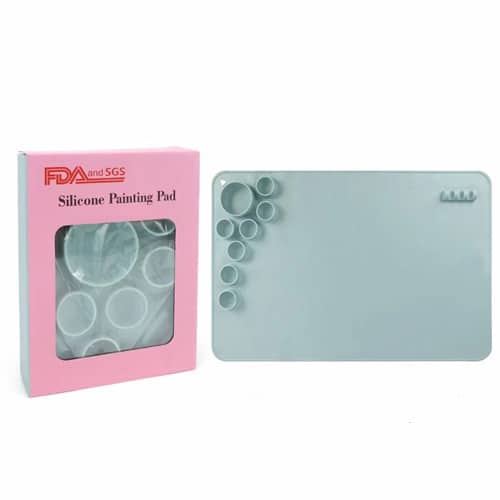

OEM & ODM solutions for your brand. Food-grade silicone mats with FDA/LFGB certification. Low MOQ from 100 pieces.

OEM & ODM Silicone Mat Solutions

Silicone mats are engineered silicone sheets or molded pads designed and manufactured for specific purposes. Custom silicone mats are great, multiple-function products used in various industries. Depending on functional requirements, their logo can be solid, embossed, perforated, or printing.

Z.S.R. is a leading food-grade silicone mats manufacturer and custom silicone mats molding solution provider in China, with over 18 years of experience in compression molding, LSR injection molding, dripping molding, and silicone fabric coating and curing processes to customize FDA & LFGB certified, OEM/ODM design, non-slip, heat-resistant silicone mats for global brands.

What Can We Customize?

Z.S.R team offering the OEM services from silicone mat design, prototyping, to silicone mat contract manufacturing, printing, package. Z.S.R team works with the brand owners, product development managers, product managers, and product designers in various industries together to offer them custom silicone mats with customized in shape, functions, sizes, and embossed logos by opening the new tooling and customizing the silicone mats’ material, hardness, color, logo, printing pattern, brand, package, label, etc.

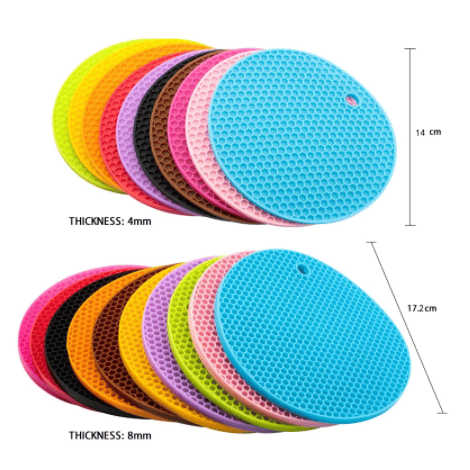

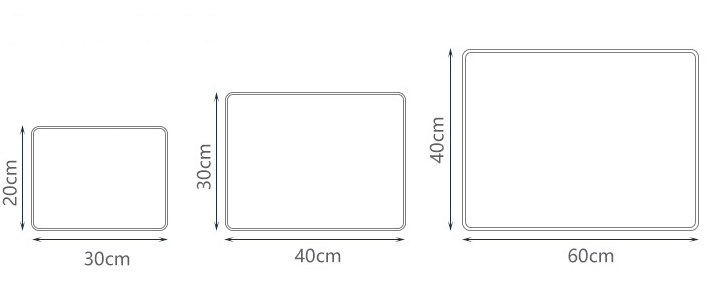

Custom Sizes

The custom silicone mat size can be designed from 10 cm to 400cm( 4″ to 160″ ). The thickness that we can make is from 0.04 to 1cm, with 0.05 – 0.3 MM lip(choose). You can customize the silicone mats to range in size and thickness. We also offer silicone sheets and can cut to size for your project. If you require food-grade silicone sheet, we recommend Platinum Cured Silicone Sheet.

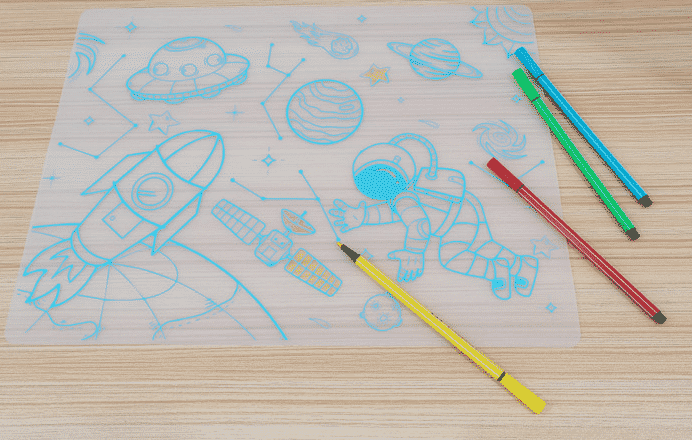

Let the mats perfect for painting, pouring, rolling dough, crafts, or baby feeding, cement/plaster, slime, clay, resin, baking and just about anything else you can dream up. If you would like to use the size that we have and print your logo and pattern on it. The existing rectangle, square silicone mats with round corners, size list for your reference:

| Type | Length (cm) | Width (cm) | Thickness (cm) | Notes (Common Uses) |

|---|---|---|---|---|

| Small | 20.5 | 15.7 | 0.1 | For small ovens, tray liners, countertop tasks. |

| 21 | 15 | 0.1 | Smaller For DAD mats | |

| 28 | 21 | 0.1 | Smaller For baby coloring mats | |

| Medium | 26 | 29 | 0.07 | General baking, pastry making. |

| 36.5 | 22 | 0.1 | General for Refrigerator mat | |

| 40 | 30 | 0.06 / 0.1 | Very common home baking/oven size and placemats size | |

| 40 | 50 | 0.07 | Idealy for placemats | |

| 41 | 31 | 0.1 | Close to standard baking sheet size. | |

| 45 | 30 | 0.1 | Idealy for placemats | |

| 45 | 65 | 0.07 | Rectangular, suitable for loaf bread, etc. | |

| 47 | 30 | 0.13 | Pet food mats, baby crawling mats, or non-slip floor mats | |

| 56.7 | 40 | 0.1 | Pet food mats, baby crawling mats | |

| Large | 50 | 70 | 0.07 | Large ovens, counter protection, work surfaces. |

| 60 | 40 | 0.1 | Bigger Pets mats | |

| 70 | 50 | 0.1 | A dough-making mat, a rolling mat, or a baby changing mat. | |

| Extra Large | 70 | 70 | 0.07 | Large worktables, commercial or special uses. |

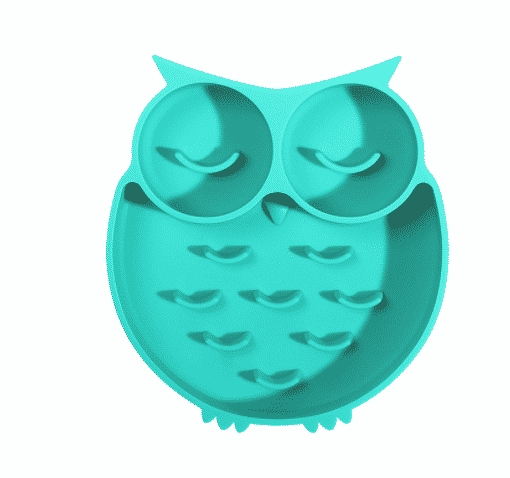

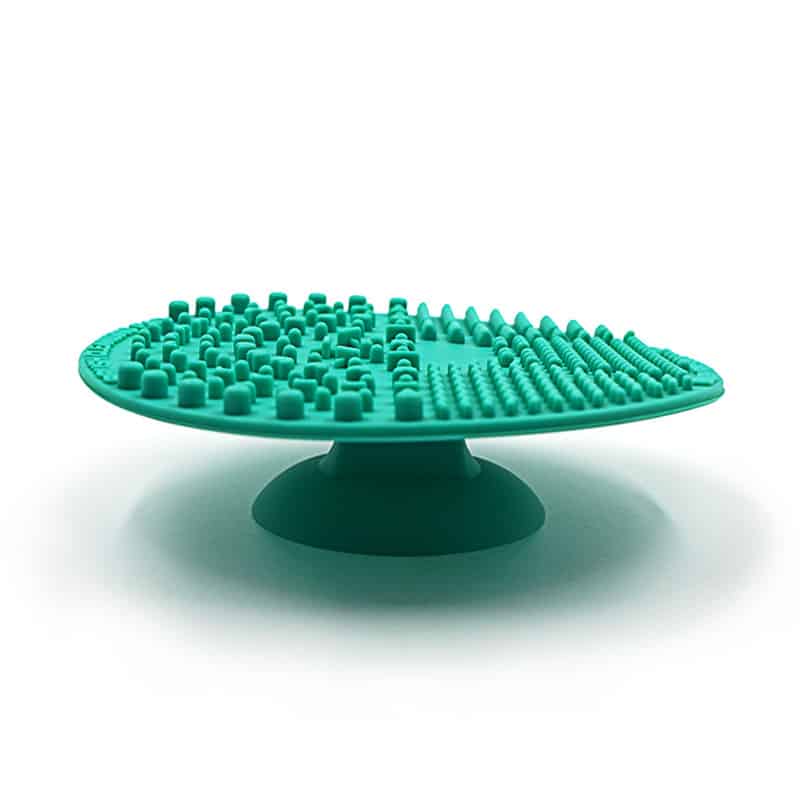

Custom Shape

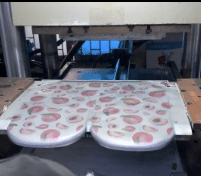

The most common shape for silicone mats is rectangles of various sizes. We can customize silicone mats in other shapes, including squares, circles, ovals, hexagons, honeycomb patterns, and other special shapes.

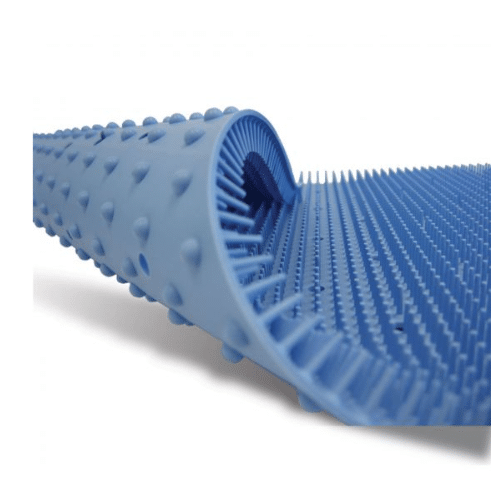

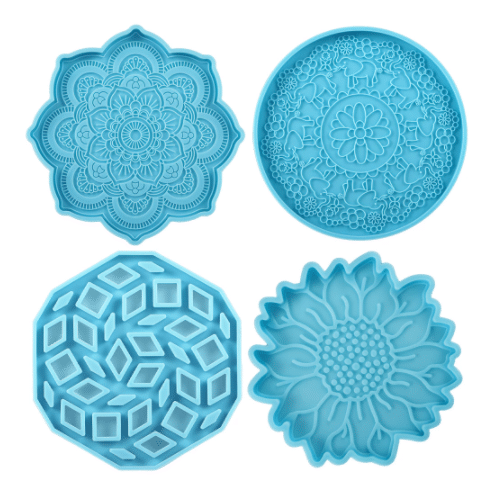

We can also use molds to customize smooth or textured surfaces for the silicone mats and embossed or debossed logos.

Special Shape mat

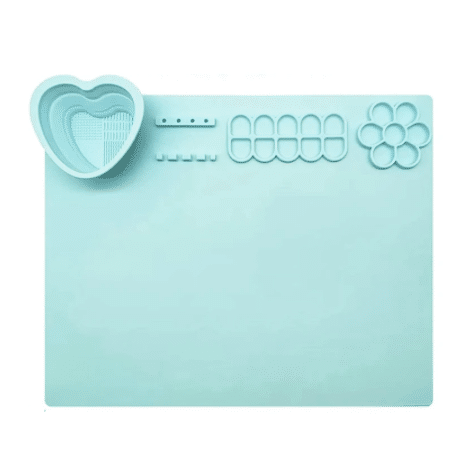

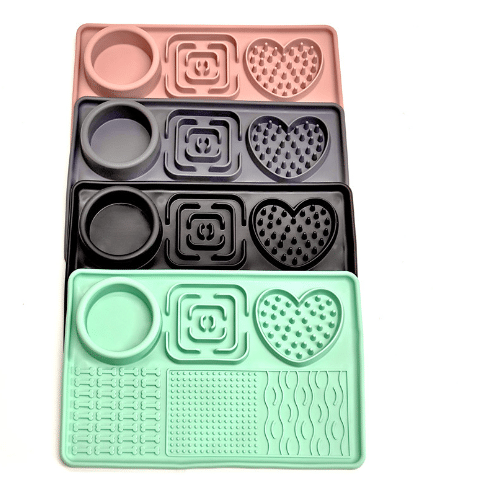

The silicone mats can be add lips and textures for special needs. It can also be used with the bristles and cups add-on for medical and painting pigment storage.

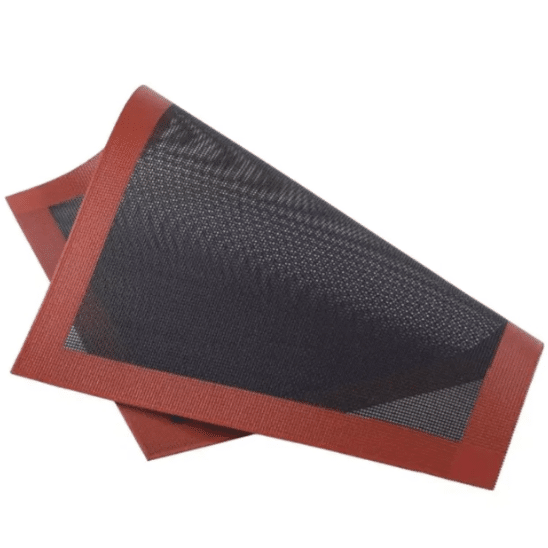

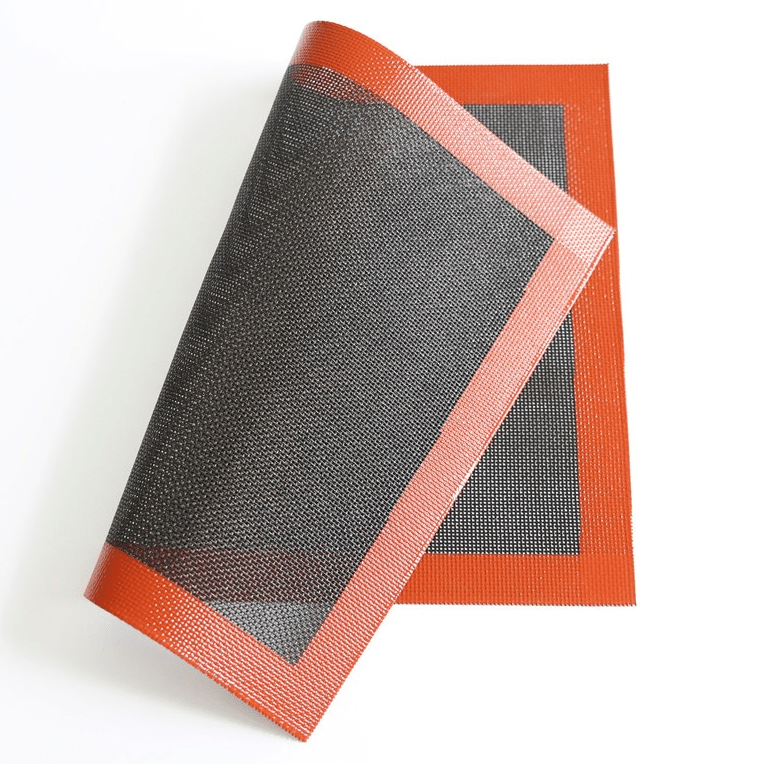

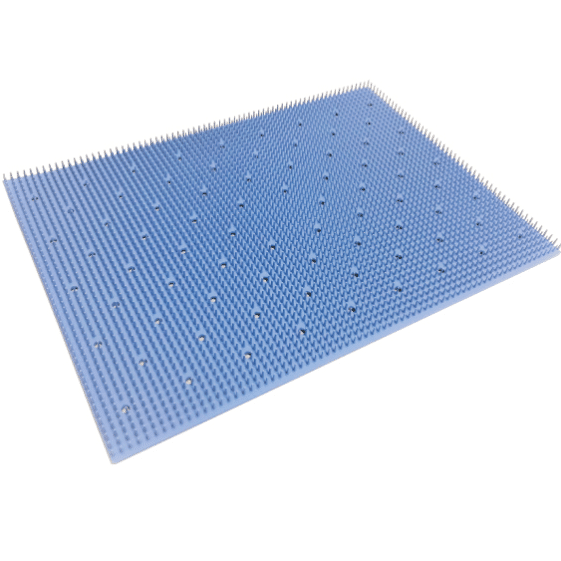

Perforated air fryer silicone mat

Silicone Draining Mat

Silicone Craft Ma

Custom Medical Silicone Pin-Mat

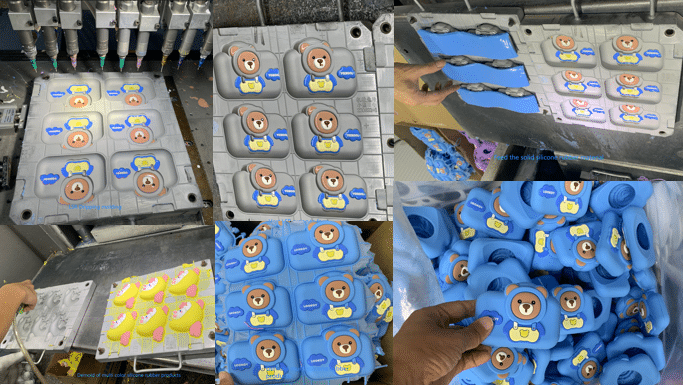

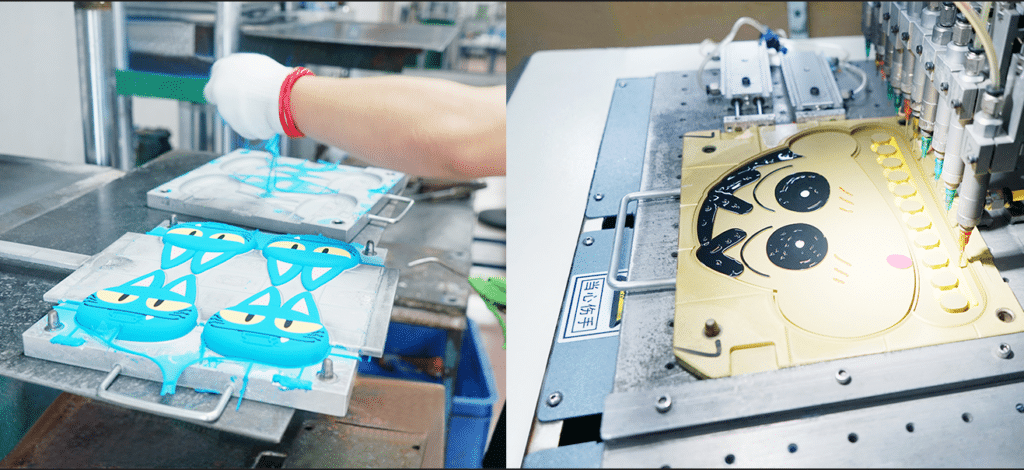

Manufacturing Processes

We use advanced molding technologies to meet your specific product requirements.

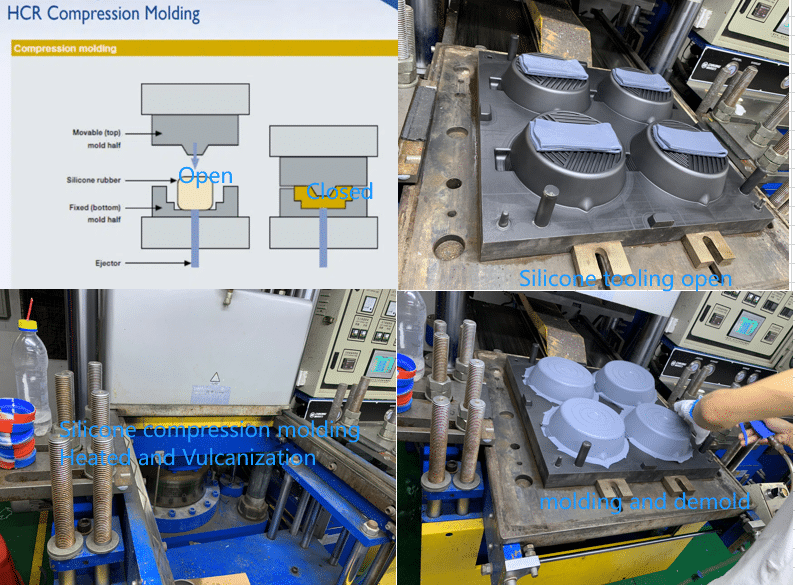

Compression molding: Mixed silicone rubber is placed in a preheated mold and pressed and cured under high temperature and pressure. It is suitable for round, square, with textures silicone mats to fit your special needs dimensions.

Calendering: The mixed silicone rubber is rolled into thin sheets using a calender, and then cut into the desired shape. Suitable for producing flat, large-area silicone mats, such as kitchen kneading mats.

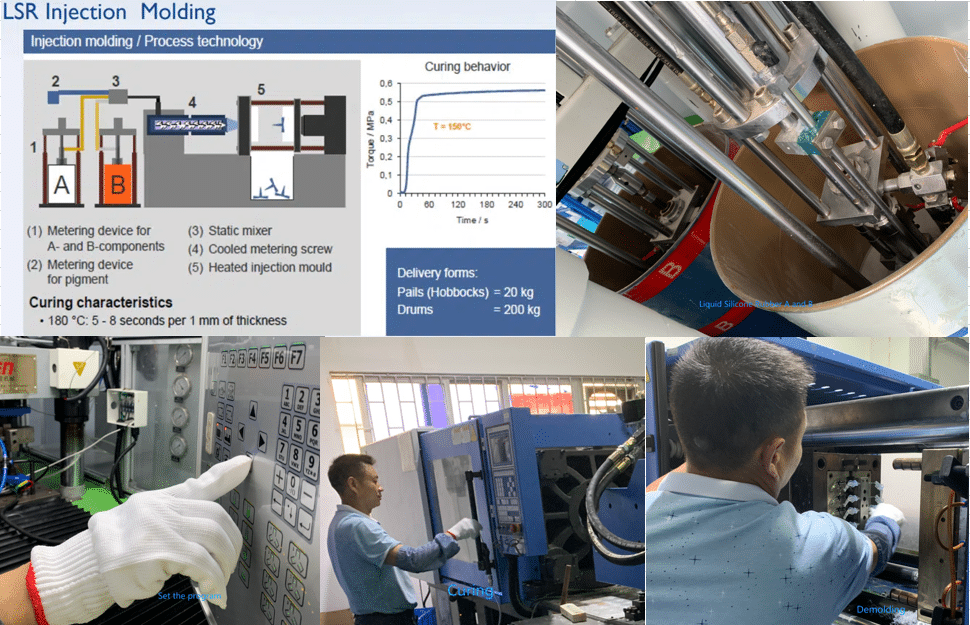

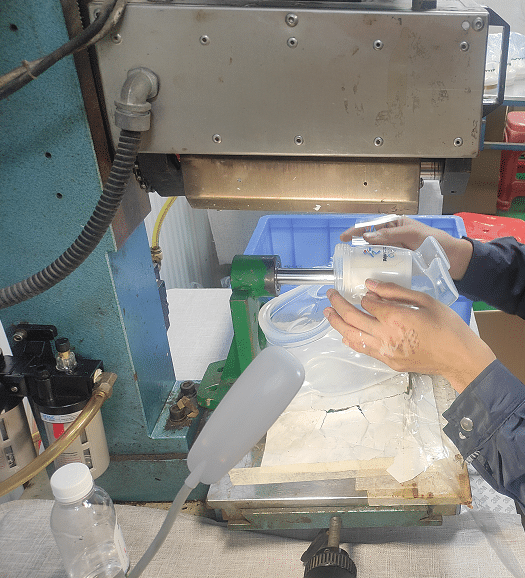

LSR Molding: LSR is injected into a mold using an injection molding machine. This method is highly automated and suitable for silicone pads with precise and complex structures with high volum request.

Drop Molding: Primarily used for small-sized decorative silicone pads with multiple colors. Liquid silicone is dripped into a mold and then heated to solidify. Then put solid silicone, curing again to be the colorful silicone mats/coasters.

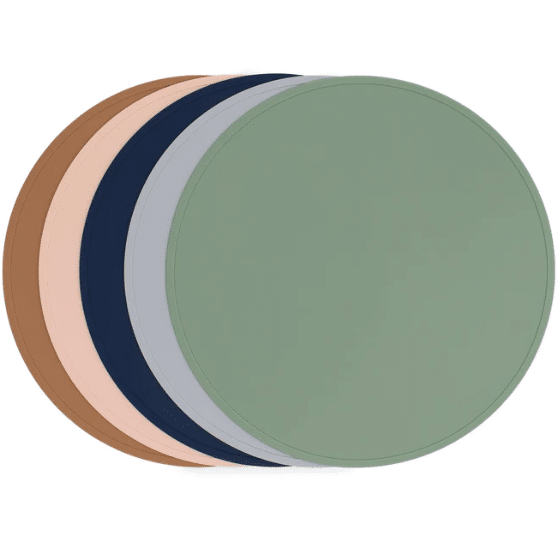

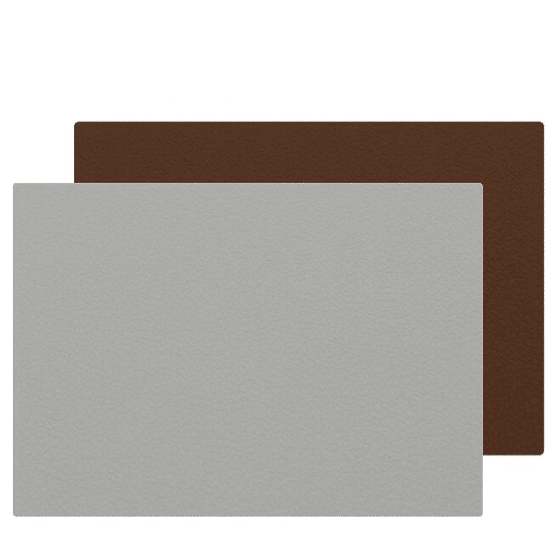

Custom color

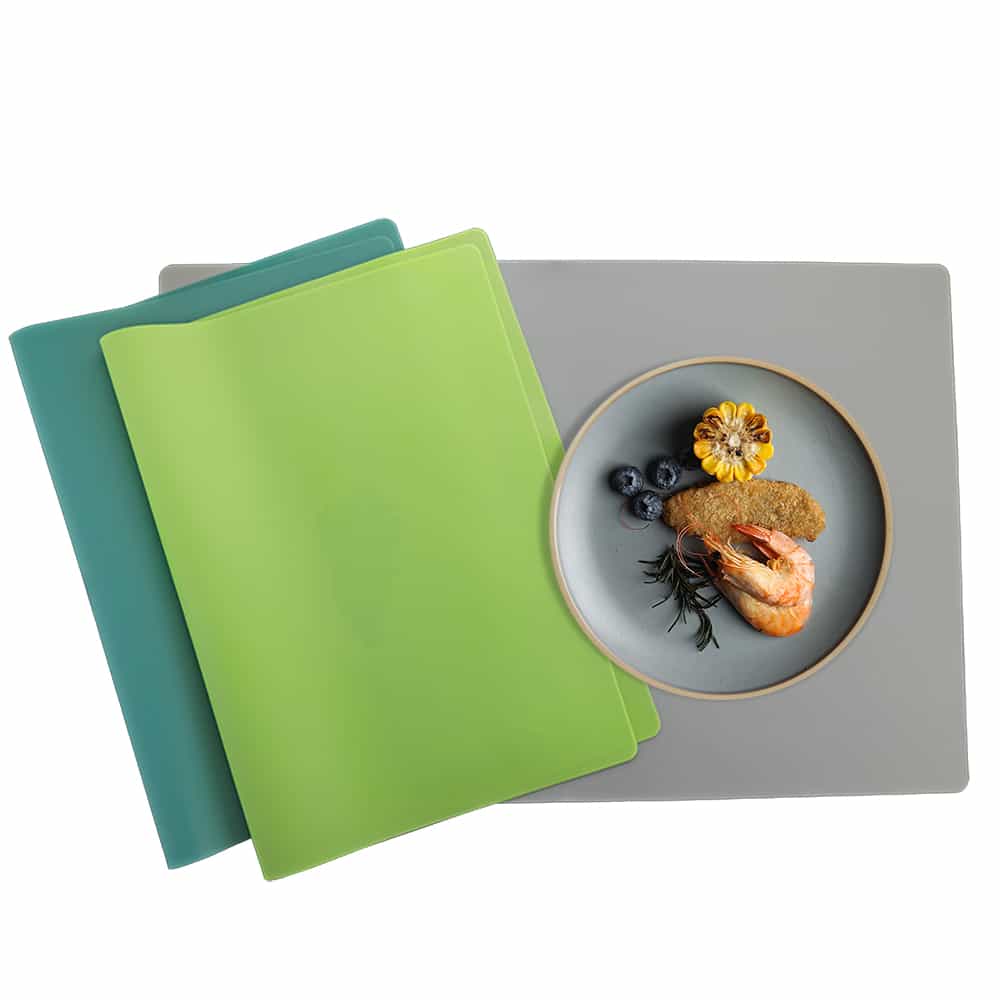

Our usual colors are Translucent, White, Tea Green, Morandi Green, and Gray. You can customize the size color according to the Pantone book.

And we can also make the double color and marble color silicone mats for you if you need:

Marble color silicone mats

Marble color silicone mats Double color placemat

Double color placemat

All the silicone mats had the color mixed. See the blog to know more about: How To Get The Colorful Silicone Mats?

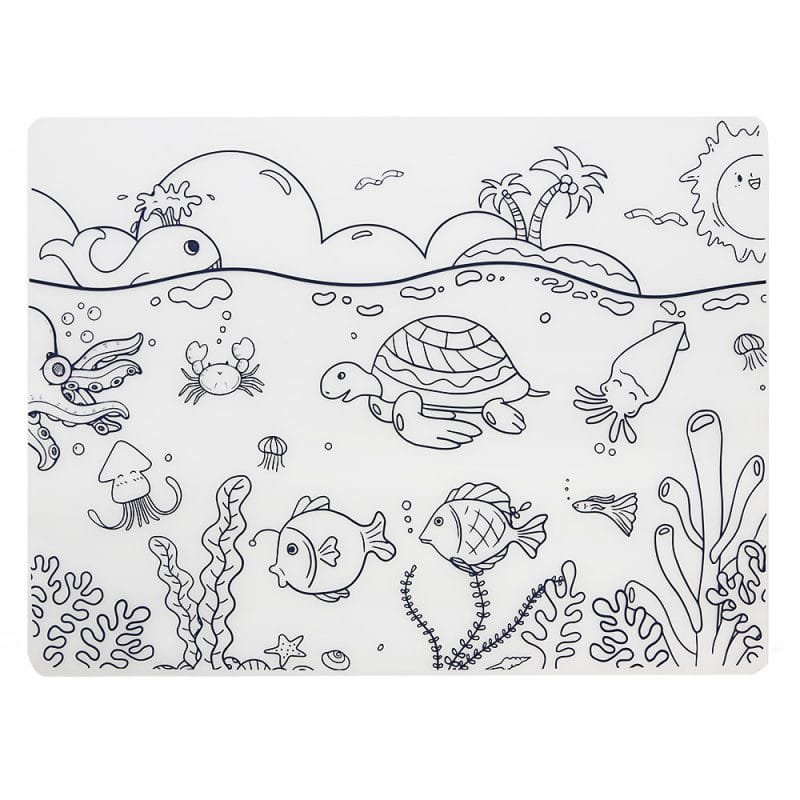

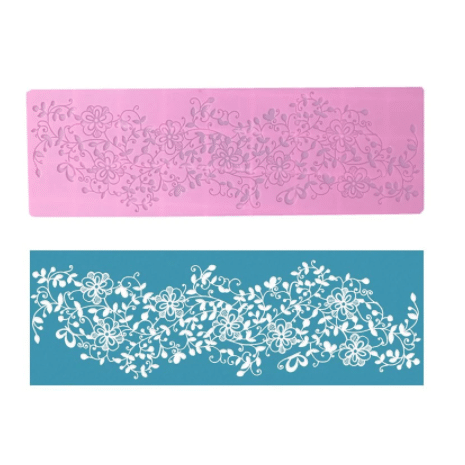

Custom logo & Pattern

We can customize different types of logos or patterns on the silicone mat, including the following styles with the printing ways:

Laser Engraving

Laser engraving uses a focused ultraviolet or fiber laser beam to irradiate the surface of silicone, causing localized physical or chemical changes in the material to form a permanent mark. Because laser processing is non-contact, it does not cause mechanical deformation to the soft silicone, maintaining the original smooth feel of the silicone mats.

Need open the jig for printing. The cost is around 100USD/jig

Silk Screen printing

Screen printing utilizes the characteristic of screen printing plates, where ink passes through the mesh openings in the image areas and blocks ink in the non-image areas. Pressure is applied using a squeegee to transfer silicone ink through the mesh openings to the surface of the substrate (such as a silicone pad). After printing, heat curing is required to ensure a strong bond between the ink and the silicone substrate. Can only print simple patterns and solid colors. This print is secure printing. They are not easy to fade as time flies. They are dishwasher safe and Food Grade. The printed jig plates are around 100USD/color.

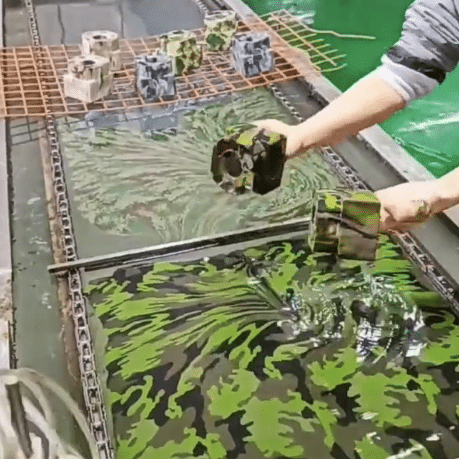

Heat Transfer printing and Water Transfer printing

Heat transfer printing on silicone mats is a process that uses heat and pressure to precisely transfer a pattern pre-printed on a transfer film onto the surface of silicone. This process has advantages such as clear patterns, rich colors, high temperature resistance, and strong adhesion, making it particularly suitable for silicone mats where high durability and aesthetics of the markings are required. This kind of printing can print very complex patterns and fading colors. You can get any pattern you like. TheThermal Transfer film cost is needed. The cost is around 299-799 USD according to the size and the pattern.

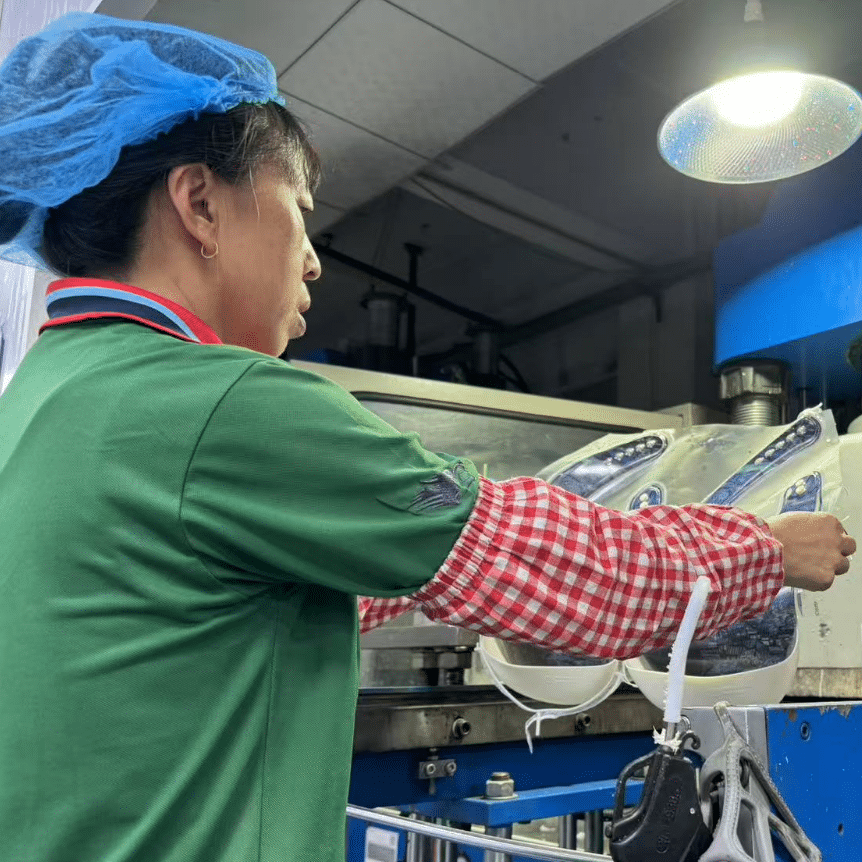

In mold Decoration

In-mold Decoration printing A process that integrates a pre-printed pattern film with silicone material during injection molding or compression molding, thereby permanently embedding the pattern into the product surface, is widely used in silicone mats where high durability and aesthetics of the markings are required. The printed mold Decoration paper cost is needed. The cost is around 599- 1599USD according to the size and the pattern.

UV printing

UV printing is an advanced process for printing high-precision, durable patterns on silicone surfaces can balance aesthetic and functional requirements. There is no jig and printed paper cost needed. The color can not as clear and the same as you need. This is also cheaper than Heat/water transfer printing and in-mold decoration.

ZSR owns the printing workshop for printing the pattern and logo by Laser Engraving, Silk Screen printing, Heat Transfer printing and Water Transfer printing, In mold Decoration, Digital printing:How To Put Logo Or Pattern On Silicone Mats?

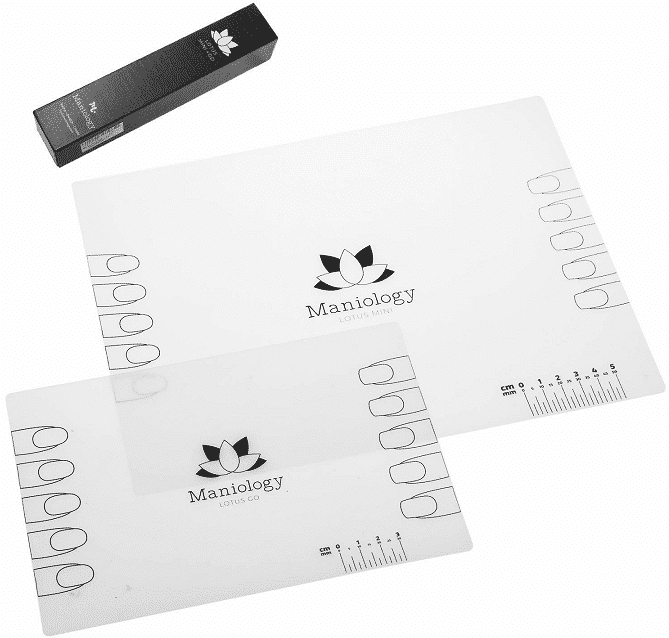

Custom Package

Z.S.R provide customized packaging solutions(Kraft wrap, custom sleeve, box, OPP) for Branded silicone mats. We offer one-stop services such as helping customers to design, develop, assemble and inspect the packaging ( Branding, UPC label, Barcode Label), ensuring the appearance of finished products is ok enough to hit the market and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished products can reach the end sellers with the highest quality.

Blister and head card

Blister with paper card package

PP bags with back card package

Colors Paper boxes

Recycled ECO-Friendly paper boxes package

Tin box package

PET package

PP bags

PP Case package

zip bag package

Get Started on Customizing Perfect Silicone Mats Today

From Mats design to delivery, we offer a complete range of services.

silicone mats Product Categories

Z.S.R. offers our partners logo-branded silicone mats to reflect their brand identity and enhance brand recognition. Discover our extensive range of customizable silicone mats, suitable for every industry and application.

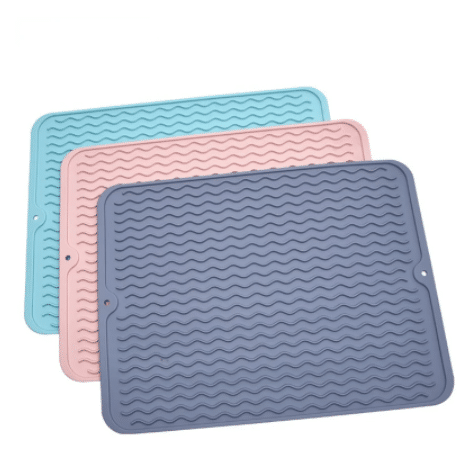

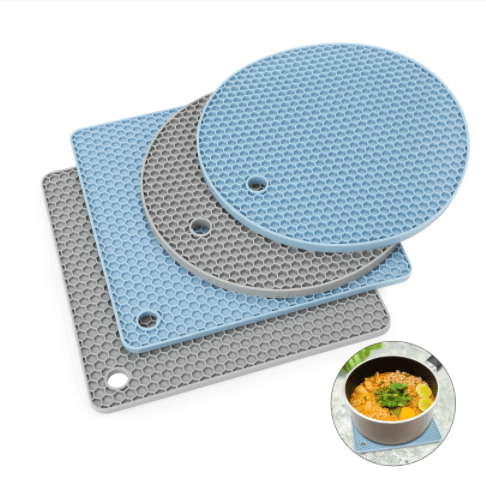

Silicone Kitchen Mats

Silicone kitchen mats are made of food-grade silicone. They are used in kitchen environments primarily for functions such as heat insulation, anti-slip, and protecting tabletops used in Home Kitchen for heat insulation and shock absorption, Baking & Pastry mats, Commercial Kitchen anti-slip mats, Sink Mat (with/without drain), Counter Mat, Countertop Mat, Faucet Mat, Dish Drying Mat, Draining Mat, etc.

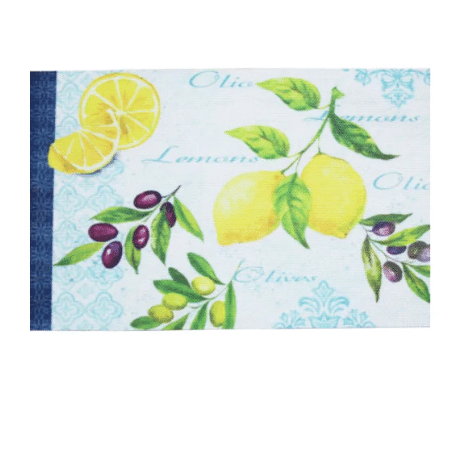

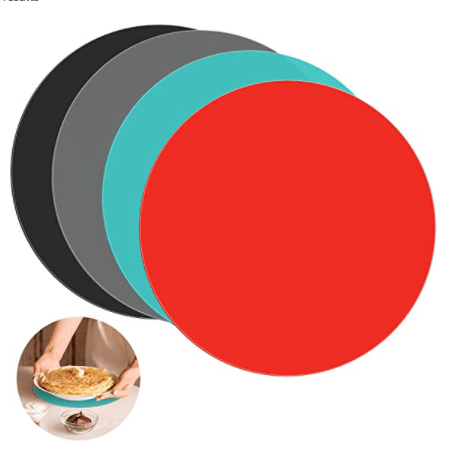

Silicone Dining Mats

Silicone placemats are placemats made of food-grade silicone material. They are mainly used to protect tabletops from high temperatures, scratches, or oil stains, while also serving multiple functions such as anti-slip and decoration.

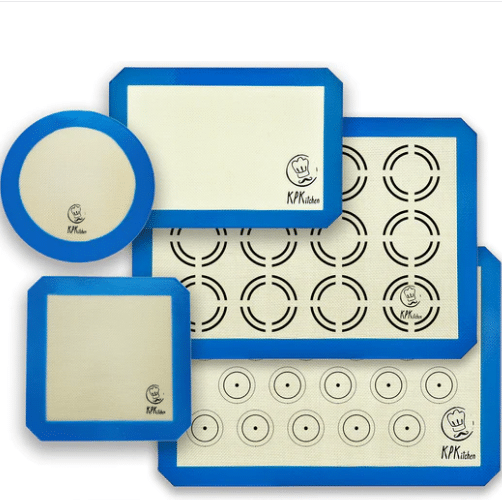

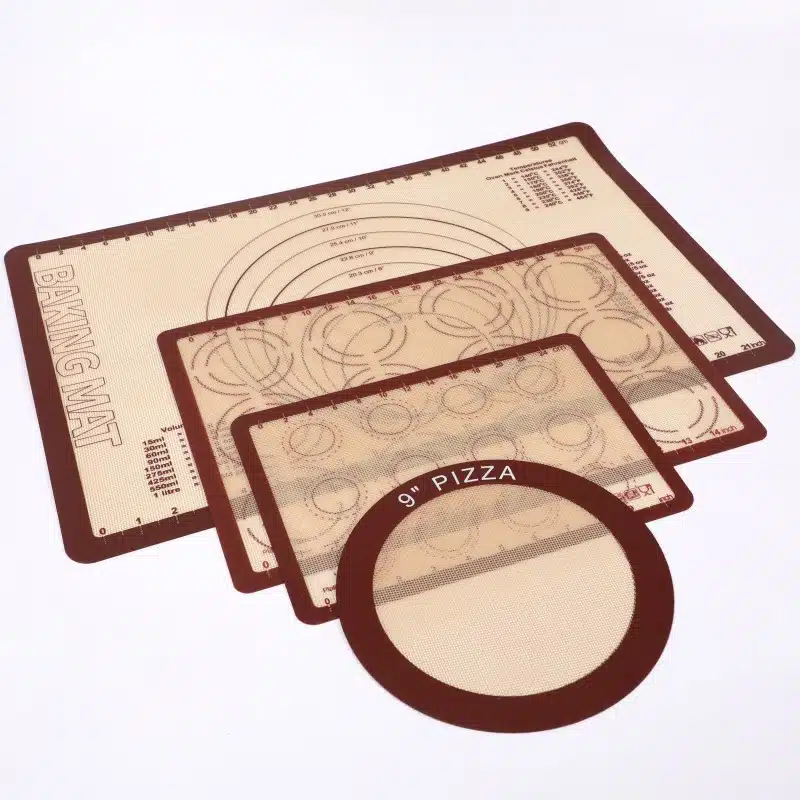

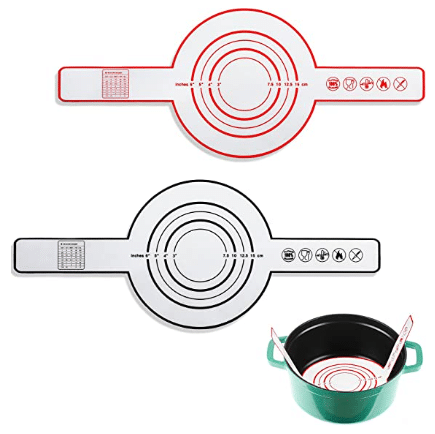

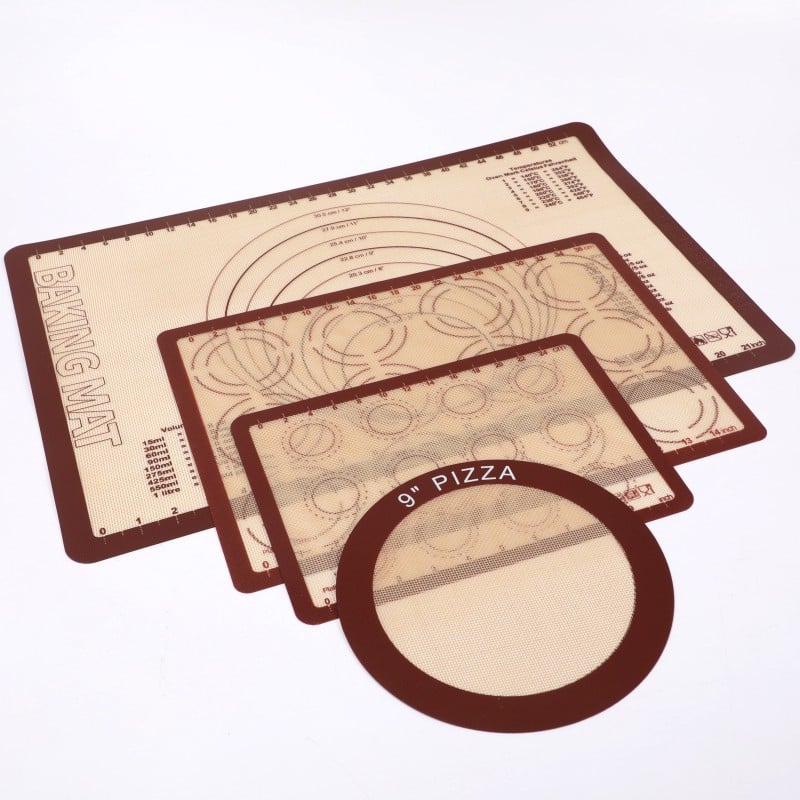

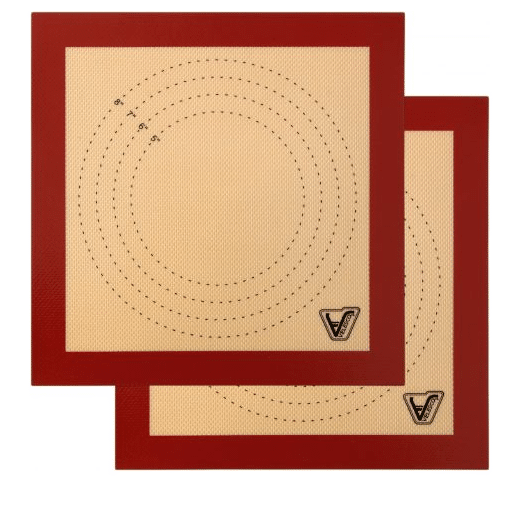

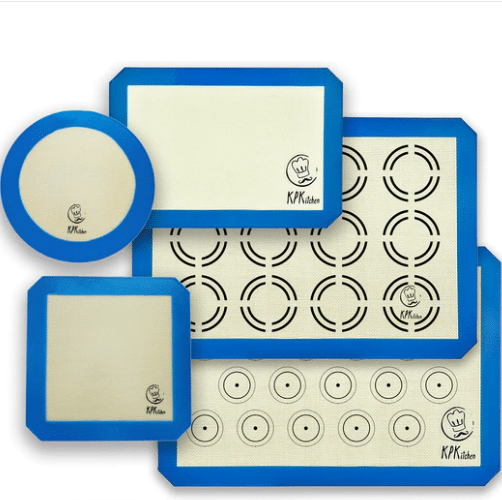

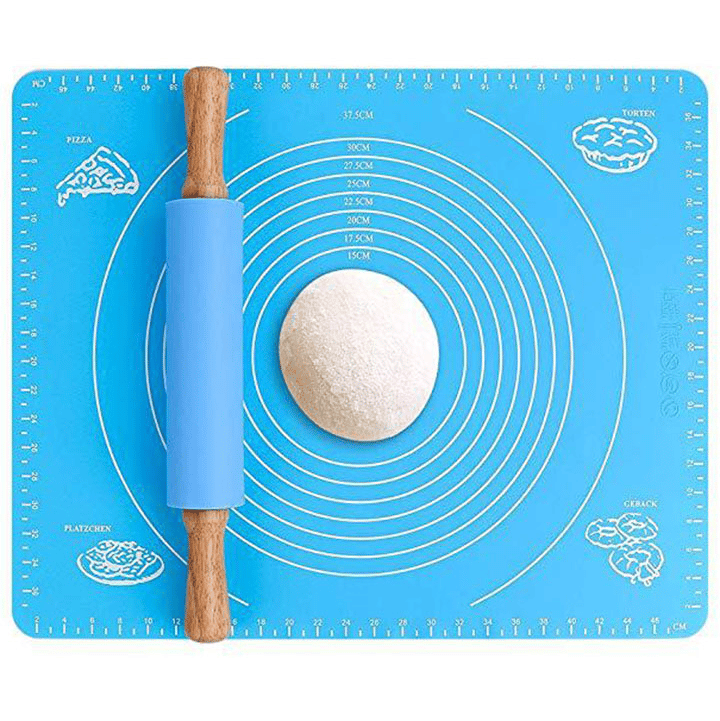

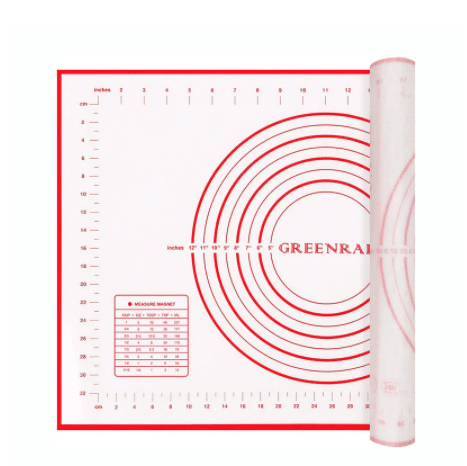

Silicone Baking Mat

Silicone baking mats are made from LSR with a heat-resistant and durable fiberglass base. They meet FDA, LFGB, and other food safety standards, are non-toxic and odorless, and can come into direct contact with food. They have excellent non-stick properties, effectively preventing dough, icing, etc., from sticking together. They are also heat and cold-resistant (common temperature range -40℃ to 280℃), making them safe for use in ovens, refrigerators, microwaves, and other similar environments.

Their surface usually has graduations for easy measurement when kneading dough, making them a reusable alternative to traditional baking paper or aluminum foil widely used in home baking, commercial bakeries, food factories, and restaurant kitchens.

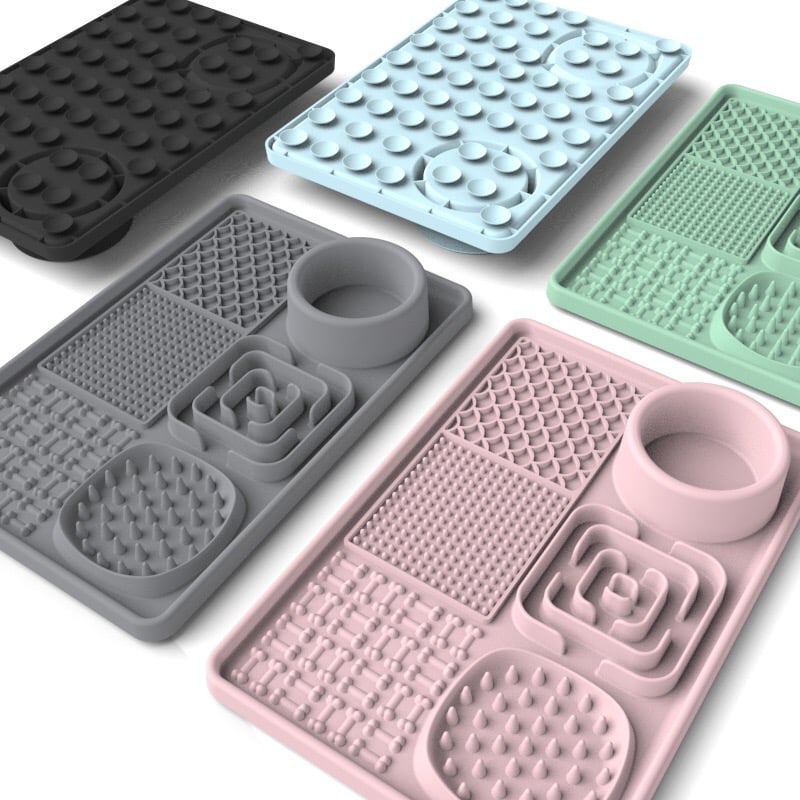

Silicone Pet Mats

Pet silicone mats are specially designed for pets, made from food-grade or safety-grade silicone material. They are primarily used in pets’ eating or resting areas and feature safety, slip resistance, water resistance, durability, and easy cleaning. Main types include: Food bowl mats, slow-feeding mats, and general-purpose resting mats/pet mats.Pet Food Mat, Pet Feeding Mat, Cat Food Mat, Slow Feeder Mat, Lick Mat / Licking Pad, Dog Lick Mat, Litter Mat

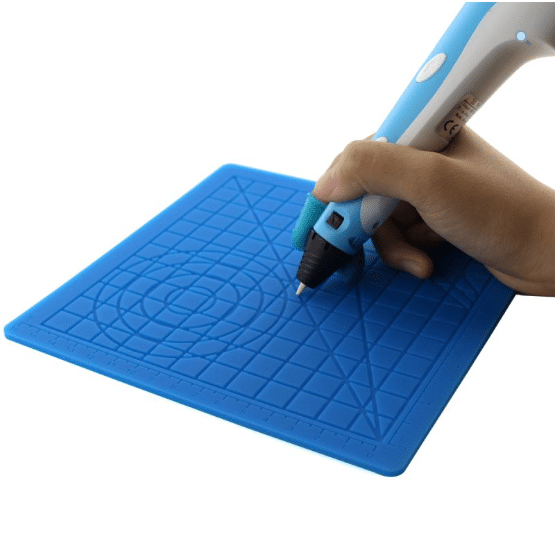

Silicone Workbench & Tool Protectors Mats

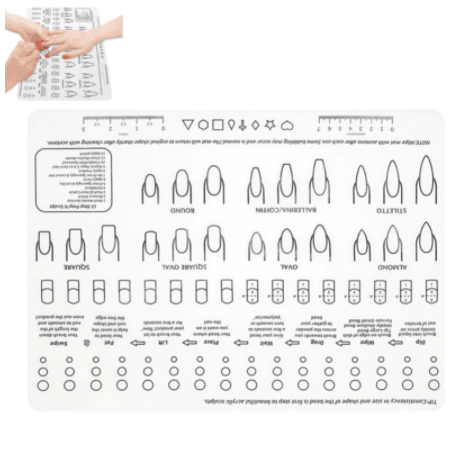

Silicone work surface mats and tool protectors are truly great partners for desktops and tools! They are non-slip, heat-resistant, corrosion-resistant, and easy to clean, making them especially suitable for scenarios requiring delicate operations, such as handicrafts, electronics repair, and the kitchen.

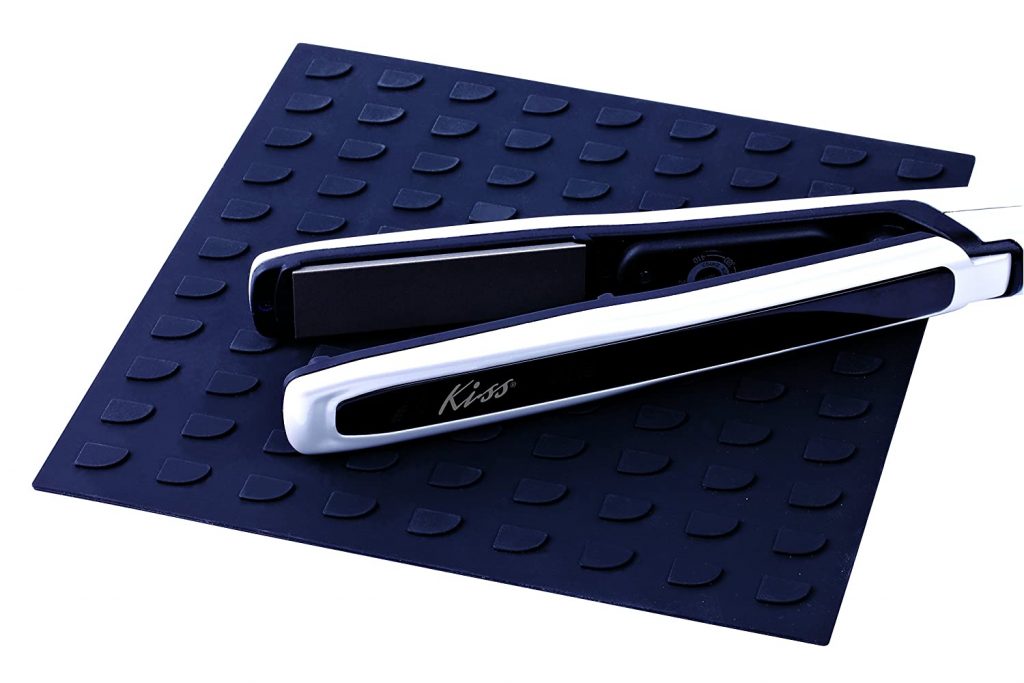

Workbench Mat, Soldering Mat, Tool Mat, Anti-slip Mat, Spill Mat. Barber station mats/salon mats, medical mats, impression mats (for soap/nails)

Silicone Floor and furniture mats

These types of mats are primarily used to increase floor friction, prevent slipping, absorb water, or provide foot comfort; they are commonly found in entrances, kitchens, bathrooms, or office areas. Floor mats, bath mats, table protectors.

Silicone Personal Care Mats

Personal Care Mats are silicone mats or functional mats specifically designed for personal hygiene, health care, and beauty care. These mats are soft, non-slip, waterproof, easy to clean, and temperature-resistant, providing a comfortable, safe, and hygienic experience for personal care activities. Personal Care Mats prioritize comfort, hygiene, and care functions, making them suitable for bathrooms, sinks, vanities, beauty areas, and home care environments.

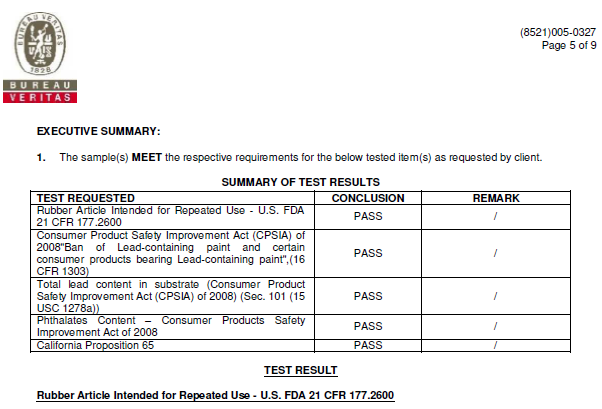

100% FDA or LFGB standard silicone mat

The silicone mats that Z.S.R manufacturing are all made from high-quality, food-grade silicone or LFGB standard silicone material,100% natural, BPA-free FDA/LFGB compliant. Our mats are heat-resistant, non-slip with protective, durable, flexible, and reusable—ideal for sustainable, high-visibility branding.All mats are safe from -40°C to 230°C Heat Insulation, ECO-friendly, Elegant appearance,Anti-Skid, non-shifting, Odorless, Draining, waterproof, easy-clean, quick-dry, and no residue making it. They are all reusable, non-stick, Non-toxic, food-grade safe, and can pass FDA, LFGB, REACH, EN71. Reduce stress and pollution on the environment; save the earth from disposable plastic; save trees..

Why Choose Z.S.R as your Silicone Mats Manufacturer?

Safety products

The silicone products what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV to let you and your clients stay safe.

Safety Factory

Z.S.R is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney. The third parties and the world’s Fortune 500 companies have helped you verify the factory strength and reliability for you.

100% safe raw material

Food-grade high-quality silicone materials, 100% high-purity food-grade platinum silicone which are safe and environmentally friendly, non-toxic and harmless. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

18 years of custom silicone products experience

Rich market experience and engineering make us familiar with the products and market (USA, EU, Japan ) requirements of different wholesale customers.

Stable production capacity

32 sets of silicone compression molding machines, 6 sets of liquid silicone rubber molding machines, 8 sets of co-injection silicone molding machines for LSR / SSR / Compression Molding over 100,000-150,000 pcs daily and export to 40+ countries.

Strict Quality Control

Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the high qualified Silicone products as the prototype they approved.

How to Order Your Silicone Mats

Z.S.R Group: As a silicone mats molding factory that can cooperate with you on any needed silicone mats, we can provide quality silicone mats, as per your project requirements. We along with you in the entire process of Silicone Mats design, tooling design, and mold manufacturing. All the silicone mats and other silicone products are produced and delivered as per your requirements.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.