Custom Silicone Products

As a leading custom silicone products manufacturer and custom silicone molding solution provider in China with more than 16 years experience.Z.S.R Group Is A Silicone Products OEM Manufacturing Brand Behind The Brands.

Z.S.R Group offer one stop custom silicone products solution for your business . Z.S.R Group work with the different industry brands owner,product development managers, product designers, product managers together offer them custom molded silicone products.

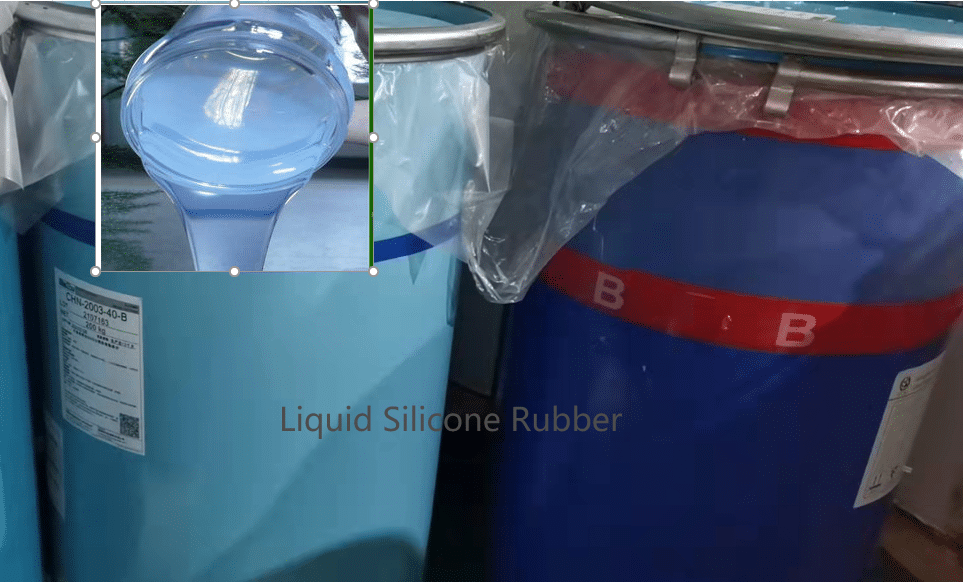

Z.S.R is a custom silicone rubber products fabrication factory. Our Core Silicone molding Service includes silicone rubber compression molding, liquid silicone rubber(LSR) molding. Precision CO-injection Dripping Molding.,Silicone fabric Coating and curing to support silicone products high-precision molding, material certification, and full customization.

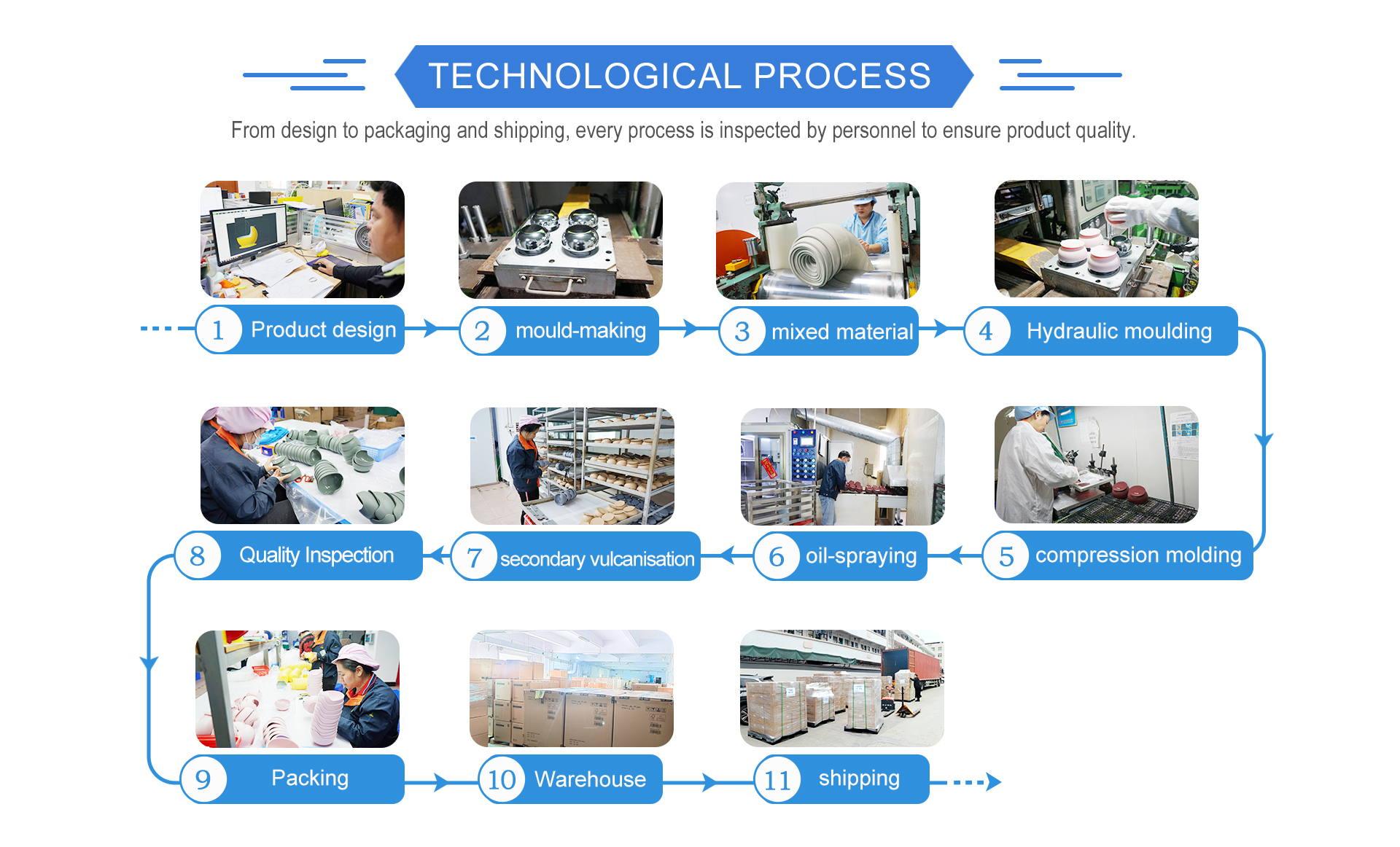

Custom Silicone Products Making Process

Z.S.R ‘s Strong engineering Design team; precision mold manufacturing workshops; the Post-forming department; the QC department, and the department of packaging. With 6 sets of advanced CNC machining centers and 4 sets of EDM spark machines for tooling; 32 sets of compression molding machines,6 sets of liquid silicone rubber molding machines, 8 sets of co-injection silicone molding machines for producing, over 10 Printing & Spray line, also owned a large Dust-free Packing workshop.

This creates a one-stop silicone solution to meet your scalability requirements for personalized silicone goods. We welcome any custom silicone products, Silicone novelties you need development or silicone technical inquiries from you.

Contact Z.S.R custom your own branded silicone products.

The silicone Products compression molding

Customized service

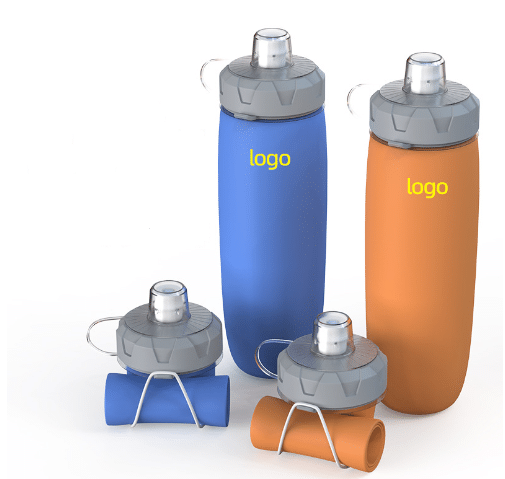

Z.S.R provide the OEM solutions from Silicone products design, prototyping to molded silicone products contract manufacturing, printing, packaging. Z.S.R ‘s Custom Silicone products service with the Custom Silicone products material, structure, design, function,shape, sizes, color, logo, pattern, package, label to ensure their silicones project success.

Contact Z.S.R to create your own business line of silicone products.

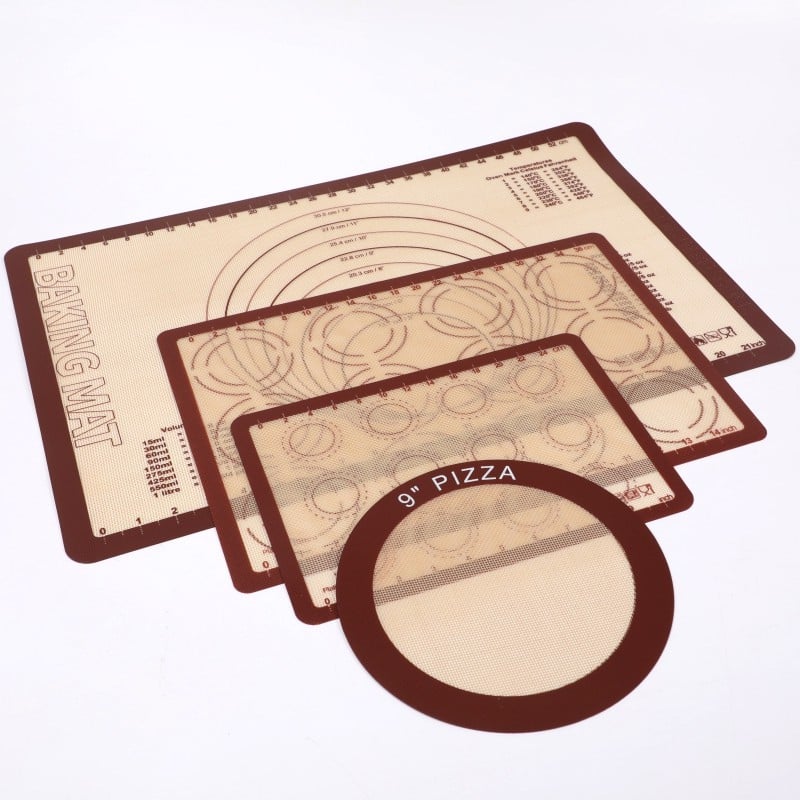

Customized silicone products

We already customized more than 10.500 silicone products projects for our partner in the past years with much experience in silicone products technical. The custom silicone products include:

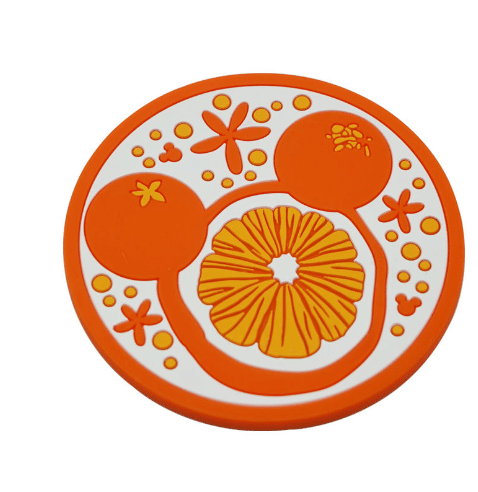

Z.S.R already customized more than 10.500 silicone products projects for our partner in these years with much experience in silicone products technical. The custom silicone products are widely used in: Silicone baby products, Silicone Beauty&Health-care products, Silicone Kitchen products, Silicone industrial Parts,Silicone Pets products, Silicone Consumer Electronic Protective Cover, Silicone Housewares Products, Silicone Promotional gifts and IP goods,silicone sport and health products etc.

We can not show all the products with details because of the NDA we signed with our clients. We are the Consumer Silicone Products OEM Manufacturing Brand Behind The Brands.

The feature of the Z.S.R Silicone products

- Chemical stability: Silicone has good chemical stability, can withstand the erosion of various chemical substances, and is not easy to age.

- Temperature resistance: Operates safely from -40°C to +230°C.Silicone products can remain stable in high temperature environments and are suitable for occasions that require high temperature resistance.

- Non-toxic and harmless: Silicone is non-toxic, odorless, insoluble in water and any solvents, harmless to the human body, and suitable for food, medical and other fields.Food & Medical Grade Options:Certified safe for skin contact, baby products, kitchenware, and medical use (FDA, LFGB, ISO10993, etc.)

- Durability & Tear Strength: Long-lasting under mechanical wear, UV, and ozone.High Flexibility & Elasticity,Returns to shape easily, even under stress.

- Custom Moldability: Easily molded into complex shapes with precise tolerances.

How To Order your Silicone products

Z.S.R Group: As a silicone molding company that can help you with any needed Silicone products, we help you with quality molded Silicone Rubber products, as per your project requirement.

We help you in the entire process of molded Silicone Rubber parts designing, tool designing, mold manufacturing, molded Silicone Rubber products production and delivering as your requirement.

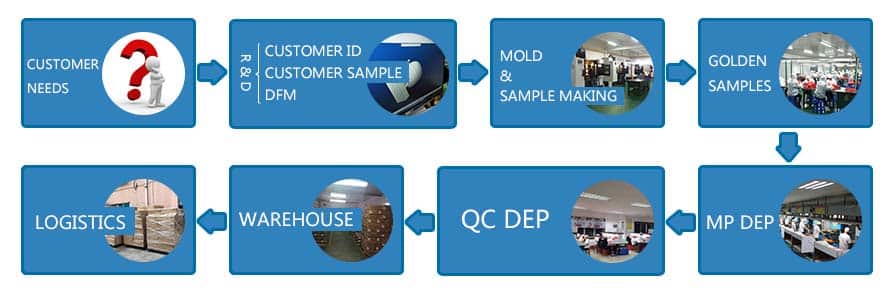

Here’s what the path to customized molded Silicone Rubber products for our customers:

Step 1: Custom Needs And Budget

The needs and budget that your company has allocated for an order determines what type of molded Silicone Rubber products you can purchase and what personalization each one will receive. When that budget is finalized, this is the time to contact Z.S.R Group. We can help navigate you in the right direction to make a perfect molded Silicone Rubber products.

Step 2: Customer Idea, Design, Sample

Just provide us a CAD file with proper specifications of your molded Silicone Rubber products project and we would take care of the rest. If you don’t have a CAD file, we can make the design from a hand-sketch or drawing, picture, samples and can make the molded Silicone Rubber products prototype mold based on that.

Step 3: Prototype Tooling To Get The molded Silicone Rubber products Samples

If you are developing a new molded Silicone Rubber products and not sure about the outcome, we can always develop a prototype so that you can check the fitment, functionality, and aesthetics before investing in the mass production tooling. Once you are satisfied with the prototype, you can proceed for the Silicone Rubber products mold development. This covers your risk and helps you test your market with low investment. Moreover, it is always easier to do design changes at prototype stage than doing the changes after the mass production tooling is done.

Step 4: Mass Production Tooling

After you are satisfied with the molded Silicone Rubber products samples. We will make the molded Silicone Rubber products mass production tooling according to the communication of the samples in our in-house tooling workshop.

Step 5: Silicone Molds And Mass Production

If you want to test the market first, you can start with a small order with Low ‘Minimum Order Quantity (MOQ)’ 3000 pcs and later can proceed for as much quantity production as you want. We also make Cheap Silicone Rubber products Molds (AL Material) as per your project requirement.

Once you confirm the molded Silicone Rubber products what we made for you, the next step is for our customers to approve the golden samples or send over any changes that may be needed. Once the molded Silicone Rubber products samples is approved, we start processing your molded Silicone Rubber products and producing the merchandise.

All of the molded Silicone Rubber products what we made were Trimming and QC in our dust-free workshop. We do 100% QC before the molded Silicone Rubber products are in the carton. To make sure all the molded Silicone Rubber products that we deliver to the clients are high-quality products and meet your requirements. we promise you well-organized operation and timely delivery of your custom-made silicone parts as per your specification

Step 6: Storage And Delivery

We have an independent Warehouse for the storage of the product before the shipment if you needed.

And the last stage is the most exciting — delivery! Delivery day is always an exciting time for us because we live to serve our customers. Once our production processes finish, we can arrange for molded Silicone Rubber products pickup, ship, or delivery, depending on your location and preference.

Z.S.R Group Makes Custom molded Silicone Rubber products.

Custom Silicone Products Making Process

The Whole Process to create Your silicone products

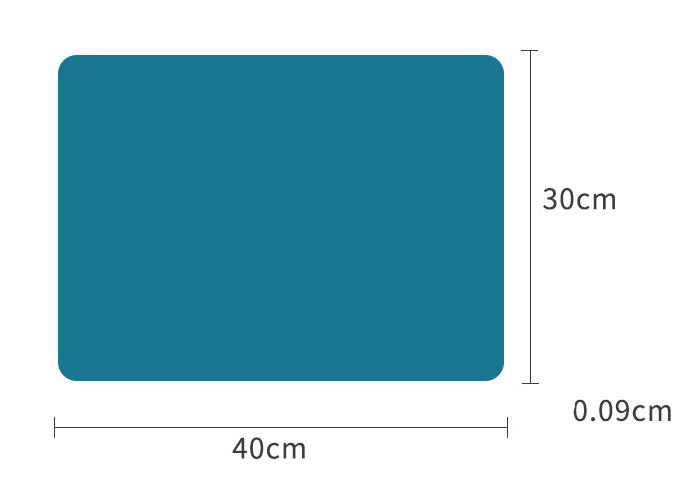

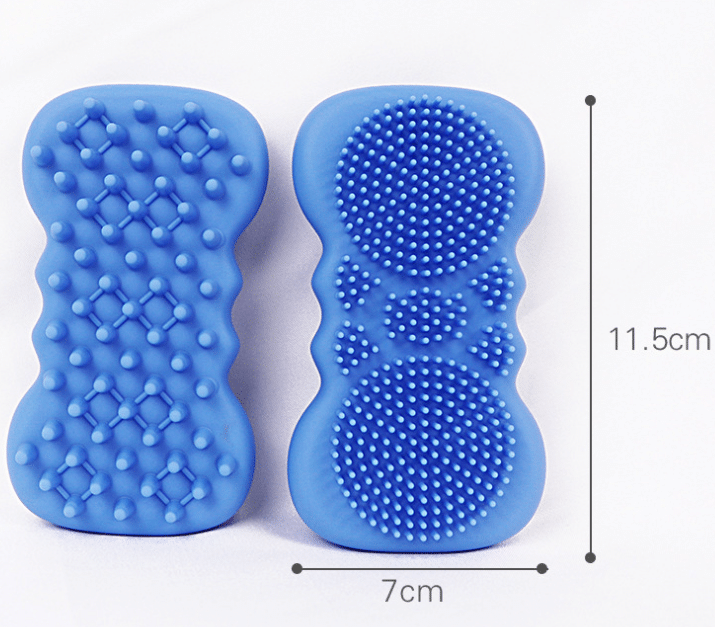

The process of customizing silicone products involves several steps to create personalized and branded silicone baking sleeves or other silicone products products. Here’s a general overview of the customization process:

Design Concept:

Define your design concept, Design 3D structure of the silicone products according to your idea: including the products desired size, shape, color, and any specific features or patterns you want on the silicone products.

Material Selection:

Choose the LSR or solid silicone as base material, ensuring it complies with safety and quality standards.

Prototype Development:

Create a prototype or sample of the customized silicone products. This step allows you to evaluate the design and functionality before mass production.

Custom Printing or Branding:

If you want your silicone products to feature logos, artwork, or branding, the customization process may include CNC on your tooling, screen printing, heat transfer printing, In mold decoration or other methods to apply your pattern to the sleeves.

Tooling and Molding:

Develop products or tools based on the approved prototype. The products will be used in the manufacturing process to create multiple silicone products with consistent shapes and sizes.

Material Mixing and Preparation:

Prepare the silicone material by mixing it according to the manufacturer’s specifications. This involves combining silicone with any required additives and pigments to achieve the desired color.

Molding and Shaping:

Inject or put the prepared silicone material into the products. Depending on the design, this may involve Liquid Silicone Rubber (LSR) molding, co-injection dripping molding or silicone compression molding.

Curing and Cooling:

Allow the silicone products to cure and cool inside the products. The curing time can vary depending on the type of silicone used and the product’s thickness.

Demolding:

Remove the cured silicone products from the products, ensuring they maintain their intended shape.

First Quality Control:

Inspect the silicone products for any defects, such as air bubbles, irregularities, or inconsistencies in color or shape. Any flawed sleeves are typically discarded.

Post-processing:

Carry out the silicone baby sleeves and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

Secondary vulcanization:

Secondary vulcanization is a process that must be handled for any product that has passed the inspection. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone products may do not need this process

LOGO or Pattern printing if needed:

Laser engraving or printing the design on. sometime, you put the silicone products logo on the silicone tooling directly.

Cleaning and Packaging:

Clean the silicone products to remove any residues or impurities. Then, package them according to your specifications, which may include sets of sleeves in specific quantities or individual packaging.

Final Quality control and testing:

After all the silicone baby sleeves making process finished, arrange the final QC for the products before the delivery.

Warehouse and Shipping:

Finished OQC personalized and branded Silicone products products in the warehouse and ready to ensure reach your destination safely

- DHL/UPS/FedEx/ with a typical transit time of 3-8 days.

- By air shipping, 10-15 days.

- By sea shipping,30-50 days

Please go through “How to create silicone products?” to know more details.

Why Choose Z.S.R as Silicone products Supplier

16 years’ custom silicone products experience

Rich market experience and engineer makes us familiar with the products and market requirements of different wholesale customers

Safety Factory

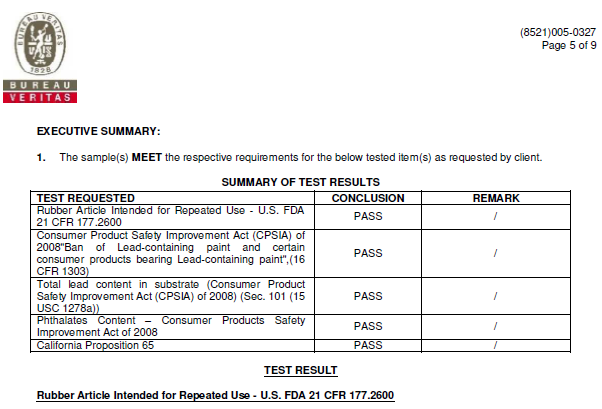

Z.S.R is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney. The third parties and the world’s Fortune 500 companies have helped you verify the factory strength and reliable for you.

100% safe raw material

Food-grade high-quality silicone materials, 100% high-purity food-grade platinum silicone which are safe and environmentally friendly, non-toxic and harmless. All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, Phthalate report etc if needed.

One Stop Service from design to whole process manufacturing

Z.S.R have the own mold workshop and mold design engineer, Complete post-processing workshop. All the silicone products cycle under one roof- from designing products & building tooling to launching into full-blown production. You will reduce the risks of working with multiple vendors, save your time to market & lower costs.

Stable production capacity

32 sets of silicone compression molding machines, 6 sets of liquid silicone rubber molding machines, 8 sets of co-injection silicone molding machines with Manufacturing 100,000-150,000 pcs daily and export to 40+ countries. Deliver your orders on time, ensuring customers do not face the risk of out of stock.

Wholesale OEM/ODM Services

Z.S.R complete OEM/ODM Services provides a variety of wholesale customization services to suit customers’ different designs and product needs. Customized service for design, color, packaging.

Strict Quality Control

Whole-process quality control system from Silicone products developments to finished products ensures that our customers can receive the qualified Silicone products as the prototype they approved before mass production.

Safety products

The silicone products what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV

Frequently Asked Questions

Still Have Questions?

If you cannot find an answer to your question in our FAQ, you can always contact us, and we will be with you shortly.