How To Print On Silicone Products?

Printed logos or pattern on silicone rubber products is a fantastic way to enhance brand visibility and create customized silicone items without developing new silicone tooling.

Whether you want to personalize promotional merchandise, create unique corporate gifts, or brand your silicone products, understanding the printing process is essential.

In this blog, we’ll provide a comprehensive guide on how to print logos or patterns on silicone rubber products, covering various techniques, including

- Laser Engraving,

- Silkscreen Printing,

- Pad Printing,

- Water Transfer Printing,

- Heat Transfer Printing,

- In-Mold Decoration,

- Digital Color Printing.

With this article, you’ll have a clear understanding of the requirements and considerations for successfully printing logos or patterns on silicone rubber products.

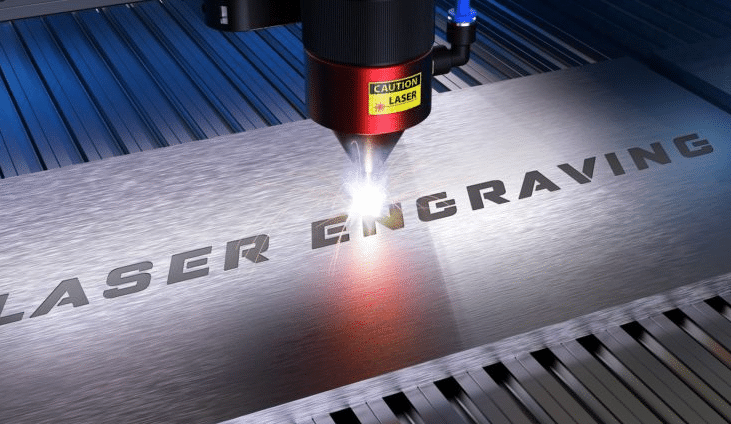

1. Laser Engraving:

Let’s begin with the Laser Engraving pattern or logo or text on the silicone products:

Laser engraving is the process of selectively removing microscopic layers of material, thus creating visible marks on the treated surface. Depending on the materials, the laser-material interactions can be different.

On harder surfaces, the mechanism of action is primarily ablation where the focused beam of laser dislodges microscopic particles from the substrate. Engraving can achieve a depth of 100μm and beyond, whereas laser marking is typically shallower.

The process is suitable for marking logos, barcodes, serial numbers, and QR codes on silicone products. Alongside laser etching, annealing, ablation, and other laser marking technologies, the process forms a set of highly reliable processes in traceability, identification, and product decoration.

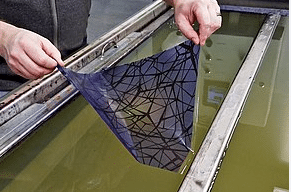

2. Silkscreen Printing:

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a silicone product, except in areas made impermeable to the ink by a blocking stencil. When the screening has been completed, an operator will then pour ink onto the screen, pushing it through the stencil. The ink will only ever go where the stencil is open.

This helps to create a printed design for a logo, pattern, or text. A stencil is used on the screen to develop the graphic, with a mesh being stretched over a wooden or metal frame. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact.

This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One color is printed at a time, so several screens can be used to produce a multi-colored image or design.

3. Pad Printing

Pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a silicon pad takes a 2-D image from a laser engraved (etched) printing plate (also called cliché) and transfers it to 3-D products.

It is printed by machine with a metal plate. The plate is flat, with the image chemically imprinted. The silicone pad is pressed onto the ink, picking up the image. Then the silicone pad is pressed onto the substrate, transferring the image to the silicone product.

The advantage of pad printing is that the printing speed is fast, and you can print several colors at the same time. Pad printing can be used on a variety of substrates, particularly oddly shaped objects that are difficult to screen print. They can print all kinds of difficult-shaped products such as curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc. which were not available with traditional printing processes.

4. Water Transfer Printing

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, water marbling, cubic printing, Hydrographics, or HydroGraphics. It is a decorative coating technology that allows you to apply detailed patterns and artwork onto 3-dimensional objects. It allows a manufacturer or brand to make silicone parts or silicone products with virtually unlimited appearance options.

It allows you to apply an elaborate graphic such as carbon fiber, wood grain, and even camouflage onto a product. The great thing about this is that it can be applied to a 3D product surface. The water transfer printing process is extensive, and it can be used to decorate items that range from vehicles to silicone items.

To begin with, we will place a water-soluble film onto the surface of the water. We will then immerse the product into the liquid bath, with the pressure created being used to wrap the item.

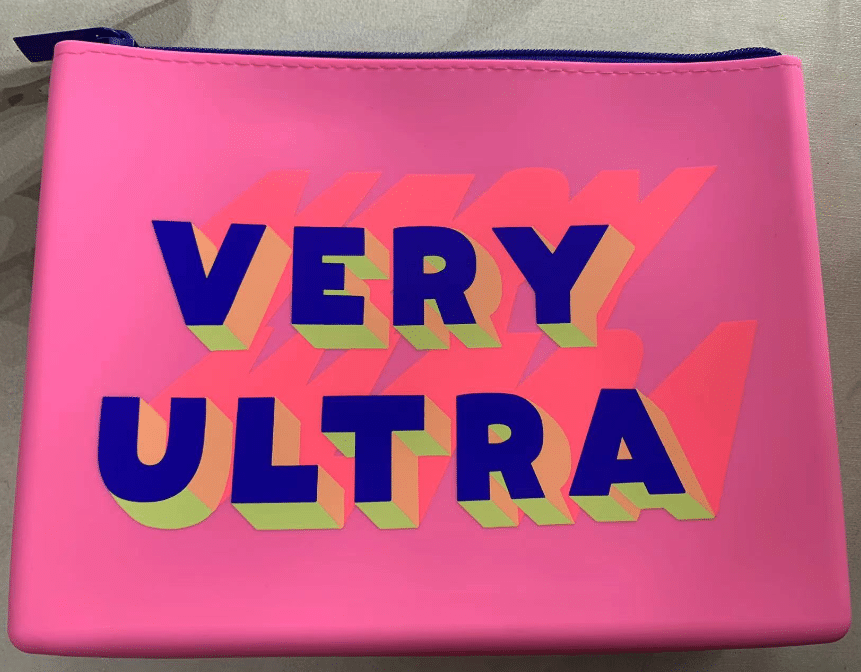

5. Heat Transfer Printing

Heat transfer printing is a popular printing method used to create designs for the decoration, pattern, logo, and text on silicone products. Heat transfer, also known as thermal printing, thermal-transfer printing, and thermal-wax transfer, is a method of printing that allows you to print a design onto an object. Heat transfer printing uses the process of heat to transfer an image created in wax to an object or garment.

This printing method is compatible with pre-painted images on a wax sheet or can be used to create an image by layering wax dye onto an object. This printing method involves using heat and pressure to transfer a design onto the silicone surface, resulting in a permanent bond between the design and the material.

6. In-Mold Decoration

In-mold decorating (IMD) is a process of labeling or decorating molded Silicone products or components during the molding cycle. The label, logo, or pattern becomes an integral part of the final product, creating a fully decorated item at the molding press.

In this process, a pre-printed label or decorated film is inserted in the open silicone compression or injection mold and held in place via vacuum ports, electrostatic charge, or another method. When the mold is closed, the Silicone resin is injected into the mold, encapsulating the label permanently within the finished products.

In-mold decoration technology gives you the freedom to design elaborate, colorful graphics and integrate them with your product. Through years of research and development, we have perfected a method that is effective, reliable, and economical.

7. Digital Color Printing

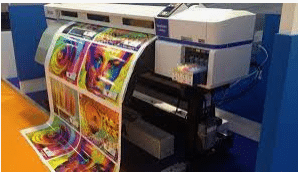

Digital printing is a method of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

Print on silicone products then you may want to print photos, pictures, logos, or even text. The requirements for silicone printing are high and for this reason, quality equipment is key. After printing, the product has to be robust in use, and it also needs to be resistant to scratches and abrasions. Chemical resistance to detergents may also be a desirable feature.

Digital printing is the process of printing digital-based images directly onto a variety of media substrates such as silicone. There is no need for a printing plate, unlike with offset printing. Digital files such as PDFs or desktop publishing files can be sent directly to the digital printing press to print on paper, photo paper, canvas, fabric, synthetics, card stock, and other substrates. it is possible to print on silicone items individually.

Conclusion

Print logos, patterns, and text on silicone rubber products allow you to create customized silicone items that reflect your brand identity and enhance brand recognition. When you choose the printing way to put your design understanding the printing process and considerations is crucial for a successful logo application. Evaluate your logo design, product requirements, and budget to determine the most suitable printing technique. By investing in quality logo printing, you can elevate your brand and create impactful silicone rubber products that stand out in the market.

Related Blog

So If you need :

Custom silicone products with Company Logos, patterns, and text for Your Business (branding), Elevate Your Business with Custom Company Logo or pattern silicone products as Promotional Gifts. Discover our wide range of customizable options and elevate your brand presence with high-quality silicone rubber merchandise. Connect with ZSR Today to Enhance Your Brand’s Visibility with Custom silicone products by printing your brand on them.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.