Custom Silicone Molds Manufacturer

OEM & ODM solutions for your brand. Food-grade silicone molds with FDA/LFGB certification. Low MOQ from 100 pieces.

OEM & ODM Silicone Molds Solutions

Silicone molds are versatile, heat-resistant, and reusable forming tools made from 100% food-grade can used for molding, shaping, or casting materials such as food, resin, wax, soap, plaster, and more.If you are looking for a silicone molding company that can help you with premium Silicone Molds, Z.S.R are here to help you.

Z.S.R is a leading silicone molds manufacturer and custom Silicone molding solution provider in China with more than 18 years of experience. We specialize in creating high-precision, food-grade, medical-grade, and industrial silicone molds through OEM/ODM services.

What Can We Customize?

Z.S.R team offers the OEM services from Silicone molds design, prototyping, to Silicone molds contract manufacturing, printing, package. All the Silicone molds what we made canbe customized in size, design, function, structure, shape, color, logo, pattern, package, label, and offer other silicone products technical support to ensure their silicone molds project.

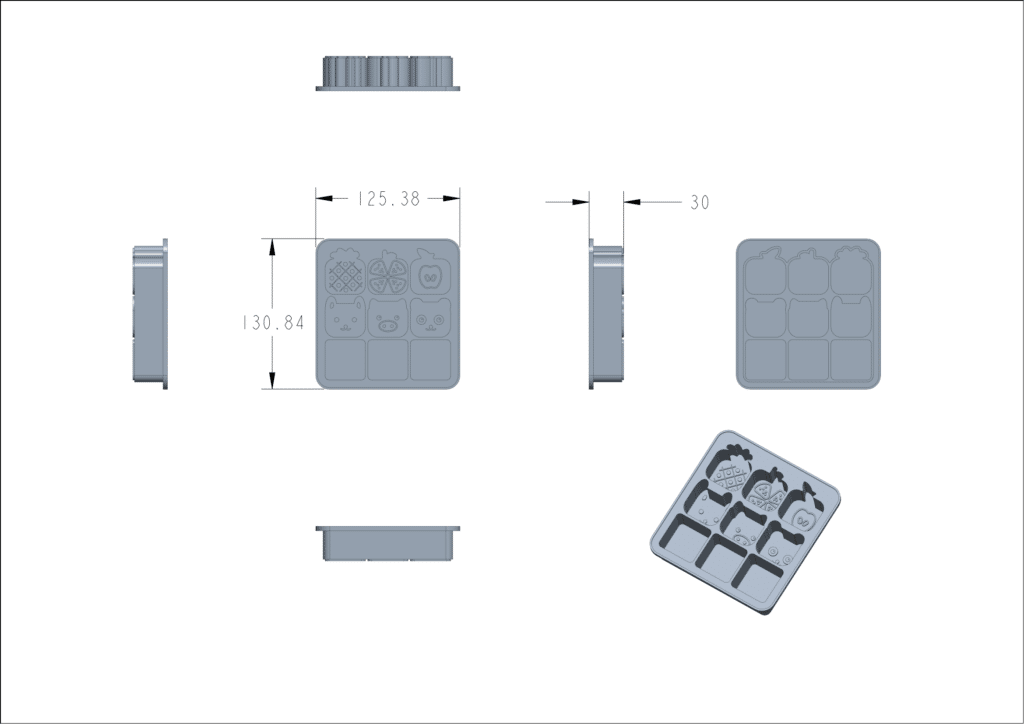

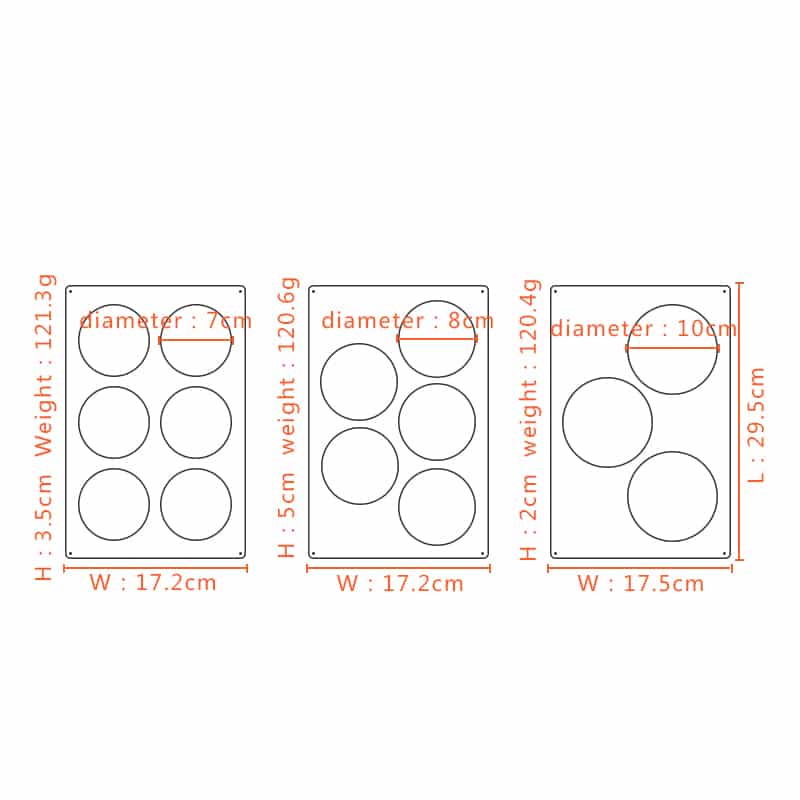

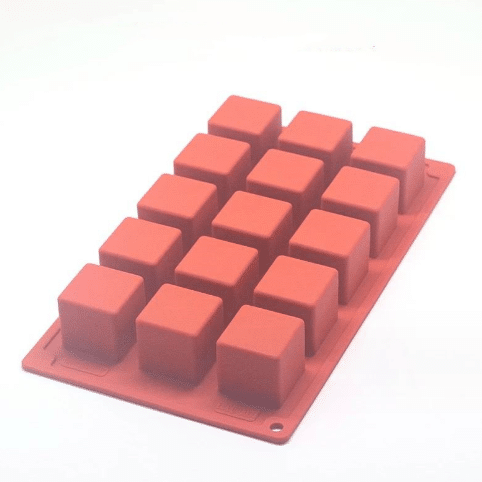

Custom Sizes

The size of the custom silicone molds can be designed as follows: height: 0.1-5 cm, width: 0.2-80cm, and length: 0.5-80cm. The thickness we can produce ranges from 0.05 to 1cm. You can customize the silicone molds to range in size and thickness.

Custom Shape

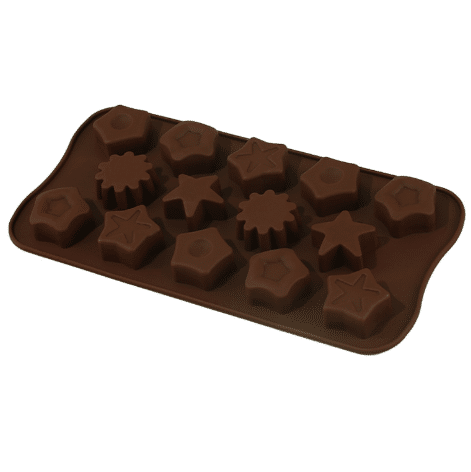

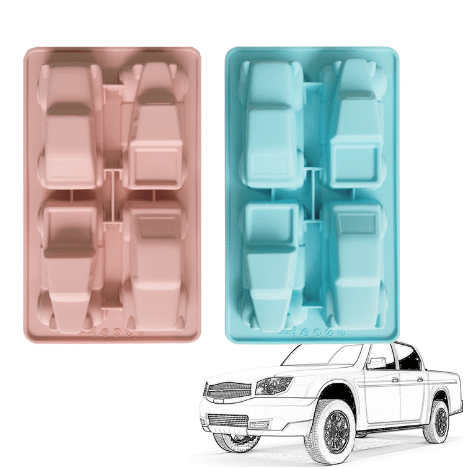

You can customize the silicone molds’ function, structure and shape, and embossed logo by opening the new tooling with CNC & EDM mold making.

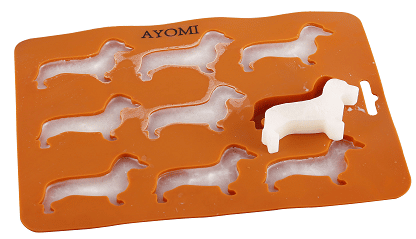

The silicone shape and structure can depend on your needs: Flower, Square, Tangle, Animal, heart, Star, etc

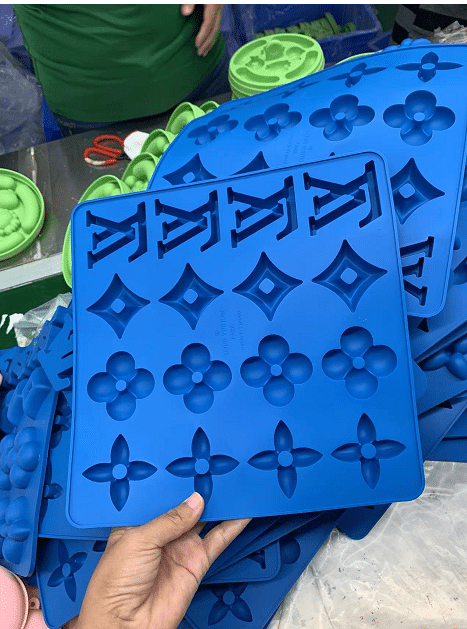

Special Shape

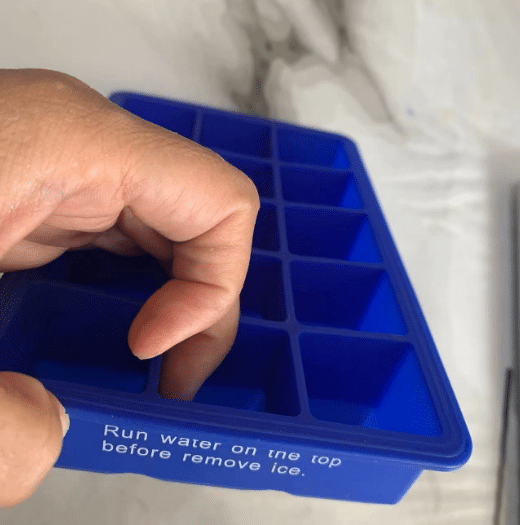

Can designed Branded ice trays, logo-shaped chocolates, or creative souvenirs. Highly popular among IP licensing, event merchandising, and promotional gift companies. All the silicone molds that your custom is Food Grade Silicone, BPA-free, Eco-friendly, and Heat-resistant.

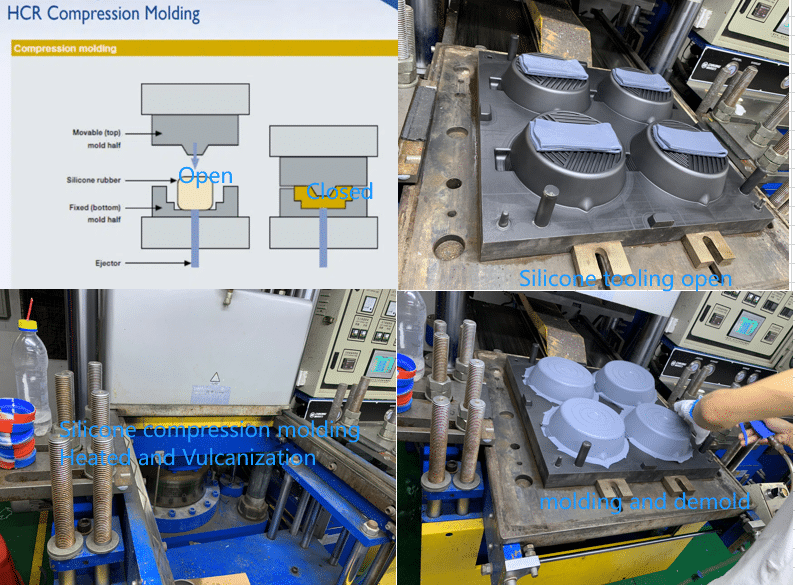

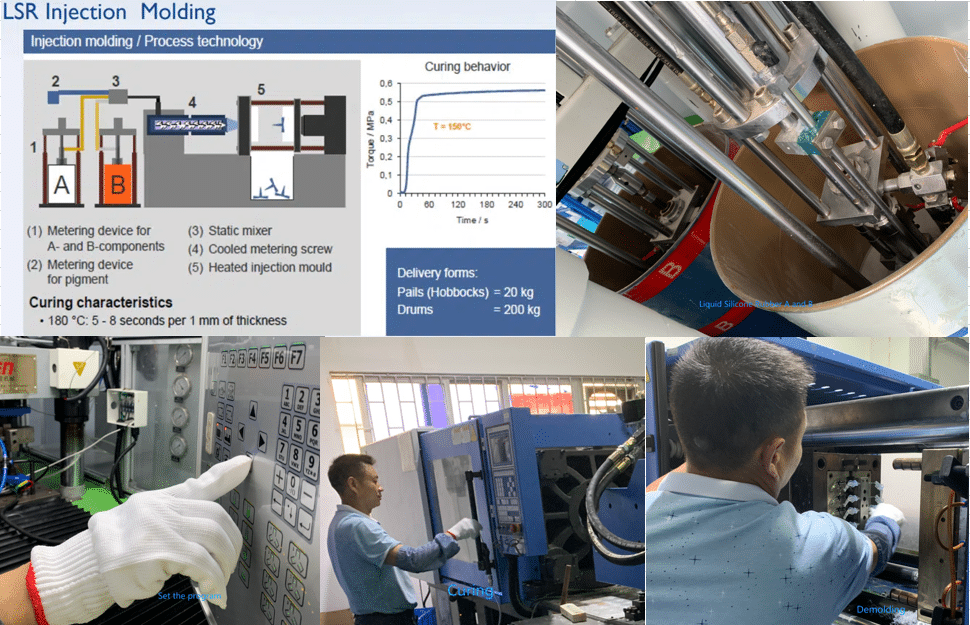

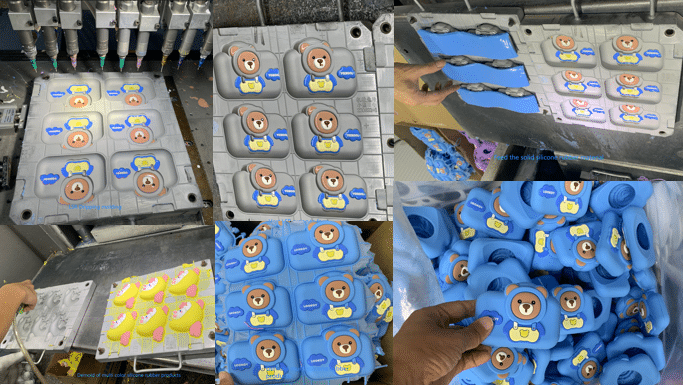

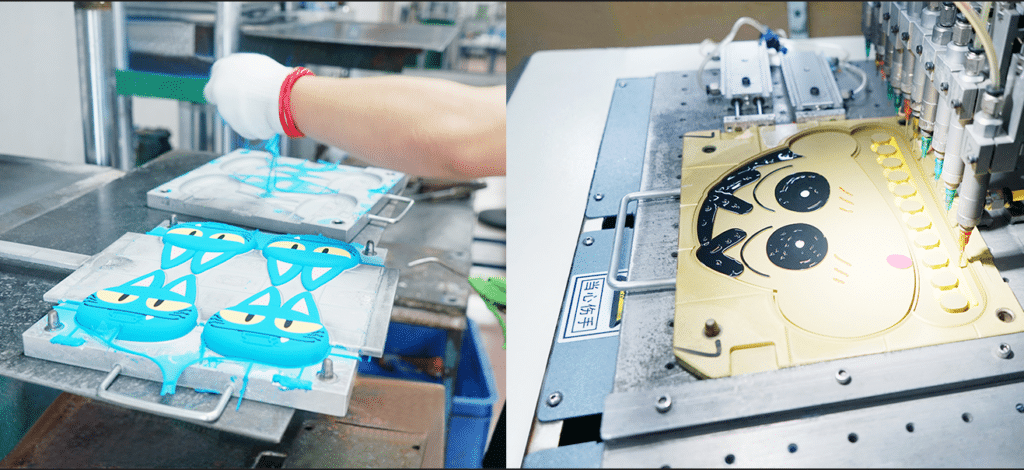

Manufacturing Processes

We use advanced molding technologies to meet your specific product requirements.

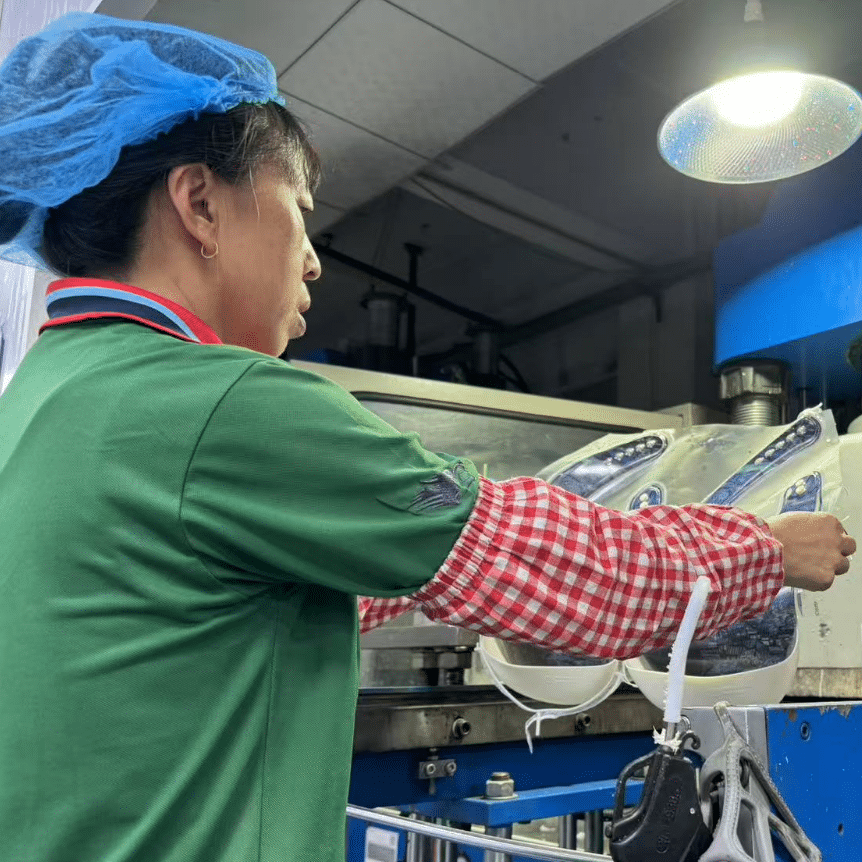

Compression molding: Mixed silicone rubber is placed in a preheated mold and pressed and cured under high temperature and pressure. It is suitable for round, square, with textures silicone molds to fit your special needs dimensions.

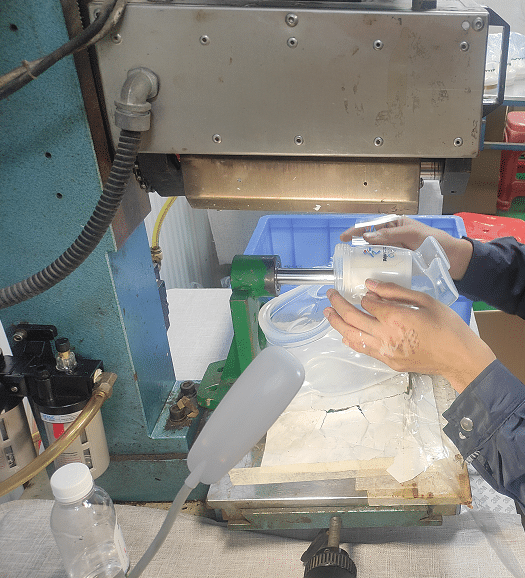

LSR Molding: LSR is injected into a mold using an injection molding machine. This method is highly automated and suitable for silicone molds with precise and complex structures with high volum request.

Drop Molding: Primarily used for small-sized decorative silicone pads with multiple colors. Liquid silicone is dripped into a mold and then heated to solidify. Then put solid silicone, curing again to be the colorful silicone molds.

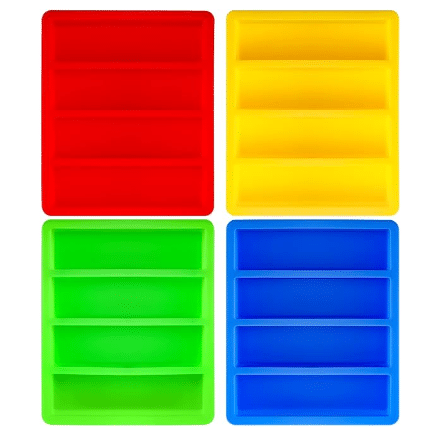

Custom color

You can customize the silicone molds color according to the Pantone book. Our usual colors are Yellow, Blue, Green, and Red. Also, can be colored as desired. ZSR can make double-colored and marble-colored silicone molds for you if you needed:

Unique bespoke molds to make your products stand out from the Markets. Have your own design on your silicone molds.

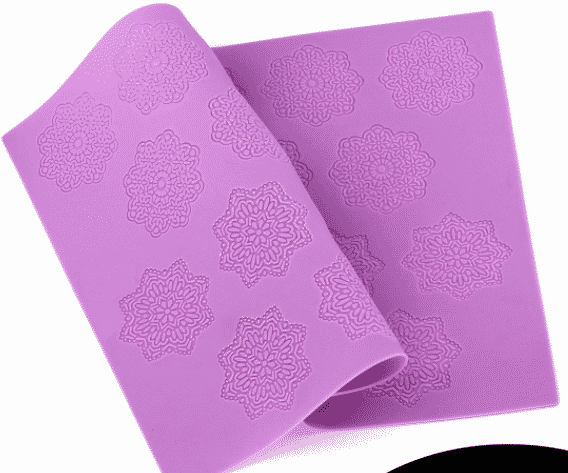

Custom logo & Pattern

We can customize different types of logos or patterns on the silicone molds, including the following styles with the printing ways:

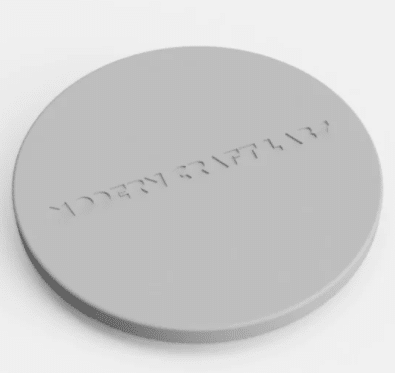

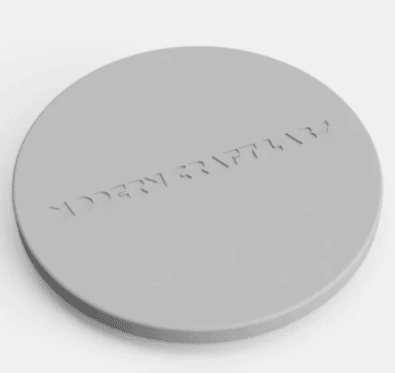

Laser Engraving

Laser engraving uses a focused ultraviolet or fiber laser beam to irradiate the surface of silicone, causing localized physical or chemical changes in the material to form a permanent mark. Because laser processing is non-contact, it does not cause mechanical deformation to the soft silicone, maintaining feel of the silicone molds.

Need open the jig for printing. The cost is around 100USD/jig

Silk Screen printing

Screen printing utilizes the characteristic of screen-printing plates, where ink passes through the mesh openings in the image areas and blocks ink in the non-image areas. Pressure is applied using a squeegee to transfer silicone ink through the mesh openings to the surface of the substrate (such as a silicone mold). After printing, heat curing is required to ensure a strong bond between the ink and the silicone substrate. Can only print simple patterns and solid colors. This print is secure printing. They are not easy to fade as time flies. They are dishwasher safe and Food Grade.

The printed jig plates are around 100USD/color.

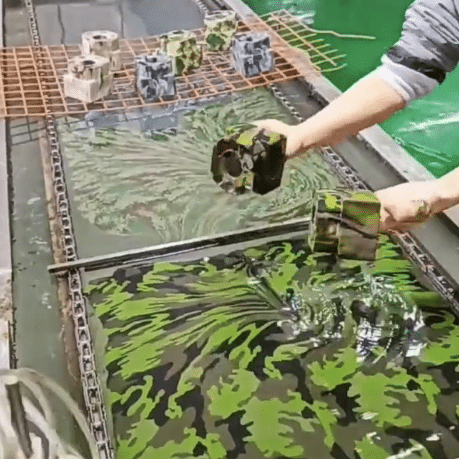

Heat Transfer printing and Water Transfer printing

Heat transfer printing on silicone molds is a process that uses heat and pressure to precisely transfer a pattern pre-printed on a transfer film onto the surface of silicone. This process has advantages such as clear patterns, rich colors, high temperature resistance, and strong adhesion, making it particularly suitable for silicone molds where high durability and aesthetics of the markings are required. This kind of printing can print very complex patterns and fading colors. You can get any pattern you like. Thermal Transfer film cost is needed.

The cost is around 299-799 USD according to the size and the pattern.

See the blog to know more about it: How To Logo Or Pattern On Silicone Molds?

Custom Package

Z.S.R group provide customized packaging solutions for manufactured silicone molds. We offer one-stop services such as helping customers to design, develop, assemble and inspect the packaging, ensuring the appearance of finished products and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished silicone molds can reach the end sellers with the highest quality.

Blister and head card

Blister with paper card package

PP bags with back card package

Colors Paper boxes

Recycled ECO-Friendly paper boxes package

Tin box package

PET package

PP bags

PP Case package

zip bag package

Get Started on Customizing Perfect Silicone Molds Today

From silicone molds design to delivery, we offer a complete range of services.

silicone Molds Product Categories

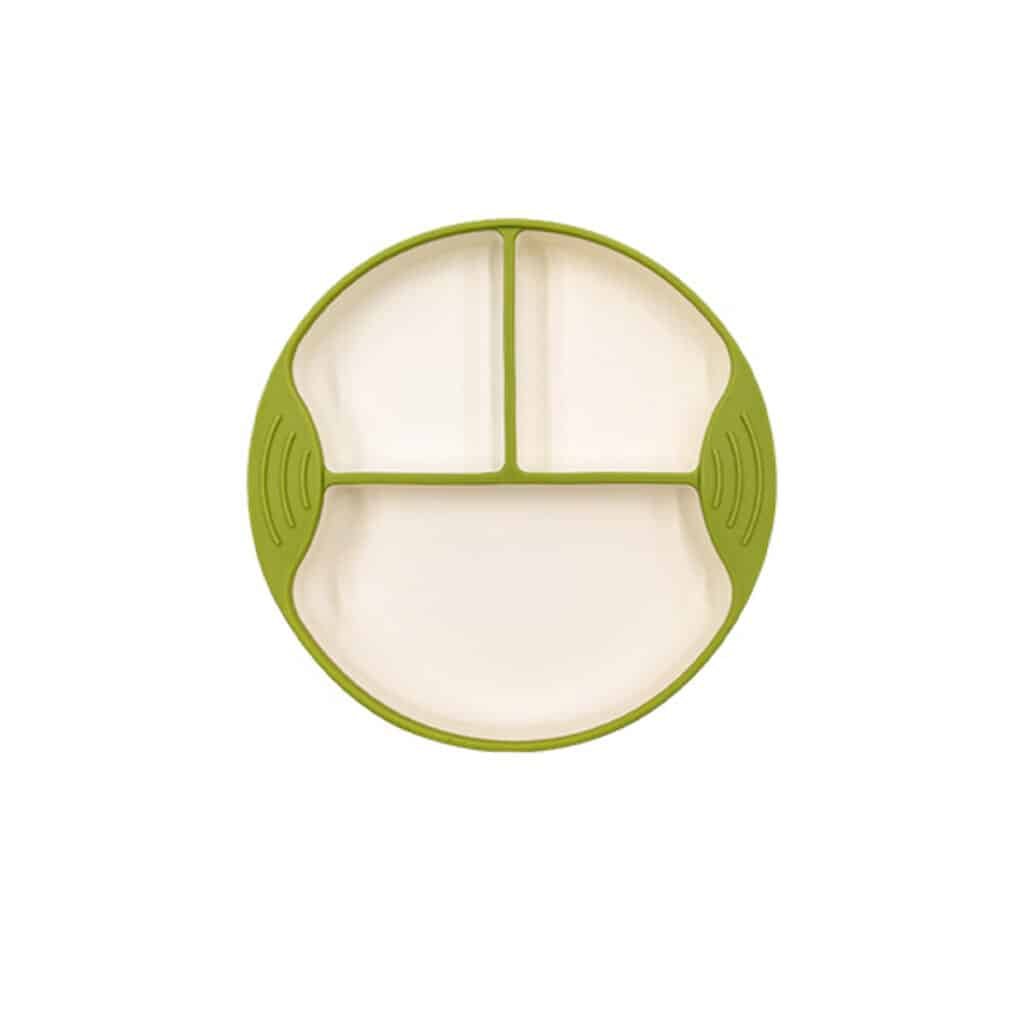

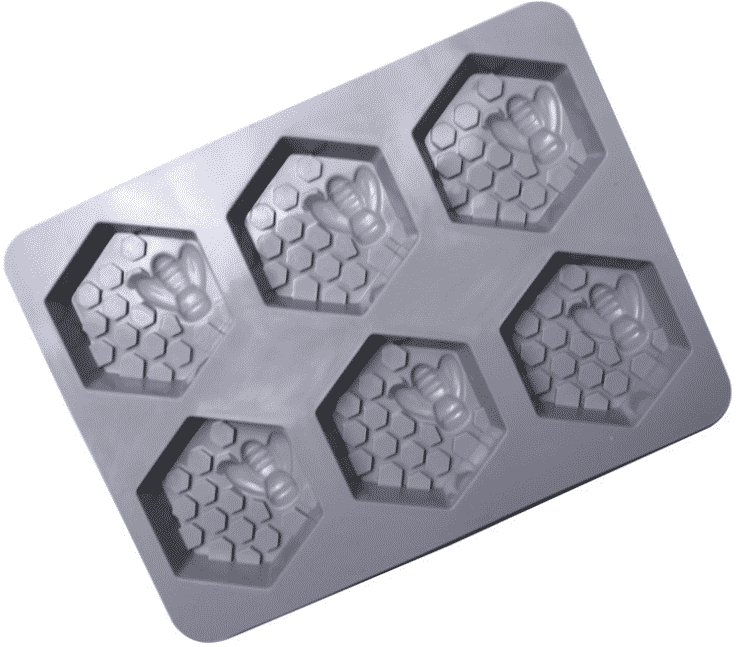

The molds what Z.S.R supplies for clients are ideal for baking, chocolates, resins, soaps, candles, or industrial use – fully customizable to your size, shape, texture, and branding needs with unique shaping designs and Complex shapes and different varieties:

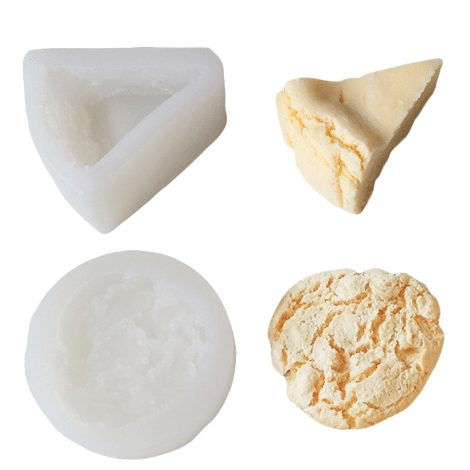

Candle, Soap & Beauty Accessory Molds

Designed specifically for high-precision replication of handmade soaps and crafts, this mold clearly reproduces delicate patterns, making it suitable for complex handmade soap designs. The same mold can also be used for non-food products such as candles and resin crafts.

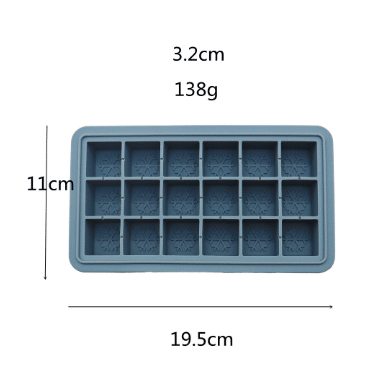

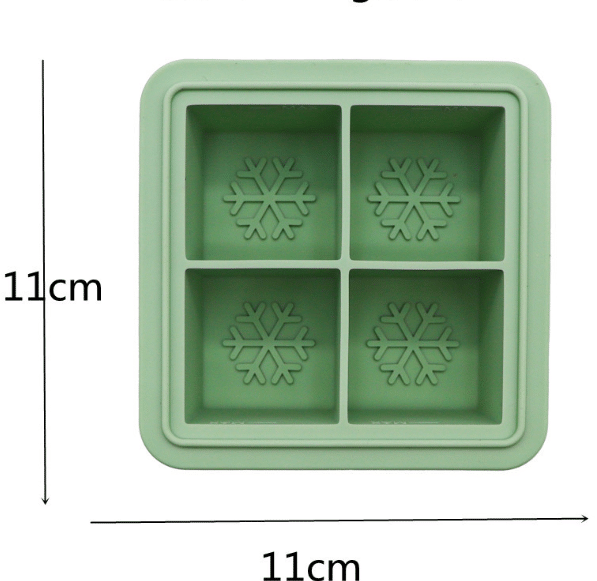

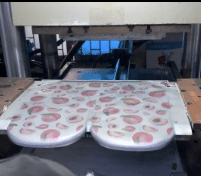

Food & Bakery molds

Specifically designed for the baking industry, it is commonly used in the production of cakes, mousses, chocolates, ice cube trays, Chocolate, candy, ice cube trays, mooncakes and other food products.

Resin Casting Molds

The molds are injection molded of various materials such as resin, gypsum, and polyurethane.

Craft & Art Molds

Crafts and arts silicone molds are suitable for the fine replication of Buddha statues, bronzes, resin crafts, candles, and copper reliefs. Supports molding with various materials including fiberglass, epoxy resin, and low-melting-point alloys.

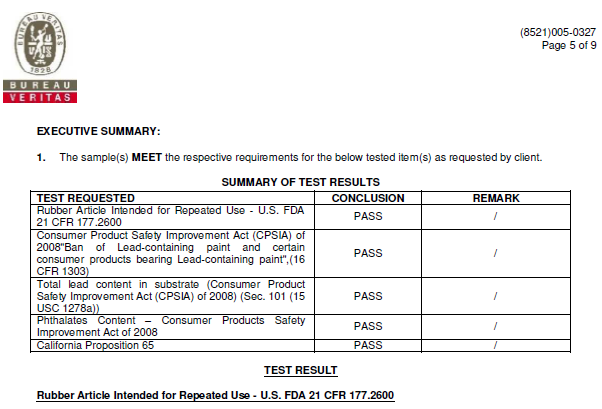

100% FDA or LFGB standard silicone Molds

All the Silicone Molds that we made use of 100% FDA (USA Food Grade) or LFGB(EU Food Grade) standard silicone material, BPA, phthalates, and harmful additives free, Eco-Friendly & Reusable. Complies with FDA, LFGB, CE, and CPSIA standards.Stand -40°C to +230°C. Flexible & Durable. All the molded Silicone products are Non-Stick & Easy to Clean, quick-dry, Antibacterial. Reduce stress and pollution on the environment, Save the earth from disposable plastic, Save the trees.

Why Choose Z.S.R as your Silicone Molds Manufacturer?

Safety products

The silicone products what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV to let you and your clients stay safe.

Safety Factory

Z.S.R is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney. The third parties and the world’s Fortune 500 companies have helped you verify the factory strength and reliability for you.

100% safe raw material

Food-grade high-quality silicone materials, 100% high-purity food-grade platinum silicone which are safe and environmentally friendly, non-toxic and harmless. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

18 years of custom silicone products experience

Rich market experience and engineering make us familiar with the products and market (USA, EU, Japan ) requirements of different wholesale customers.

Stable production capacity

32 sets of silicone compression molding machines, 6 sets of liquid silicone rubber molding machines, 8 sets of co-injection silicone molding machines for LSR / SSR / Compression Molding over 100,000-150,000 pcs daily and export to 40+ countries.

Strict Quality Control

Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the high qualified Silicone products as the prototype they approved.

How to Order Your Silicone Molds

Z.S.R Group: As a silicone molds molding factory that can cooperate with you on any needed silicone molds, we can provide quality silicone molds, as per your project requirements. We along with you in the entire process of silicone molds design, tooling design, and mold manufacturing. All the silicone molds and other silicone products are produced and delivered as per your requirements.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.