How to Logo or Pattern on Silicone Molds?

Silicone Molds are widely used in our daily life. Such as silicone baking mold, silicone soap mold, silicone Epoxy Resin mold, silicone freeze mold, silicone Popsicles Molds, Silicone Candle molds etc.

What is silicone molds and what is the use of silicone molds?

Silicone molds are created by pouring silicone into a prepared shape, mold box or mold die. The silicone forms the shape of the container or the item placed in the container. Silicone molds are very popular with hobbyists and artists who create candles, jewelry and figurines.

Baking molds are sometimes made of silicone.

There are four types of silicone molds: block, block multiple piece, glove and cast glove. All these types of molds require a room temperature working space, protective gloves, plastic sheets, mixing containers, stirring sticks and a mold box. The different types of molds are used to create different products and the appropriate mold should be selected based on your desired result.

The Benefits of the Silicone Molds

- Flexibility: If bent, the mould will regain its shape.

- Indestructible: Unbreakable and cannot be damaged when compared to moulds made from glass, metal, etc.

- Optimized Food Storage: Renders the consumption of only part of the mixture, conserving the rest in the fridge.

- Minimize Use of Space: Little room for storage required.

- Thermal Stability: Usable across a temperature range from (-40 to +230 °C).

- Practical Maintenance: Can be cleaned in the dishwasher.

- Versatility: Can be taken from the oven/microwave and placed immediately in the fridge freezer and vice versa.

- Stable Aging Process:3000 uses guaranteed.

- Odorless: Mold does not release odor during cooking.

- Food Regulation Compliance: All materials used are tested in accordance with the Foods Standards Agency.

- Wide Range: Offer a range of packaging, color and form options.

- Eye Catching Design: For innovation in the kitchen.

- Stability and Thermal Resistance: Greater stability and thermal resistance in comparison to metal molds.

- Smokeless: The molds do not produce smoke during cooking.

- Safety Guaranteed: Each mold is treated by a thermal process lasting between 6-7 hours , which results in the elimination of potentially toxic residue.

- Safe Ring: Includes a removable support ring.

- Minute Detail: Faithfully reproduces all details of the mold.

- Healthy Eating: No butter or other fats are required to grease the molds.

What Are The Benefits Of Printing A Logo or pattern On your silicone Molds?

There are many benefits to printing a logo on silicone Molds, including:

Brand Awareness: Showcase Your Brand with Custom silicone Molds Featuring Your Company Logo : With top-of-the-line custom silicone Molds with company logos.

Promotional Opportunities: The silicone Molds was Designed exclusively for businesses, resellers, and promotional product suppliers

Customization: The custom silicone Molds not only deliver outstanding , but they also serve as a powerful means to personalize devices and elevate your brand’s presence.

Versatility. Boost Your Brand Recognition with Custom silicone Molds with Company Logo,Maximize Profit Potential with Wholesale Custom silicone Molds for Resellers and Retailers

Printing your logo on silicone Molds is an excellent way to promote your brand and increase awareness. It offers a wide range of benefits, including durability, customization, versatility, and high-quality image reproduction. Whether you are looking to create promotional items or simply brand your products, printing a logo on silicone rubber Molds is an affordable and effective way to achieve your marketing goals.

CNC milling logo on the silicone mold/tooling on the silicone mold.

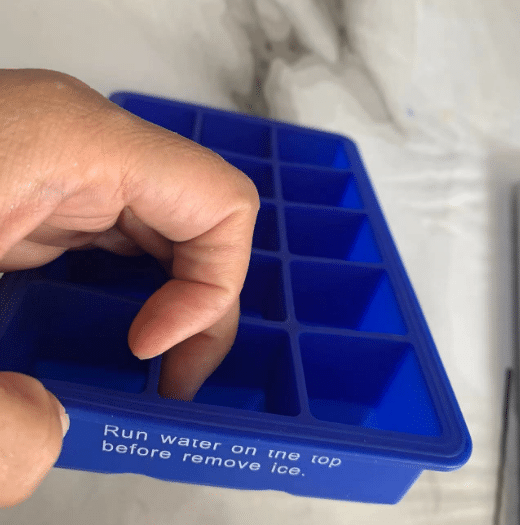

Debossed or embossed logo are engraved directly on tooling during CNC mold-making process is one choice to put your logo or pattern on your silicone molds. That will save the cost for post process.

Embossed logo or pattern on the silicone molds

Debossed logo or pattern on Silicone Molds

Laser Engraving Logo or pattern on Silicone Molds

Engraving, marking, etching: call it what you want, but this technology is great for imprinting images onto a surface. It’s a permanent mark that simply can’t wear off.

You also can choice put your silicone molds logo or pattern by laser engraving.

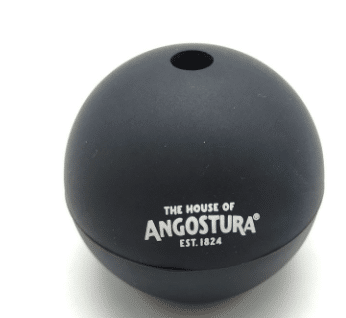

Screen Printing LOGO or pattern on Silicone Molds

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. You may can choice put your pattern or logo on silicone molds by screen printing.

Pad Printing LOGO or pattern on Silicone Molds

The pad presses into the ink on the printing plate. The image sticks to the pad and transfers easily to anything from bowls to lightbulbs to silicone molds.

Related Blog

Conclusion

Printing a logo or pattern on silicone molds is a great way to give your brand a professional look and feel. With the right tools and techniques, you can easily print your logo on to silicone molds with high-quality results. We hope that our guide has helped you understand how to print a logo or pattern on silicone molds so that you can create stunning products for your business.

So If you need :

- Custom silicone molds with Company Logos for Your Business

- Elevate Your Business with Custom Company Logo silicone molds as Promotional Gifts

- Connect with ZSR Today to Enhance Your Brand’s Visibility with Custom silicone molds.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.