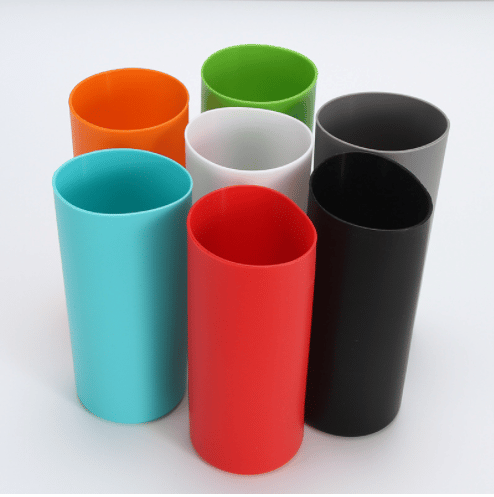

Custom Silicone Bottle Sleeve

Z.S.R Group is a Silicone bottle sleeves manufacturer and custom Silicone bottle sleeves molding solution provider in China help more than 10.500 success silicone project in the past 16 years. Z.S.R team work with the different industry brand owner, product development manager, product manager, Senior product designer together offers them OEM services from Silicone bottle sleeves design, prototyping to contract manufacturing, printing, packaging.

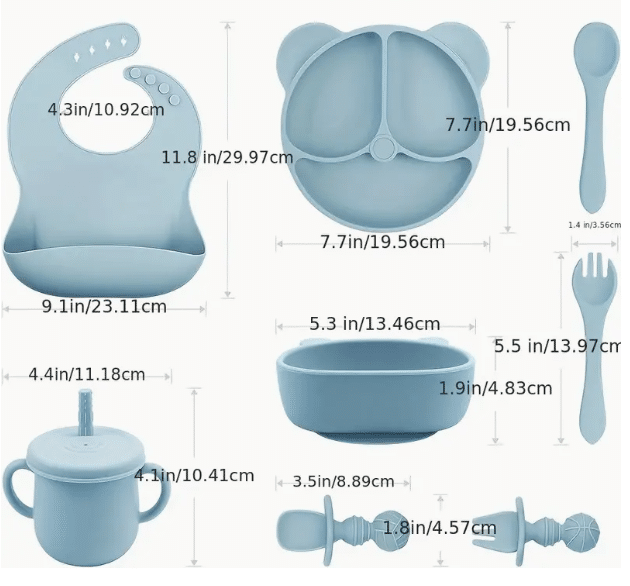

Z.S.R ‘s Customized Silicone bottle sleeves Service with the Customized material, size, design, function, structure, shape, color, logo, pattern, package, label and other silicone products technical support to ensure our partners project success.

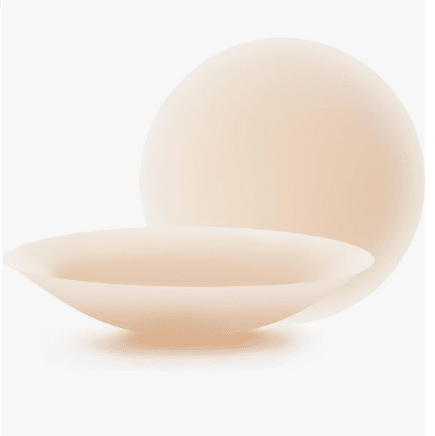

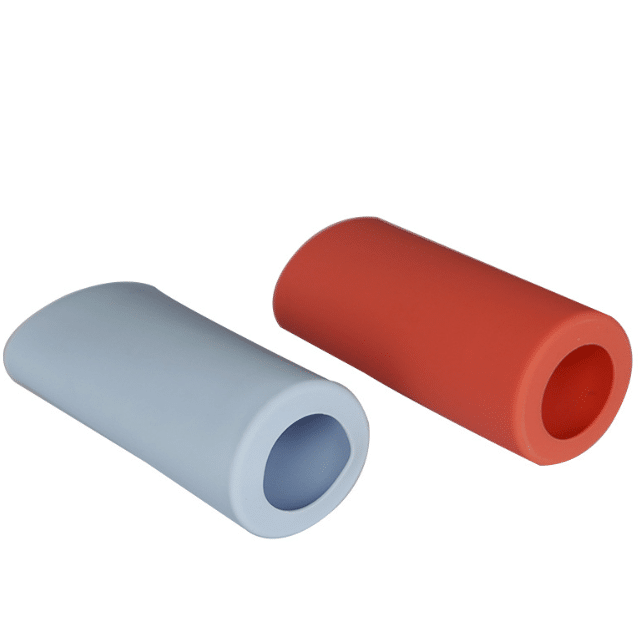

The silicone bottle sleeve provides excellent impact protection or daily protection, when your water glass are dropped and bumped, the silicone sleeves will tightly attach to your glass jar, absorbing shocks and drops to protect your water bottle perfectly. They also can help prevent daily wear, which is great for extending the life of your water bottles.

MOQ: MOQ (standard products) is 100 PCS. For custom requirements, please contact us to get accurate quotations and discounts.

Product Details

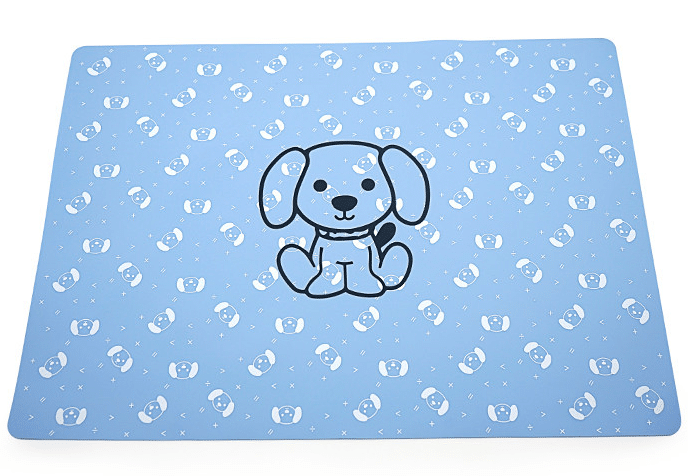

Design: Our Silicone bottle sleeve proprietary textured and printed design creates a natural, nonslip grip that eliminates condensation slippage and provides a safe, snug fit.

All of our Silicone bottle sleeves are made from non-toxic, non-taste, BPA free food grade, strong and sturdy silicone material, which can allow you to drink more water happily and will not tear, damage or stretch in normal service, they are reusable and environmentally friendly, a very worthy choice.

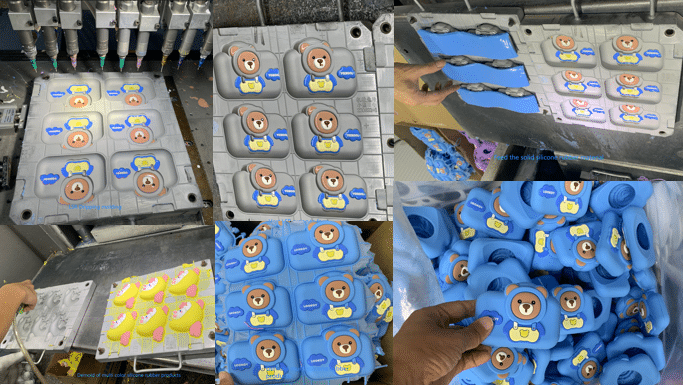

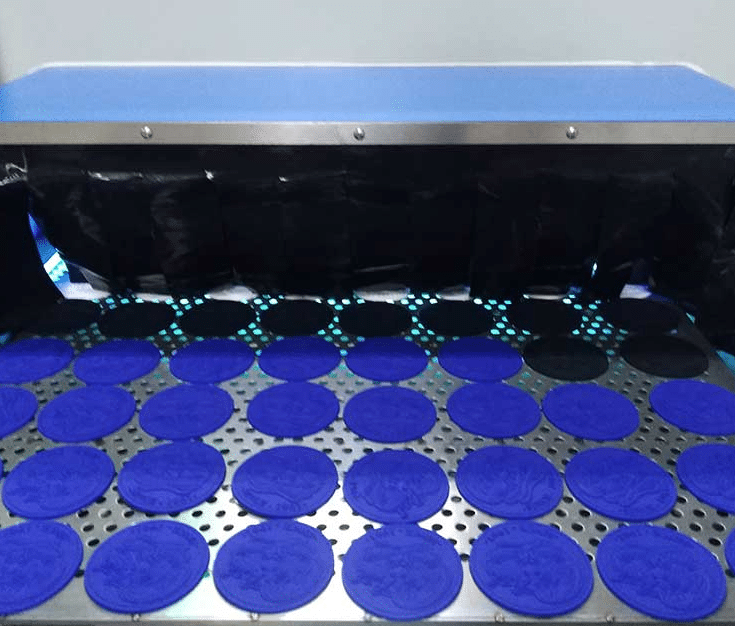

Multi-Color Dripping Molding

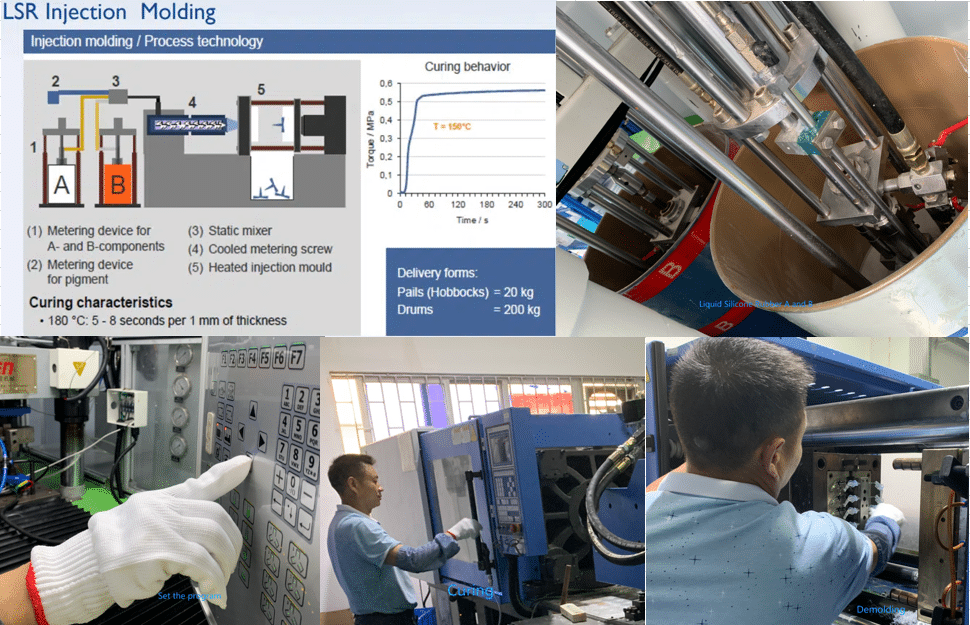

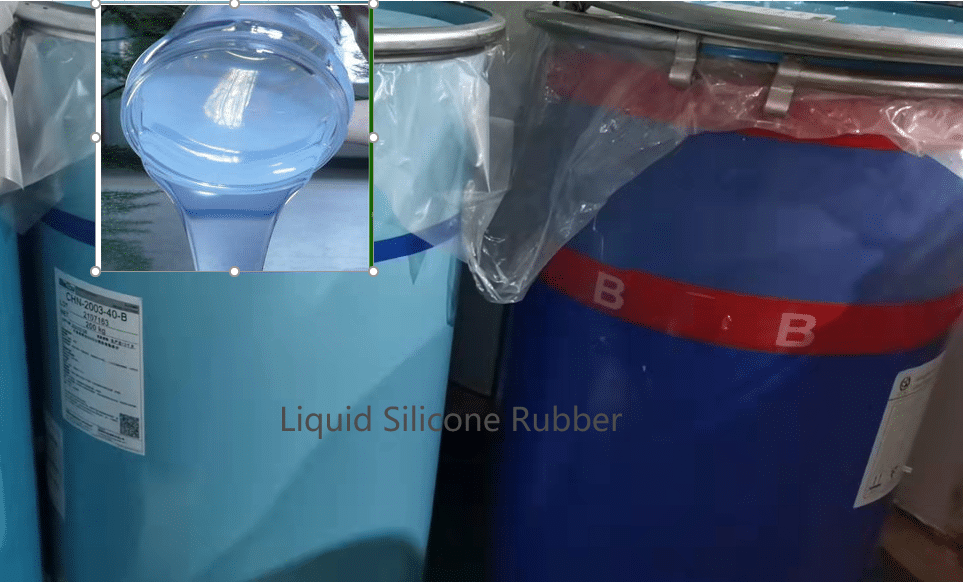

Liquid Silicone Rubber (LSR) Injection Molding

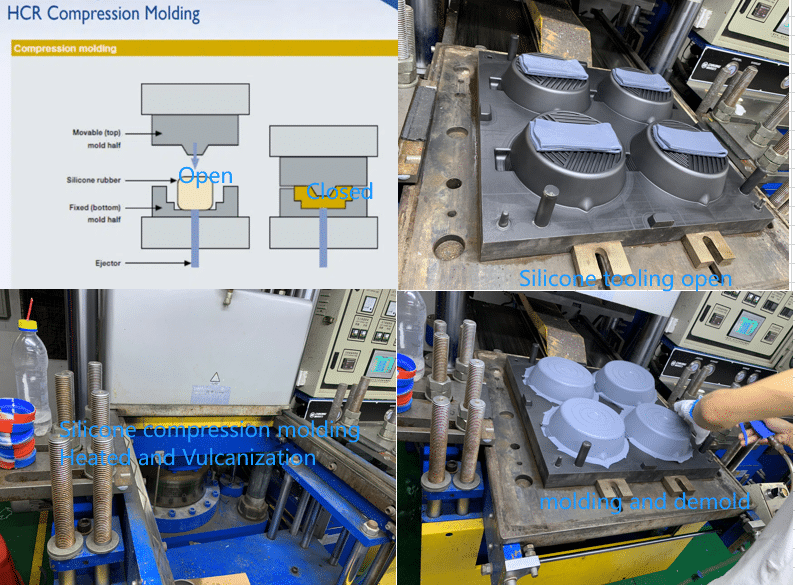

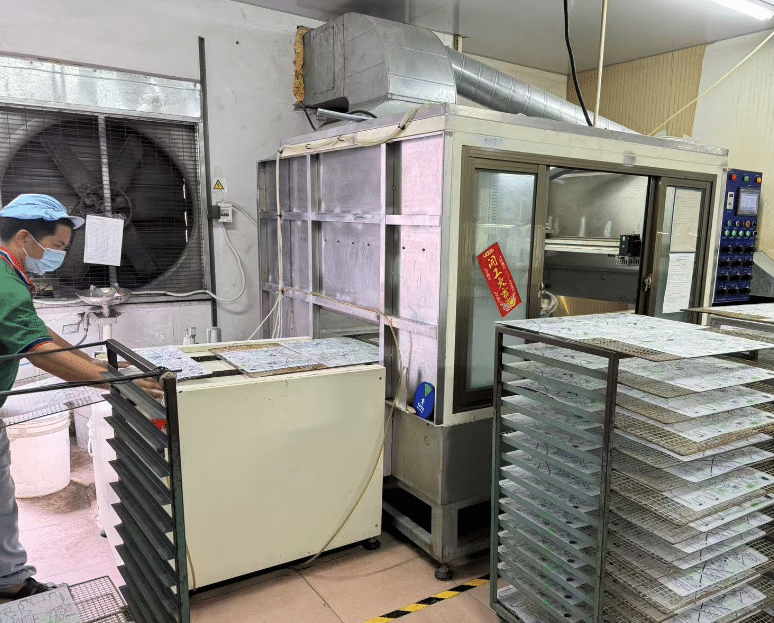

Silicone Compression Molding

customized options

We offer a wide range of customization options for you. Work with us to create unique and competitive silicone products.

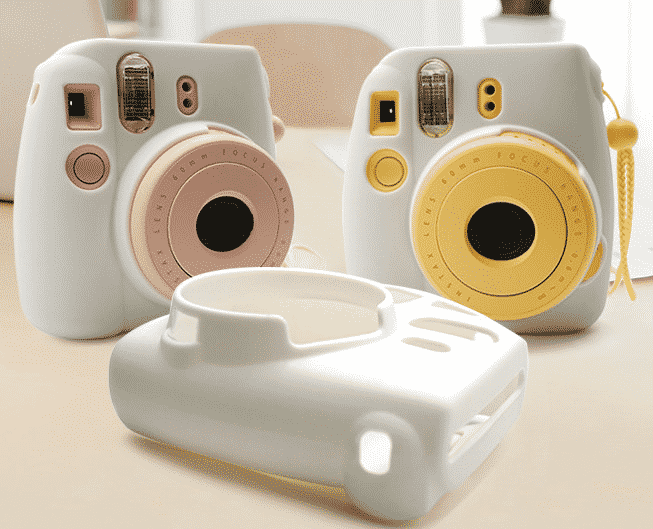

You can customize silicone product color according to the Pantone book. We will add the FDA Color Paste to the silicone material when the material mixed. Our usual colors are White, Red, Green, and Gray. We also can make the double color, marble color and multi-colored Molded silicone products for you if you needed

ZSR own the printing workshop for printing the pattern or logo color by Silk Screen printing,Pad printing,Heat Transfer printing and Water Transfer printing, In mold Decoration, Digital printing.

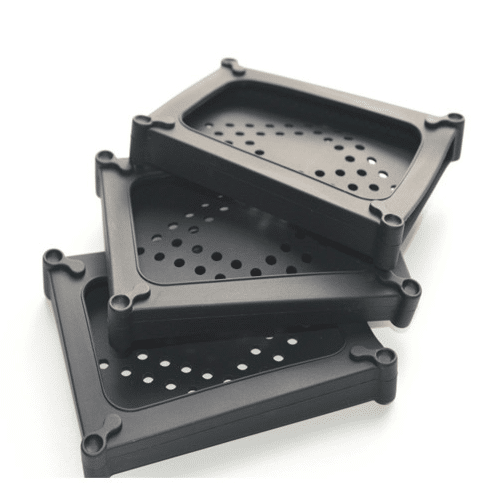

Z.S.R’ s Own three kinds of silicone molding line

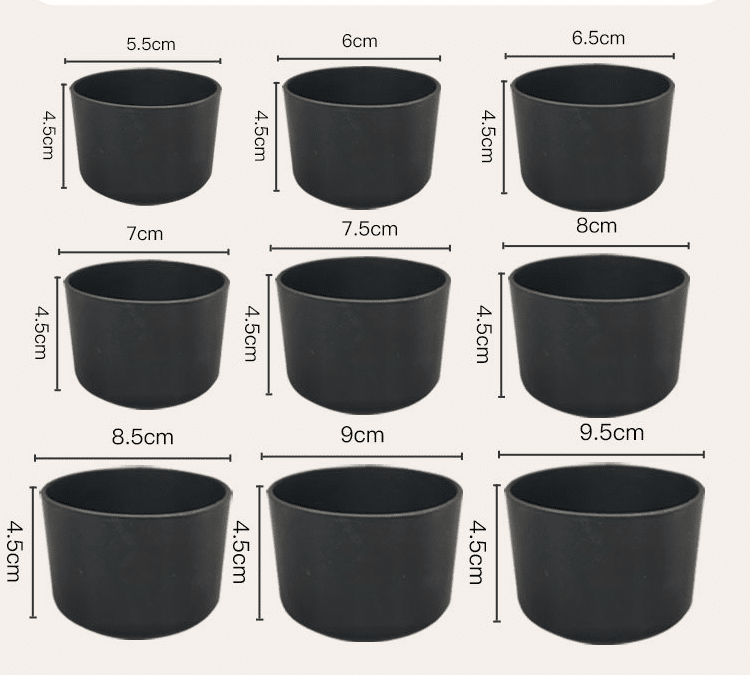

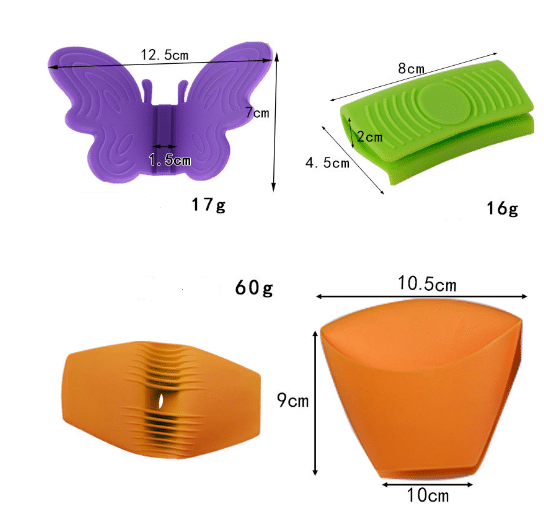

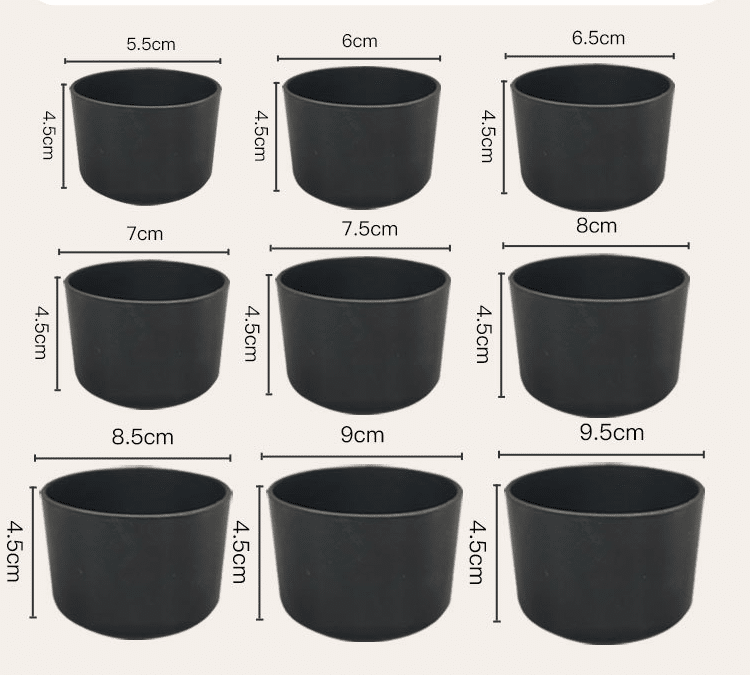

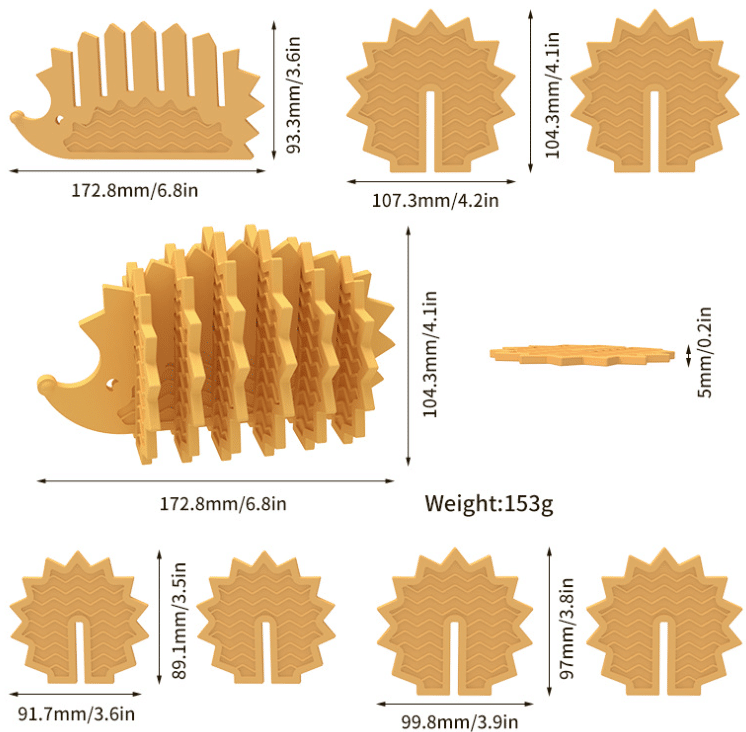

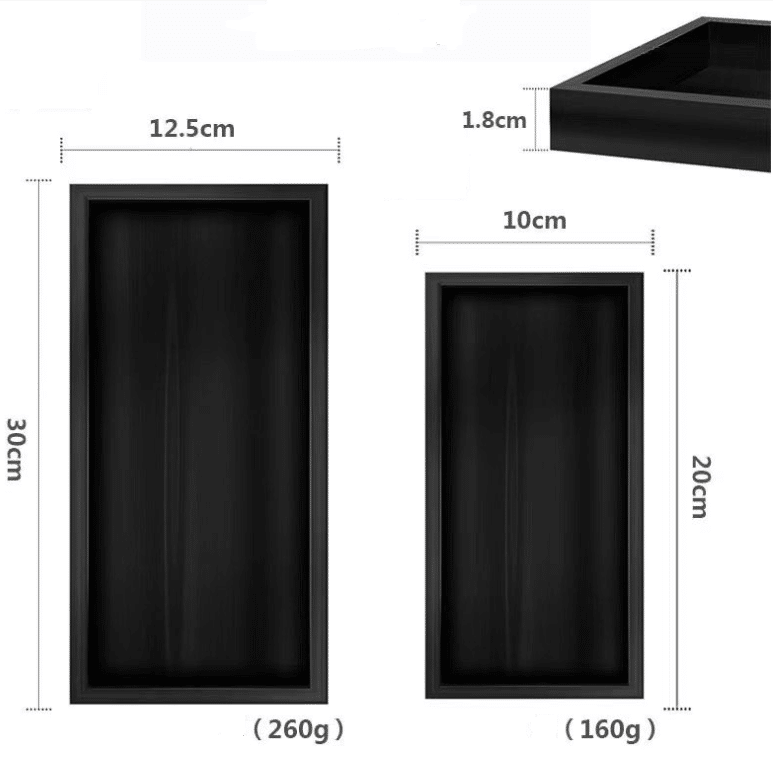

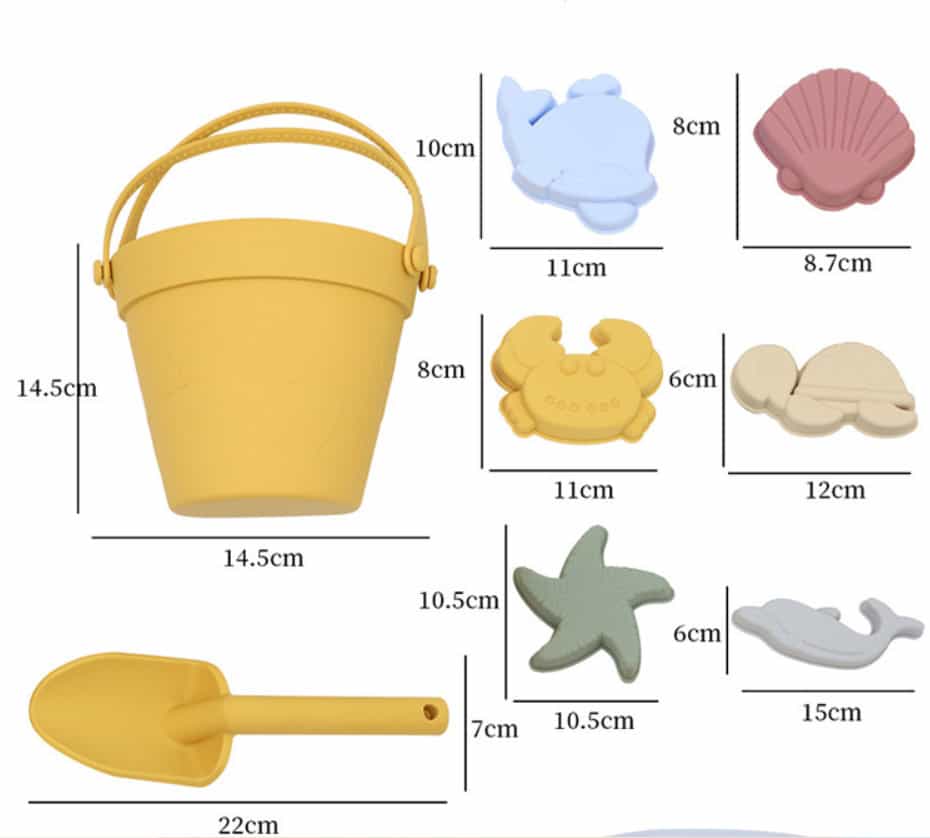

The machine press 50T-600T, so we can make the Molded silicone products size from 0.1cm to 127 cm (0.02″ to 50″), The thickness of the silicone products that we can make is from 0.01-1cm.

All the silicone products Z.S.R made from precision parts to huge finished silicone products to meet your different project needs.

Silicone product size & Shape

Z.S.R International Group(HONG KONG)CO., LIMITED helps companies create custom logo silicone products that make your brand stand out. Z.S.R custom Logo silicone products, promotional silicone merchandise, gift giveaways, and logo silicone items that you’ll love. We offer logo branding services to the Promotional and License industries. We work with the promotional, Marketing and Advertising, Licensor, Licensee, wholesale, retail chain, gifts store, and product development companies together offer molded logo silicone products to the whole world to expand your brands and Market.

In Z.S.R group, we offer more than 5 ways to put your logo and pattern on. The different logo and patterns may need different methods. Click Here to get rough information for the different performance with the different printing ways.

After you confirm your products function and the structure. You may need choice the correct material to achieve this function. Z.S.R offer the Customized silicone product service from Customized the silicone products raw Material.

Our expert Engineer will recommend the most suitable raw materials according to your Molded silicone product requirements (e.g. Liquid silicone rubber or Solid silicone, tensile strength, tearing strength, etc.; different standards such as FDA and LFGB or medical grade or different Brands).

Grade

- Ordinary Silicone Rubber.

- Food Grade Silicone Rubber. FDA (USA Standard), LFGB (EU Standard), DGCCRF (France Standard),

- Medical Silicone Rubber

Brand

- Import: Wacker, Dow Corning, ShinEtsu, Elkem, DELO, Dow,

- Domestic: Xin’an Chemical, Dongjue Silicone, Tianan Chemical,

Physical Properties

- HTV Solid silicone.

- LSR Liquid Silicone Rubber.

Making Process

- Precipitated silicone rubber.

- Fumed silicone rubber property.

Z.S.R provide customized packaging solutions for manufactured molded silicone product

We offer one-stop Molded silicone product services such as helping customers to design, develop, assemble and inspect the packaging include:

For ensuring the appearance of finished Molded silicone products and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished Molded silicone product can reach the end sellers with the highest quality.

With the Silicone products various surface treatment processes, including Mechanical grinding, polishing, sandblasting, printing, oil spraying, UV modification, laser engraving, electroplating, spraying, which can improve the silicone products appearance quality, durability and safety to meet different client’s needs.

Z.S.R own’s surface treatment process allows us give your silicone products a unique look and feel with different options. With the right surface treatment applied, you can make an even greater impact on potential customers who appreciate the attention to detail.

Custom the molded silicone product Quality Control Inspection.

Our common molded silicone product Quality Control Inspection is from supplier selection, production specification, In-process Inspection, Before shipment inspection (OQC). We also accept the customer hire the 3rd party to pre-shipment QC include Full inspection if needed.

About ZSR

Z.S.R International Group(HONG KONG) CO., LIMITED,is a one-stop supplier and silicone molding solution provider in the complete silicone consumer products field founded in 2007. We support our partner consumer silicone products from idea to market. We are the partner of choice for leading silicone consumer products companies and retailers. Recognized for delivering innovative products, manufacturing expertise, and technical solutions.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.