Is Silicone Leather Weather-Resistant

Z.S.R Silicone leather has excellent weather resistance and can used in various harsh environmental conditions:

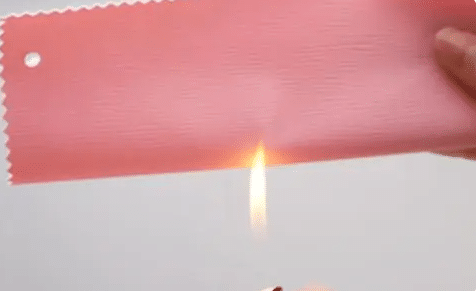

Resistant to high and low temperatures

The range of high and low-temperature resistance of silicone leather is -50℃ to 250℃. This feature allows silicone leather to maintain good elasticity in various environments. So, silicone leather-made products can used in snow and very cold areas and high temperatures like deserts. It also can used in the manufacturing process to stand the high temperatures of 250℃.

hydrolysis resistance

After more than ten weeks of testing, under the conditions of temperature 70±2℃ and humidity 95±5%, the surface of silicone leather did not show degradation phenomena such as stickiness, shiny, and brittleness. Then, the silicone leather made products can use in wet area, rainy and snow days.

resistant to illumination

Silicone leather is resistant to ultraviolet rays and excellent in resisting fading caused by sunlight. Even after ten years of exposure, it can maintain color stability and not change color. These properties enable silicone leather to maintain its performance and appearance in various environments without the need for frequent maintenance and upkeep. All the products need long-term sun exposure can use the silicone leather to making.

salt spray resistance

the performance retention rate of the silicone leather after 1000 hours of salt spray aging is more than 95%: the performance retention rate after 1000 hours of wet heat aging is more than 90%. All the products near the ocean, have to stand the salt spray. So, the seat and Furniture used in the beach and boats can use the silicone leather

Can silicone leather be used outdoor products?

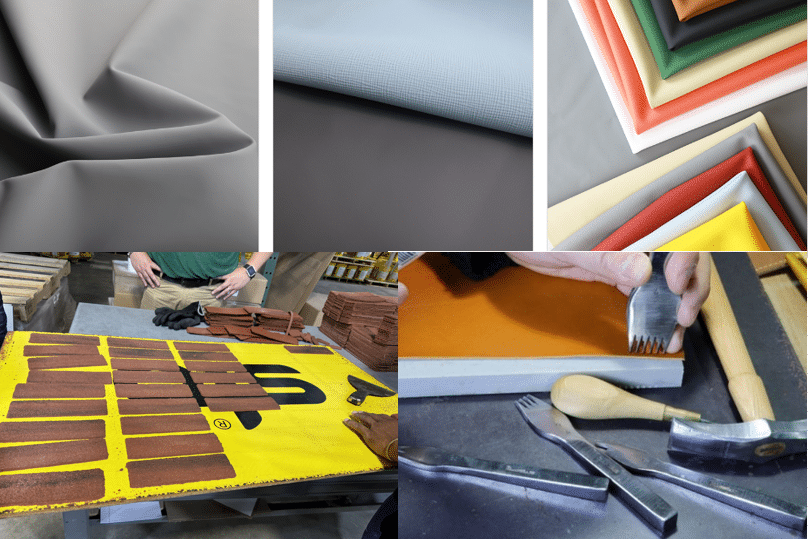

As a high-performance material, Z.S.R silicone leather has excellent stain resistance and easy cleaning, waterproof, anti-slip, wear resistance, aging resistance and UV resistance, which make it very suitable for outdoor activities. Silicone leather products can be widely used in outdoor shoes, gloves, backpacks, tents, watches, mobile phone cases and other products to provide better performance and protection.

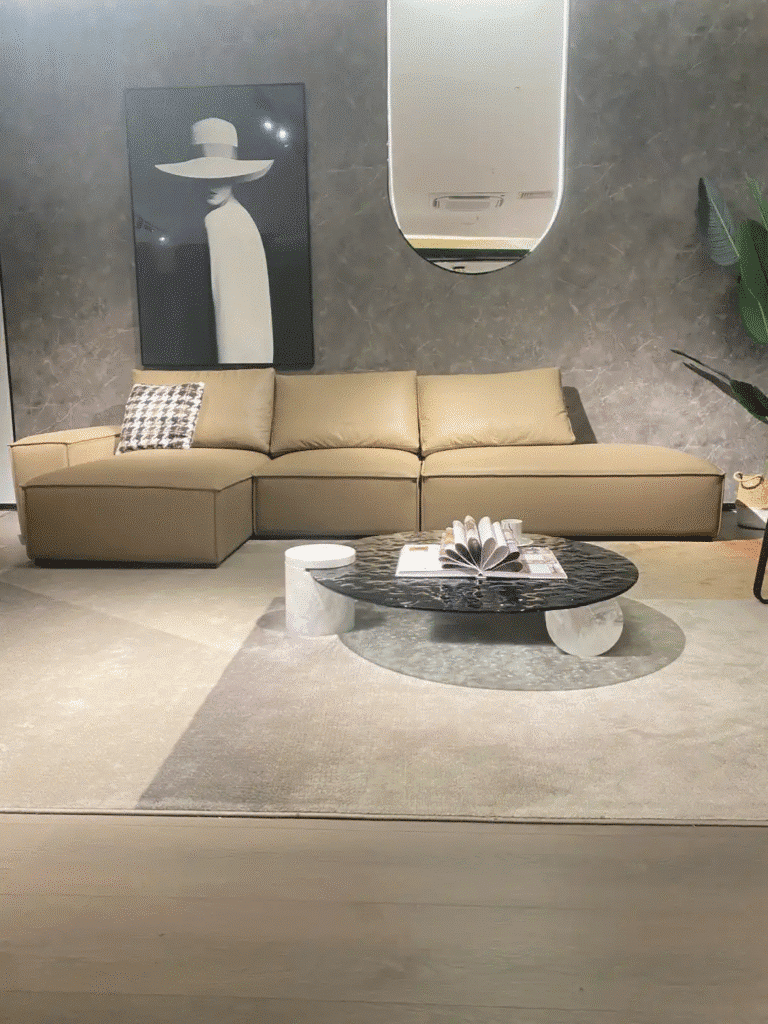

Z.S.R Silicone leather also has good weather resistance and durability and can be used in various environments, including outdoor furniture, car seats, etc. It also has good tensile and tear resistance and can withstand greater pressure and friction, which makes silicone leather an ideal choice for various fields, especially in outdoor products that require high-performance materials, and has broad application prospects in outdoor furniture, car seats and other fields

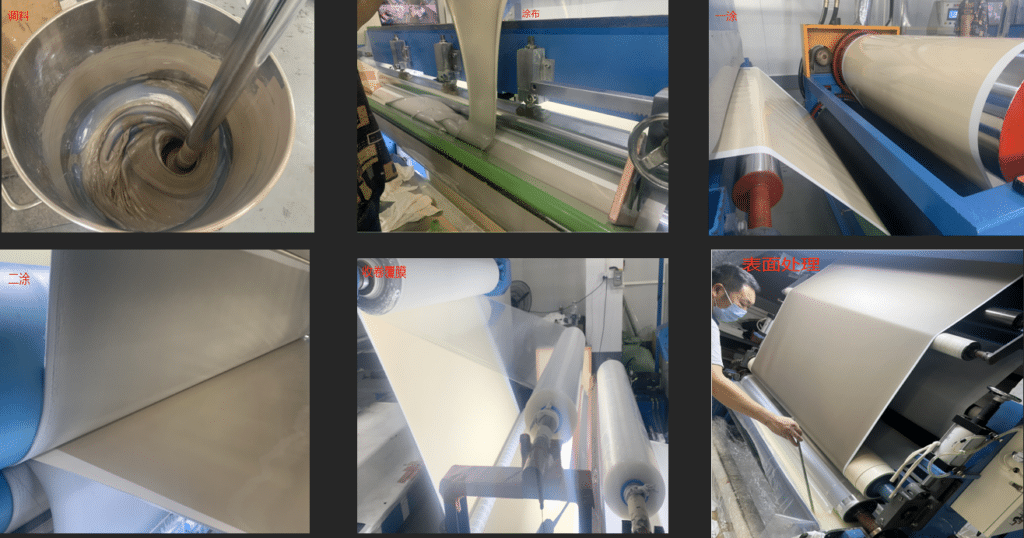

What is silicone leather?

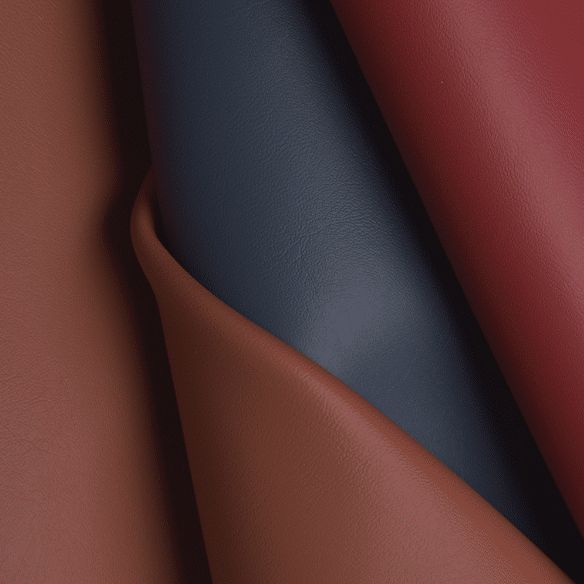

Silicone leather can be divided into full silicone leather and semi-silicone leather. Full silicone leather means that the entire leather product is made of silicone material, while semi-silicone leather means that part of the material is silicone and the other part is other materials. This material is soft, durable, waterproof, and easy to clean and maintain.

Silicone leather has many excellent properties, such as wear and scratch resistance, natural anti-fouling and waterproof, yellowing resistance, corrosion resistance, and aging resistance. These properties make silicone leather recognized in the high-end market and widely used in various products. In addition, silicone leather has excellent biocompatibility and low cytotoxicity, which meets the standards of the medical field. Full silicone leather means that the entire leather product is made of silicone material, while semi-silicone leather means that part of the material is silicone and the other part is other materials.

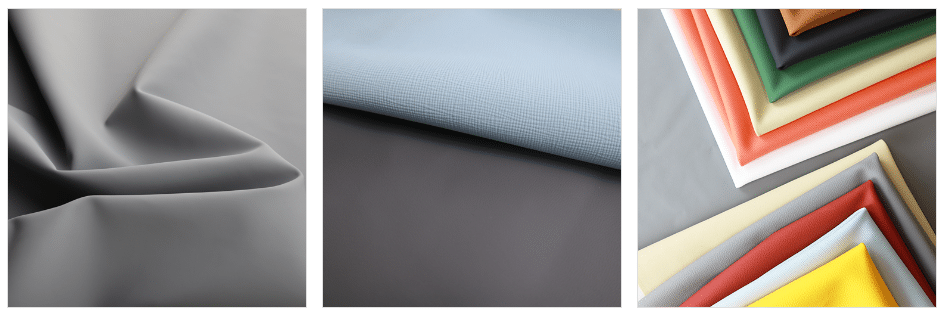

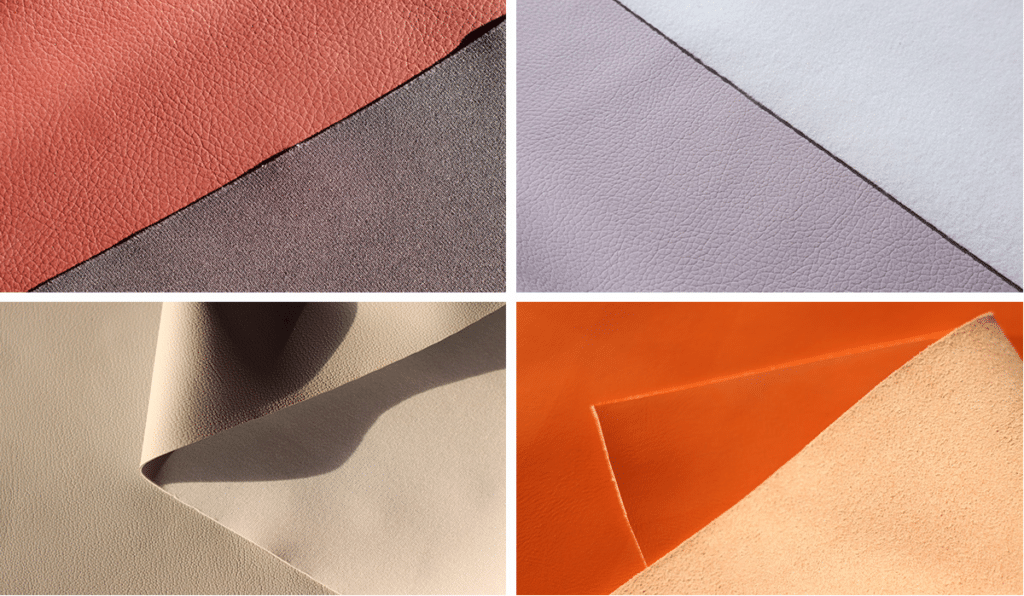

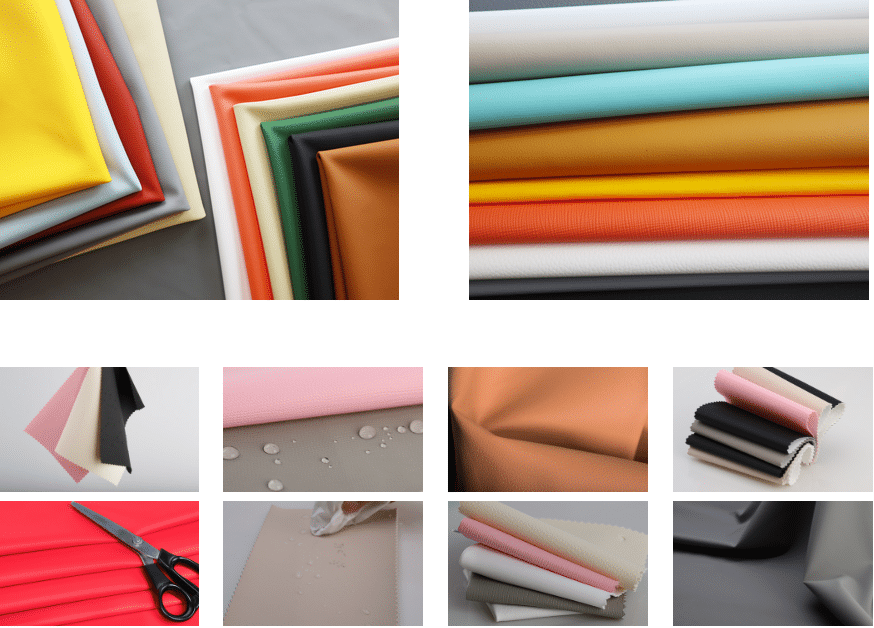

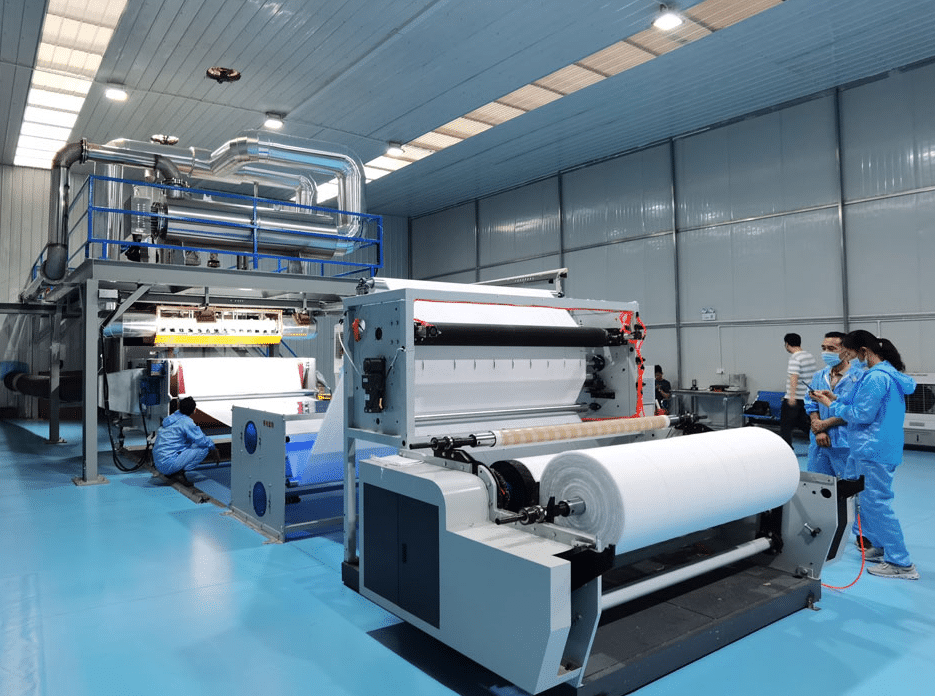

custom silicone leather

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

| PROPERTIES | VALUES |

|---|---|

| Material | silicone vegan leather |

| Wide | 1370mm+100mm fabric margin |

| Thickness | fabric thickess+coating thickness |

| 0.4mm leather=0.2mm Silicone±0.02mm+fabric 0.2mm±0.05mm | |

| 0.6mm=leather=0.2mm Silicone±0.02mm+fabric 0.4mm±0.05mm | |

| 0.8mm leather=0.2mm Silicone±0.02mm+fabric 0.6mm±0.05mm | |

| 1.0mm leather=0.2mm Silicone±0.02mm+fabric 0.8mm±0.05mm | |

| 1.2mm leather=0.2mm Silicone±0.02mm+fabric 1.0mm±0.05mm | |

| Color | PMS color or follow sample color |

| Surface layer | 100% baby pacifier material |

| Texture | Lychee/plain/carbon fiber/crocodile/star/kid skin |

| Base fabric | Micro Fibric, Cotton, Lycra, Pique, micro suede, stretchy fabric, Knitted fabric, Non-woven fabric, flannelette, PET, PC, TPU, PI FILM 3M adhesive tape etc |

| Pattern | Lichi Grain, Plain grain, Lambskin Grain, Pigskin Grain, Pin Grain, Crocodile Grain, Giant Pebble, Hami melon Grain, Bark Grainetc |

| Application | Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronic, Baby product. |

| Production Capacity | 1000m-24000m |

Summary

In summary, Z.S.R silicone leather is indeed very suitable for outdoor products due to its excellent performance and durability, providing better protection and performance for outdoor activities.

Z.S.R silicone leather series provides high design freedom with a wide variety of tailored options in colors, textures, and fabric. We work with the waterproof product development manager, product designer, product manager together designs and make the custom silicone skin to fit the waterproof product’s needs. Contact Z.S.R silicone to get your own needed silicone leather for your waterproof products now.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.