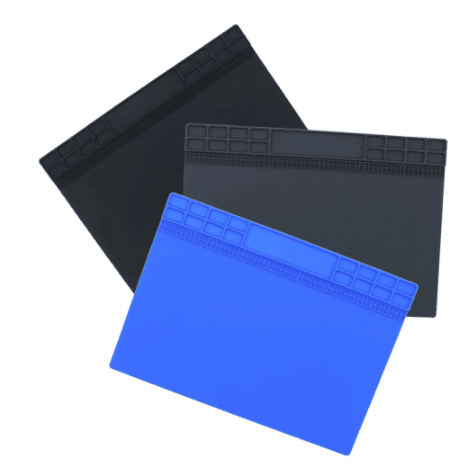

Custom Silicone Soldering Mat

Z.S.R Group is a Silicone Soldering Mat manufacturer and custom Silicone Soldering Mat molding solution provider in China help more than 10.500 success silicone project in the past 16 years. Z.S.R team work with the different industry brand owner, product development manager, product manager, Senior product designer together offers them OEM services from Silicone Soldering Mat design, prototyping to contract manufacturing.

Z.S.R ‘s Customized Silicone Soldering Mat Service with the Customized material, size, design, function, structure, shape, color, logo, pattern, package, label and other silicone products technical support to ensure our partners project success.

The Silicone Soldering Mat protects your workspace from burns by resisting temperatures. Maintain a clean and organized soldering work environment. Ensure no small parts or tools are lost with individual compartments and placement slots for efficient organization. Silicone soldering mat includes a built-in ruler and four magnetic areas for secure storage.

MOQ: MOQ (standard products) is 100 PCS. For custom requirements, please contact us to get accurate quotations and discounts.

Product Details

Design: The Silicone Soldering Mat designed to reduce unnecessary tools placement and increase the area of the work area. You no longer have to worry about the mat is too small to complete your work. It can provide more space to meet the repair needs of lager electronic devices and soldering projects, such as repair computer, laptop, MacBook, tablet, iPad, iphone, drone, circuit board, camera and more. It is very suitable for repair shops, DIYer and workshops.

The Silicone Soldering Mat made of 100% high-quality food grade silicone material, non-toxic and odorless, no harmful to human body; Flexible and durable, it’s no problem with service life of 10 to 15 years if normal use, and easy to clean with water.

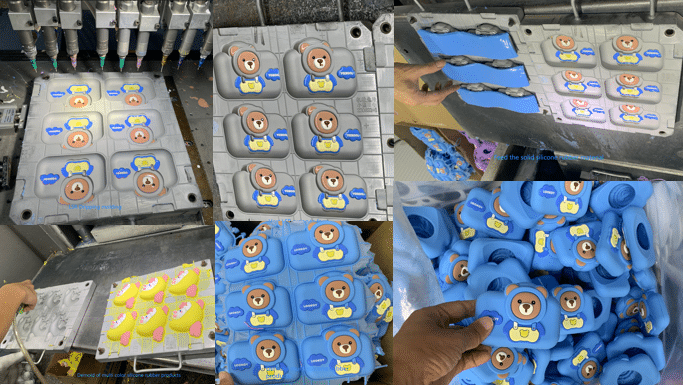

Multi-Color Dripping Molding

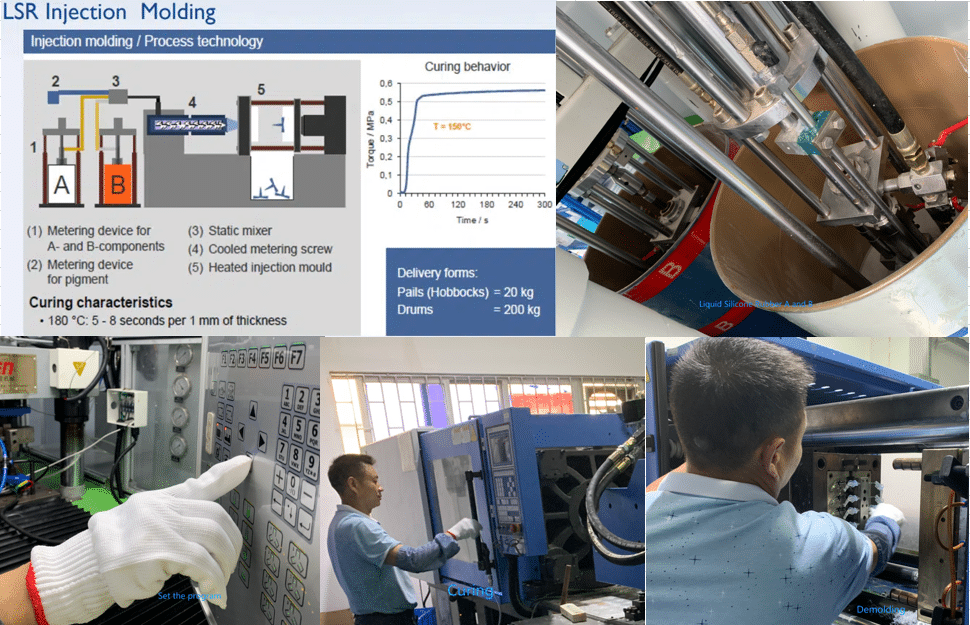

Liquid Silicone Rubber (LSR) Injection Molding

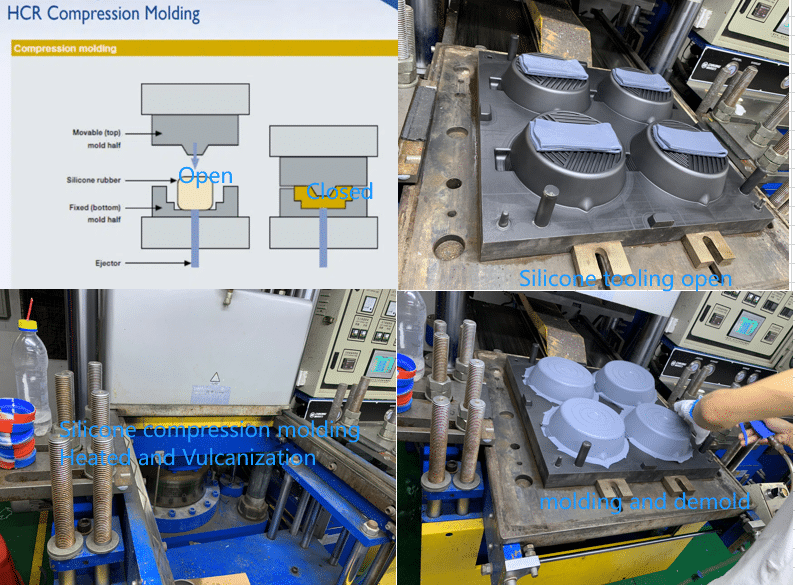

Silicone Compression Molding

About ZSR

Z.S.R International Group(HONG KONG) CO., LIMITED,is a one-stop supplier and silicone molding solution provider in the complete silicone consumer products field founded in 2007. We support our partner consumer silicone products from idea to market. We are the partner of choice for leading silicone consumer products companies and retailers. Recognized for delivering innovative products, manufacturing expertise, and technical solutions.

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.