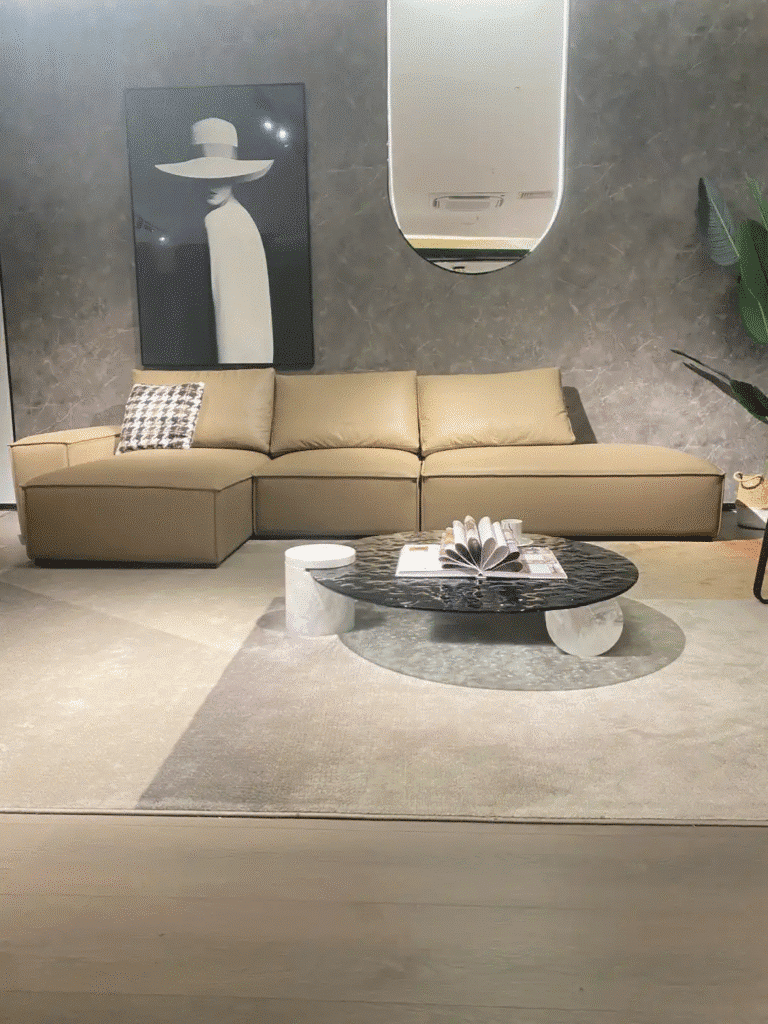

Silicone Leather for Office Chair

Z.S.R Office Chairs leather is made of high-quality silicone vegan leather, using base layer back-coated, microfiber, PK cloth + silicone coating process to ensure its excellent Safety, Environmental protection, hydrolysis and light resistance, Waterproof and anti-fouling, wear-resistant and other properties, and is not easy to produce scratches and wrinkles. Compared with traditional artificial leather, Office Chairs silicone leather is closer to the touch of genuine leather, does not contain plasticizers, DMF, etc., and complies with EU REACH, Rohs and other standards.

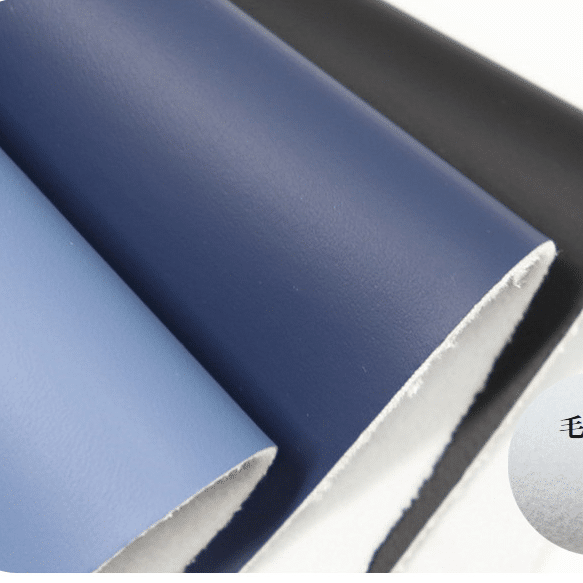

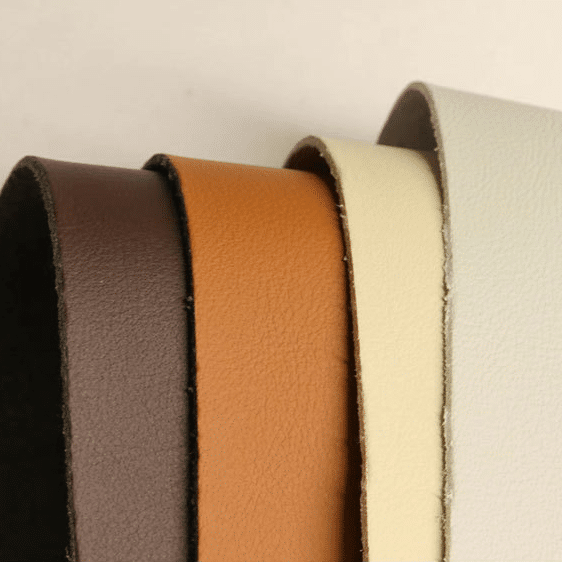

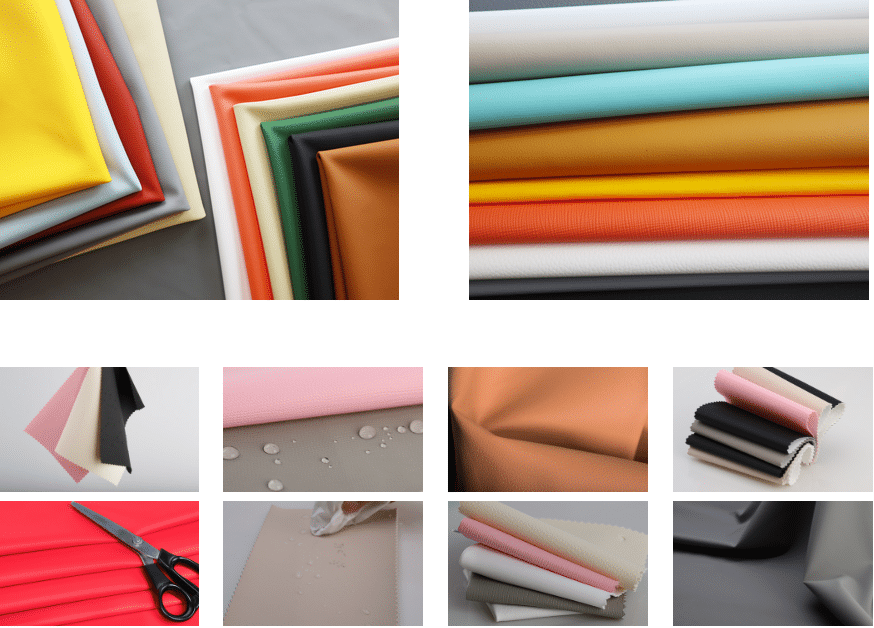

Z.S.R team work with the product development manager in the Office Chairs seating manufacturers and provide them Office Chairs silicone leather of different thicknesses and colors, and can cut it as required. Most Dining chair manufacturers choose silicone leather colors as Black, white and brown. Black office chairs are classic and stable, suitable for formal office environments. White office chairs are simple and bright, which can enhance the sense of openness of the workspace. Brown office chairs give people a warm and natural feeling, suitable for offices that need to create a warm atmosphere.

Please choose the needed silicone leather color according to your projects. It is recommended to use 0.9-2.0MM thickness silicone leather with Lychee /cross/ant/crocodile/bamboo pattern, the specific parameters are as follows:

|

Material |

Back-Coated, Microfiber, Pk Cloth + Silicone |

|

Width |

1.37-1.40 M, 54” |

|

Thickness |

0.9-2.0mm |

|

Texture |

Lychee/cross/ant/crocodile/bamboo pattern |

|

Color |

Black, white and brown or customization color as the customer requests |

|

Application |

Office Chairs |

|

MOQ |

300 m |

About this Product

Office Chair Silicone Leather specification

|

PROPERTIES |

VALUES |

|---|---|

|

Material |

100% Silicone + back-coated, microfiber, PK cloth |

|

Backing fabric technics |

nonwoven fabric |

|

Texture |

Lychee /cross / ant /crocodile/bamboo pattern or customization |

|

Width |

54/55” 1.37-1.40 M |

|

Thickness |

0.4MM-2.2MM |

|

Weight |

400-1300 gsm |

|

Color |

Black, white and brown or customization colors |

|

Finish |

Available in matte, glossy, and textured finishes |

|

Tensile Strength |

Warp >400 N/200mm, Weft>400 N/200mm (ISO 3376) |

|

Elongation at Break |

Warp >15% , Weft > 20% (ISO 3376)) |

|

Tear Strength |

>18-25 N (ISO 3377-2) |

|

Peeling Strength |

>30 N/30mm (ISO11644) |

|

Anti-mildew |

Excellent (ASTM G21) or can added as the client’s request |

|

Abrasion Resistance |

> 50,000 (Martindale Wear ISO 12947) |

|

Color Fastness to Rubbing |

Dry Rubs 5000 cycles, Wet Rubs 500 cycles, Ethanol ≥ (10 times) Neutral soap solution ≥ (100 times) Grade 4/5 (AATCC-8) |

|

Odor |

No Odor |

|

Color Migration |

Temperature 50±2℃, press with 5KG weight for 18 hours no color migration |

|

Heat aging resistance |

1. (80±2)℃, relative humidity <10%, |

|

High temperature resistance |

Oven 120℃, 168H No obvious cracks on the surface |

|

Cold temperature resistance |

-30℃, 24 hours, no obvious cracks on the surface |

|

Light fastness |

≥ 4 (ISO 105 B02) |

|

Anti-adhesion |

The sample coating is bonded to the coating, placed in a constant temperature of 80 (±2)℃ and pressed with a load of 10N, kept at the constant temperature for 3 hours, taken out, and the bonded sample can be peeled off by hand |

|

Bursting strength |

Müller Bursting Strength Tester ≥ 1MPA |

|

Hydrolysis Resistance |

70℃95%RH*10W, 15,000 cycles, no cracking, no color change (ASTM-D3690) |

|

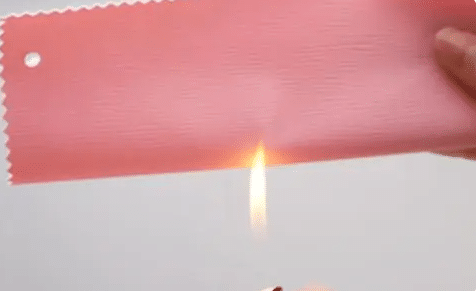

Flame Resistance |

≤100 mm/min (FMVSS302, CA117) |

|

Anti-yellow |

Grade 4, QUV*200hours (HG/T3689) |

|

Bending Resistance |

Normal temperature, 100,000 cycles, no cracking,-10℃,70,000 cycles, no cracking |

|

Anti-Stain |

Italian dressing/Lipstick/Mustard/Suntan Oil/ Instant coffee/ketchup/ blue or black ballpoint pen /cola/soy sauce/chocolate milk/saturated sodium chloride solution ≥ level 4 |

|

Waterproof |

Excellent |

|

Chemical Resistance |

High resistance to chemicals, stains, and UV exposure Eco-Friendly Aspects Non-toxic, PVC-free, phthalate-free, recyclable |

|

Feature |

Durability, waterproof, antifouling, easy cleaning, environmental friendliness, and good touch and visual effects |

|

Application |

Office Chairs leather, Office Chairs cover |

|

Usage |

Office Chairs Manufacturing |

|

Storage Conditions |

Store in a cool, dry place away from direct sunlight |

|

Cleaning Instructions |

Easily cleaned with mild soap and water; stain-resistant |

|

Certifications |

REACH, RoHS, and OEKO-TEX Standard 100 compliant |

|

Customization Options |

Texture, color, and backing fabric customization available |

|

Place of Origin |

China |

|

MOQ |

300 Meters |

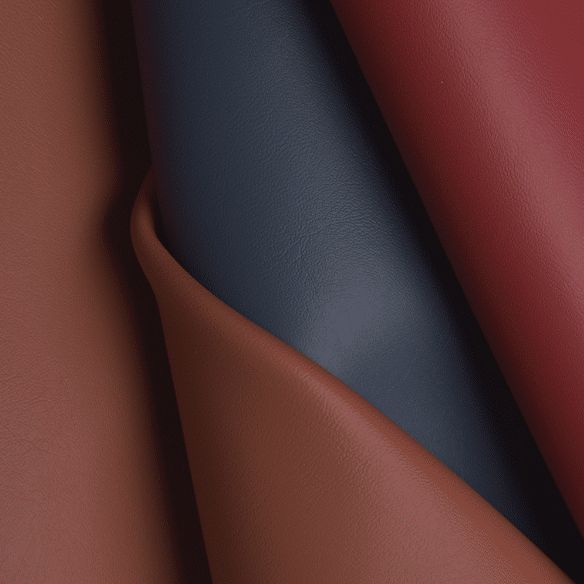

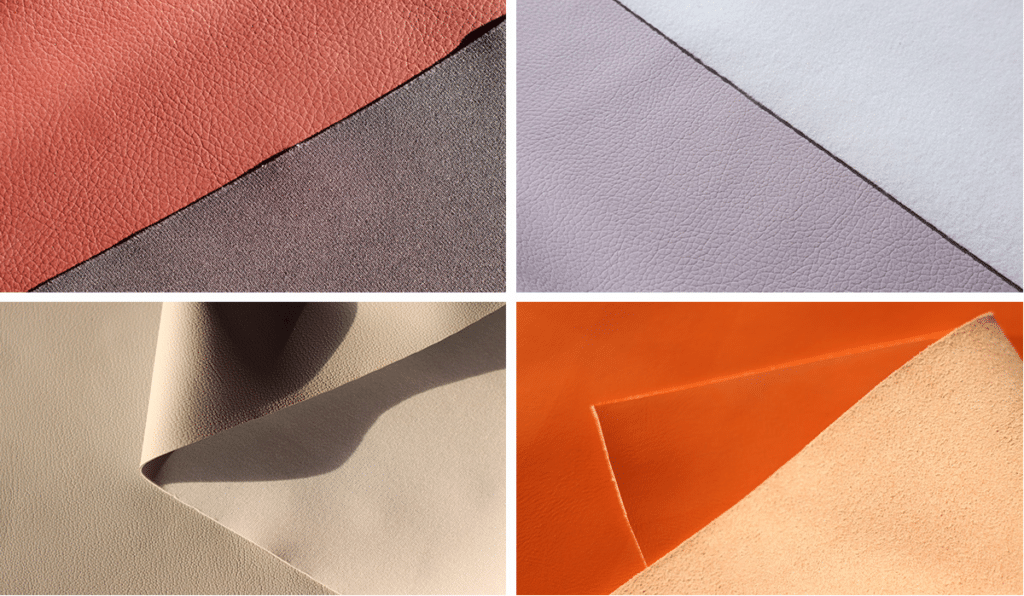

Common Office Chair Silicone Leather color

Our existing color silicone leather is white, green, orange, grey and milk white ect. You can choice our existing color silicone leather directly and contact our expert to get the free samples.

Our existing fabric base and texture silicone leather is Microfiber cloth/imitation lint cloth/flannelette cloth base and Lychee/plain/carbon fiber/crocodile/star/kid skin.

Related information download

Benefits of Silicone Leather for Office Chair

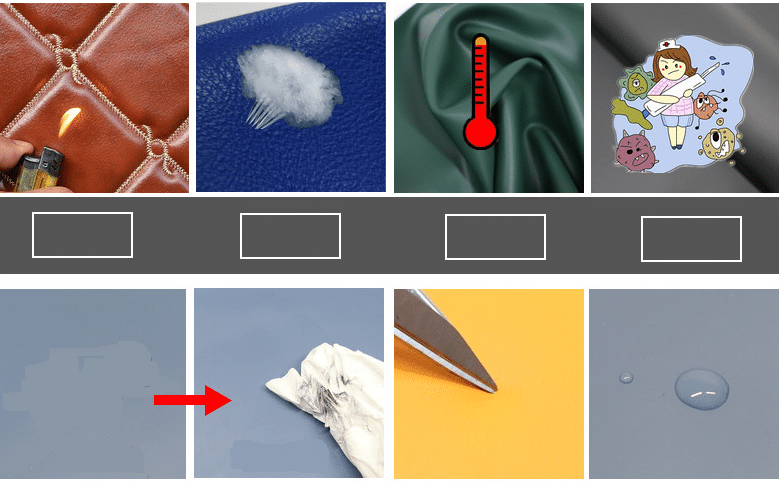

Safe and environmentally friendly: Silicone leather does not use harmful solvents and plasticizers in the production process, which reduces environmental pollution and meets the modern people’s pursuit of green life.silicone leather is biocompatible, physiologically inert and anticoagulant to the human body, and is non-carcinogenic, so silicone leather office chairs are also safer and more environmentally friendly during use.

Comfortable: Silicone leather feels soft, smooth, delicate and elastic, which makes it popular in clothing, footwear and other fields. Whether it is in direct contact with the skin or as a decorative fabric, silicone leather can bring excellent touch and comfort. The silicone leather office chair to remain comfortable during long-term use.

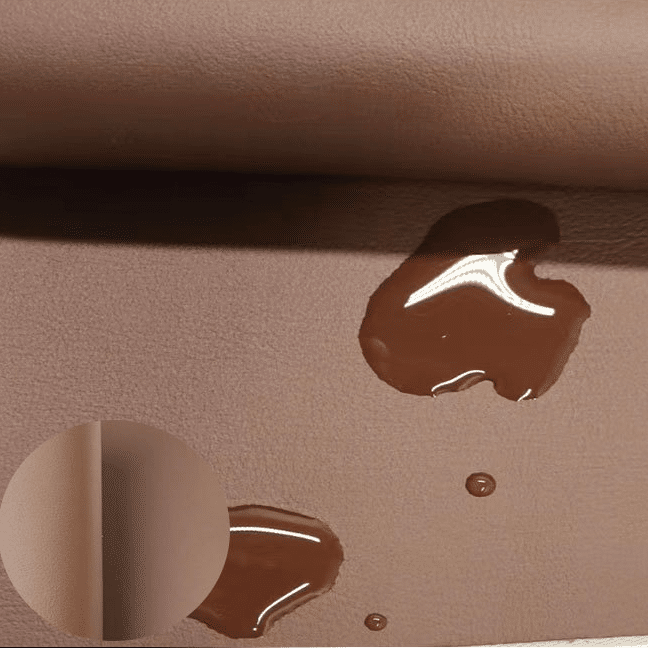

Waterproof and anti-fouling: The surface of silicone leather has a unique waterproof layer that is difficult for water molecules to penetrate. Even if there are a lot of water stains, it only needs to be wiped gently to be clean. This feature makes silicone leather an ideal choice for products such as automotive interiors, sofas, luggage, etc. It is not only easy to clean, but also effectively extends its service life. The surface of silicone leather is not easy to be stained.

Even if it is stained with colored liquids such as coffee and cola, it will gather into drops and stay, and will not penetrate into the interior, which makes cleaning and maintenance relatively simple of the silicone leather office chair.

Strong weather resistance and Durability: Silicone leather has excellent hydrolysis and light resistance. In a high temperature and high humidity environment, the surface of silicone leather remains flat, without stickiness, shiny, brittleness and other degradation phenomena. Its color fastness is excellent, and the color remains stable even after long-term exposure to strong sunlight. This allows the silicone leather office chair to maintain a good appearance and performance during long-term use.

Widely used: Silicone leather has a wide range of applications, from car seats, interior decoration to clothing fabrics, outdoor products, and even medical supplies. The silicone leather office chairs to perform well in a variety of environments.

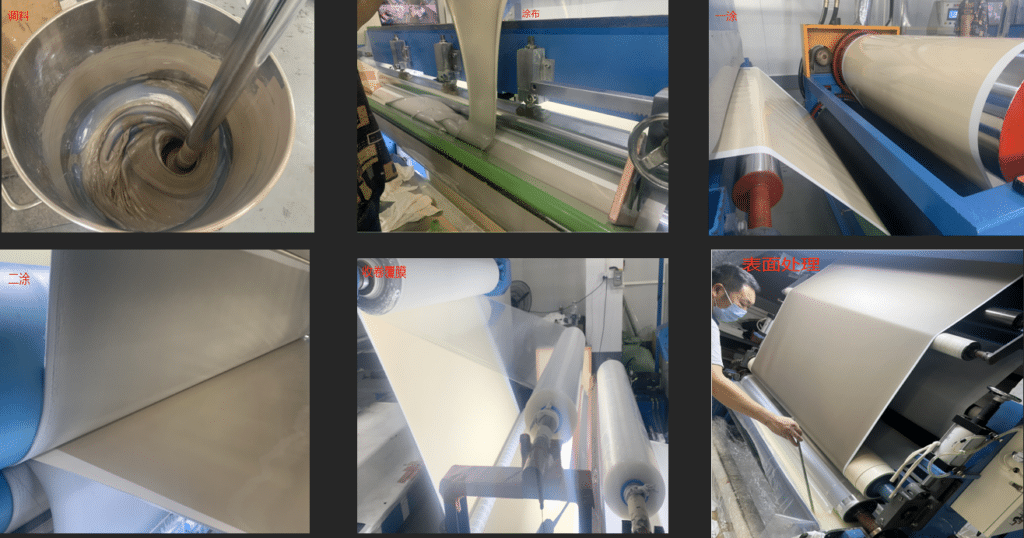

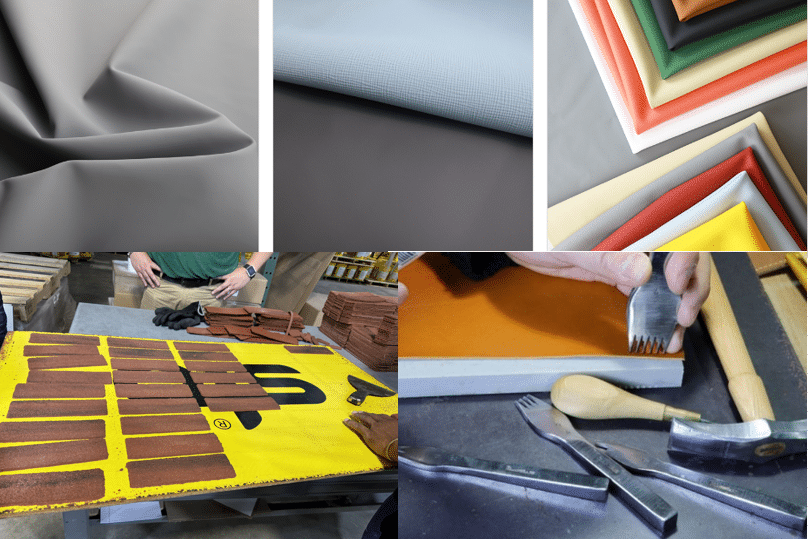

Silicone leathers Making Process

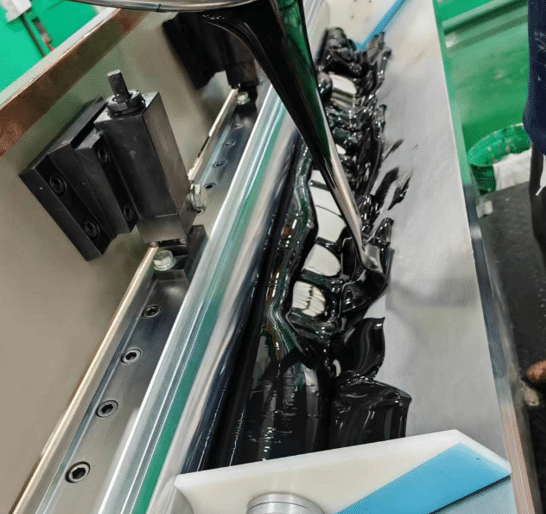

1. Prepared Material: Mixed the Liquid silicone rubber material color according to the confirmed samples ‘color. Prepare the confirmed base fabric layer.

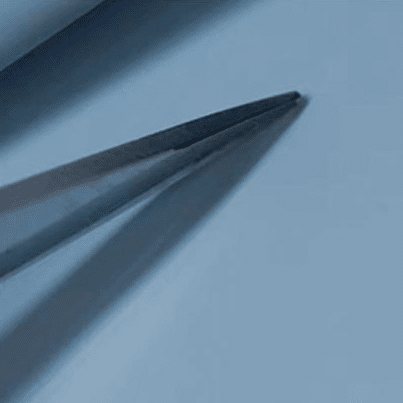

2. Set up and coating:Put mixed LSR on the machine, then coating the liquid silicone rubber. lt is the First coating with the liquid silicone rubber on the surface. Embossed for the silicone leather texture in this process.

3. Heat the first coating silicone leather in the oven to dry.

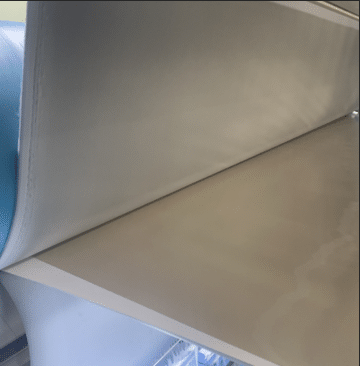

4. Second coating: Second coating the liquid silicone rubber in bottom and then sticker with the base fabric layer

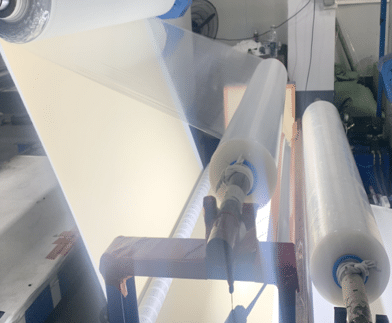

5. Lamination: Collection the half-finished silicone leather with plastic film in order to keep the surface clean

6. Painting Dusty Free oil: Painting the different oil to get different surface (gloss or matt) and different touch feeling silicone leather. (Skin, dry, smooth) and let the silicone leather keep dusty free and easy to clean.