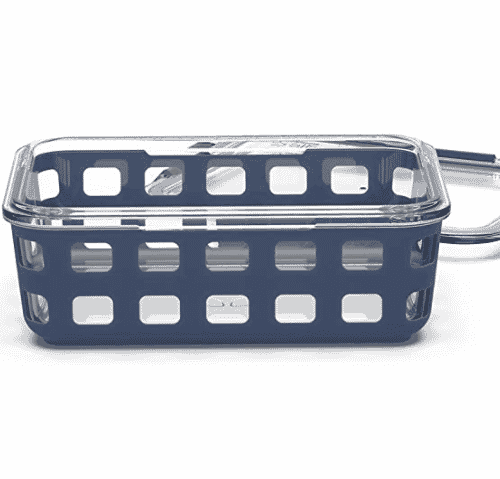

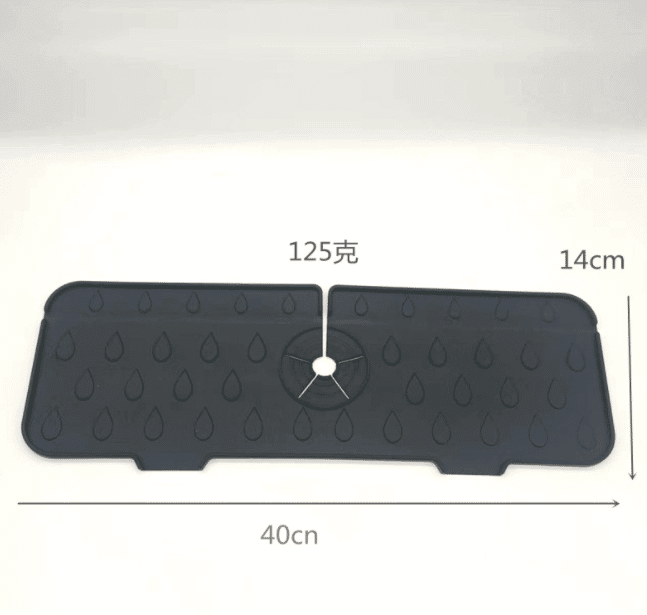

Custom Silicone Grips

Z.S.R Group is a molded Silicone Grips manufacturer and custom Silicone Grips molding solution provider in China help more than 10.500 success silicone project in the past 16 years. Z.S.R team work with the different industry brand owner, product development manager, product manager, Senior product designer together offers them OEM services from Silicone Grips design, prototyping to molded Silicone Grips contract manufacturing.

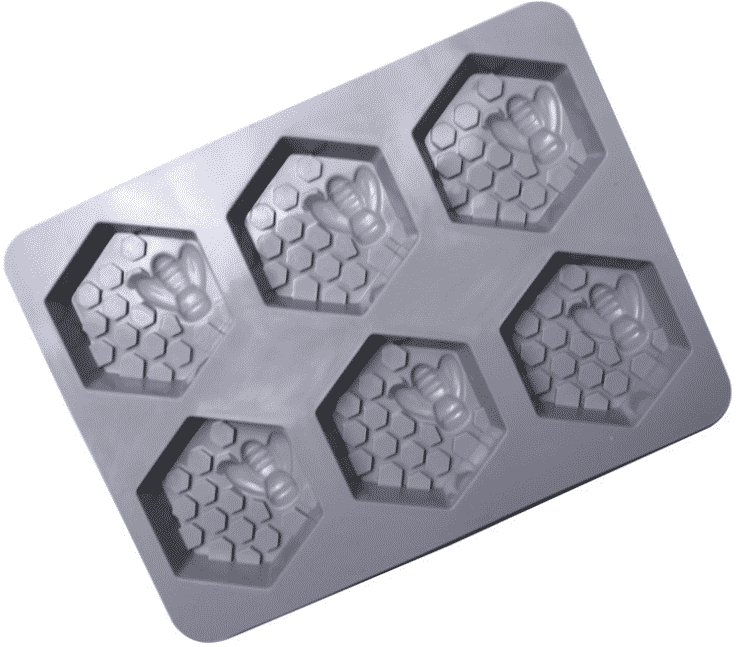

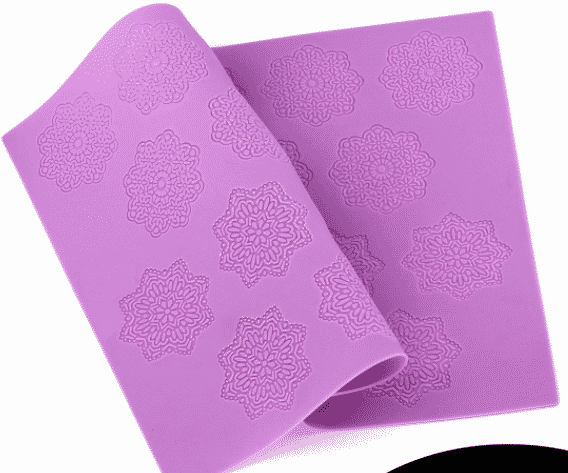

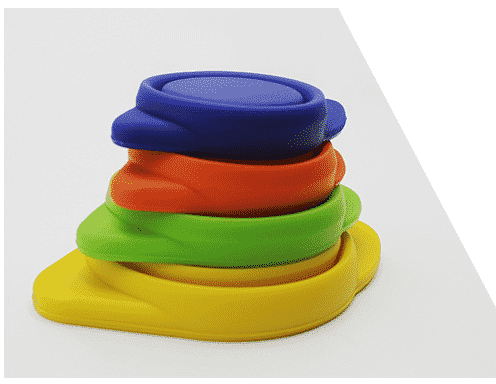

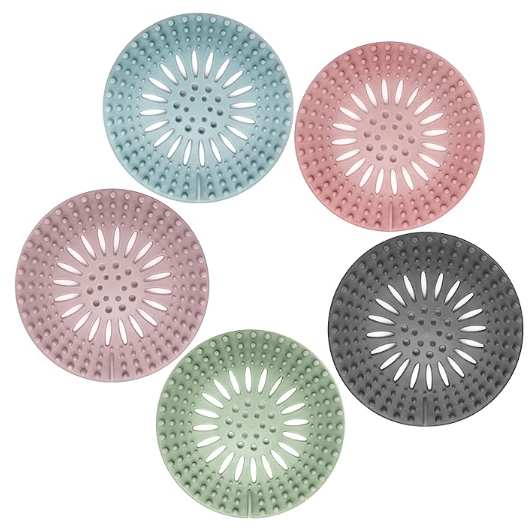

Z.S.R ‘s Customized Silicone Grips service with the Customized Silicone Grips material, size, design, function, structure, shape, color, logo, pattern, package, label and other silicone products technical support to ensure their Silicone Grips project success.

The Silicone Grips can be used to hot frying pan & pot hand grips, protects your fingers from burning. Safer to use than typical cloth mitts & small pot holders.keep your family safe ,for home wife,kids health gift.

MOQ: MOQ (standard products) is 100 PCS. For custom requirements, please contact us to get accurate quotations and discounts.

Product Details

100% Certificated food safe Food-Grade Silicone. Heat resistant -40°F to 482°F(-40°C to 250°C) ,Durable and Dishwasher

CHEMICAL AND BPA FREE: Made from food-grade silicone, BPA free, odorless, non-toxic, environmentally friendly and reusable.

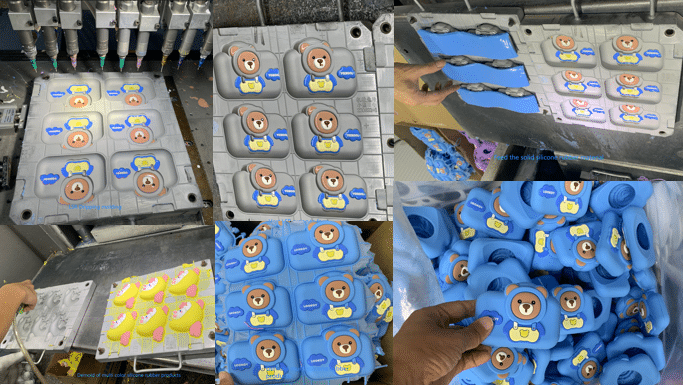

Multi-Color Dripping Molding

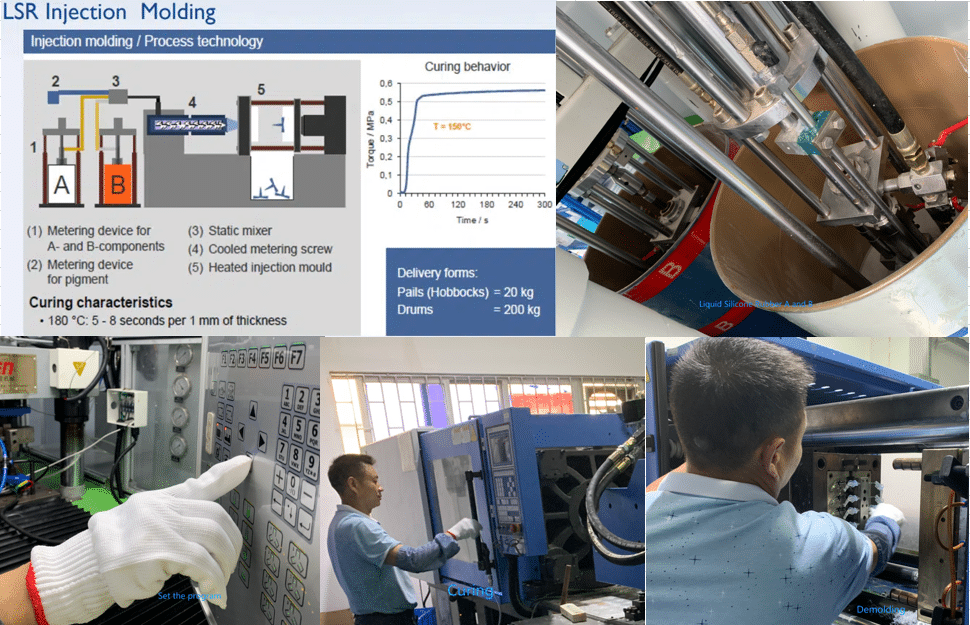

Liquid Silicone Rubber (LSR) Injection Molding

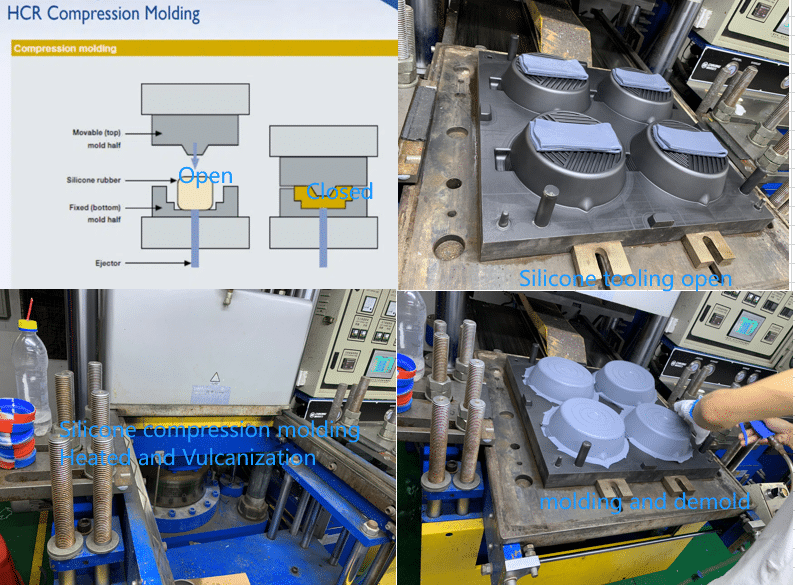

Silicone Compression Molding

About ZSR

Z.S.R International Group(HONG KONG) CO., LIMITED,is a one-stop supplier and silicone molding solution provider in the complete silicone consumer products field founded in 2007. We support our partner consumer silicone products from idea to market. We are the partner of choice for leading silicone consumer products companies and retailers. Recognized for delivering innovative products, manufacturing expertise, and technical solutions.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.