Silicone Leather Guide

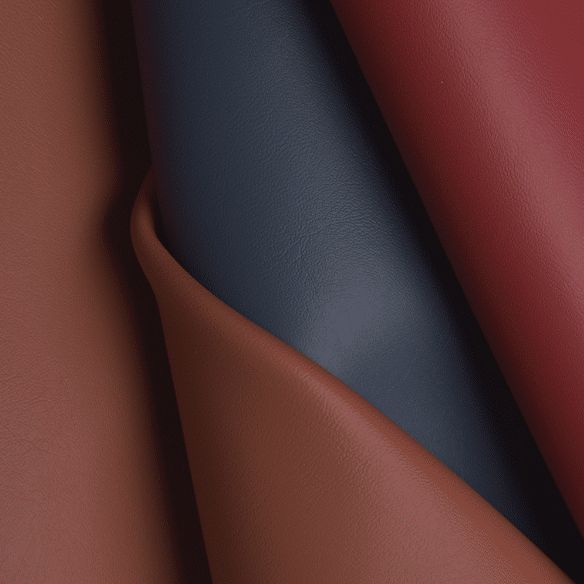

What is silicone leather?

Silicone leather is a high-end and fashionable revolutionary Artificial leather material. Silicone synthetic leather fabric that is environmentally friendly and extremely durable with a soft and supple feel.Silicone Leather are eco-friendly, sustainable, easy to clean, weatherproof, and highly durable performance fabric that can be applied in various applications, even in extreme environments.

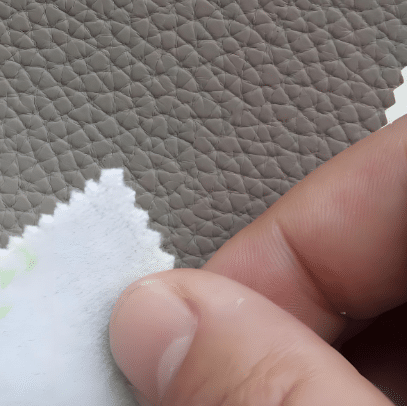

The surface layer is made from 100% silicone, it has a superior soft skin feel touch and handle which makes it fantastic to work with but still remains ultra-tough even for the most demanding high-traffic environments. Silicone leather has the softness, wear resistance, durability and waterproof characteristics of silicone, and also has the texture and beauty of leather. It is characterized by excellent hand feel and extremely high elasticity, and is wear-resistant, waterproof, anti-corrosive, anti-pollution, and has a long service life.

In addition, silicone leather has a uniform and delicate texture, is soft and comfortable, and is not easy to oxidize, discolor, or deform.Silicone is also inherently flame retardant, UV & weather resistant, stain & ink resistant, anti-bacterial/anti-microbial resistant, hydrolysis & tear resistant without the need of any extra chemicals or substances.

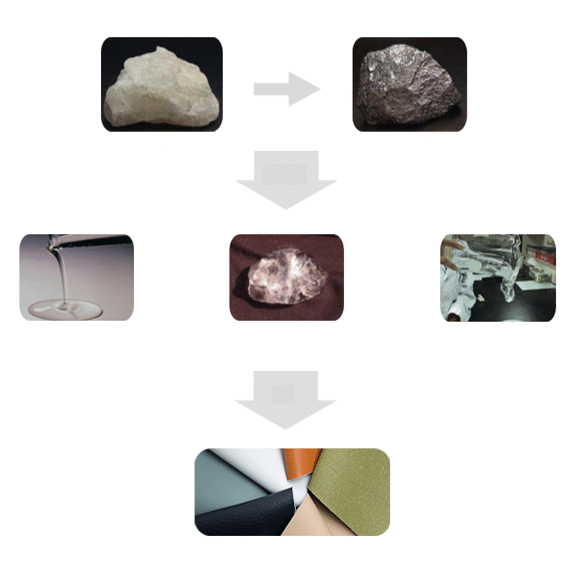

What is silicone leather made of?

Silicone leather is a synthetic leather made of Liquid silicone rubber (LSR) material. It is made of a mixture of raw materials such as liquid silicone rubber and fabric. The silicone leather its main component includes silicon dioxide. The liquid silicone rubber material has the characteristics of an inorganic polymer. Through solvent-free technology, silicone is coated on the surface of the substrate to form a new type of environmentally friendly artificial leather.

The surface layer of ZSR Leather is 100% silicone material, and the middle layer is bonded with a 100% silicone bonding layer to bond the silicone material and the base fabric. The base fabric and surface leather texture and thickness can be freely selected to achieve different uses and application scenarios of leather.

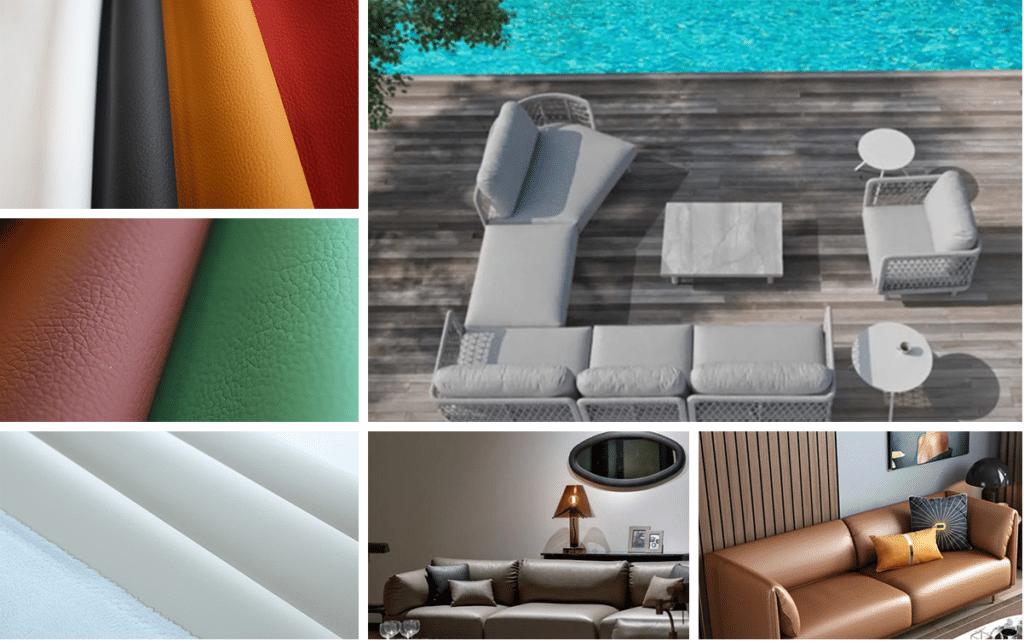

With the layer surface is silicone, The silicone Leathers offer an alternative to traditional textiles with a modern look, comfortable feel, and they are much easier to clean and care for.And the silicone leather can handles extreme weather conditions and can withstand hospital-grade cleaners and bleach making it a perfect choice in nearly all environments from industries including indoor/outdoor furniture, automotive, marine, aviation, sports, hospitality, medical, aged care, baby care,education and many more.

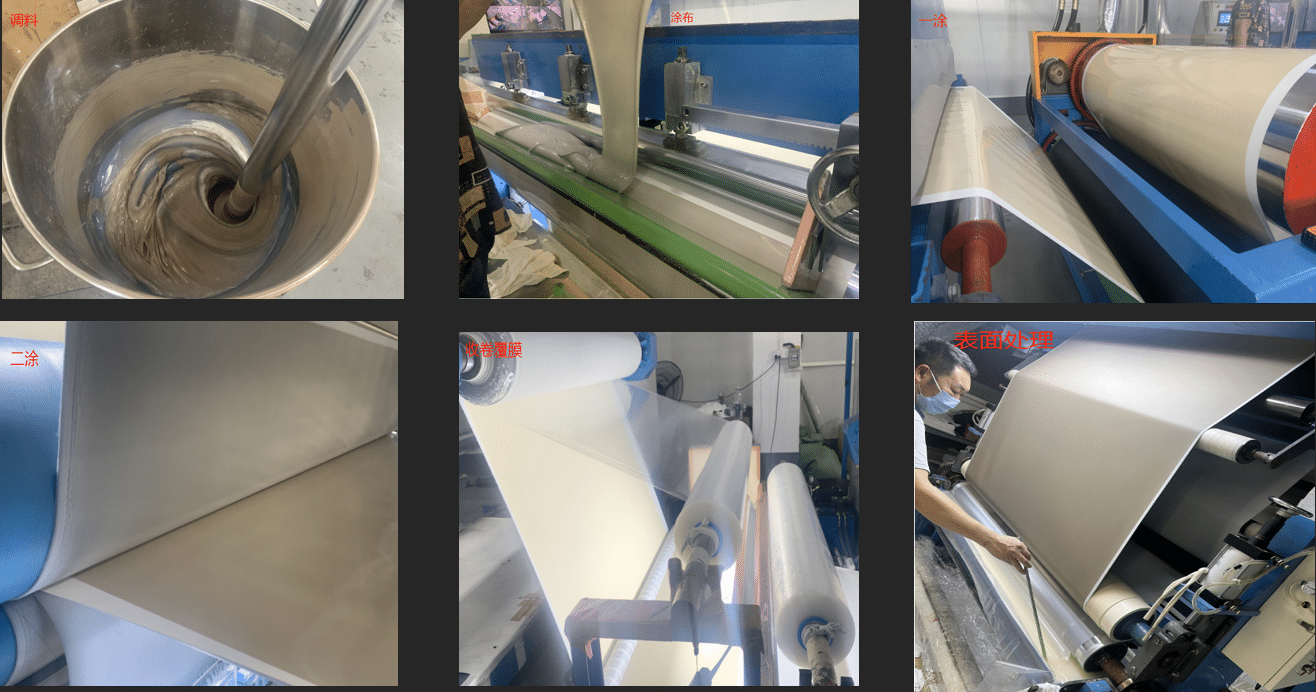

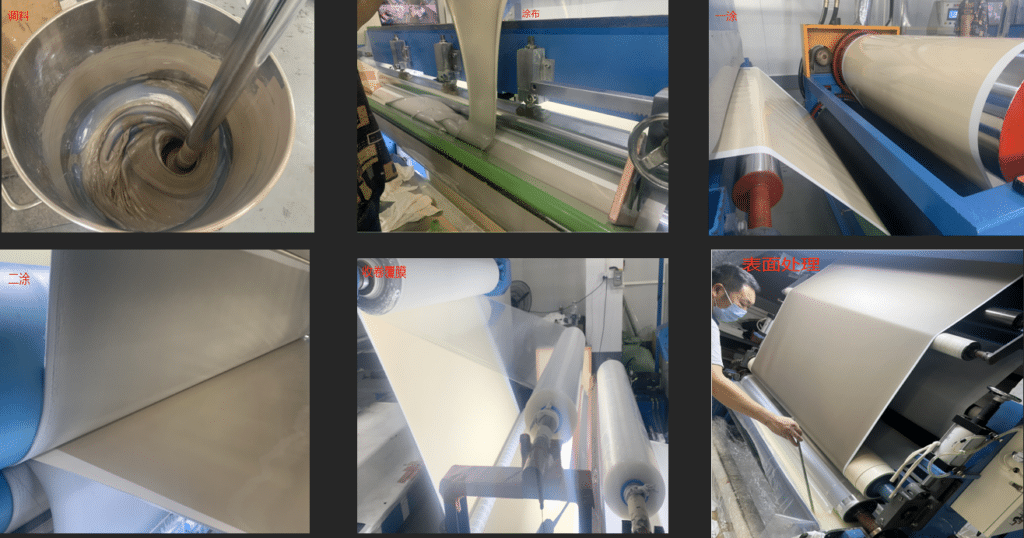

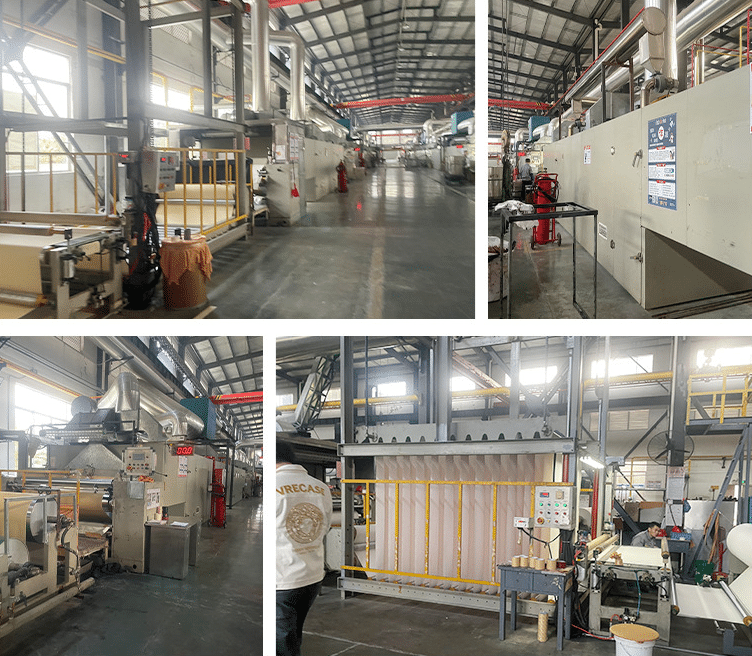

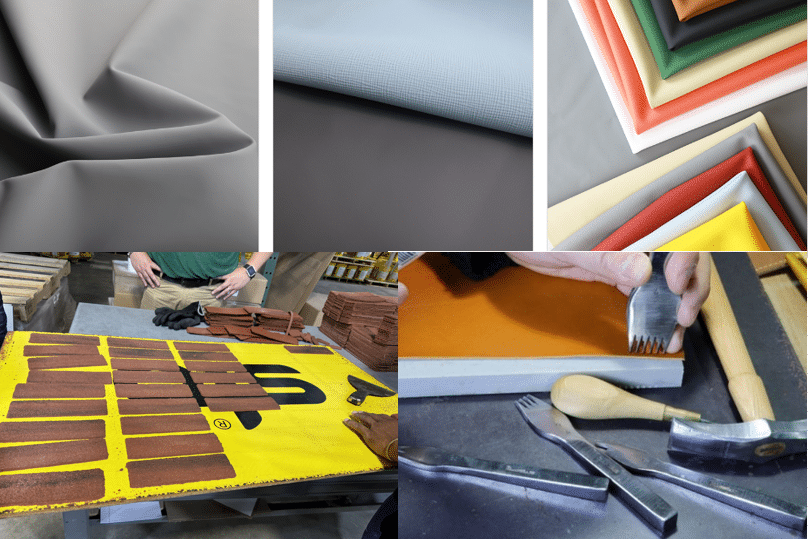

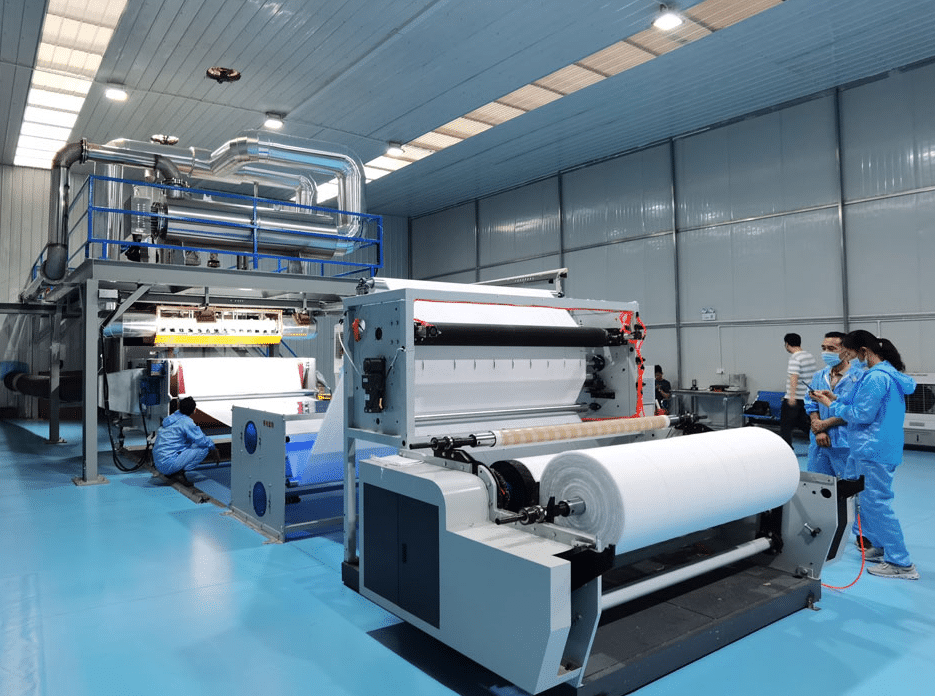

How is the silicone leather made?

The silicone leather was made by the process of silicone fabric Coating and curing.

The silicone leather was made by liquid silicone rubber (LSR) raw material and fabric (knitted fabric, nonwoven fabric or the like, and natural fiber, synthetic fiber, or regenerated fiber may be used as the fiber type). The making process is silicone with fabric Coating and curing – a method of manufacturing a silicone synthetic leather superior in abrasion resistance.

Uncured silicon is made into a film of a certain thickness with a roller. coated on the fabric, and then completely hardened by pressing the silicon surface with a heat roller having a specific pattern, And a step of coating with a surface treating agent after the above-mentioned process. ZSR Silicone leather is made of organic silicone coated and bonded to various substrates utilizing a solvent free technology.

- Mixed liquid silicone rubber, color paste, and platinum vulcanizer evenly and coated once. The uncured silicone is made into a film of a certain thickness by a roller, and then the surface of the silicone is completely cured by a hot roller with a specific pattern to obtain a silicone sheet with a textured film;

- The silicone sheet with a textured film is pressed with the base layer, initially vulcanized, and the textured film is peeled off to obtain a silicone leather semi-finished product with a texture;

- Hand-feel oil is applied on the texture surface of the silicone leather semi-finished product with a texture, and finally vulcanized.

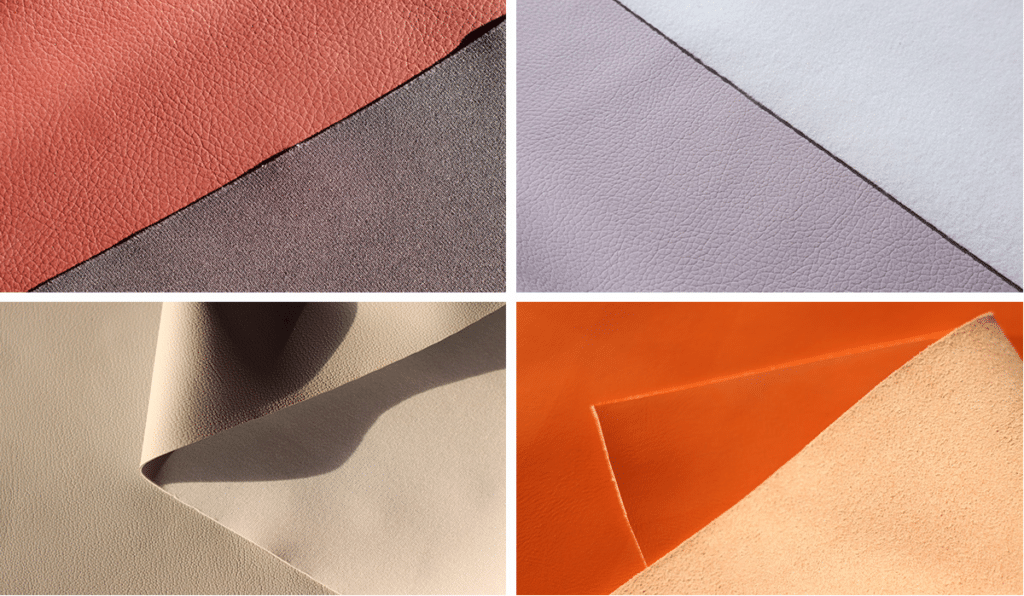

custom silicone leather

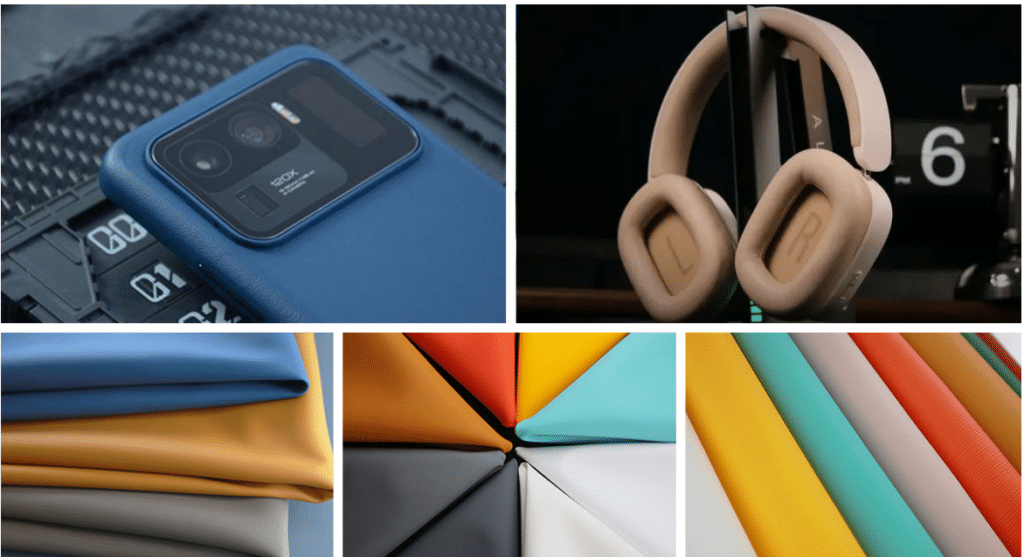

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

| PROPERTIES | VALUES |

|---|---|

| Material | silicone vegan leather |

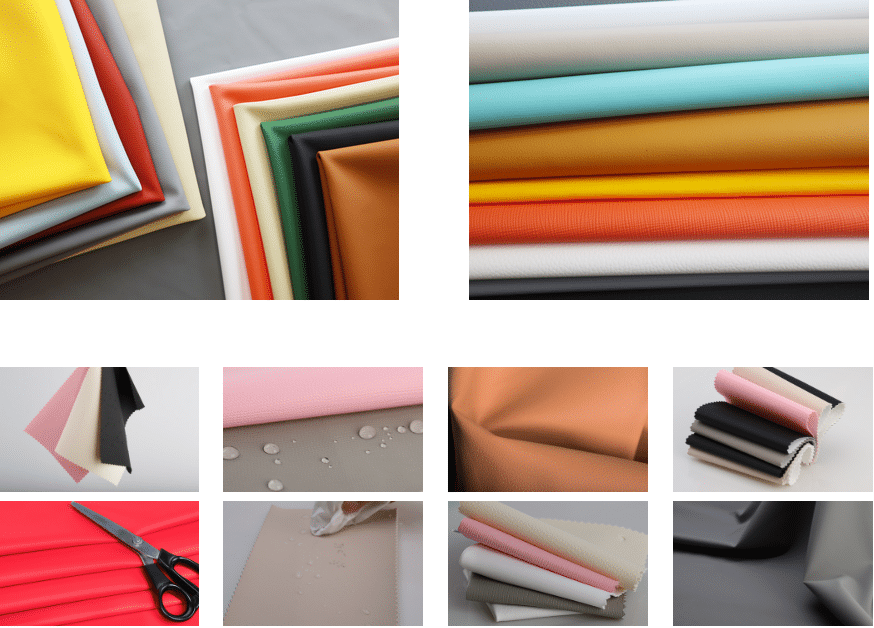

| Wide | 1370mm+100mm fabric margin |

| Thickness | fabric thickess+coating thickness |

| 0.4mm leather=0.2mm Silicone±0.02mm+fabric 0.2mm±0.05mm | |

| 0.6mm=leather=0.2mm Silicone±0.02mm+fabric 0.4mm±0.05mm | |

| 0.8mm leather=0.2mm Silicone±0.02mm+fabric 0.6mm±0.05mm | |

| 1.0mm leather=0.2mm Silicone±0.02mm+fabric 0.8mm±0.05mm | |

| 1.2mm leather=0.2mm Silicone±0.02mm+fabric 1.0mm±0.05mm | |

| Color | PMS color or follow sample color |

| Surface layer | 100% baby pacifier material |

| Texture | Lychee/plain/carbon fiber/crocodile/star/kid skin |

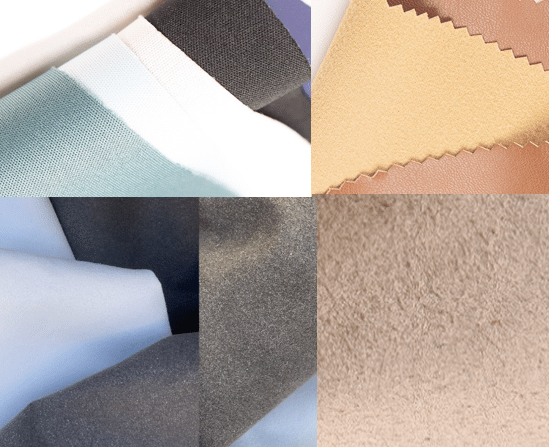

| Base fabric | Micro Fibric, Cotton, Lycra, Pique, micro suede, stretchy fabric, Knitted fabric, Non-woven fabric, flannelette, PET, PC, TPU, PI FILM 3M adhesive tape etc |

| Pattern | Lichi Grain, Plain grain, Lambskin Grain, Pigskin Grain, Pin Grain, Crocodile Grain, Giant Pebble, Hami melon Grain, Bark Grainetc |

| Application | Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronic, Baby product. |

| Production Capacity | 1000m-24000m |

The creation of our Silicone Synthetic Leather is environmentally responsible by using less water than traditional vinyls and incorporates a solvent-free production process and has no off gases. It contains no flame retardants, polyvinyl chloride (PVC), plasticizers, phthalates, heavy metals, BPA, or formaldehyde are used or added. Quartz contains ultra-low VOC emissions, creates no indoor air pollution, and is in compliance with RoHS and REACH making it a perfect choice for customers with skin sensitivity or allergies.

The advantage of silicone leather?

Silicone leather is distinguished by its exceptionally high performance, environmental protection, comfort, beauty, biocompatibility, weather resistance, water resistance, chemical corrosion resistance, wear resistance, breathability, safety, yellowing resistance, corrosion resistance, aging resistance, high and low-temperature resistance, softness, wear resistance, durability and waterproof.

1. Natural weather resistance

The surface material of silicone leather is composed of a silicon-oxygen main chain. This unique chemical structure maximizes the weather resistance of silicone leather, such as UV resistance, hydrolysis resistance, temperature resistance (temperature -40-250℃, humidity 95±5%), and salt spray resistance. the Martindale wear test of silicone leather can reach more than 150,000 times, and the Taber wear resistance (CS-10) is more than 3,000 turns.

It can maintain excellent surface integrity in high-friction use environments and can effectively deal with common scratches from hard objects such as keys and jeans in life. Yellowing and aging resistance: the silicone leather and PU leather were put into a fluorescent UV aging test box for 1000 hours. The comparison shows that the white silicone leather has no yellowing, while the P leather has obvious yellowing.

The performance retention rate of the silicone leather after 1000 hours of salt spray aging is more than 95%: the performance retention rate after 1000 hours of wet heat aging is more than 90%. Anti-aging, even if used outdoors for up to 5 years, it can still be as perfect as new.

2. Natural anti-fouling: anti-fouling and easy to clean

Silicone leather has an inherent anti-fouling property. In daily life, stains such as pen and ink, sweat, and dust are difficult to adhere to the leather surface: chemical stains such as lipstick, nail polish, reefs, and oil stains are also difficult to react with silicone leather, and can be easily wiped clean with a damp cloth.

Most pollutants can be easily removed with clean water or detergent without leaving any traces, which greatly saves the cleaning time of internal and external decorative materials and reduces the difficulty of cleaning, catering to the simple and fast life concept of modern people.

3. Natural environmental protection: environmentally friendly and recyclable materials

Z.S.R. Silicone leather adopts the most advanced coating process, and refuses to use organic solvents and chemical additives in the production process, so as to ensure that all our silicone leather products meet different environmental protection requirements:

- No PVC and PU components

- No plasticizers, heavy metals, phthalates, heavy metals and bisphenol (BPA)

- No per fluorinated compounds, no stabilizers

- Extremely low VOCs, no formaldehyde, and continuously improve indoor air quality

- Products are safe and non-toxic, non-allergenic

- Recyclable, sustainable materials are more conducive to environmental improvement

4. Natural skin-friendly touch

The silicone leather uses the same raw materials as baby pacifiers. From raw materials to finished leather, all links are green and pollution-free. The product has passed RoHS testing and Reach SVHC224 high-concern substance testing. The artificial leather feels more skin-friendly after surface treatment. Silicone leather has a soft and delicate touch like baby skin, softening the cold and hardness of modern reinforced concrete, making the whole space open and tolerant, giving everyone a warm experience.

5. Natural disinfect ability: Silicone is an inert and stable material

Chemical stability: The silicone leather has excellent chemical stability, and daily care can make the leather look brand new with a wet towel. In the face of chemical cleaners such as alcohol and 84 disinfectant that have certain damage to PU leather and PVC leather, the silicone leather can also deal with it calmly, which makes the product have a wide range of application prospects in the field of medical devices.

In the high-frequency disinfection and cleaning process in various public places such as hospitals and schools, silicone leather can resist various detergents and disinfectants. Common alcohol, hypochlorous acid, hydrogen peroxide and quaternary ammonium disinfectants on the market do not affect the performance of silicone.

6. Natural biocompatibility:

Silicone leather is biocompatible. The safety of silicone leather is due to the characteristics of silicone itself. Silicone shows biocompatibility, physiological inertness and ant coagulability to the human body, and is non-carcinogenic. These characteristics make silicone widely used in modern medicine, such as artificial joints and artificial skin. So the safety of silicone leather, which uses silicone as one of the raw materials will be very good.

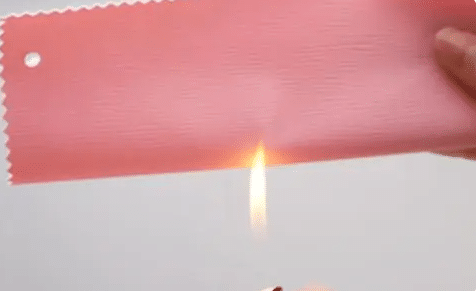

7. Natural flame retardancy:

Silicone leather, as a new type of synthetic material, has unique physical and chemical properties, and its flame retardant properties are particularly outstanding, thanks to the raw materials and special production process it uses. The flame retardant effect of silicone leather is significantly higher than that of PU leather.

The silicone product is mainly composed of three elements, CSi, 0, and the combustion products are H0, Si0, C0, which are non-toxic and pollution-free (shown as white when burned by flames), and are flame-retardant. The vertical burning test result is V0 level. It can be used in the leather field with fire-proof requirements with fire-proof base cloth. This advantage is mainly due to the selection of its raw materials, which enables silicone leather to show good flame retardancy when facing fire sources, effectively reducing the risk of accidental fires.

8. Natural waterproof performance:

The silicone on the surface of silicone leather has excellent waterproof performance, water molecules cannot pass through, and the water on the surface will not penetrate under the base fabric.

Silicone leather VS Traditional leather

The silicone leather does not contain DMF, phthalates, or lead. The silicone leather can pass Reach, ROHS(Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

Traditional leather, including animal leather, artificial leather (PU or PVC leather).

The artificial leathers such as polyurethane rubber (PU) synthetic leather and polyvinyl chloride (PVC) commonly found in the finished leather market are not resistant to aging, high temperature, easy to hydrolyze, easy to stain, and have a short lifespan. They will cause certain pollution to the environment during the manufacturing and use process.

Due to its high chlorine content, PVC creates toxic pollution in the form of dioxins, which accumulate in animals’ fat and upwards through the food chain.

Isocyanates in PU irritate the eyes, nose, throat, lungs and skin BPA, BPS and phthalates are subject to FDA limits and restrictions in the US – with even stronger restrictions in the EU, Canada and other countries.

Higher-end PU/PVC manufacturers market phthalate-free products, but many avoid mentioning BPA and BPS Plastics break down into microplastics which are bad for the planet and bad for our health. Microplastics bioaccumulate.

Other more information, check the following sheet

| Item | Silicone Leather | Nature Leather | PVC | PU | Microfiber |

|---|---|---|---|---|---|

| Breathability | Excellent | Good | Bad | Medium | Good |

| Fire Resistance | Excellent | Good | Good | Bad | Medium |

| Solvent/chemical resistance | Excellent | Bad | Good | Medium | Medium |

| Acid resistant | Excellent | Bad | Good | Medium | Good |

| Alkali resistance | Excellent | Bad | Good | Medium | Good |

| Hydrolysis resistance | Excellent | Medium | Good | Medium | Good |

| Durability | Excellent | Good | Medium | Bad | Good |

| Color fastness | Excellent | Bad | Medium | Better than PVC | Medium |

| Antibacterial and mildew resistance | Excellent | Bad | Medium | Medium | Medium |

| Normal Fixture | Excellent | Good | Bad | Medium | Medium |

| Low temperature Fixture | Excellent | Medium | Bad | Medium | Good |

| Tear intensity | Excellent | Good | Medium | Medium | Medium |

| Peel intensity | Excellent | Excellent | Medium | Medium | Good |

| break intensity | Excellent | Good | Medium | Medium | Medium |

| Stitch intensity | Excellent | Excellent | Bad | Medium | Good |

| High temperature resistance | Excellent | Good | Medium | Good | Good |

| Abrasion resistance | Excellent | Medium | Good | Medium | Medium |

| Anti-Wrinkle | Excellent | Good | Bad | Medium | Medium |

| Quality uniform | Excellent | Bad | Medium | Excellent | Medium |

| Tailorability | Excellent | Bad | Excellent | Excellent | Excellent |

| Post Processing | Easy | Bad | Easy | Easy | Easy |

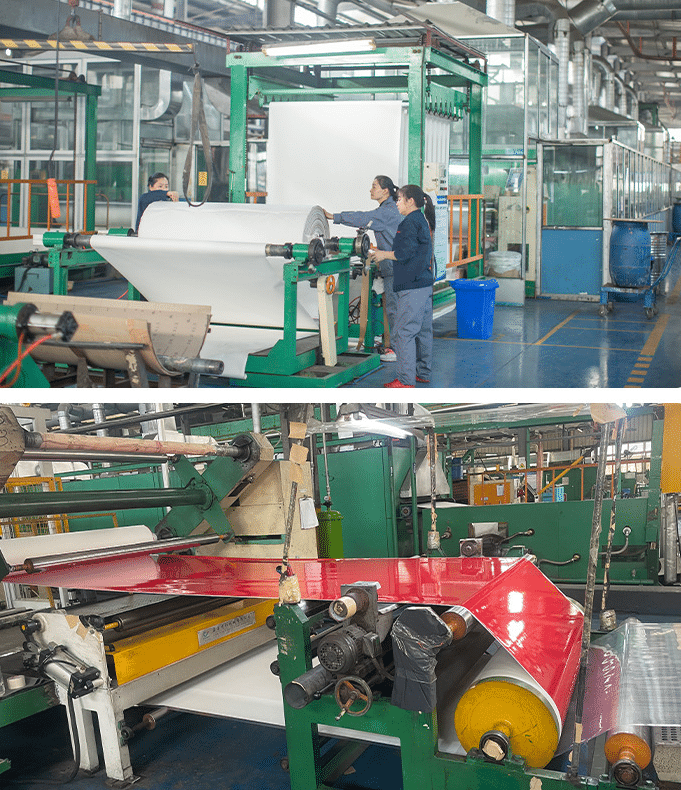

How to make the silicone leather in Z.S.R?

In Z.S.R Silicone, we make the silicone leather according to the client’s needs and idea. We try our best to deliver the quality silicone leather to our customer.

In Z.S.R Silicone, we custom the silicone leather Base fabric layer, custom silicone leather color, custom silicone leather texture, custom silicone leather application, custom silicone leather sizes, custom silicone leather logo, custom silicone leather printing, custom silicone leather pattern, brand, package for your silicone leather, if you would like to custom your brands silicone leather, contact Z.S.R

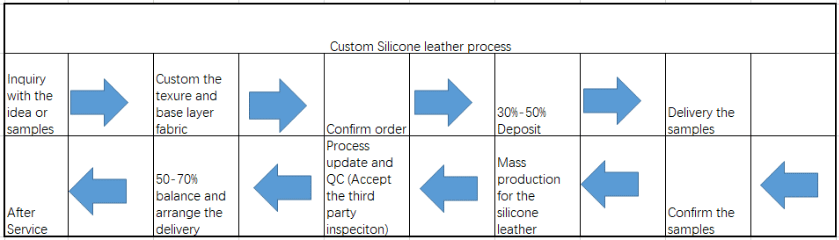

The process of custom the silicone leather in Z.S.R:

Step 1: Customer silicone leathers Needs and Budget

The function needs and budget that your company has allocated for an order determines what type of silicone leathers you can purchase and what personalization each one will receive. When that budget is finalized, this is the time to contact Z.S.R Group. We can help navigate you in the right direction to make a perfect silicone leather product.

Step 2: Customer Idea, Design, Sample

Just provide us a useful file with proper specifications of your Silicone leathers project and we would take care of the rest. we also can make the design from your picture, samples and can make the Silicone leathers samples based on that.

Step 3: Get the Silicone leather Samples

If you are developing a new silicone leathers products and not sure about the outcome, we can always offer silicone leather samples so that you can check the fitment, functionality, and aesthetics before investing in the mass production. Once you are satisfied with the samples of the silicone leather, you can proceed for the silicone leathers mass production. This covers your risk and helps you test your market with low investment. Moreover, it is always easier to do design changes at samples stage than doing the changes after the mass production is done.

Step 4: Mass Production

If you want to test the market first, you can start with a small order with Low ‘Minimum Order Quantity (MOQ)’ 300 meters and later can proceed for as much quantity production as you want.

Once you confirm the silicone leathers products what we made for you, the next step is for our customers to approve the golden samples or send over any changes that may be needed. Once the silicone leathers samples are approved, we start processing your silicone leathers and producing the merchandise.

All of the Silicone leathers what we made were Trimming and QC in our dust-free workshop. We do 100% QC before the silicone leathers are in the carton. To make sure all the silicone molded products that we deliver to the clients are high-quality products and meet your requirements. we promise you well-organized operation and timely delivery of your custom-made silicone parts as per your specification.

Step 5: Storage And Delivery

We have an independent Warehouse for the storage of the product before the shipment if you needed.

And the last stage is the most exciting — delivery! Delivery day is always an exciting time for us because we live to serve our customers. Once the silicone leather production processes finish, we can arrange for silicone leathers products pickup, ship, or delivery, depending on your location and preference.

In Z.S.R silicone, all the silicone leather from raw material selection to molding, curing, and quality control, each step plays a vital role in creating silicone leather that meet safety standards and perform well in their intended applications.

Understanding the silicone leather manufacturing process is essential for sellers, allowing them to offer high-quality, safe products to their customers.

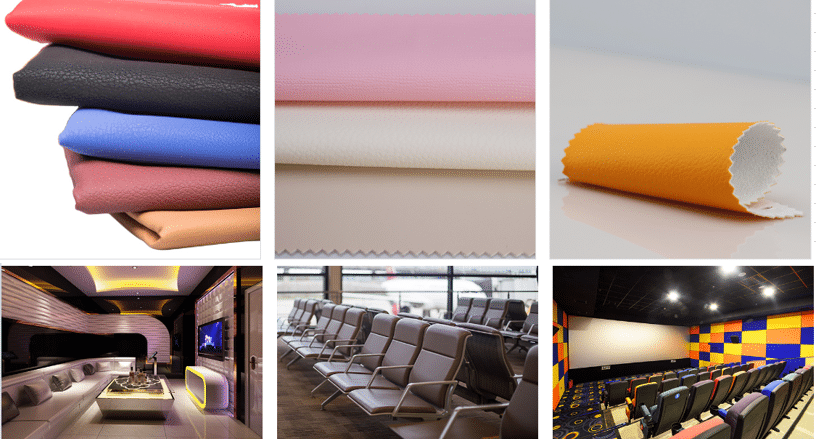

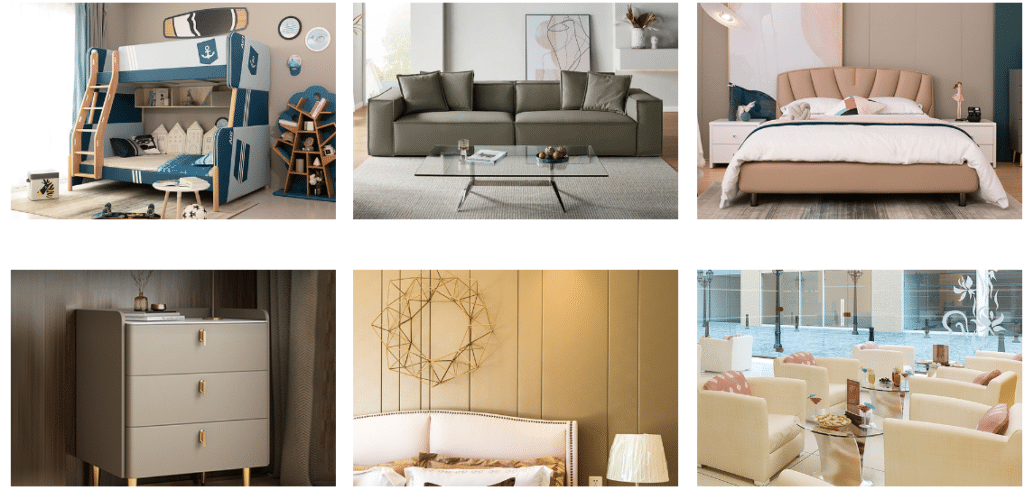

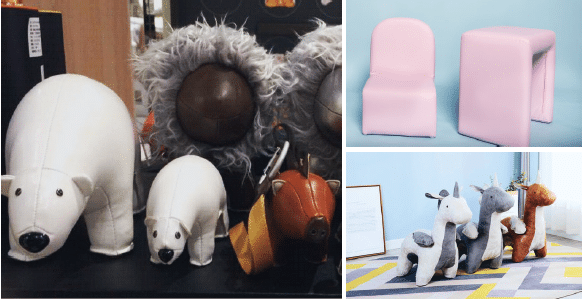

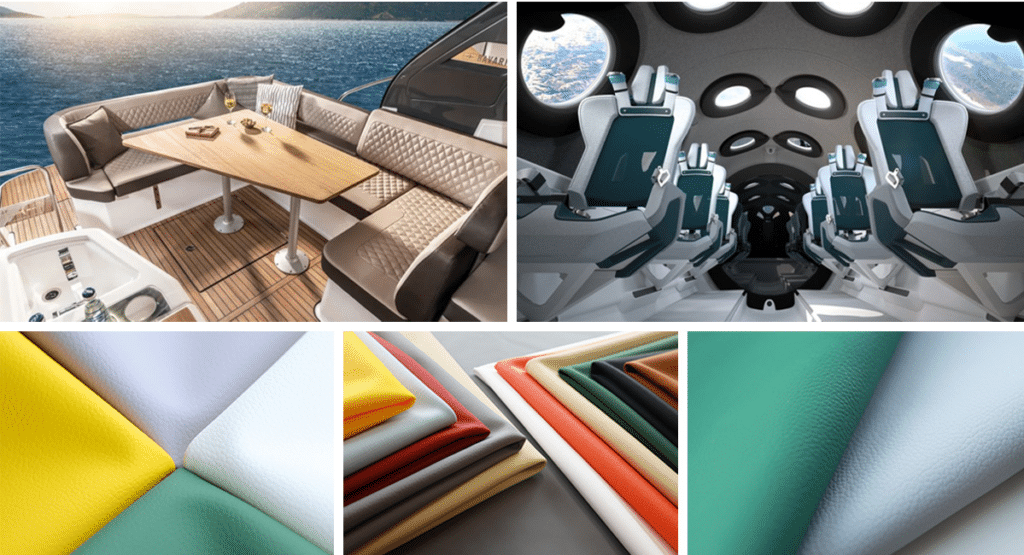

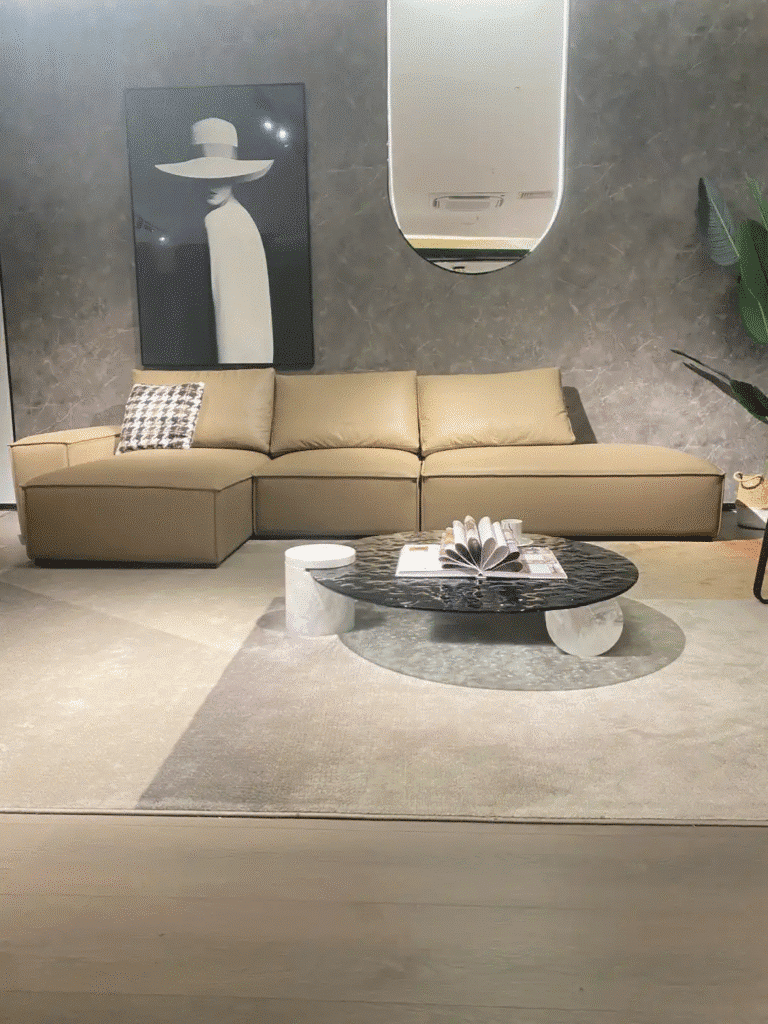

The application of silicone leather:

The organic silicon leather has the characteristics of environmentally friendly production process, no solvent, no harmful volatiles, hydrolysis resistance, stable anti-fouling, yellowing and aging resistance, wear resistance and scratch resistance, smooth feel, affinity to the human body, etc.

Based on the above excellent characteristics, the application field of organic silicon leather is very wide, covering furniture, yachts and ships, soft package decoration, car interior, public outdoor, sports goods, shoes, bags and clothing, medical equipment and other fields.

How Can You Choose the Different Silicone Leather?

And when you buy the silicone leather, you need consider:

Final Conclusion

The new type of organic silicone leather use baby’s pacifier material, liquid silicone coating on different base fabrics, without any chemical substance added and post-processing. The surface tender than natural leather with various colors and textures, it is a high health safety leather easy to clean, weather resistant, abrasion resistant, chemical resistant, breathable, anti-allergic, flame resistant etc.

Silicone Leather is much suitable for high-demand leather application industries such as Yachts, Cruiser ships outdoor furniture, electronica products, medical equipment, leather wearing and bags. The silicone leather can be customized according to the needs of customers, with fabric base, textures, thicknesses and colors.

Our engineers provide sample analysis, which can quickly match customer needs and 100% match samples to meet the customized of different customers’ requests.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.