Liquid Silicone Rubber (LSR) Injection Molding

For more than 10 years, Z.S.R Group has offered Our liquid silicone rubber injection molding to Brands, Wholesalers, Retailers for Medical and consumer goods.

liquid silicone rubber injection molding Services

- LSR molding, Liquid silicone rubber over-molding, LSR Multi-Shot (LSR/Thermoplastic/Metal)

- Single, multi-cavity, and family molds

- Liquid Silicone Rubber

- Ideal for serial production of silicone products

- Rapid tool production in up to 3 weeks

Start A New Molding Quote

STEP | STP | CAD | PDF

Please upload your technical drawings here for a quote.

Z.S.R LSR injection molding Capacities

Injection molding is widely used in medical and sanitary products except for Industrial, daily necessities (such as silicone housewares, kitchenware, silicone gifts, etc.), baby products and other fields that require high levels of safety and environmental protection. They are in :

After the LSR injection molding, our Post-processing department does the post-processing and treatment, such as trimming, grinding, polishing, spraying, inspection, secondary vulcanization, LOGO or Pattern printing if needed, Final Quality control and testing, package and Warehouse. If you would like to know more information:

what is LSR molding

LSR molding: Liquid Silicone Rubber (LSR) molding is used to create robust, pliable, high-precision, high-quality parts in large numbers. It enables high-volume production, fast cycle times, automated processing and manufacturing of intricate shapes

Liquid Silicone Injection Molding produces parts that are highly water-repellent and resistant. As such, coupled with the precise nature of their sizing, they’re ideal for use as seals, membranes, electrical connectors, and a variety of other medical, commercial and domestic applications.

Liquid injection molding, or LIM, is a production process commonly used to make silicone products or to make products that need to withstand extreme conditions, regardless of the industry. The process is an injection molding process at the heart, meaning that materials are injected into a pre-made mold, where they’re then left to sit and curate. Then, the process repeats itself until the part run is complete.

Characteristics Of Liquid Silicone Rubber (LSR)

LSR Silicone Rubber.

A: Precipitated silicone rubber.

B: Fumed silicone rubber.

The hardness range of this series is 20-70 SHA, with excellent resistance to high and low-temperature performance(from -50℃ to +200℃), weather resistance, electrical performance, etc.

Products are widely used in electronics and electrical appliances, suitable for all kinds of keyboard, sundries, electrical wire&cable, tube, general O-ring, gaskets, seals, etc.

Translucent and able to meet the requirements of LFGB food grade(mainly for Europe).

The characteristics:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids. In comparison to other elastomers, liquid silicone rubber is resistant to bacteria growth and will not stain or corrode other materials. LSR is also tasteless and odorless and can be formulated to comply with stringent FDA requirements. The material can be sterilized via a variety of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam and numerous other techniques.

Durable: Liquid Silicone Rubber parts can withstand extreme temperatures, which makes them an ideal choice for components under the hood of cars and in close proximity to engines. Parts fabricated via liquid silicone rubber injection molding are fire retardant and will not melt— a serious problem for components created through plastic injection molding methods.

Chemical resistance: Liquid Silicone Rubber resists water, oxidation and some chemical solutions such as acids and alkali. liquid silicon rubber temperature range

Temperature resistance: Compared to other elastomers, molded silicone can withstand a wide range of high/low-temperature extremes. For example, Silastic LSR by Dow Corning for continuous use can remain stable through temperatures ranging from –60°C to +180°C.

Mechanical properties: Liquid Silicone Rubber has good elongation, high tear and tensile strength, excellent flexibility and a hardness range of 5 to 80 Shore A.

Electrical properties: Liquid Silicone Rubber has excellent insulating properties, which offer an appealing option for a host of electrical applications. Compared to conventional insulating material, silicone can perform in far higher and lower temperatures.

Transparency and pigmentation: Liquid Silicone Rubber possesses a natural transparency, this attribute makes it possible to produce, colorful, custom, molded products.

From the above information, you can see that:

The FDA (Food and Drug Administration) is standard in America( US FDA is internationally applied.) LFGB is standard mainly for Europe, Silicone products that pass either one of these tests are safe for human use. In terms of pricing, products in LFGB standard will be more expensive than FDA standard, so FDA is more widely used.

The difference between LFGB and FDA lies on the different way of testing methods, and LFGB is more comprehensive and more strict

Liquid silicone rubber’s characteristics and chemical properties make it an ideal material for applications spanning several different industry verticals. Keep reading to learn more, or contact ZSR directly for more information.

LSR molded Part Design And Materials

The most common material used in the Silicone LIM process is a high-purity platinum core silicone that’s able to create the highly durable parts that are utilized in so many industries. For example, liquid silicone rubber is especially cherished in the medical industry, as tools and instruments made from the material are biocompatible, well made and reduce the risk of contamination. Fluoro liquid silicone rubber is another material that is making headway via the LIM process, especially when it comes to automotive parts, smaller parts or parts that require extreme precision.

LSR Tooling & LSR Molding

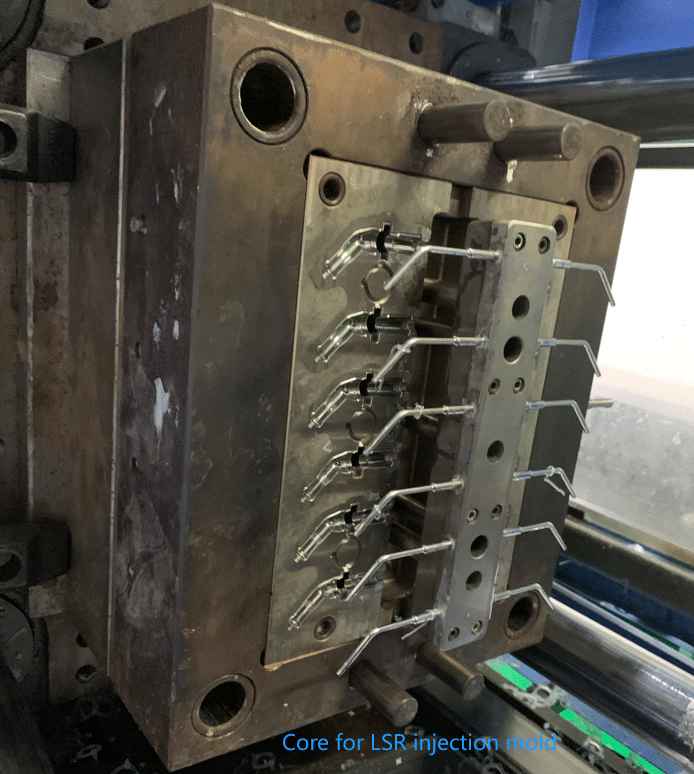

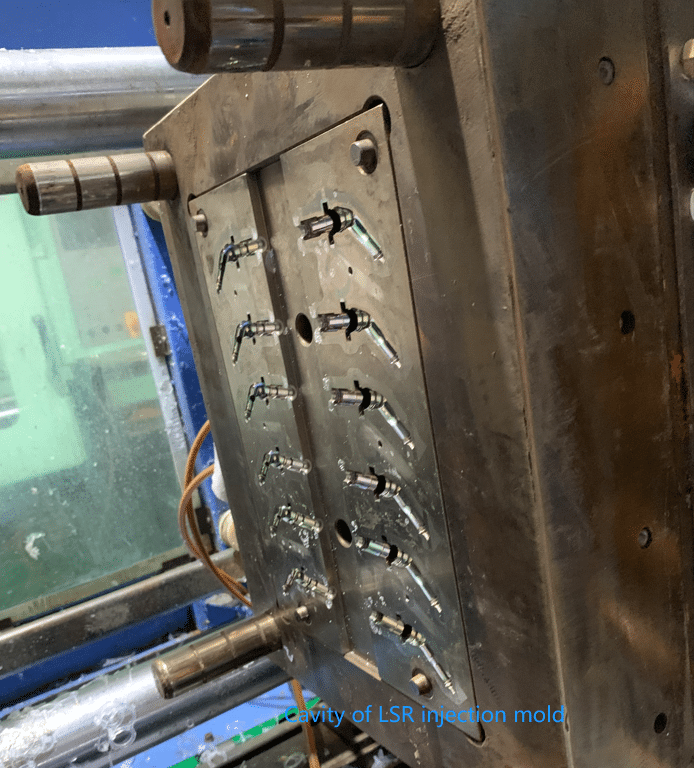

LSR tooling

LSR tooling is expensive, and building molds requires high precision and expertise beyond what’s needed for rubber and thermoplastics.

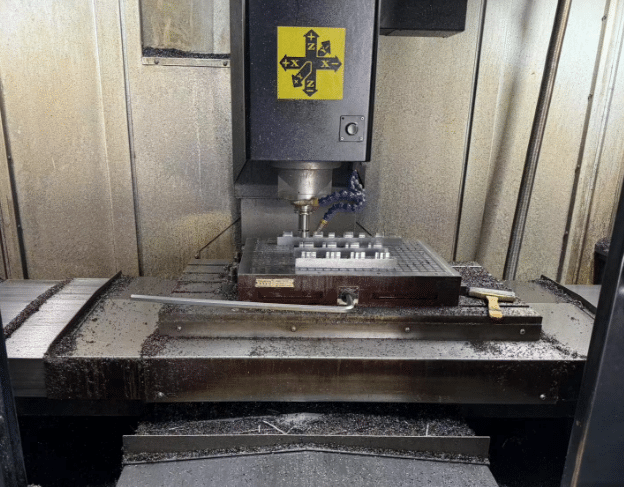

In our Z.S.R Group, we own our in-house silicone tooling workshop allows us to react quickly to customers changing requirements. Customized CNC tooling and EDM machine can fasten the LSR production process.

LSR Molding

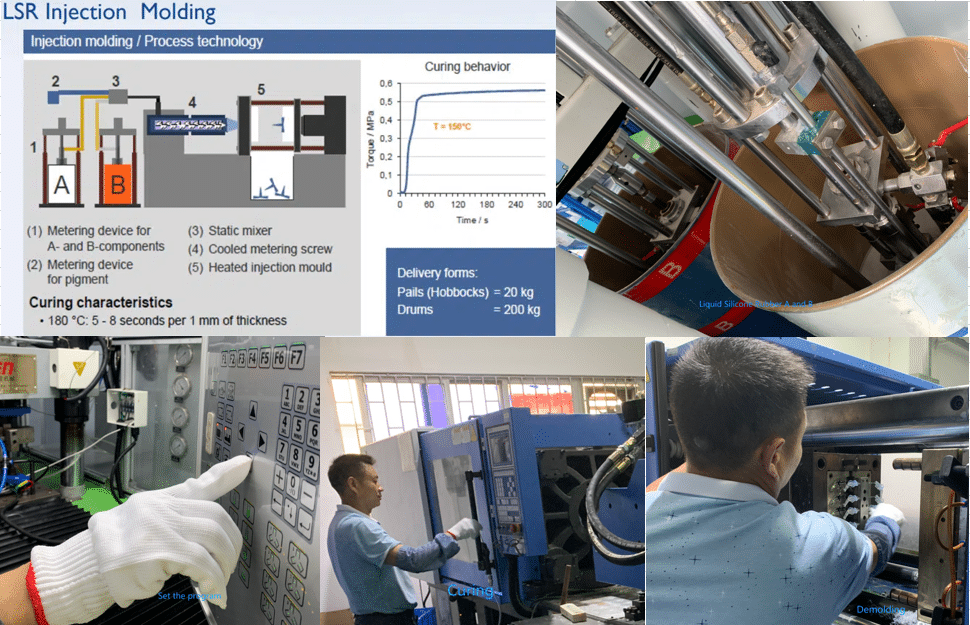

Liquid injection molding is used with liquid silicone rubber (LSR) to fix the material from an uncured state into a cured part.

Liquid Silicone Rubber (LSR) can be processed in a liquid injection molding (LIM) process. The liquid raw material is mixed from two separate components in a ratio of 1:1 and injected via a cold-runner system into a hot mold. Curing takes place within seconds, offering the advantage of fast cycling and the production of large quantities.

The process of LSR injection molding:

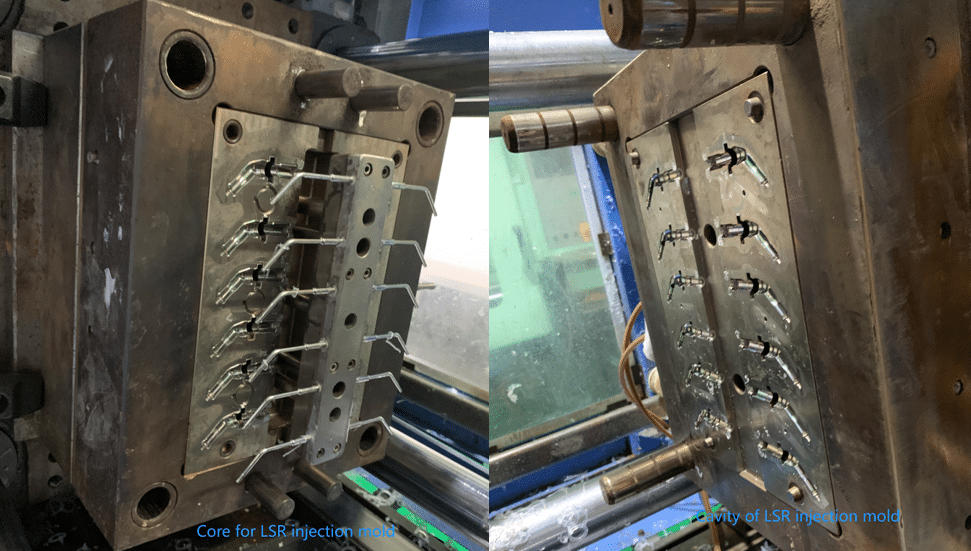

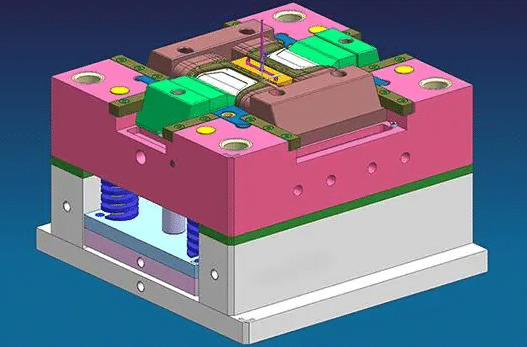

Design and make the LSR injection mold: Most of the silicone mass production injection mold was made by steel. Before you make the LSR injection mold, you should design the LSR molds according to the products requirements, size, structure, function.

Z.S.R expert engineer can design the mold for you. LSR molded part has certain inherent characteristics. It is a strong, elastic material with excellent thermal, chemical, and electrical resistance. LSR parts also maintain their physical properties at extreme temperatures and can withstand sterilization. LSR is biocompatible so it works very well for products that have skin contact. Those benefits lend themselves well to automotive, medical and food appliance industries, typically in the form of seals, gaskets, valves, and cables.

Designing parts for LSR and thermoplastics are similar, but there are some LSR-specific guidelines to consider:

Material Specifications, Grades and Durometer, The most common material used in the Silicone LIM process is a high-purity platinum core silicone that’s able to create the highly durable parts that are utilized in so many industries. For example, liquid silicone rubber is especially cherished in the medical industry, as tools and instruments made from the material are biocompatible, well made and reduce the risk of contamination. Fluoro liquid silicone rubber is another material that is making headway via the LIM process, especially when it comes to automotive parts, smaller parts or parts that require extreme precision.

- Part Size

- Shot Size

- Dimensional Accuracy

- Shrinkage

- Drafts and Undercuts

- Parting Lines/ Split Lines

- Gates

- Aesthetics

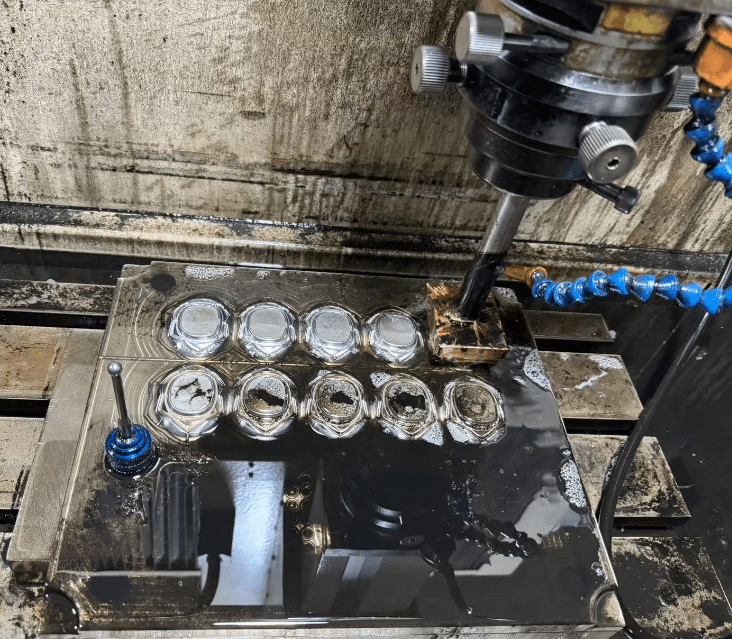

Creating a steel mold involves several precise steps. CNC milling machines carve out the mold’s cavities and cores from steel or aluminum, following the 3D CAD model.

For finer details, Electrical Discharge Machining (EDM) is used. Once the machining is done, the cavities are polished to achieve a smooth finish.

The necessary textures or surface are added through etching, laser engraving or polishing.

Z.S.R is a silicone products fabrication factory. In our Z.S.R Group, we own our in-house silicone tooling workshop allows us to react quickly to customers changing requirements. Customized CNC tooling and EDM machines can fasten the LSR production process.

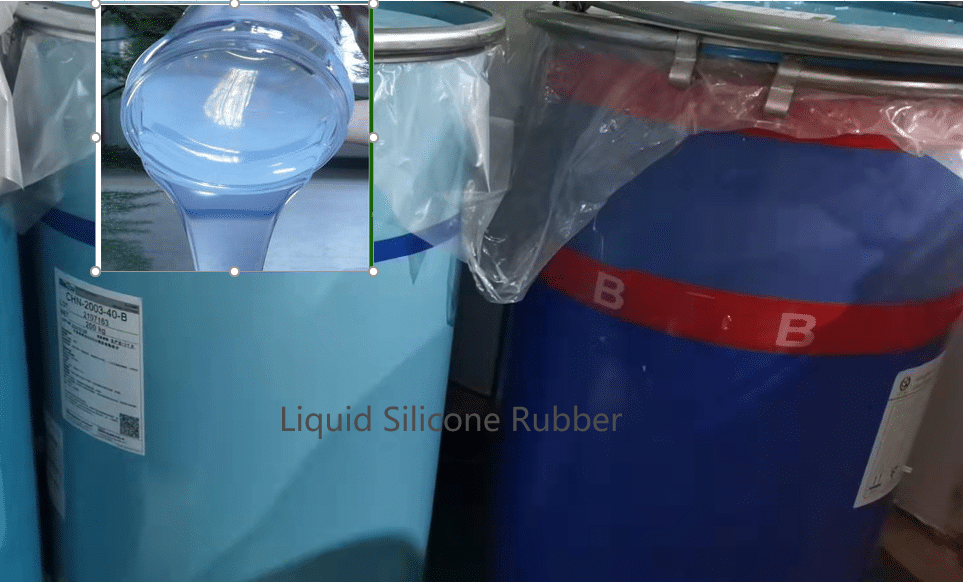

Prepared LSR molding material

Liquid silicone rubber is supplied in two parts (Part A and Part B). The liquid raw material is mixed from two separate components in a ratio of 1:1 And we also need prepare the additives like pigment before LSR molding. The uncured liquid silicone starts in two containers, Compound A and Compound B, which connect to the pumping system. Barrel A holds the base-forming material, and Barrel B contains a catalyst. A metering unit automatically releases the two substances at a constant one-to-one ratio, as well as any pigmentation additive.

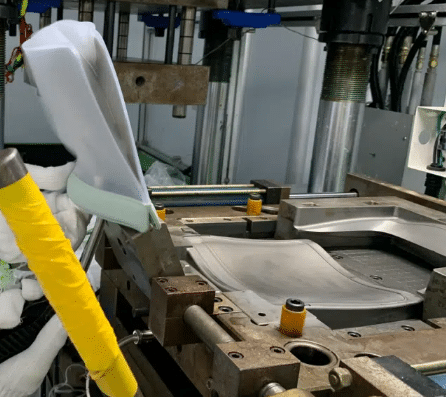

LSR Injection molding

The molder can program and customize the automated injection-molding machine and have the injection setting deliver the appropriate shot size for each job. The platens and pistons, which align and close the mold, have settings for the temperature, pressure, injection rate, and cycle time-adjusted in accordance with the customer’s specifications.

After the completion of the setup, the molding machine heats the mold to the appropriate temperature and applies the appropriate clamping force. The mold closes in coordination with the machine’s injector, pump, and supply. The injection mechanism then pushes the material into the mold and cavities.All silicone raw materials and pigments mixed then injected via a cold-runner system into a hot LSR injection mold by the silicone injection molding machine- inject the silicone raw materials into the mold cavity through heating and pressure to fill the entire mold cavity.

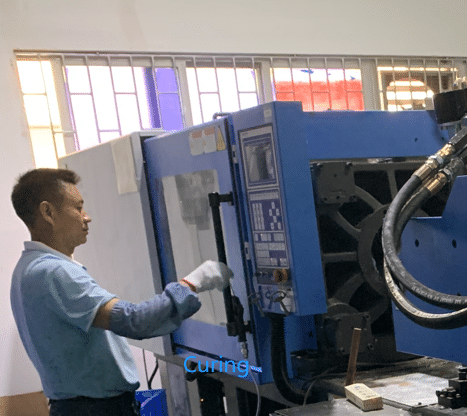

Curing

Then the curing takes place within seconds by the heated and pressure, offering the advantage of fast cycling and the production of large quantities. After the completion of the setup, the molding machine heats the mold to the appropriate temperature and applies the appropriate clamping force.

The mold closes in coordination with the machine’s injector, pump, and supply. The injection mechanism then pushes the material into the mold and cavities.

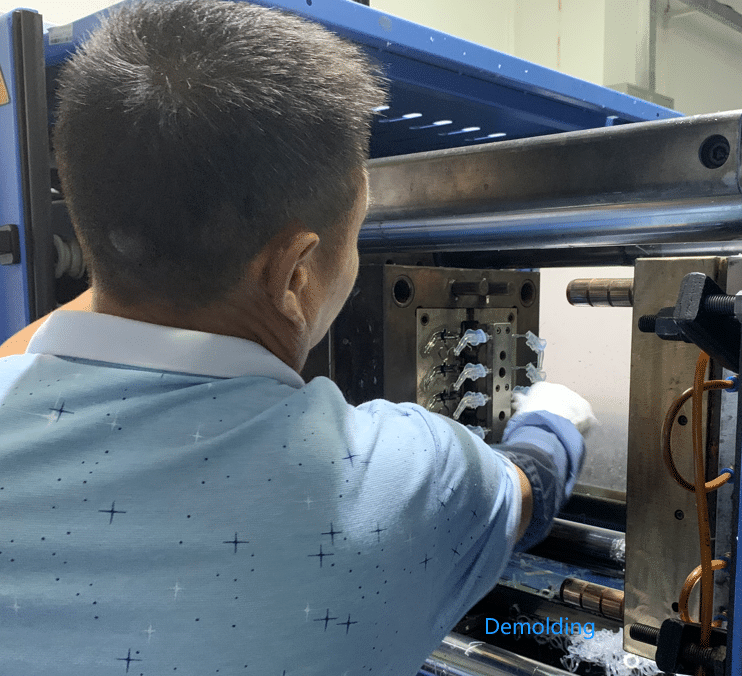

Demolding

After the silicone is cured and formed, The LSR mold open and you can take out the molded LSR product out. This step requires careful operation to avoid damaging the finished product. Sometimes, we use the hand to take the LSR molded parts out and also can use automated systems to have a better efficiency. After the removal of the item from the mold, the post-molding process may include de-flashing, post-curing, inspection, and packaging.

Post-processing: Trim, clean and inspect the LSR molded silicone products after demolding to ensure that the quality and appearance of the products meet the requirements.

Packaging: Finally, the finished LSR molded products are packaged for transportation and sales.

Complex part geometries and tight tolerances can be achieved.

Two-part material supplied in pail kits to avoid any contamination for medical silicone parts

Cold runner and flashless technology resulting in zero secondary operations

High efficiency, robust process and can be fully automated

Producing quality parts rapidly is essential in the LSR molding market. Liquid injection molding provides the most efficient and economically viable process using Liquid Silicone Rubber (LSR).

Due to the flexibility in design and tooling, LSR injection molding is ideal for producing complex geometries and can consolidate various functional features into a single part. It also offers significant advantages in terms of product reliability and total cost of ownership.

Similarly, the terms liquid silicone rubber molding, liquid silicone rubber injection molding, liquid silicone molding, silicone liquid molding, liquid silicone injection molding, silicone injection molding, LIM molding, silicone rubber molding and silicone molding are all used frequently and mostly interchangeably.

And there is 2 kind of Liquid Silicone Rubber Molding:

- LSR injection molding

- LSR over molding:LSR over molding with different material(Silicone, Metal, plastic, etc)

Silicone Over Silicone – First a silicone substrate is molded. Then another silicone is molded onto or around the substrate. The silicone could differ in color and/or hardness.

Silicone Over Plastic – First a rigid plastic substrate is molded. Then a soft Silicone is molded onto or around the substrate. This is often used to give a soft grip area to a rigid part.

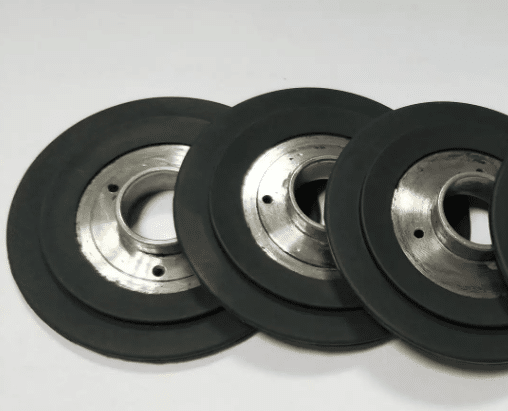

Silicone Over Metal – First a metal substrate is machined, cast or formed. Then, the substrate is inserted into a liquid silicone molding tool and the silicone is molded onto or around the metal. This is often used to capture metal components in a silicone part.

Liquid Silicone Rubber injection Products Production

For more than 10 years, Z.S.R Group offer Our liquid silicone rubber injection molding to the Brands/Wholesalers/Retailers for Medical and consumer goods. As we own 6sets of the liquid silicone rubber molding machine. we’ve been manufacturing a wide range of silicone products, mainly focused on customized silicone consumer products and medical products. Our one-stop silicone products manufacturing factory operates at a high capacity and is focused on producing your personalized silicone products to meet your scalability requirements

Benefits Of LSR Injection Molding

Limitless design – Enables production of part geometries and technical solutions not possible otherwise

Consistent – Provides the highest consistency in the product dimension, precision and overall quality.high level of accuracy in production of Silicone LIM parts.

Pure – Liquid Silicone Rubber is one of the most extensively tested biomaterials with a long history of safe use

Precise – Flashless, wasteless tool design concepts for parts weighing from 0.002 grams to several hundred grams

Reliable – Using the latest technology in machinery, tooling and automation

Quality – Zero-defect quality level through in-process controls

Fast – Enables highest volume production due to short cycle times, from several thousand to millions

Clean – Utilizing state-of-the-art processing techniques and production in Class 7 and 8 cleanrooms

Cost-effective – Offers lowest Total Cost of Ownership

Tensile Strength -To piggyback off of the above advantage, Silicone LIM parts are strong which makes them applicable for a variety of industries.

Flexibility – Silicone LIM parts can exhibit elongation up to six times in length before breakage.

Automation – LIM is a process that can run around the clock with minimal supervision.

Less Waste – Don’t expect excess flash here, an injection molding produces less scrap and waste.

Liquid silicone rubber injection molding provides customers with a consistent, efficient and cost-effective processing method appropriate for a wide variety of applications.

Industries And Applications

The Liquid silicone rubber Industries and applications include:

The liquid silicone rubber is widely used in medical and sanitary products except for Industrial, daily necessities, mother and child care products and other fields that require high levels of hygienic, safety and environmental protection. They are in :

- Home & housewares & Appliances ( Kitchen & dinning&table & Drink ware &household.etc.)

- Baby & Toys ( Baby care & Baby Feeding & Baby Toy & kids learning toy etc)

- Health & Beauty & Personal Care (Oral care & Beauty tools/Accessories & hair care ,etc.)

- Stationery & Office Products(Arts & Crafts& School products & Office products etc. )

- Sports & Outdoor & Garden ( Sports and fitness & Travelling & Outdoor portable etc. )

- Pets Supplies

- Electronic & Cell Phones Accessories ( Protective cover& Case, holder etc.)

- Automotive & Aerospace & Military

- Smoking products

- Promotional products (Licensed products & Mascot & Gifts & Blind box products)

- Medical products

Especially in Valves and gauges, Membranes and seal rings, Irrigation and filtration parts, Pressure exit, check and one-way valves, Lighted panel buttons

When in high quantity, Liquid silicone rubber injection molding provides a consistent, efficient and cost-effective processing method appropriate for a wide variety of applications.

LSR Quality Standards

From product design, tooling, prototyping or new product build, the silicone rubber molding manufacturer must have the capabilities to satisfy the most demanding specifications and an unwavering commitment to delivering the quality you expect. The most rigorous quality assurance standards for liquid silicone rubber injection molding should include the following elements:

Stringent in-process inspection procedures: LSR parts receive constant monitoring for defects, damage, or any other inconsistencies withdrawing.

Quality programs need to get the part production right the first time to save you time, money and your reputation. As an ISO 9001:2015, ISO 14001:2015 company, The Z.S.R Group quality assurance system has made more than 1000 projects to the Babycare and Medical brand as well as other businesses from around the globe the proven ability to produce high-precision products of impeccable quality.

Custom Molded LSR Solutions For Your Business

In Z.S.R Group, we work with your timeline and budgets. We dedicated its focus exclusively to molded silicone rubber component manufacturing. We have mastered the production of both high-quality LSR products and LSR 2-Shot products. Z.S.R Group provides LSR molding Solutions™, taking “custom” to a new level. We have been a leading Liquid Silicone Rubber parts manufacturer, serving some of the world’s largest companies. Our advanced capabilities encompass all aspects of the design and production processes. We can help you choose the right grade of LSR for your part, offer part design support to optimize manufacturability (DFM) and part performance, provide premium-quality tooling, and high-volume parts production and packaging solutions that keep your overhead costs low.

We produce custom-designed and manufactured, high-quality LSR products and LSR 2-Shot parts for our customers in the automotive, medical, life sciences, industrial and consumer markets. Contact us today for a quote.

Our cost-effective prototypes can be populated in small production runs that align with your schedule. We work closely for achieving high-quality custom LSR molded silicone products for your company. Get in touch to learn more and order your custom silicone rubber products.