Aviation

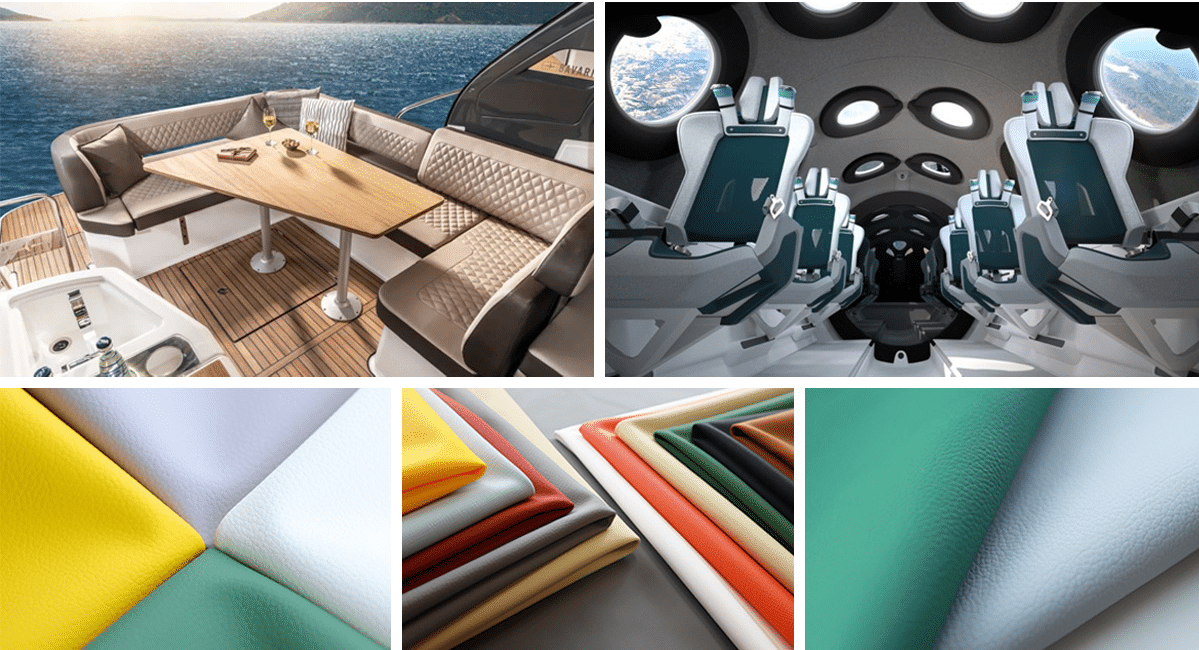

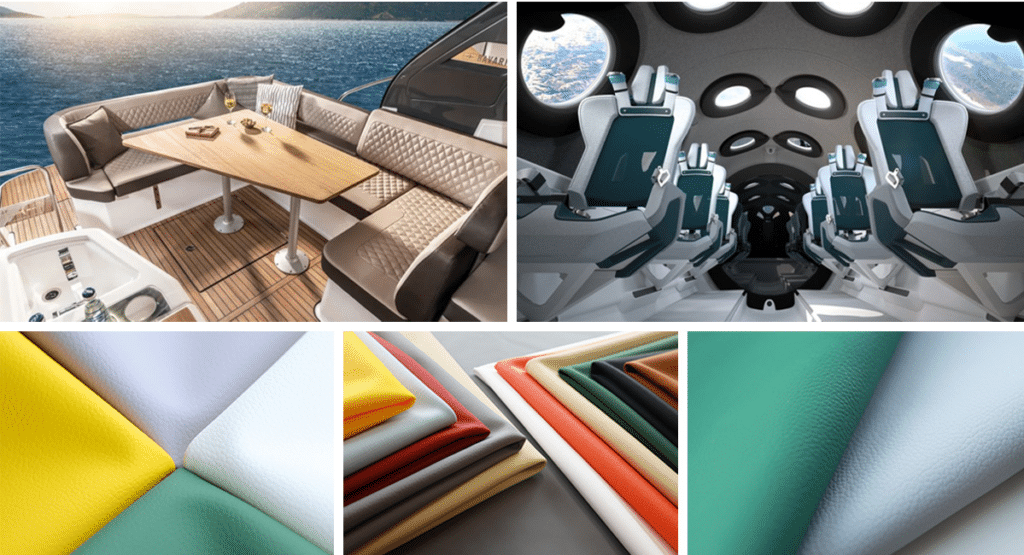

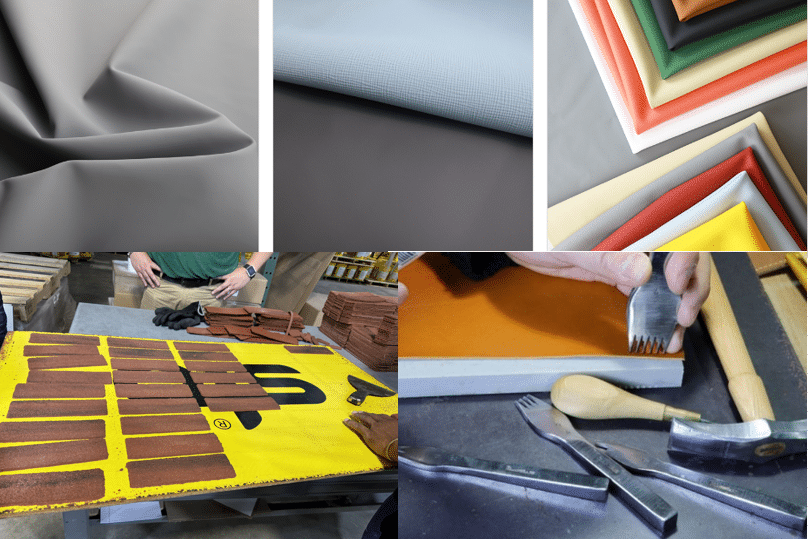

When silicone leather is applied to aircraft seats and aircraft interiors, even if it is accidentally stained with cola, milk tea, snacks, oil, etc., it will not produce stains or penetrate into the interior. The silicone coating has low surface tension, is hydrophobic and non-polar to repel water, and has strong pollution resistance. We work with the Aviation product development manager, product designer, Fabric Selection Designers, product manager together designs and make the custom silicone skin to fit their product’s needs.

Silicone leather has unique physical and chemical properties, which ensures that silicone leather can maintain good physical properties and durability under extreme environmental conditions, as well as environmental friendliness, making it an ideal choice for the aerospace industry:

For Aircraft chairs

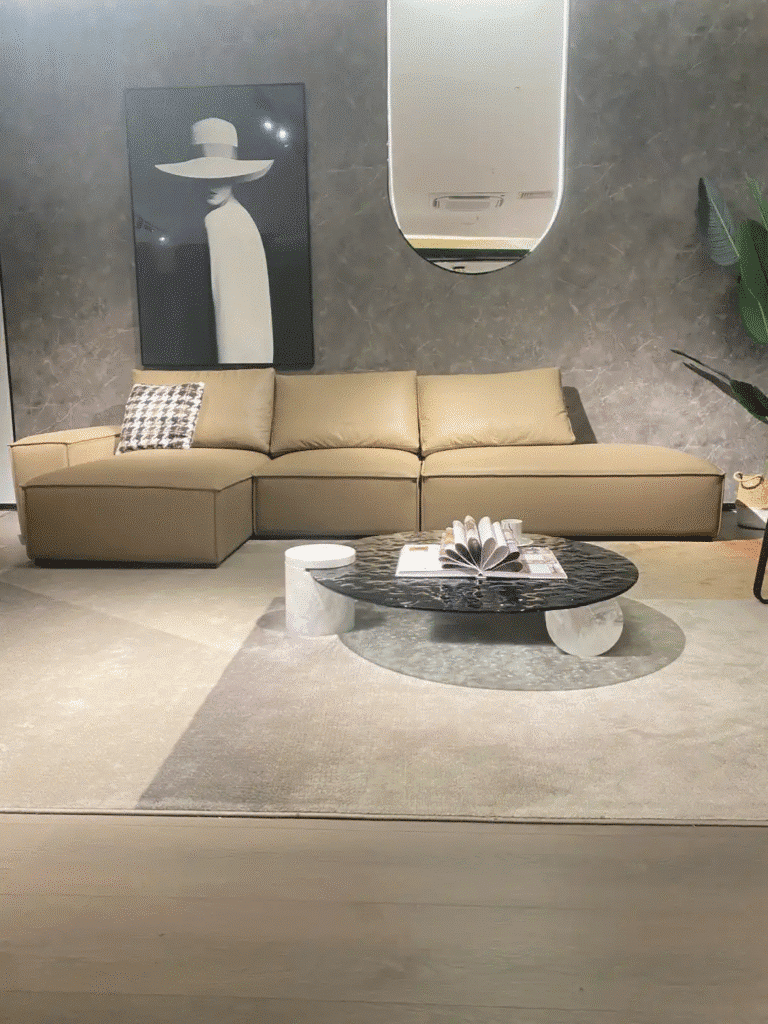

The characteristics of silicone leather make it an ideal material for aircraft seats. It is wear-resistant, waterproof, and not easy to catch fire. It also has anti-ultraviolet and anti-oxidation properties. It can resist some common food stains and wear, making it more durable and making the entire aircraft seat more hygienic and comfortable.

for Cockpit Decoration

The beauty and waterproof properties of silicone leather make it an ideal material for making aircraft cabin decoration elements. Airlines can customize colors and patterns according to personalized needs to make the cabin more beautiful and improve the flight experience.

For Aircraft interiors

Silicone leather is also widely used in aircraft interiors, such as aircraft curtains, sun hats, carpets, interior components, etc. These products will suffer varying degrees of wear and tear due to the harsh cabin environment. The use of silicone leather can improve durability, reduce the number of replacements and repairs, and significantly reduce after-sales costs.

The raw materials of silicone leather determine its durability, and it also has unique advantages in softness and durability. Compared with genuine leather, the material of silicone leather comes from nature and is very environmentally friendly. The use of silicone leather is a major trend in all walks of life in the future.

Silicone Leather Performance Benefits in Aviation

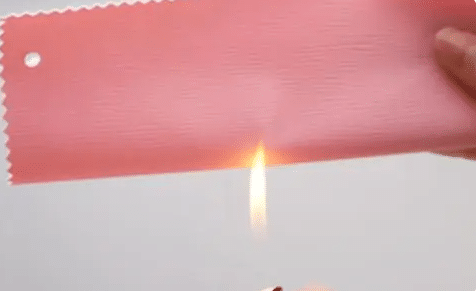

1. Environmental protection: We all know that leather comes from animals and can only be used after chemical treatment. The combustion of PU will produce some harmful and irritating plastic gases, such as hydrogen cyanide, carbon monoxide, ammonia and nitrogen-containing compounds (nitric oxide, nitrogen dioxide, etc.). Silicone leather is made of silicone raw materials for baby pacifiers, and no harmful gases are released during combustion.

2. Flame retardancy: As an indispensable tool in public life, people are particularly concerned about the safety of airplane interiors. Flame retardancy naturally becomes one of the points of concern. Whether it is genuine leather or PU, flame retardants need to be added to achieve flame retardant effects. Silicone leather has natural flame retardant and self-extinguishing properties, which can ensure product safety and environmental protection. On the premise of using its own unique silicon-oxygen chemical bond, oxygen is further isolated to achieve a good flame retardant effect.

3. Sustainability: After using genuine leather, we all know that it cannot be recycled. Although PU can be recycled, it cannot achieve the recycling effect. Silicone is not only recyclable, but also recyclable. This is of great significance to the sustainable development of society.

4. Lightweight: silicone leather is lightweight, Lightweight materials to reduce aircraft weight and improve fuel efficiency.

5. Durability: The wear test of the silicone leather can reach more than 150,000 times, and the Taber wear resistance (CS-10) is more than 3,000 turns. It can maintain excellent surface integrity in high-friction use environments and can effectively deal with common scratches from hard objects such as keys and jeans in life.

The Z.S.R Silicone leather surface is not only resistant to various pollution, but also very easy to clean, acid, alkali, salt, water, sweat and corrosion resistant, but also super soft to the touch, healthy and skin-friendly, non-toxic and harmless, tensile strength, tear strength, hydrolysis resistance, heat resistance (can withstand 240 degrees high temperature without deformation), cold resistance (still soft at -40 degrees low temperature), bending resistance, yellowing resistance, solvent resistance, corrosion resistance, UV resistance, easy to clean, breathable, waterproof, antibacterial, mildew-proof, aging-resistant, high stitching strength, good elasticity, good softness, good feel, etc. The aviation fabrics we designed can withstand harsh environmental factors and have properties such as salt spray resistance, anti-fouling, weather resistance, hydrolysis resistance and UV resistance.

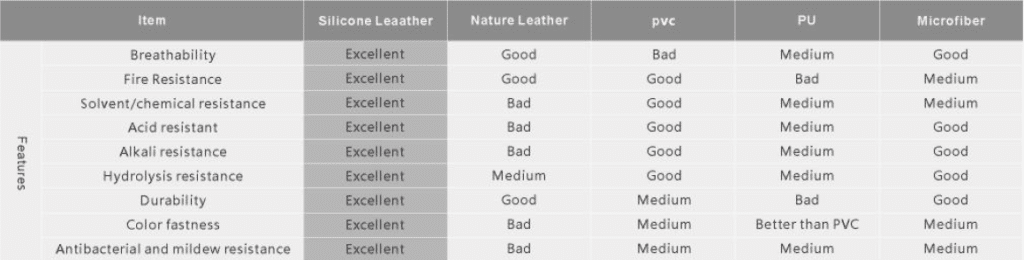

Silicone leather vs traditional leather

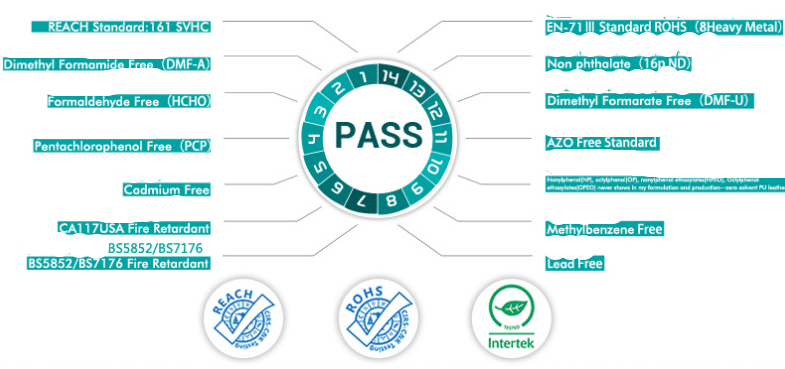

The silicone leather not contain DMF, phthalates, lead. The silicone leather can pass Reach, ROHS (Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

Artificial leathers such as polyurethane rubber (PU) synthetic leather and polyvinyl chloride (PVC) commonly found in the finished leather market are not resistant to aging, high temperature, easy to hydrolyze, easy to stain, and have a short lifespan. They will cause certain pollution to the environment during the manufacturing and use process.

File Download: Silicone leather

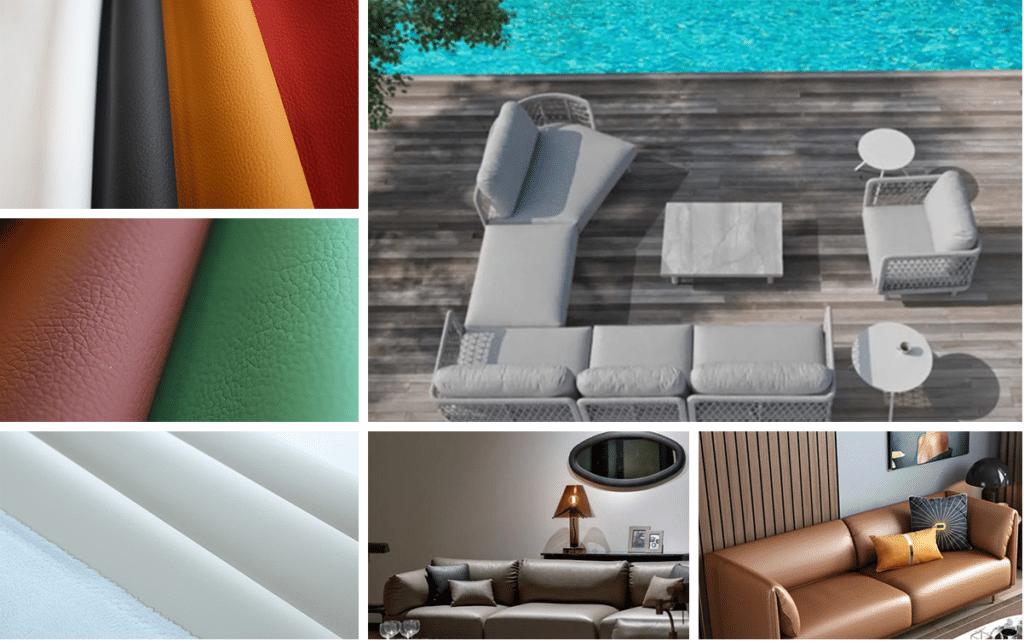

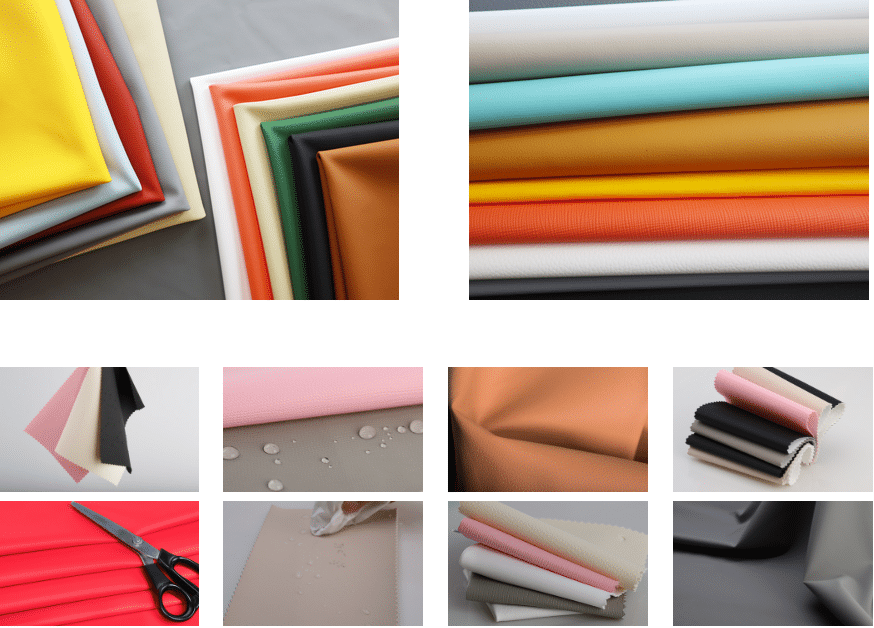

Custom silicone Aviation leather:

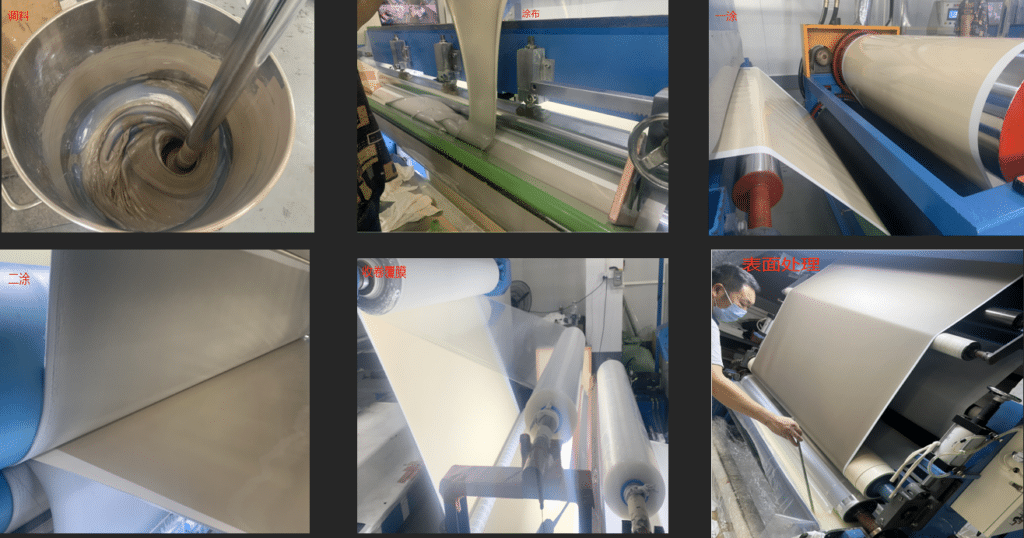

- Surface Layer: 100% Liquid silicone Rubber

- Base Fabric: PK cloth/flannelette cloth can be customized

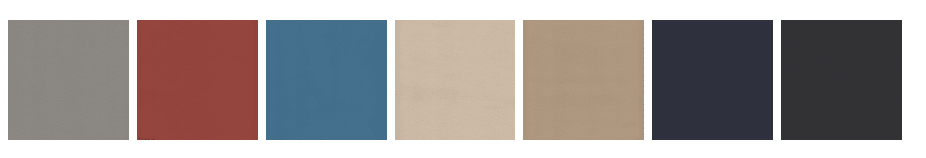

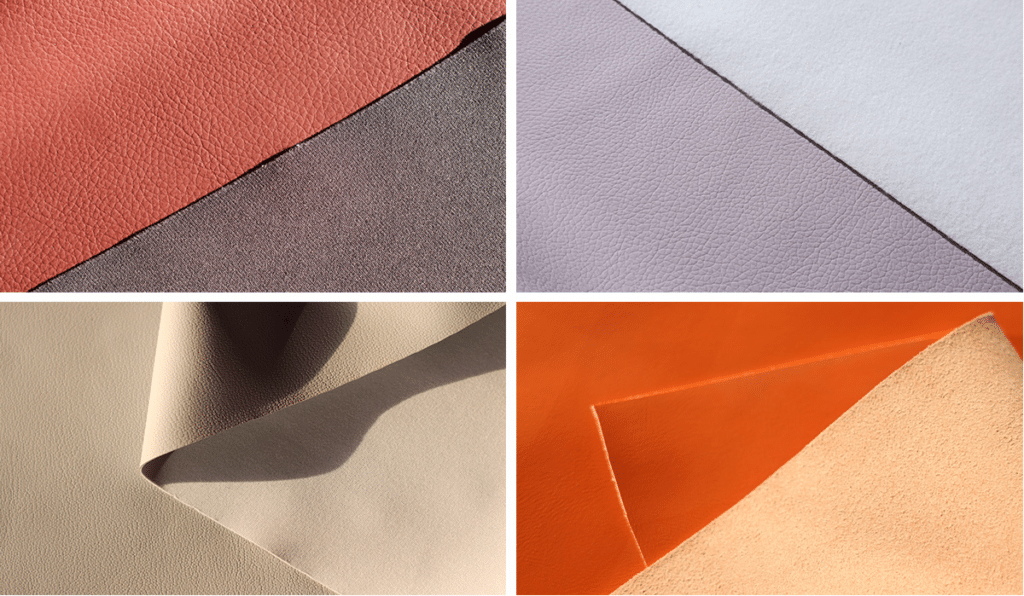

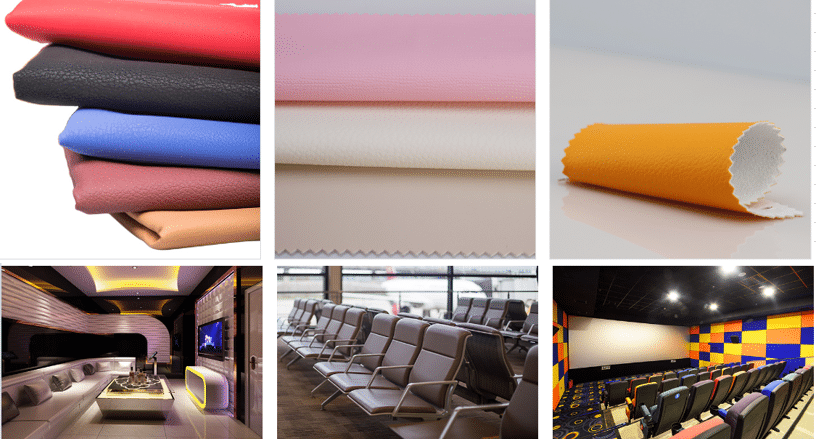

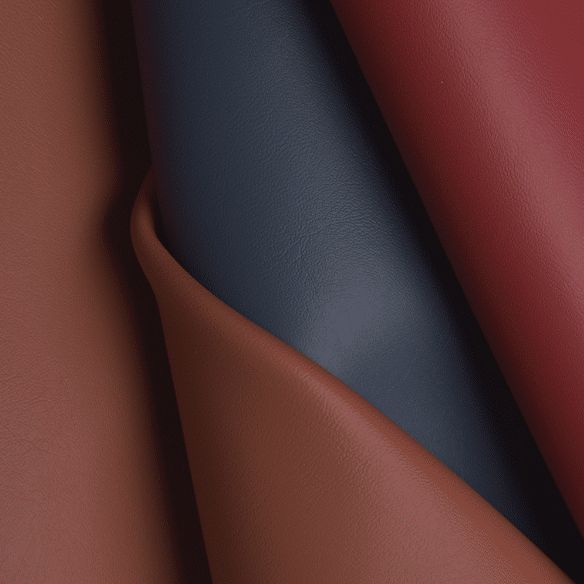

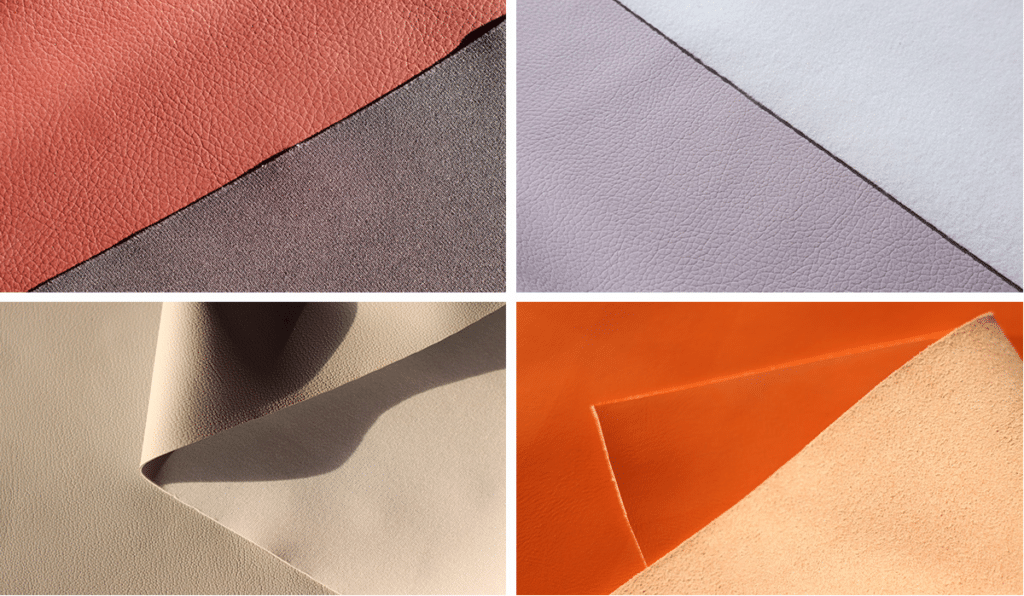

- Color: Our stock color is Blue, Milk, Brown etc, or Pantone customized

- Texture: Lychee/plain/carbon fiber/star/kid skin/customized

- Wide: 1.37m(54inch)

- Thickness: 1-1.6MM /Can be customized

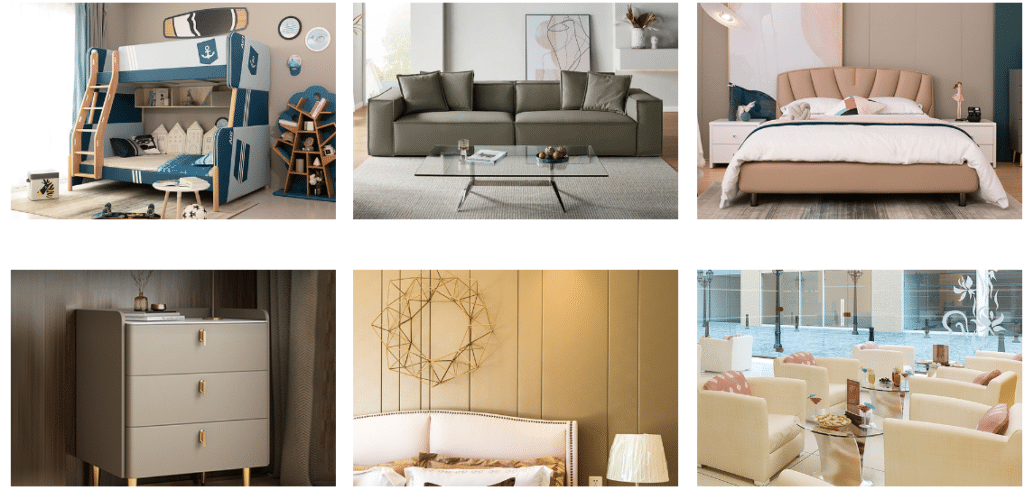

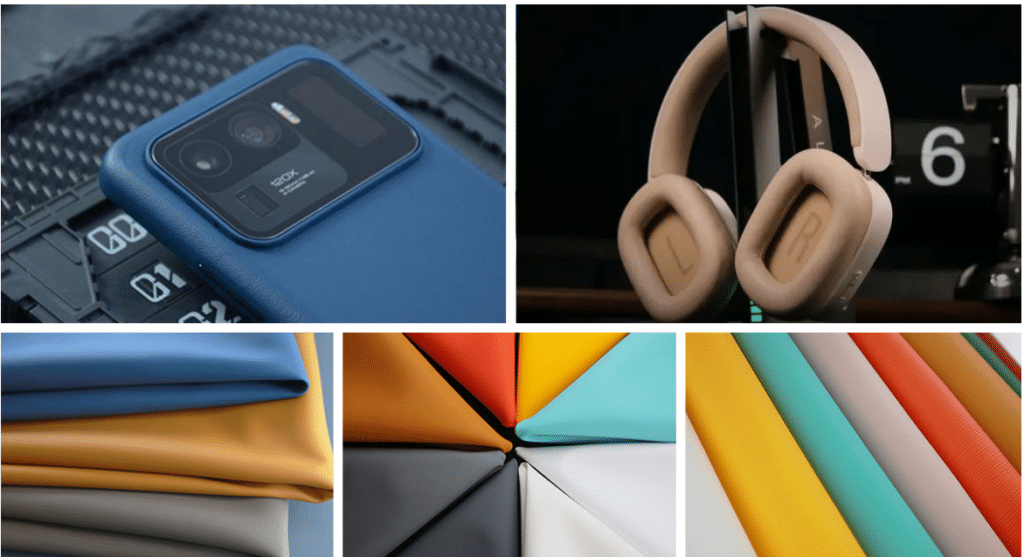

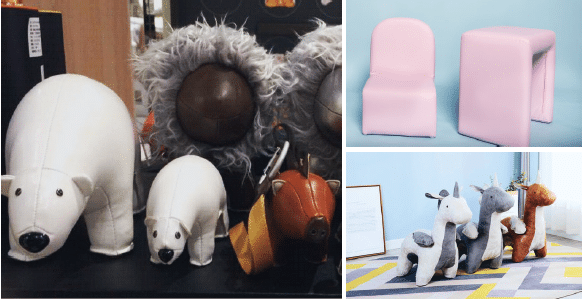

Z.S.R silicone leather series provides high design freedom with a wide variety of tailored options in colors, textures, and fabric. We work with the Aviation product development manager, product designer, product manager together designs and make the custom silicone skin to empowering their Project success.

We are confident to satisfy your requirement, and we anticipate to unlocking new possibilities with you! Please check our custom service and talk with our expert to get you custom silicone leather suggestion now.

custom silicone leather

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

Certifications:

The silicone leather Z.S.R sells can pass Reach, ROHS (Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, and DMFU&DFMA Free.

Contact Z.S.R silicone to purchasing your own needed silicone leather for Aviation now.