Custom Silicone Products & Silicone Molding Service

The Silicone Products OEM Manufacturing Brand Behind The Brands. One-Stop Supplier For Molded Silicone Products And Custom Silicone Molding Solution Provider From Idea To Market

About ZSR

One-stop silicone molding solution

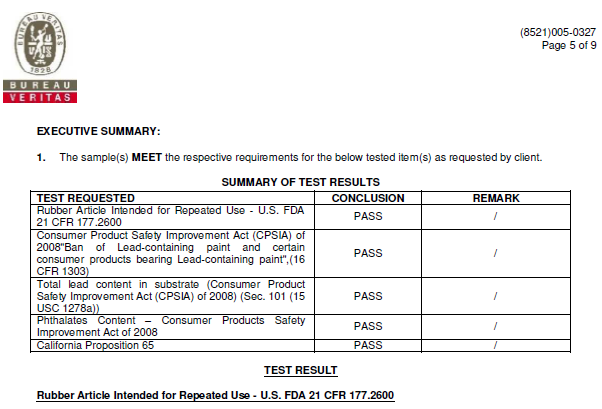

Z.S.R International Group (HONG KONG) CO., Limited, is one stop molded FDA silicone products manufacturer and professional custom silicone molding solutions provider founded in 2007 with certified by ISO9001,ISO 14001 ,BSCI SEDEX4p,SA8000,and Disney FAC-020760 more than 18 years.

Your professional brand partner choice of silicone products solutions for global leading silicone products brands and retailers. Recognized for delivering innovative custom FDA molded silicone products, silicone products manufacturing expertise, and silicone technical solutions to meet your silicone products brand’s functional and design needs.

WHAT WE DO

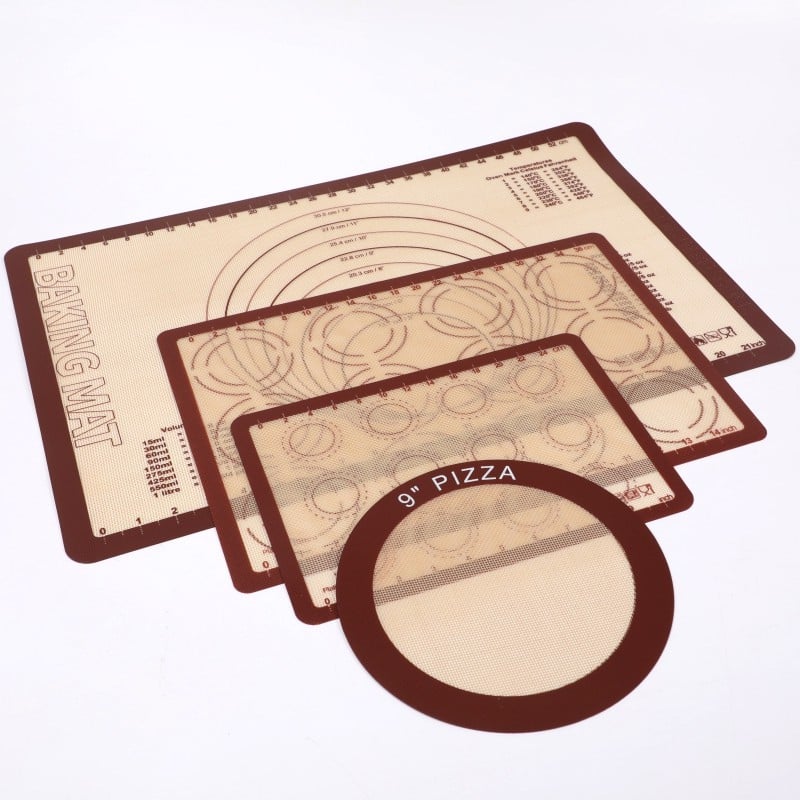

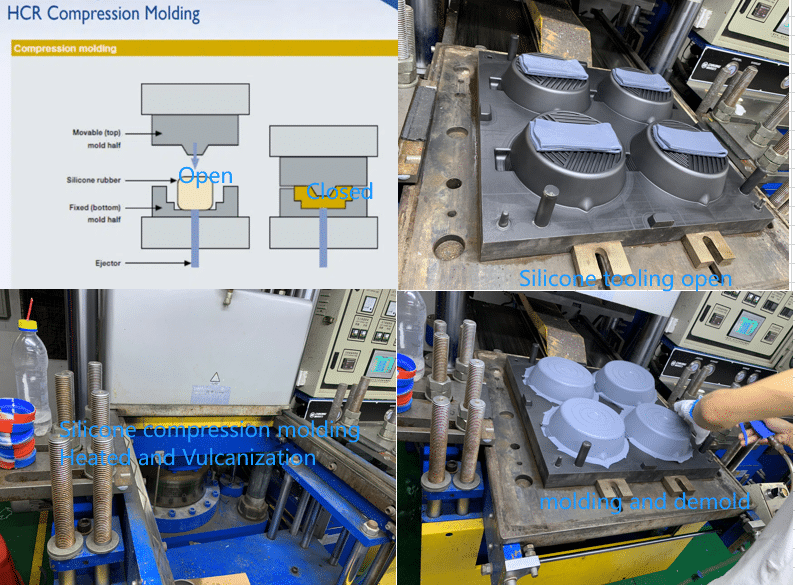

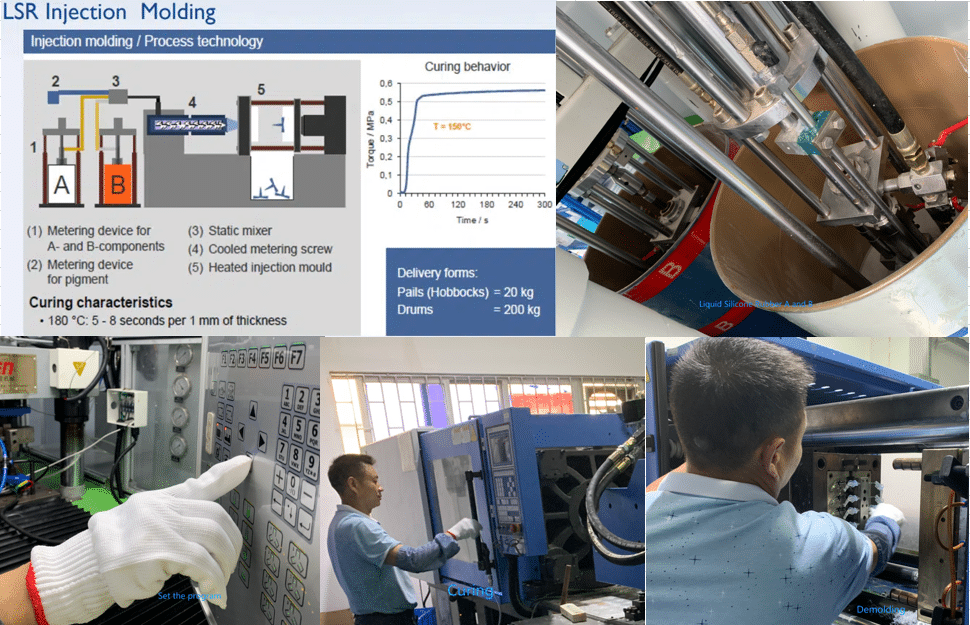

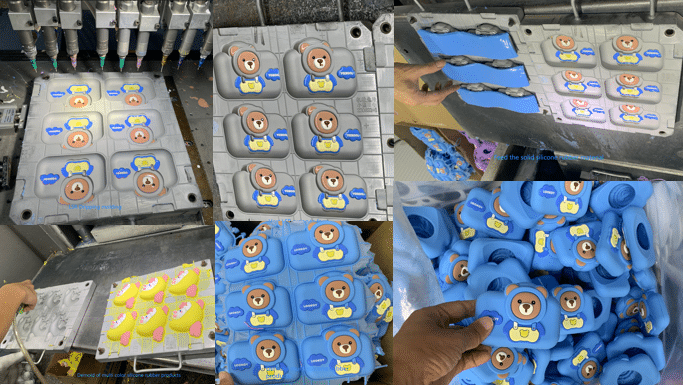

Z.S.R’s team work with the different industries brand’s Owners, products development managers,products managers, products designers together and offer them OEM ODM solution from molded silicone products design,prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success. We have the capability for producing silicone toolings, producing HTV Silicone products, LSR molded silicone products, Molded multi-colored Silicone products. We also Custom silicone toolings,Custom silicone molding,Custom HTV molding, Custom Silicone compression molding, Custom injection molding,Custom LSR molding, Custom silicone Dripping injection dispensing (co-injection) , Custom silicone fabric coating and curing molding.

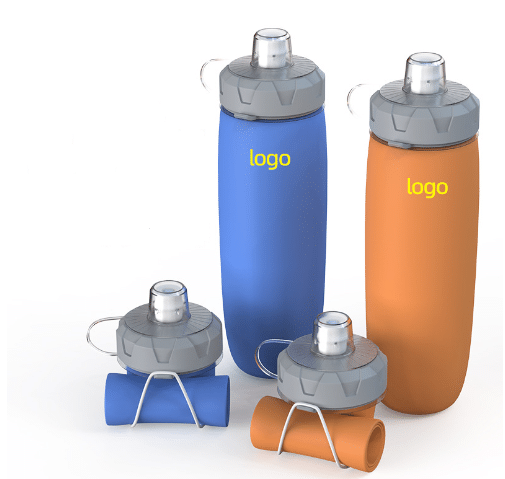

Customized silicone products

You design it, we bulid it , box it.

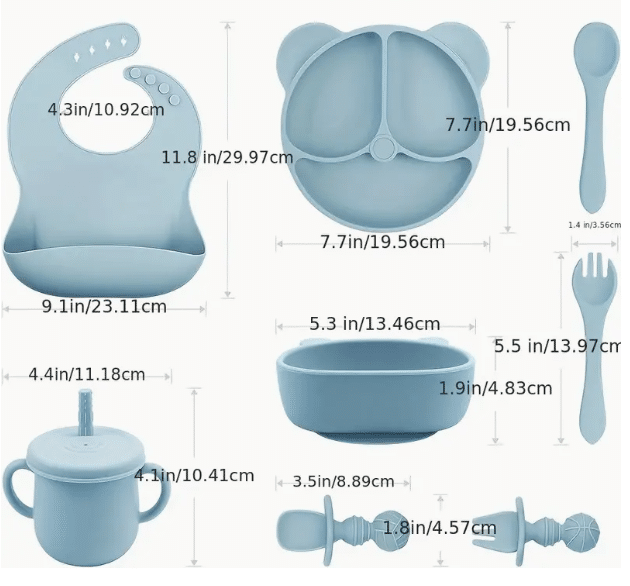

Z.S.R is a full-service custom FDA silicone products manufacturer offering end-end customization from mold development, prototyping to mass production and packaging for our business partners. Z.S.R already has worked with Fortune 500 companies,Trusted by Disney / McDonald’s / Olympic projects etc. to develop customized silicone products for 16 years with 10,500 sets of projects successful experience in silicone products technical solution.The custom silicone products include:

All the silicone products what Z.S.R made are stable and highly durable, resistant to heat or cold (- 40 °C – 230 °C ), chemicals,and UV damage.PVC and BPA-free, no phthalate and lead,safe with Non-toxic and harmless,environmentally friendly ,food touch safe,good biocompatibility. Molded wide variety of shapes,sizes,structure,colors, soft, flexibly, comfortable, Sustainable & Recyclable.Easy cleaning.All can pass FDA 21 (USA Standard),CPSIA, CP65, LFGB German §31,EN-71 (EU Standard) or Others’s needed.

Whether you’re a brand,retailer, wholesaler ,distributor , e-commerce seller, Amazon seller ,Design Studios,promotional campaigns. Z.S.R is here to collaborate and OEM your silicone items idea into a reality.We will never show our cooperation Clients brands or design when we sign the NDA with you.

Unlimited customized options

Z.S.R offer a wide range of customization options for you. You can work with us to create unique and competitive silicone products for your business.

You can customize silicone products color according to the Pantone book. We will add the FDA Color Paste to the silicone material when the material mixed. Our usual colors are White, Red, Translucent,Green, and Gray. We also can make the double color, marble color and multi-colored Molded silicone products for you if you needed

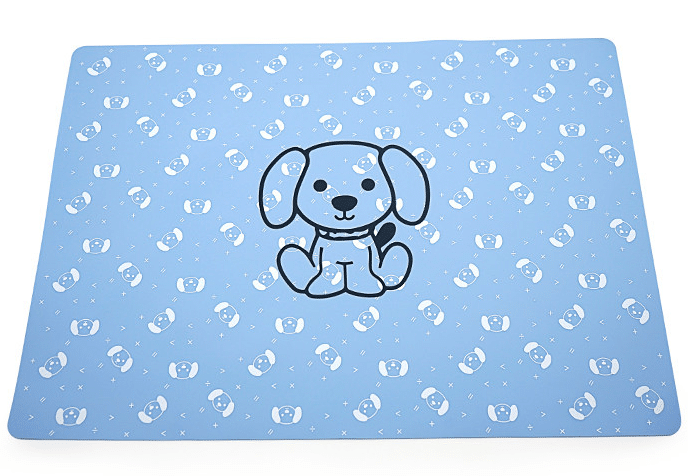

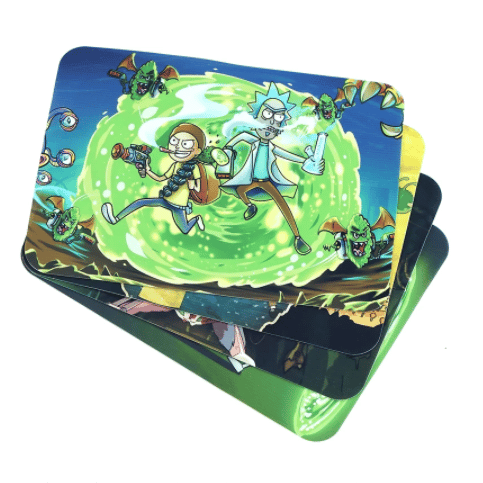

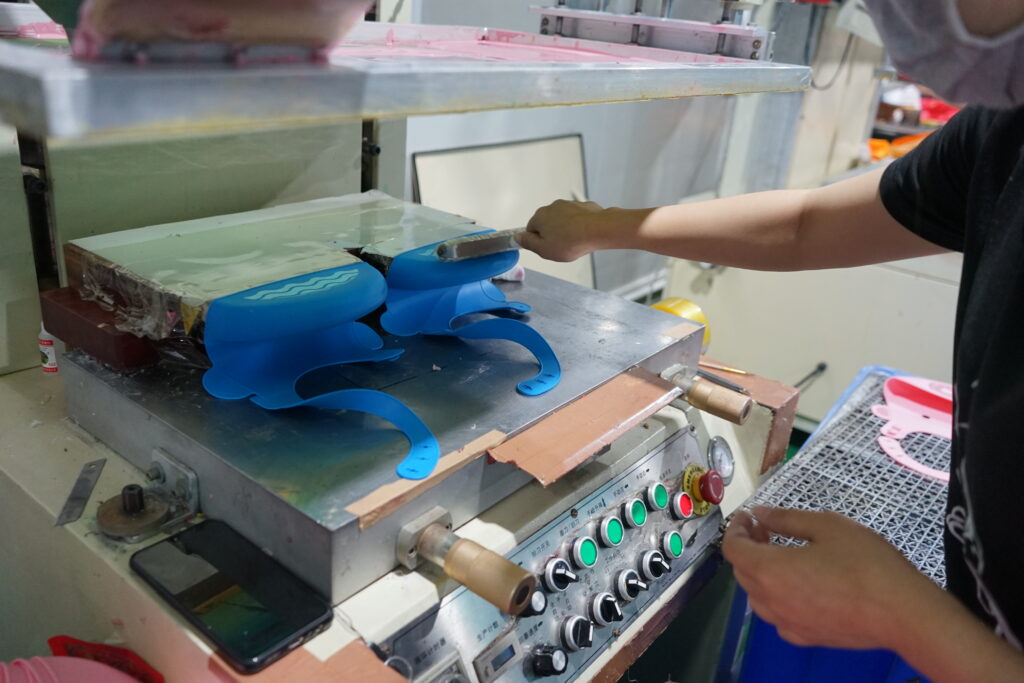

ZSR own the printing workshop for printing the pattern or logo color by Silk Screen printing,Pad printing,Heat Transfer printing and Water Transfer printing, In mold Decoration, Digital printing.

Z.S.R’ s Own three kinds of silicone molding line

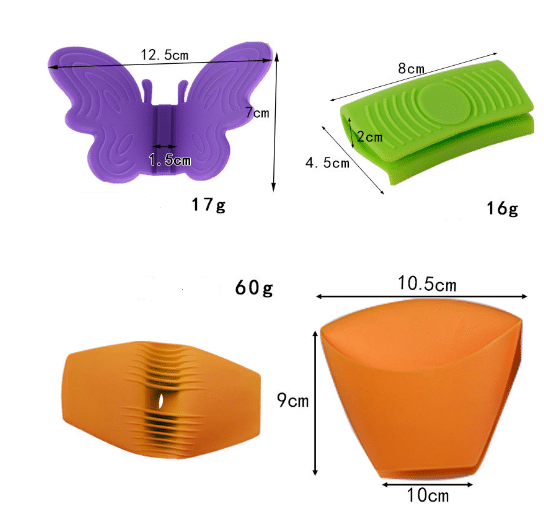

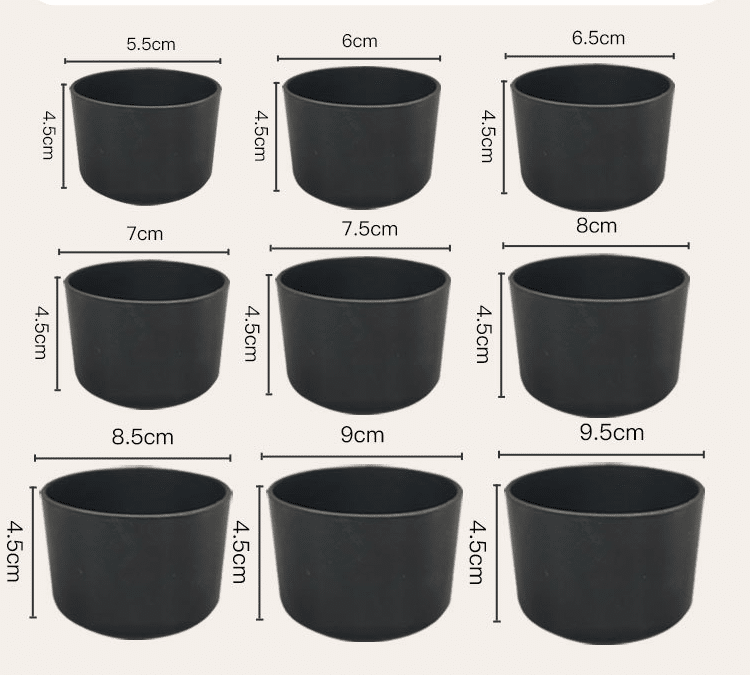

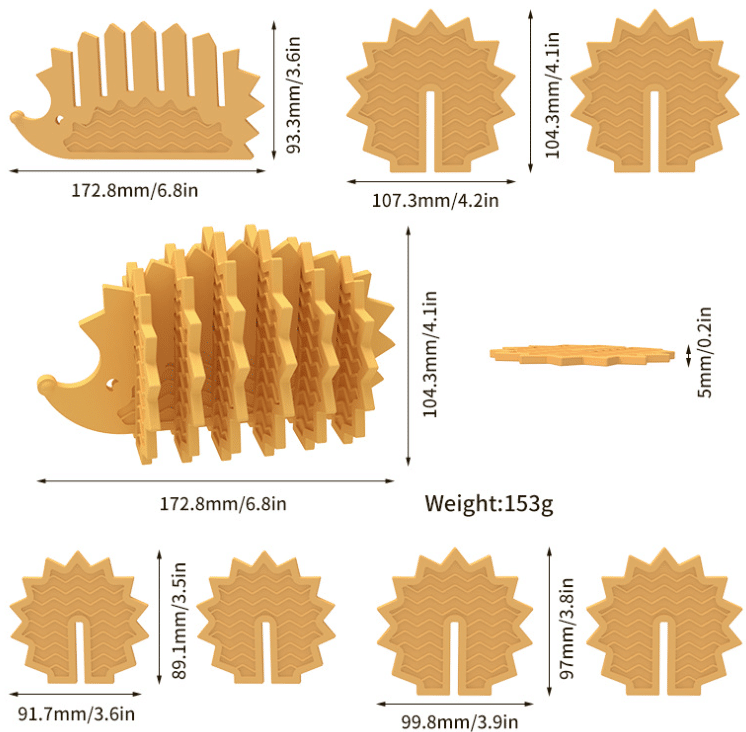

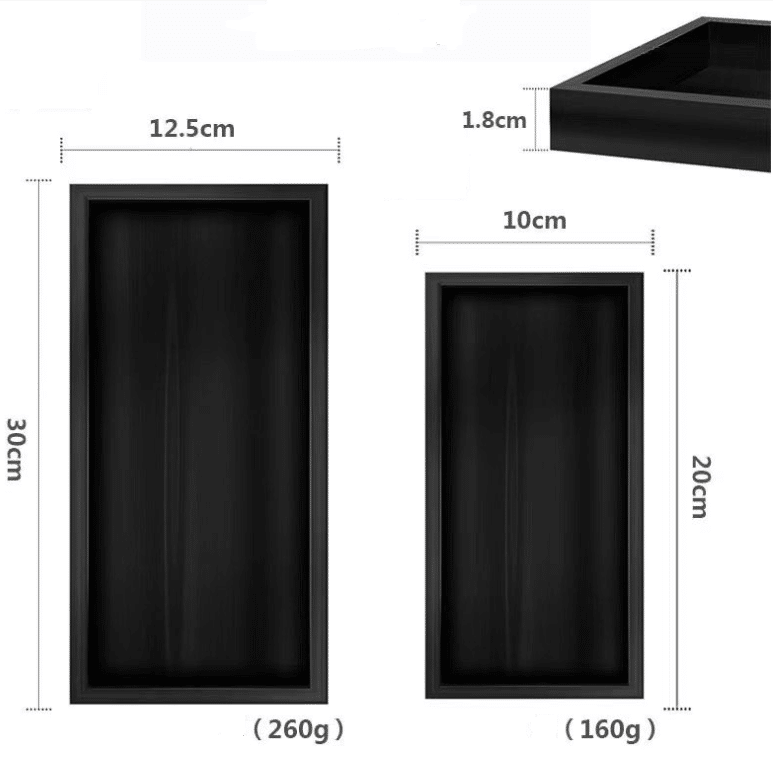

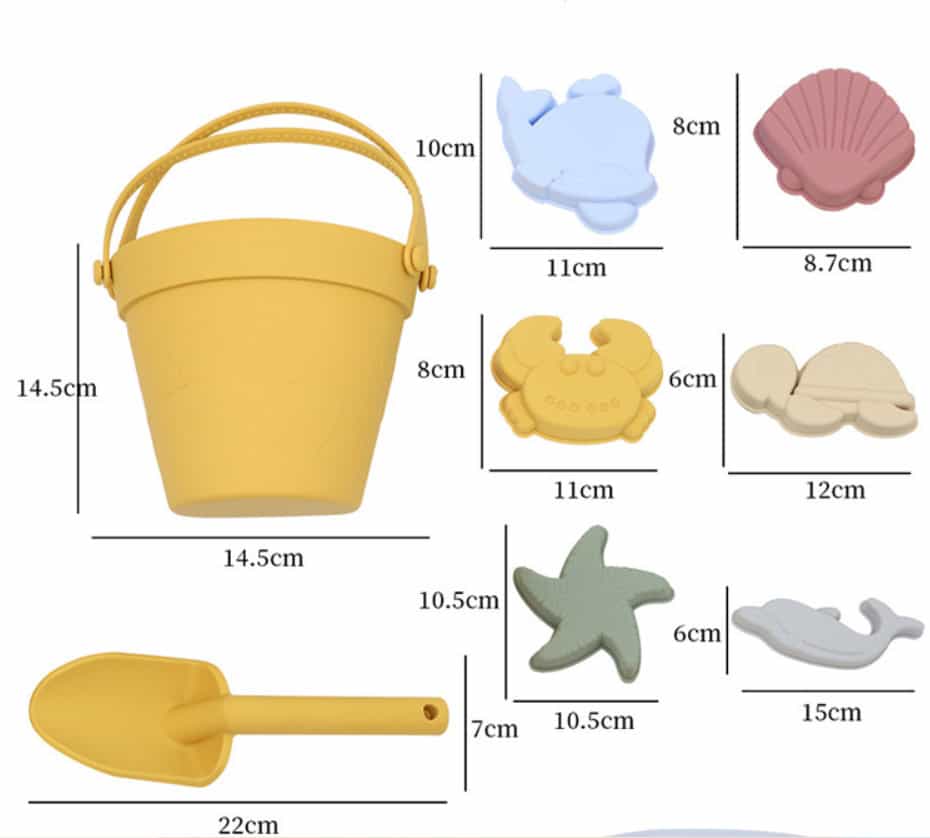

The machine press 50T-600T, so we can make the Molded silicone products size from 0.1cm to 127 cm (0.02″ to 50″), The thickness of the silicone products that we can make is from 0.01-1cm.

All the silicone products Z.S.R made from precision parts to huge finished silicone products to meet your different project needs.

Silicone product size & Shape

Z.S.R International Group(HONG KONG)CO., LIMITED helps companies create custom logo silicone products that make your brand stand out. Z.S.R custom Logo silicone products, promotional silicone merchandise, gift giveaways, and logo silicone items that you’ll loved. We offer logo branding services to the Promotional and License industries. We work with the promotional, Marketing and Advertising, Licensor, Licensee, wholesale, retail chain, gifts store, and product development companies together offer molded logo silicone products to the whole world to expand your brands and Market.

In Z.S.R group, we offer more than 5 ways to put your logo and pattern on. The different logo and patterns may need different methods. Click Here to get rough information for the different performance with the different printing ways.

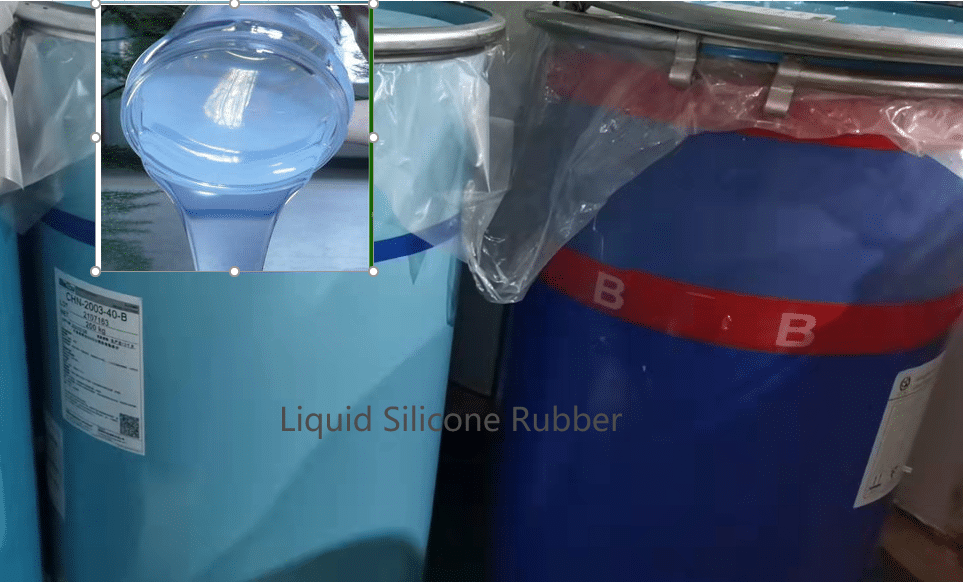

After you confirm your products function and the structure. You may need choice the correct material to achieve this function. Z.S.R offer the Customized silicone products service from Customized the silicone products raw Material.

Our expert Engineer will recommend the most suitable raw materials according to your Molded silicone product requirements (e.g. Liquid silicone rubber or Solid silicone, tensile strength, tearing strength, etc.; different standards such as FDA and LFGB or medical grade or different Brands).

Grade

- Ordinary Silicone Rubber.

- Food Grade Silicone Rubber. FDA (USA Standard), LFGB (EU Standard), DGCCRF (France Standard),

- Medical Silicone Rubber

Brand

- Import: Wacker, Dow Corning, ShinEtsu, Elkem, DELO, Dow,

- Domestic: Xin’an Chemical, Dongjue Silicone, Tianan Chemical,

Physical Properties

- HTV Solid silicone.

- LSR Liquid Silicone Rubber.

Making Process

- Precipitated silicone rubber.

- Fumed silicone rubber property.

Z.S.R provide customized packaging solutions for manufactured molded silicone products

We offer one-stop Molded silicone products services such as helping customers to design, develop, assemble and inspect the packaging include:

For ensuring the appearance of finished Molded silicone products and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished Molded silicone product can reach the end sellers with the highest quality.

With the Silicone products various surface treatment processes, including Mechanical grinding, polishing, sandblasting, printing, oil spraying, UV modification, laser engraving, electroplating, spraying, which can improve the silicone products appearance quality, durability and safety to meet different client’s needs.

Z.S.R own’s surface treatment process allows us give your silicone products a unique look and feel with different options. With the right surface treatment applied, you can make an even greater impact on potential customers who appreciate the attention to detail.

Custom the molded silicone products Quality Control Inspection.

Our common molded silicone products Quality Control Inspection is from supplier selection, production specification, In-process Inspection, Before shipment inspection (OQC). We also accept the customer hire the 3rd party to pre-shipment QC include Full inspection if needed.

More Support

Flexible customization, providing sample testing and design assistance services.

ONE-sTOP OEM/ODM silicone molding SERVICES

We Have Much Experience, Capability, and R&D Engineers to Make Your Custom Silicone Products Run Up from Idea to Market Successful!

Our technical capabilities

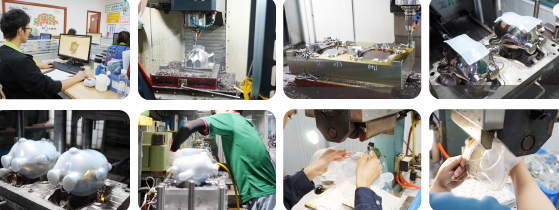

16 years silicone molding factory in China, Z.S.R’s Precision Silicone mold /tooling (6 EDM,10 CNC) ,Silicone Compression molding(48sets), Silicone over-molding, Liquid Silicone Rubber Injection molding(12 sets): LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding(13 lines ), capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc with Stable large-volume supply capabilities. Custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality silicone products for different industry application from industrial,consumer,commercial to medical.

The Process of Customized Silicone products

The process of customizing silicone products involves several steps from silicone products Design Concept, Material Selection, Prototypes Development, logo Branding or Printing, Silicone Tooling and Mold, Material Mixing and Preparation, Silicone Molding and Shaping, Curing and Cooling, Demolding, Quality Control, Cleaning and Packaging to shipping for creating personalized and branded silicone molded products or other silicone products.

1. product design

Our expert team will be your first point of contact, ready to get a better grasp on your needs and provide exemplary design services and engineering support.

2. prototype and tooling

Manufacture of high-precision metal molds after thorough engineering evaluations available for prototype or mass production according to you needs.

3. Mass production

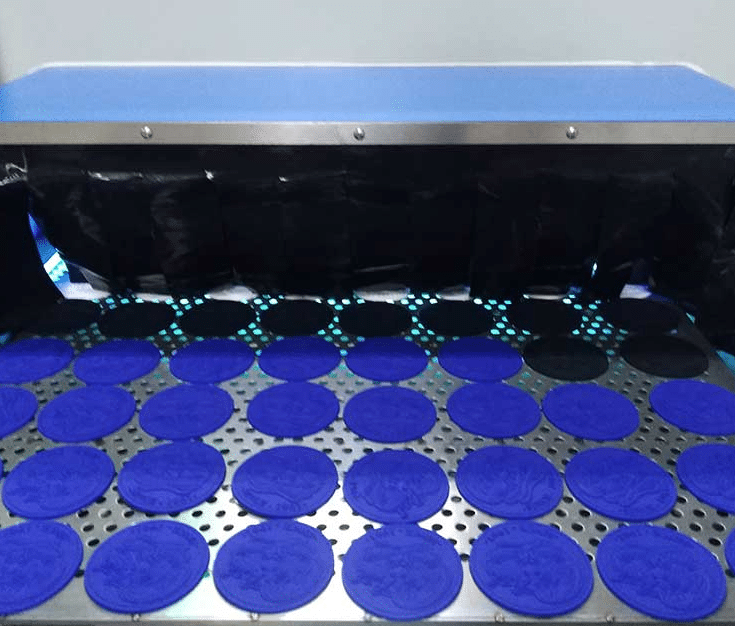

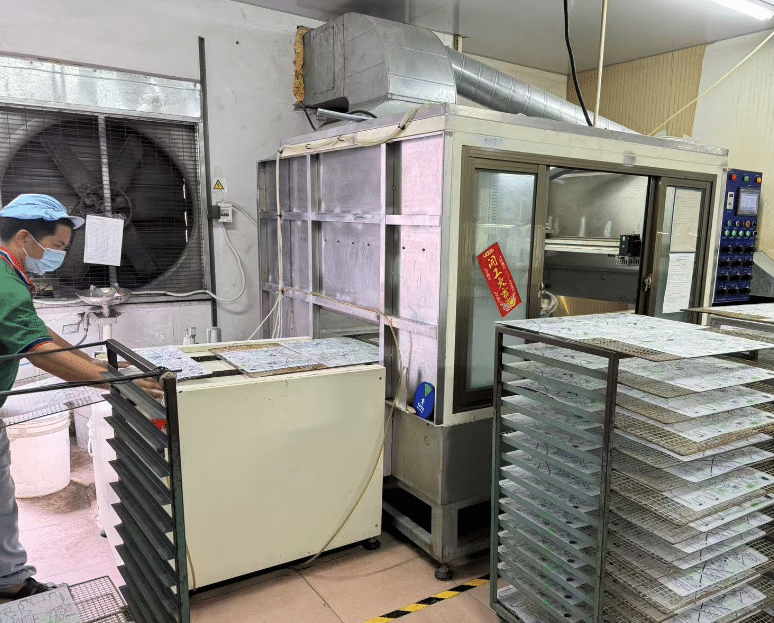

According to the production schedule, the raw silicone material will be manufactured into a real product through precise molding, demolding, and post-curing processes.

4. IPQC

Z.S.R perform multiple rigorous tests throughout the manufacturing process to ensure that the quality of the product meets expectations when it leaves the factory.

5. Printing

Print logos or customize pattern for your products on demand to enhance your brand influence. One-stop solution that eliminates the hassle of docking multiple suppliers.

6. OQC

OQC – Before Shipment Inspection, Our Factory Final Full-Inspection , Customer Hire 3rd Party for Pr-Shipment Inspection.

7. Package

Packing – Custom packaging solutions you need. We will work as a resource and an extension of your company to help you from start to finish, and save your time and money.

8. shipping

Our fast-shipping service guarantees that your products arrive safely, be it by sea or via courier. You can also rely on us for comprehensive support in case of any issues.

Please go through the How to make silicone products and how to put the logo on silicone products to know more details

How to work with ZSR?

Z.S.R is a silicone products fabrication factory.From initial silicone products design to final delivery, we provide comprehensive one stop services. You do not need deal with multiple suppliers or coordinate different aspects of the project yourself. Simplify the entire process and save your valuable time.

Confirm requirement

Choose the existing style or Design 3D Drawing(stp) according to you needs and get our Engineer Support

Cost Evaluation

Z.S.R offer the quote according to your design, quantity, color and other specific requirements.

Prototype and Tooling

Once you approve the quote and make the payment, production will begin from prototype, tooling.

Mass production

Prepared Silicone Material according to your material selection and mixed, molding, Demold And First Quality Inspection, Deflash, Trimming, Secondary vulcanization And Branding Packaging.

Quality inspection

Z.S.R perform multiple rigorous tests throughout the manufacturing process to ensure that the quality of the product meets expectations when it leaves the factory.

Afterservice

Z.S.R established and improved the after-sales system, timely and comprehensive grasp of customer information, and achieved timely service contact and coordination to slove the aftersevice problem your ocured.

Our Customer Testimonials

Rated Products

Looking for a professional FDA silicone products manufacturer? As a custom silicone products manufacturer more than 16 year experience with more than 300 employees in China. Z.S.R provide high end OEM/ODM services for high-quality custom silicone products. We produces and supplies variety of food safe silicone products widely used in: Silicone baby products, Silicone Beauty&Health-care, Silicone Pets, Silicone Consumer Electronic Protective Cover, Silicone Housewares Products, Silicone outdoor Products,Silicone IP licensed goods.No matter you want to creat your new silicone brands/add a new silicone products line in your old brands or events giveways silicone products. Our experienced team is dedicated to assisting you in crafting the ideal silicone products tailored to your needs.

Contact us to create durable, compliant, brand-ready silicone solutions.