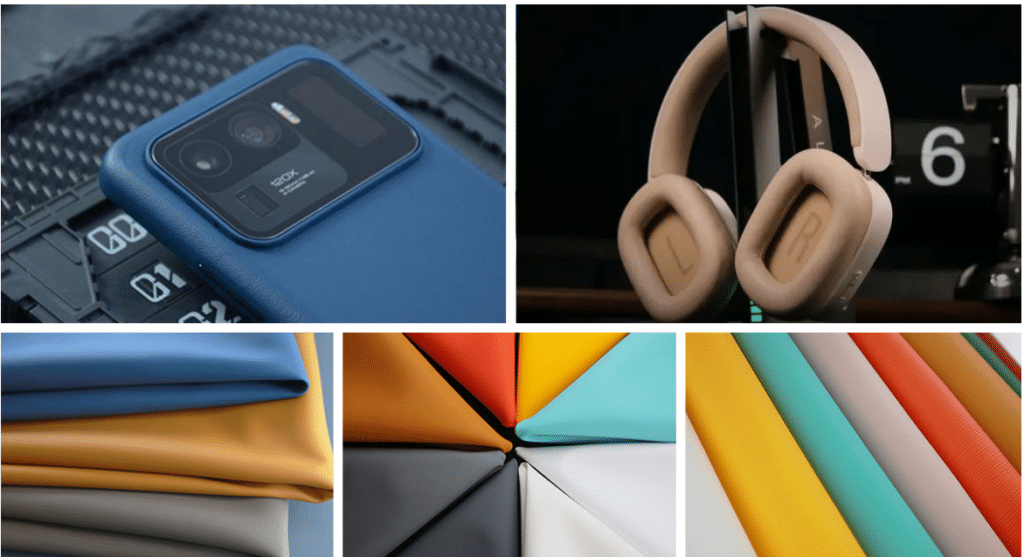

Industrial

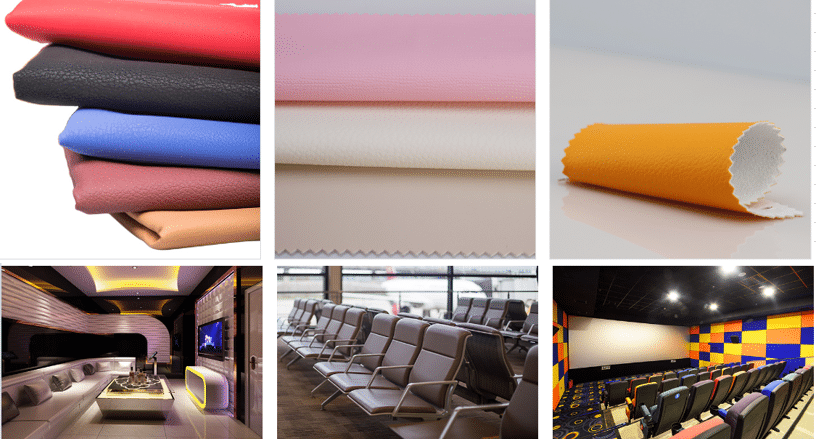

Z.S.R Silicone Leather can be used for building material baking, molding, sponge molding, protect fragile and valuable items, providing a non-slip, durable surface material, protect mechanical equipment and tools and needs to be durable, waterproof and chemical resistant.

We work with industrial and manufacturing product development managers, product designers, product managers,R&D Engineers to design and create custom silicone leathers in a variety of durable and Heat/Cold temperature resistance to empowering their project’s success.

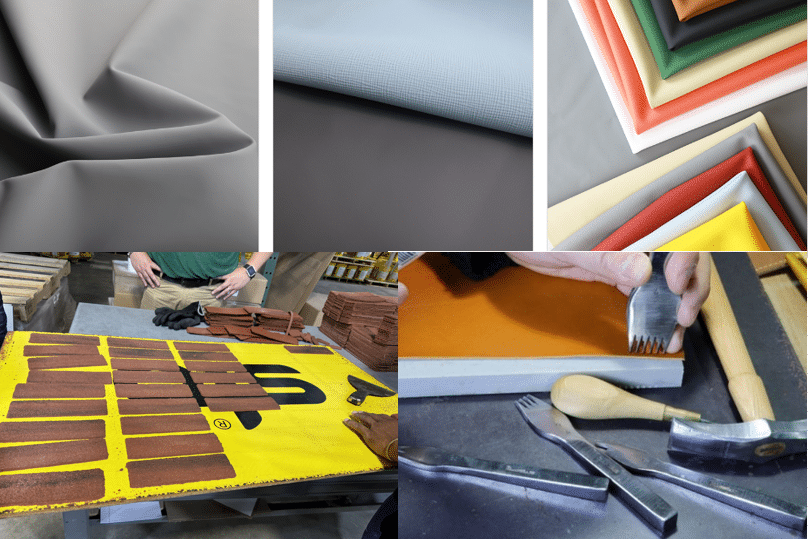

In the field of Industrial and Manufacturing products, silicone leather has been used in many applications, such as silicone baking mats, silicone protector liner, silicone protector covers, etc.

for silicone baking mat

Silicone mats used in the field of building materials manufacturing are easy to clean, high temperature resistant (250°), and can be used repeatedly. It is the best material to instead of the film or kraft paper waxed to protect the environment.

for Silicone protector liner

The extruded silicone mat made by silicone leather is required to be resistant to strong acids, strong alkalis, 10,000 tons of pressure, and repeatedly squeezed more than 300 times.

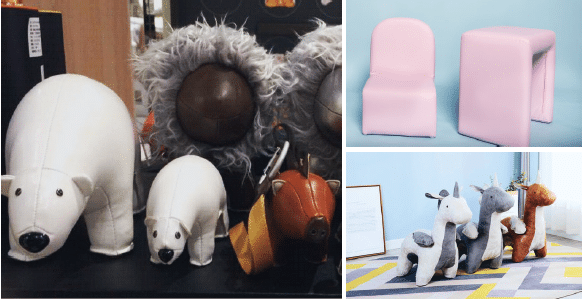

for Silicone protector cover

The silicone leather cover is used to protect mechanical equipment and tools and needs to be durable, waterproof and chemical resistant.

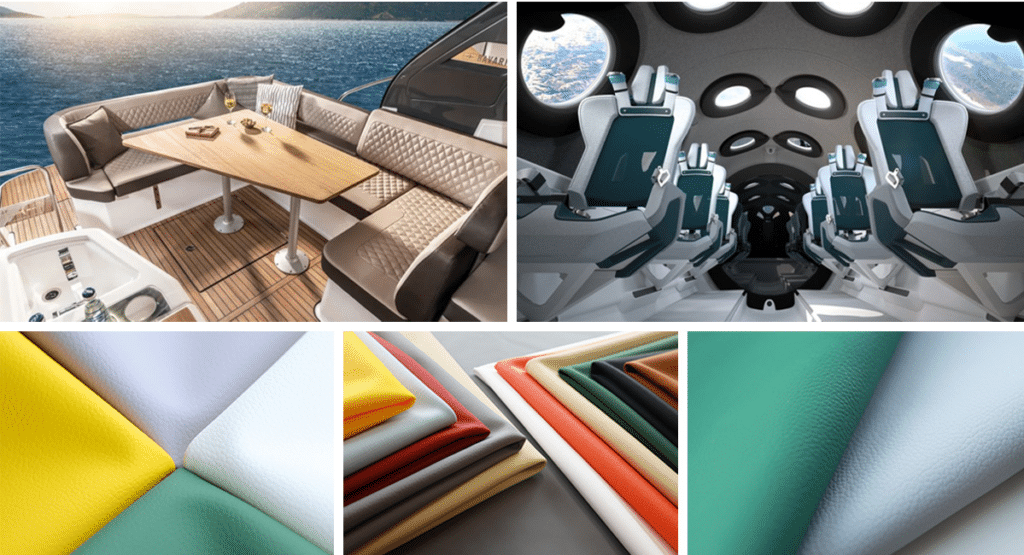

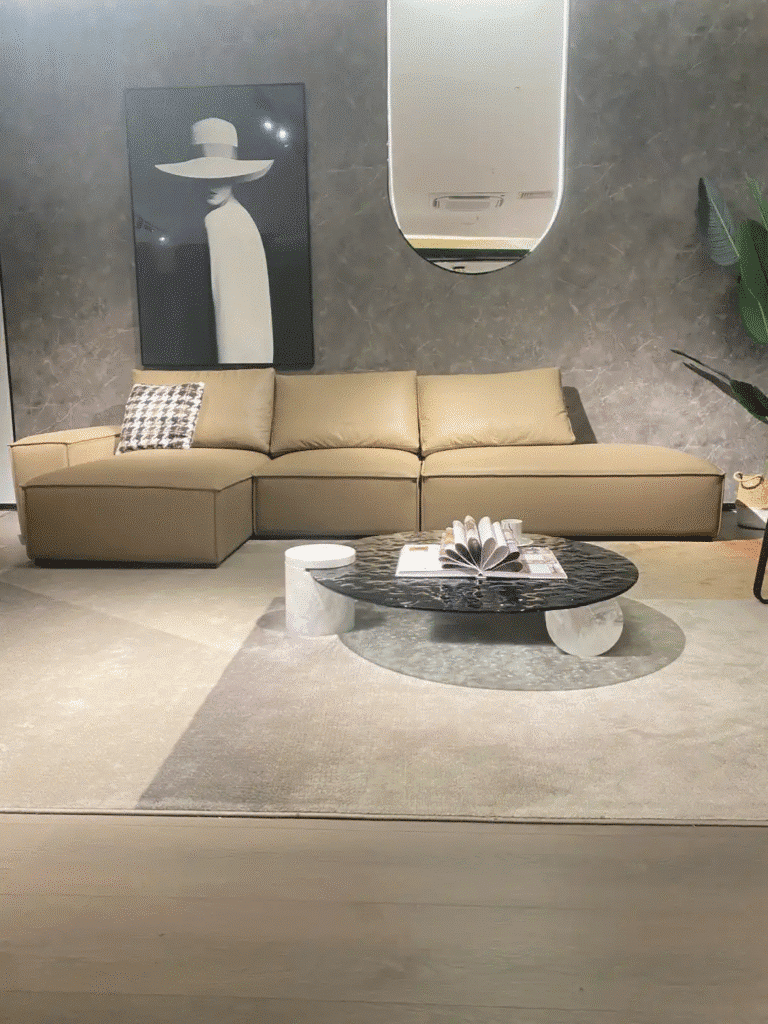

The raw materials of Silicone skin determine its durability, and it also has unique advantages in softness and durability. Compared with genuine leather, the material of Silicone skin comes from nature and is very environmentally friendly. The use of Silicone skin is a major trend in all walks of life in the future.

Silicone Leather Performance Benefits

Durability

Tear resistance, The material can withstand high-frequency use and remain in good condition for a long time. And there will be no problems with scratching with keys or steel wool. The surface of the Silicone leather is free of cracks and wear. The wear test of silicone leather can reach more than 150,000 times, and the Taber wear resistance (CS-10) is more than 3,000 turns. It can stand high pressure of more than 30T in 300 cycles with no tear It can extend the service life of Industrial and Manufacturing equipment and improve the Industrial and Manufacturing experience.

Chemical resistance

The silicone leather has excellent chemical stability. The material is resistant to a wide range of chemicals and solvents found in industrial environments.

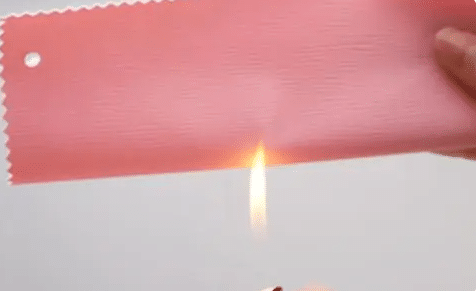

Temperature resistance

This unique chemical structure maximizes the temperature resistance (temperature -40-250℃, humidity 95±5%), and salt spray resistance. Even in these environments, the silicone leather can work well.

The Z.S.R Silicone leather surface is not only resistant to various pollution, but also very easy to clean, acid, alkali, salt, water, sweat and corrosion resistant, but also tensile strength, tear strength, hydrolysis resistance, heat resistance (can withstand 250 degrees high temperature without deformation), cold resistance (still soft at -40 degrees low temperature), bending resistance, yellowing resistance, solvent resistance, corrosion resistance, UV resistance, easy to clean, breathable, waterproof, antibacterial, mildew-proof, aging-resistant, high stitching strength, good elasticity, good softness, good feel, etc.

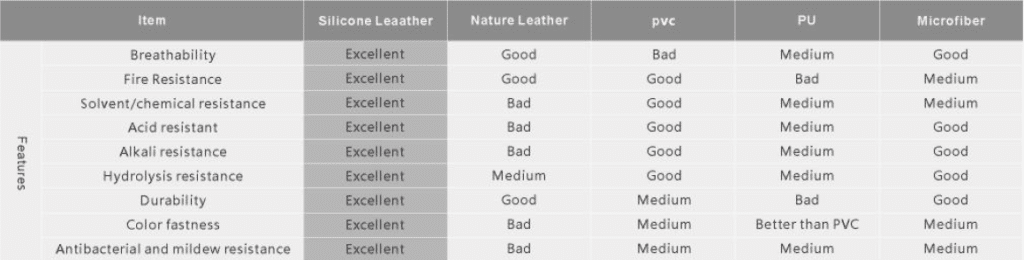

Silicone leather vs traditional leather

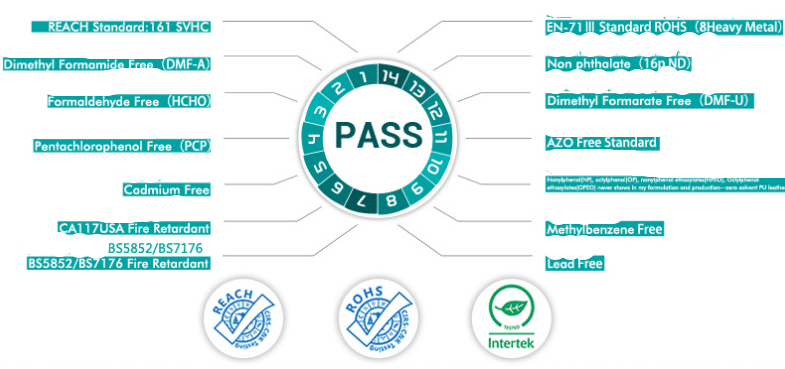

The silicone leather not contain DMF, phthalates, lead. The silicone leather can pass Reach, ROHS (Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

Artificial leathers such as polyurethane rubber (PU) synthetic leather and polyvinyl chloride (PVC) commonly found in the finished leather market are not resistant to aging, high temperature, easy to hydrolyze, easy to stain, and have a short lifespan. They will cause certain pollution to the environment during the manufacturing and use process.

File Download: Silicone leather

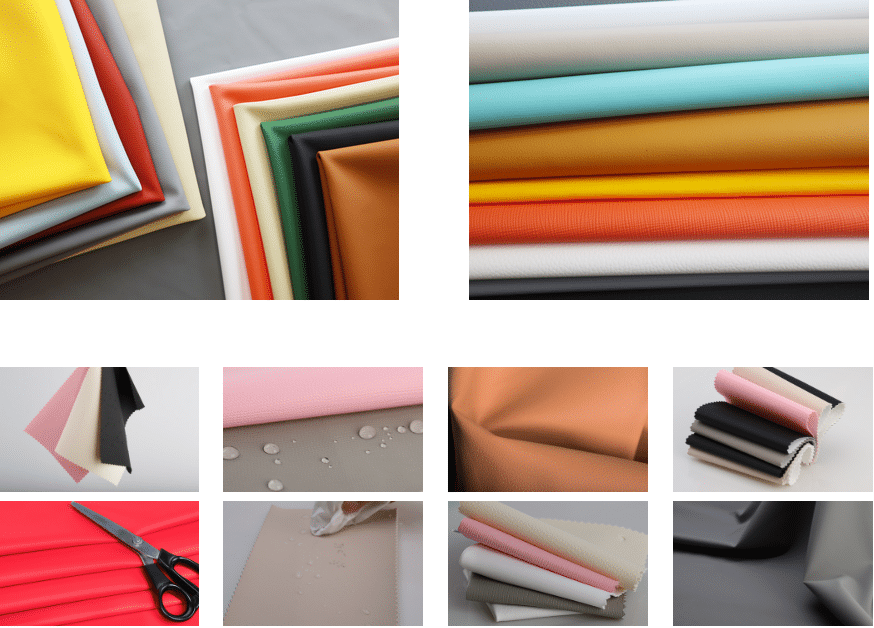

Custom silicone leather

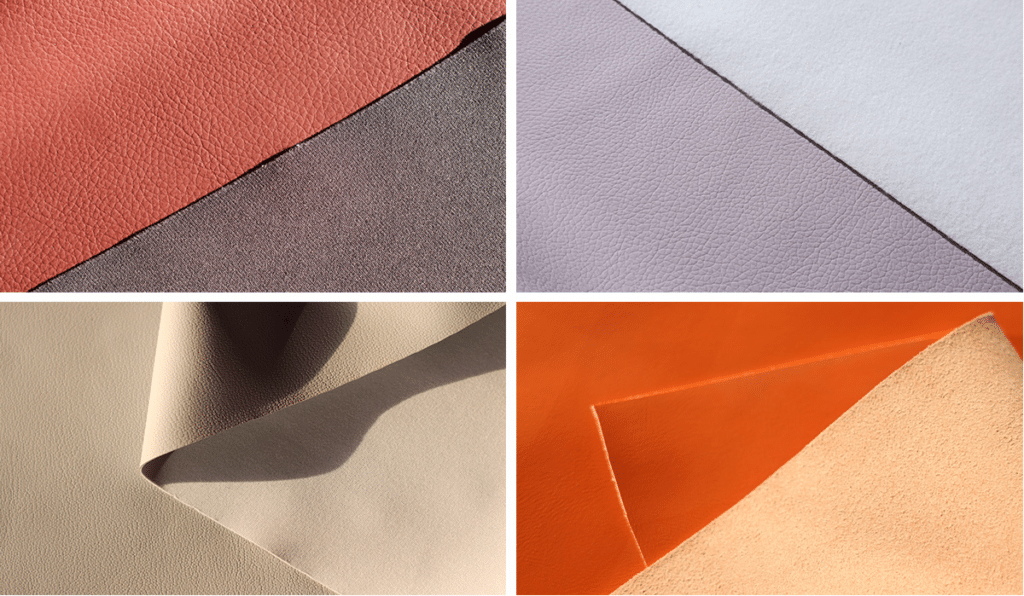

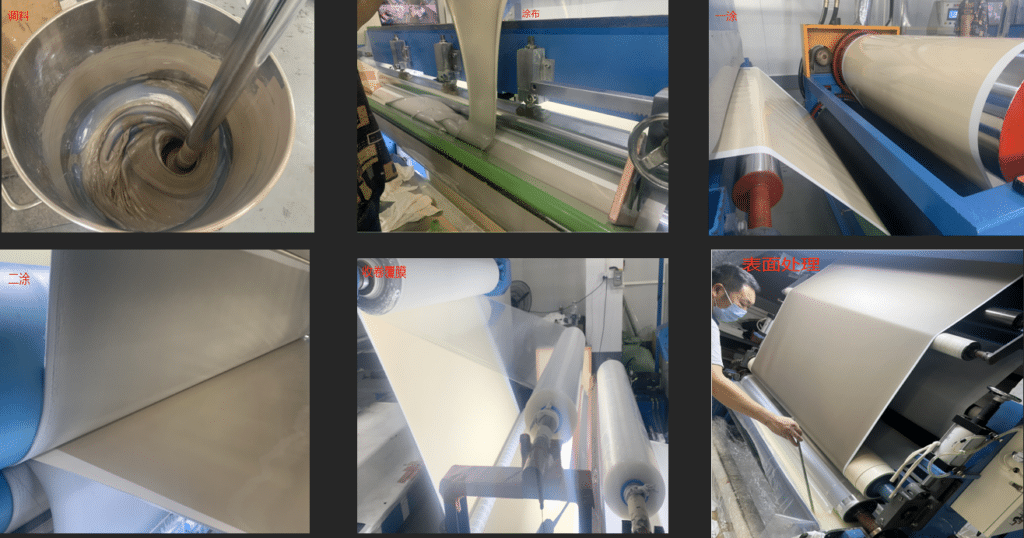

- Surface Layer: 100% Liquid Silicone Rubber

- Base Fabric: fiber glass/fiber cloth/flannelette cloth/ can be customized

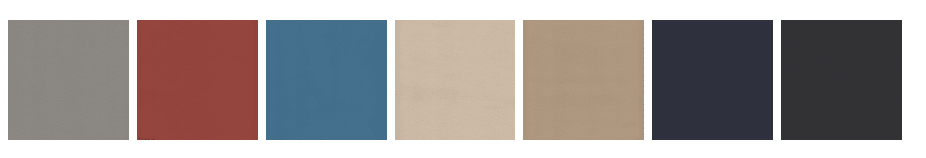

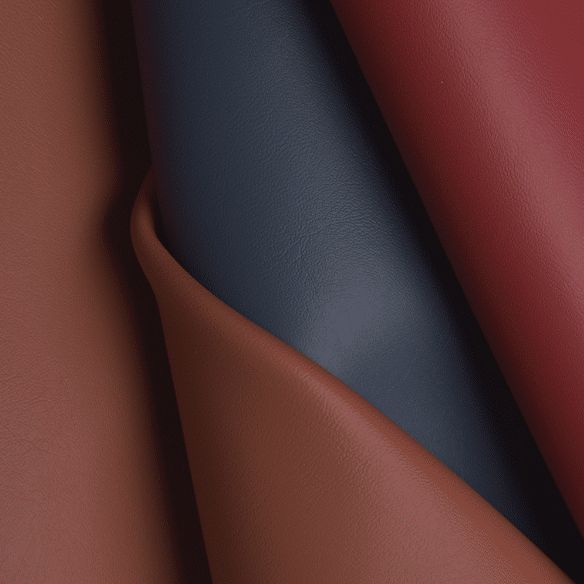

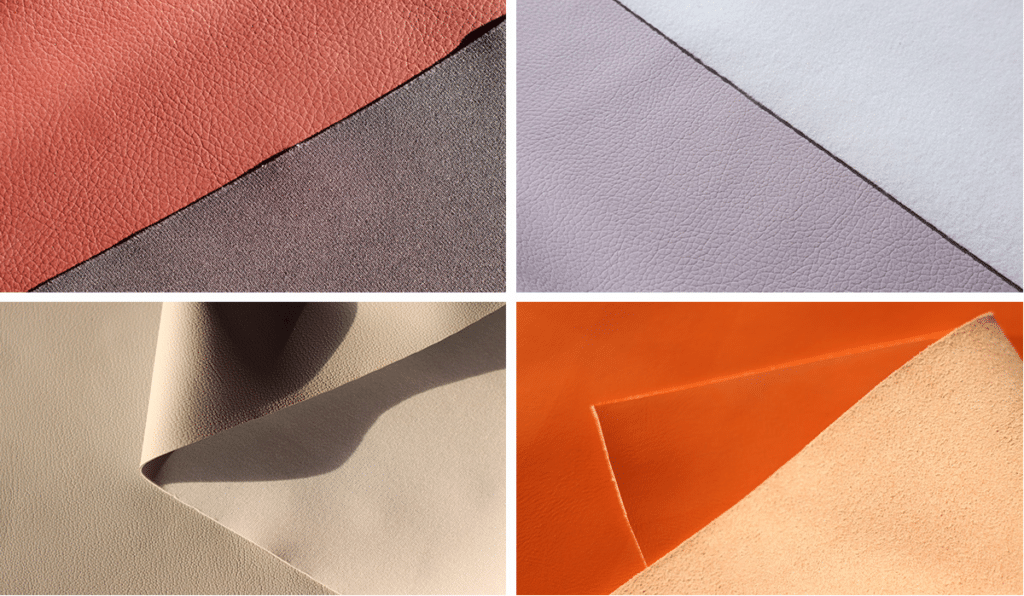

- Color: Our stock color is Blue, Milk, Brown etc, or Pantone customized

- Texture: Lychee/plain/ customized

- Wide: 1.37m(54inch)

- Thickness: 0.7-1.5 MM/Can be customized

Z.S.R Silicone leather series provides high design freedom with a wide variety of tailored options in colors, textures, and fabric. We work with the Industrial and Manufacturing product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of tear strength, hydrolysis resistance and Temperature resistance to empowering their projects success.

We are confident to satisfy your requirements, and we anticipate to unlocking new possibilities with you! Please check our custom service and talk with our expert to get you custom Silicone leather suggestion now.

custom silicone leather

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

Certifications

The Industrial and Manufacturing silicone leather what Z.S.R sells all can passed Reach, ROHS (Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

Contact Z.S.R silicone to purchasing your own needed silicone leather for Industrial and Manufacturing products now.