Custom Silicone Beads

As a leading silicone beads manufacturer and custom silicone beads molding solution provider in China. Z.S.R specializes in manufacturing custom silicone beads that are food-grade, chew-safe, and fully customizable for baby teething accessories, jewelry, crafts, and sensory products. Ideal for brand builders, Etsy sellers, and wholesalers looking to create unique silicone bead collections.

Our teams work with brand owner, product development manager, product manager, product designer in Maternal and infant brands, craft accessories suppliers, e-commerce platform sellers offer them custom silicone beads service with the custom silicone beads design, function, material, shape, sizes, structure, texture, colors, logo, pattern printing, brand, label, package and other silicone products technical support to the baby, kids, jewelry making, crafting kits,Advertising Promotion and other fields industry.

Z.S.R help more than 2000 success silicone beads project in the past 16 years with our experienced expert.

Customized service

Z.S.R team offers the OEM services from Silicone bead design, prototyping to molded Silicone bead contract manufacturing, printing, packaging. Z.S.R ‘s Customized Silicone bead service with the Customized Silicone bead design, function, material, size, structure, shape, texture, color, logo, pattern, package, label to ensure their Silicone bead project success.

Our common silicone beads Quality Control Inspection is from supplier selection, production specification, In-process Inspection, Before shipment inspection (OQC). We also accept the customer hire the 3rd bead to pre-shipment QC include Full inspection if needed.

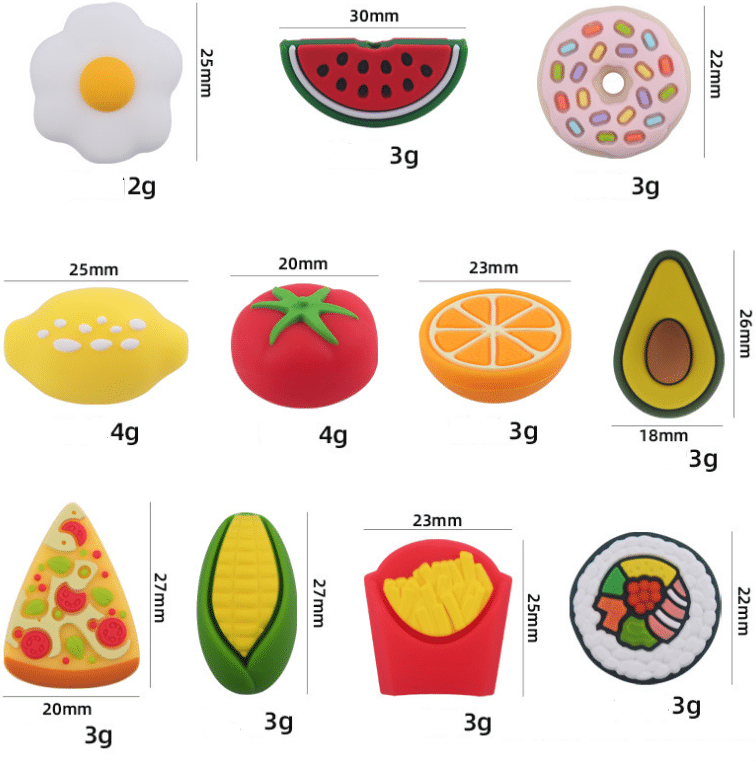

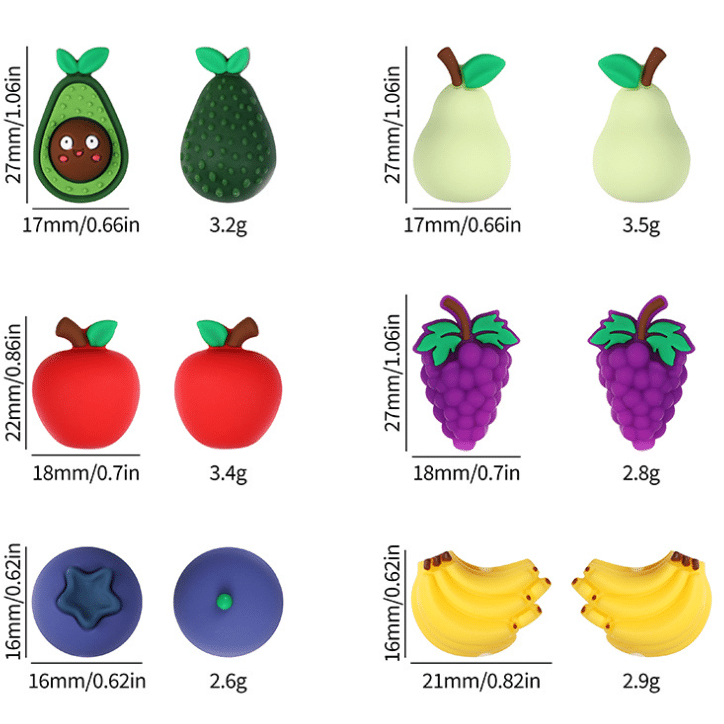

Silicone beads Products

Silicone beads refer to small granular or bead-like objects made through the silicone molding process. These beads are usually made of silicone material and have the characteristics of softness, good elasticity, and compressibility. They are widely use in Baby teether pendant / Baby teething toys /pacifier clip, Calming toys / chewing chains, DIY silicone bead jewelry/Creative keychains / backpack pendants, Sensory and fidget tools, Promotional and craft kits, Bracelets, necklaces, holiday gift decorations.

Z.S.R is one of the leading silicone beads manufacturers. We cooperate our partners create silicone beads. High-precision toolmaking and state-of-the-art fully automated liquid injection molding are the basis for custom-engineered beads into applications where consistent precision, quality and performance reliability in high quantities are critical in application.

You can get the silicone beads using customized injection molding or custom compression molding.

100% FDA or LFGB standard

The Silicone boots are all made of 100% natural, BPA-free, and FDA (US Food Grade) or LFGB (EU Food Grade) standard Silicone material.Waterproof, dustproof, chemical-resistant.Temperature resistance: -40°C to 230°C.Anti-slip and impact-absorbing performance.Easy to install and reusable Save the earth from disposable plastic, and save the trees.

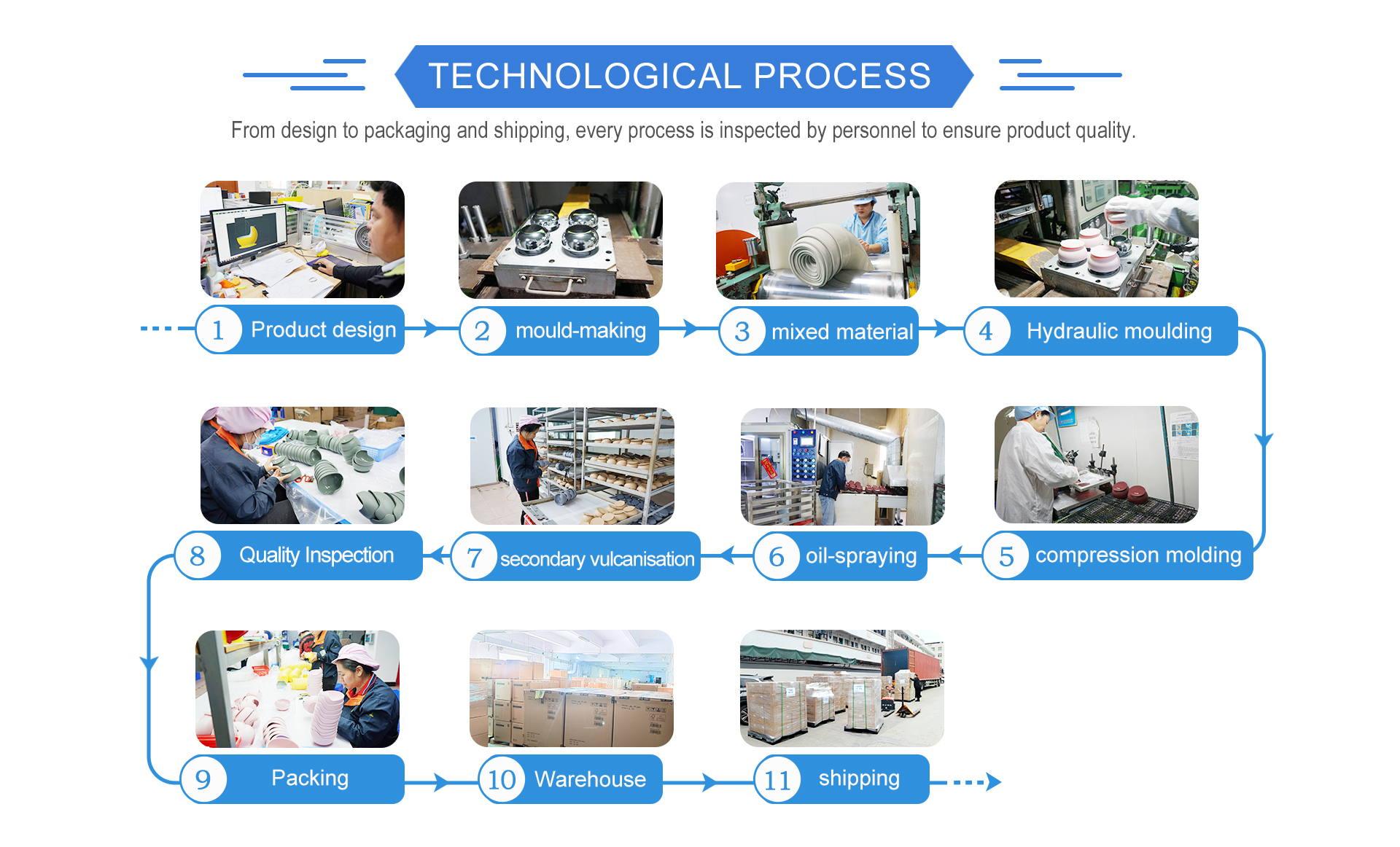

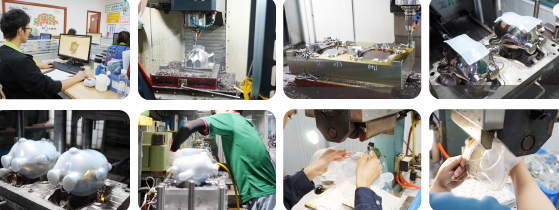

Custom Silicone bead Making Process

The Whole Process to create Your silicone Beads

The process of customizing silicone Beads involves several steps to create personalized and branded silicone baking beads or other silicone Beads products. Here’s a general overview of the customization process

Design Concept:

Define your design concept, Design 3D structure of the silicone Beads according to your idea: including the beads desired size, shape, color, and any specific features or patterns you want on the silicone Beads.

Material Selection:

Choose the LSR or solid silicone as base material according to your molding method, ensuring it complies with safety and quality standards.

Prototype Development:

Create a prototype or sample of the customized silicone Beads. This step allows you to evaluate the design and functionality before mass production.

Custom Printing or Branding:

If you want your silicone products to feature logos, artwork, or branding, the customization process may include CNC on your tooling, water transfer printing, heat transfer printing, In mold decoration or other methods to apply your pattern to the beads.

Tooling and Molding:

Develop products or tools based on the approved prototype. The products will be used in the manufacturing process to create multiple silicone products with consistent shapes and sizes.

Material Mixing and Preparation:

Prepare the silicone material by mixing it according to the manufacturer’s specifications. This involves combining silicone with any required additives and pigments to achieve the desired color.

Molding and Shaping:

Inject or put the prepared silicone material into the molds. Depending on the design, this may involve Liquid Silicone Rubber (LSR) molding, co-injection dripping molding or silicone compression molding.

Curing and Cooling:

Allow the silicone beads to cure and cool inside the molds. The curing time can vary depending on the type of silicone used and the product’s thickness.

Demolding:

Remove the cured silicone beads from the steel molds, ensuring they maintain their intended shape.

First Quality Control:

Inspect the silicone beads for any defects, such as air bubbles, irregularities, or inconsistencies in color or shape. Any flawed beads are typically discarded.

Post-processing:

Carry out the silicone beads and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

Secondary vulcanization:

Secondary vulcanization is a process that must be handled for any product that has passed the inspection. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone beads may do not need this process

LOGO or Pattern printing if needed:

Laser engraving or printing the design on. sometime, you also can put the silicone beads logo on the silicone tooling directly.

Cleaning and Packaging:

Clean the silicone beads to remove any residues or impurities. Then, package them according to your specifications, which may include sets of beads in specific quantities or individual packaging.

Final Quality control and testing:

After all the silicone beads making process finished, arrange the final QC for the beads before the delivery.

Warehouse and Shipping:

Finished OQC personalized and branded silicone beads in the warehouse and ready to ensure reach your destination safely

- DHL/UPS/FedEx/ with a typical transit time of 3-8 days.

- By air shipping, 10-15 days.

- By sea shipping,30-50 days

Why Choose Z.S.R as your Silicone Beads Supplier?

16 years’ custom silicone products experience

Rich market experience and engineer makes us familiar with the products and market requirements of different wholesale customers

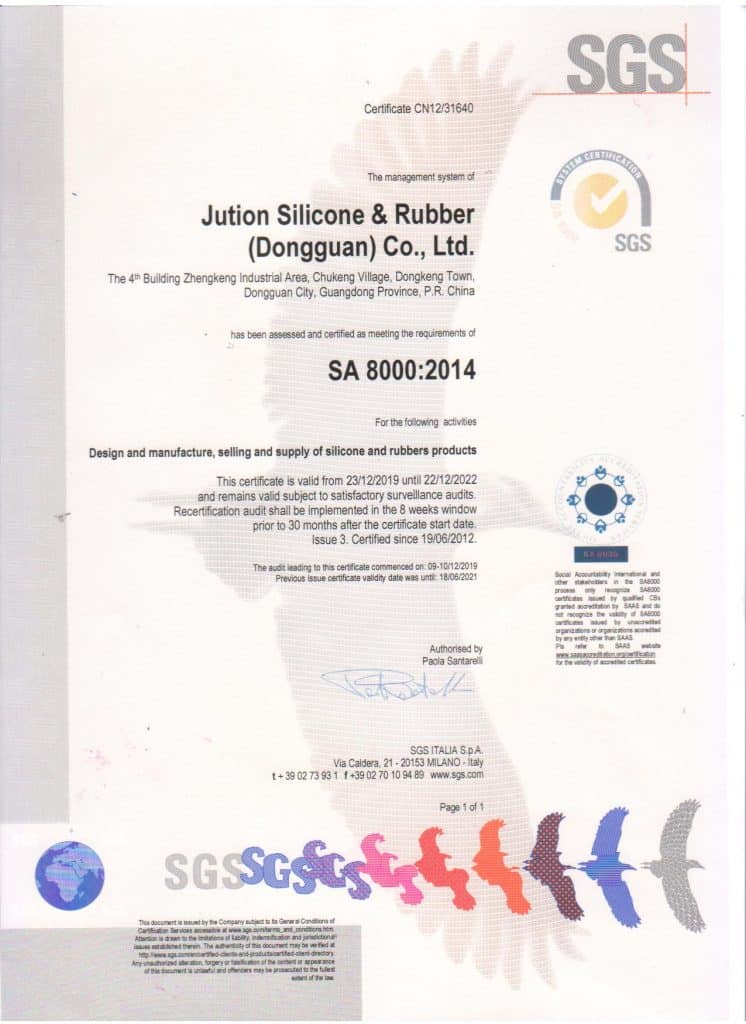

Safety Factory

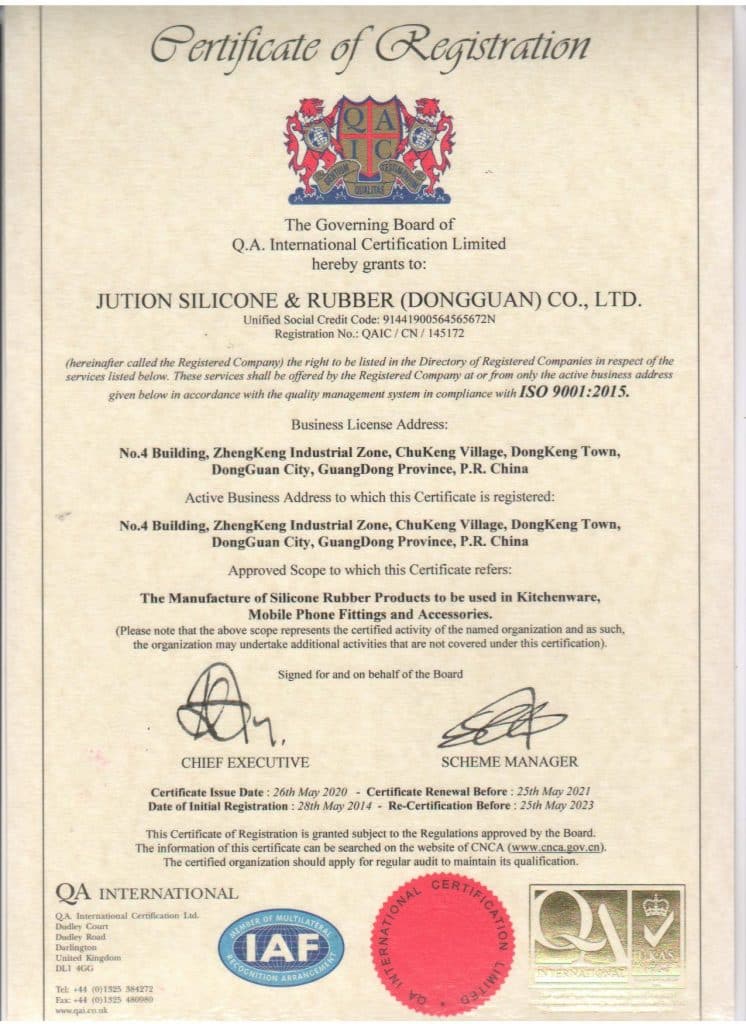

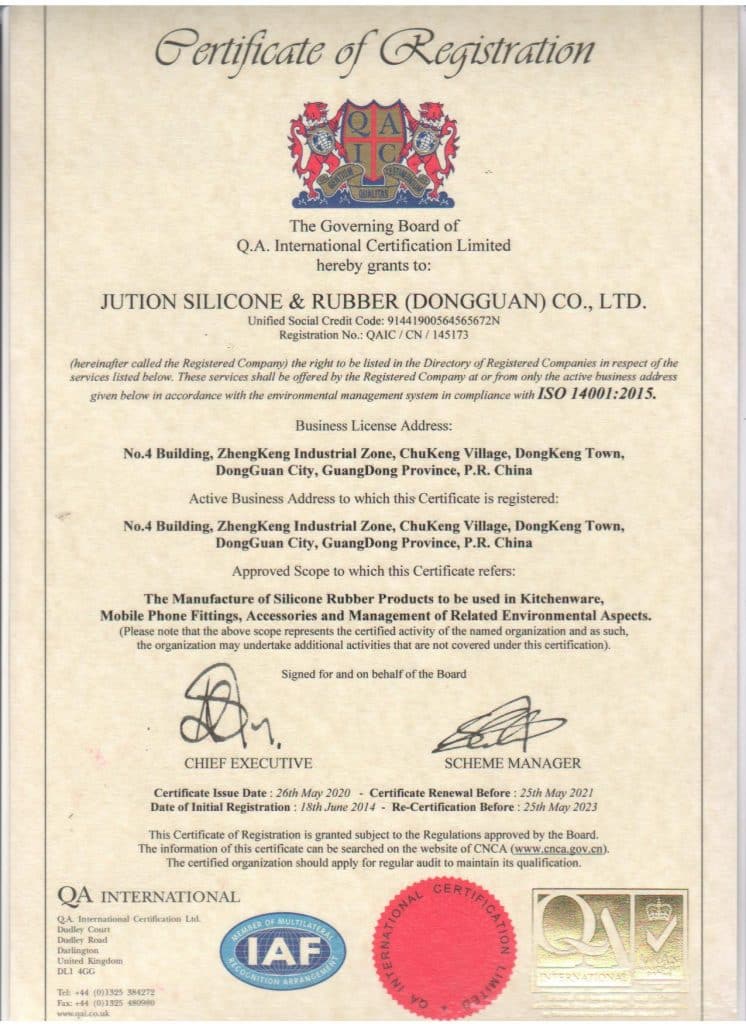

Z.S.R is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney. The third parties and the world’s Fortune 500 companies have helped you verify the factory strength and reliable for you.

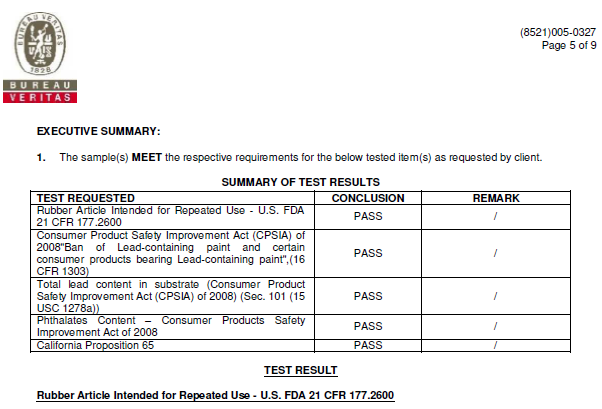

100% safe raw material

Food-grade high-quality silicone materials, 100% high-purity food-grade platinum silicone which are safe and environmentally friendly, non-toxic and harmless. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

One Stop Service from design to whole process manufacturing

Z.S.R have the own mold workshop and mold design engineer, Complete post-processing workshop. All the silicone products cycle under one roof- from designing products & building tooling to launching into full-blown production. You will reduce the risks of working with multiple vendors, save your time to market & lower costs.

Stable production capacity

32 sets of silicone compression molding machines, 6 sets of liquid silicone rubber molding machines, 8 sets of co-injection silicone molding machines with Manufacturing 100,000-150,000 pcs daily and export to 40+ countries. Deliver your orders on time, ensuring customers do not face the risk of out of stock.

Wholesale OEM/ODM Services

Z.S.R complete OEM/ODM Services provides a variety of wholesale customization services to suit customers’ different designs and product needs. Customized service for design, color, packaging.

Strict Quality Control

Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the qualified Silicone products as the prototype they approved before mass production.

Safety products

The silicone products what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV

Certification

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.