What Is The Difference Between PU Leather And Silicone Leather

What is PU leather

PU artificial leather

PU artificial leather

PU leather is the abbreviation of Polyurethane (referred to as PU) synthetic leather, and its chemical name is “polyurethane”. PU leather is widely used in the fields of luggage, clothing, shoes, vehicles and furniture decoration, and is welcomed by the market because of its excellent performance and relatively low price.

What is silicone leather

Silicone leather is a new composite material that combines the properties of silica gel and leather. It forms a protective film by coating the surface of the leather with a layer of silicone, thereby retaining the natural texture and beauty of the leather, while enhancing its durability and water resistance.

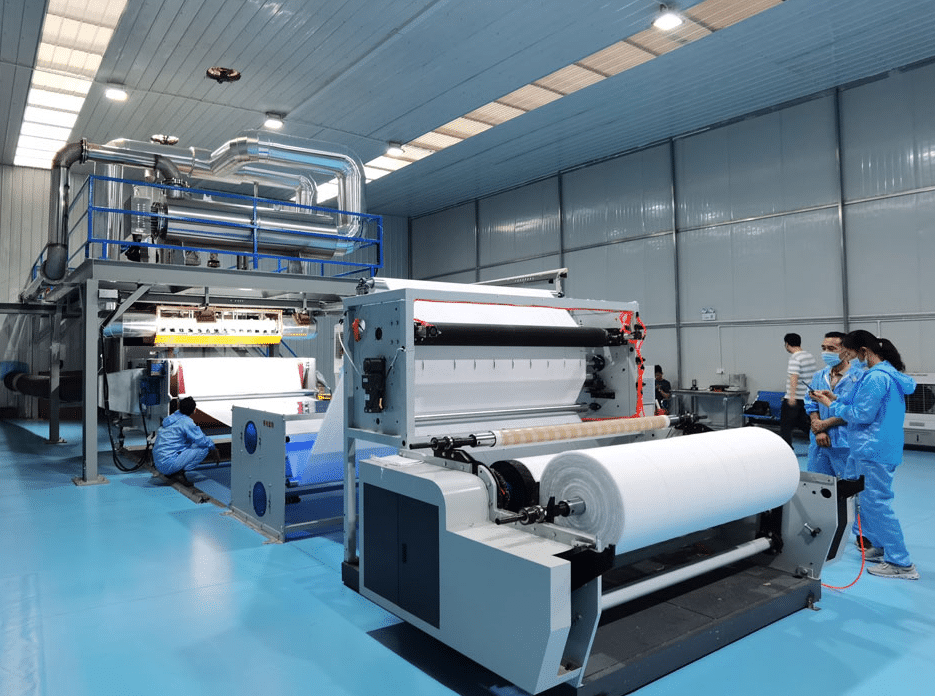

Z.S.R is a silicone leather manufacturer in China. Z.S.R offer series custom silicone leather provides high design freedom with a wide variety of tailored options in colors, textures, base layer fabric.

Z.S.R work with the different industry product fabric selection designers, product developer, R&D engineer, product manager together designs and make the Silicone leather fabric in an assortment of tear strength, hydrolysis resistance, waterproof and stain resistant, Wear resistant and scratch resistant, Heat/Cold temperature resistance, base layer, colors and texture to empower their product’s project success in design and functional requirements.

Silicone Leather Fabric Material Manufacturer

How is PU leather and silicone leather made?

PU leather production process

Mixing waste: Polyurethane resin is mixed with pigments, etc., to form a good solid shape.

Coatings: The mixed material is coated on the wet fabric and the polyurethane material is cured through the water tank.

Surface treatment: The coated material is embossed, color adjusted or pattern printed.

Embossed PU leather

Embossed PU leather

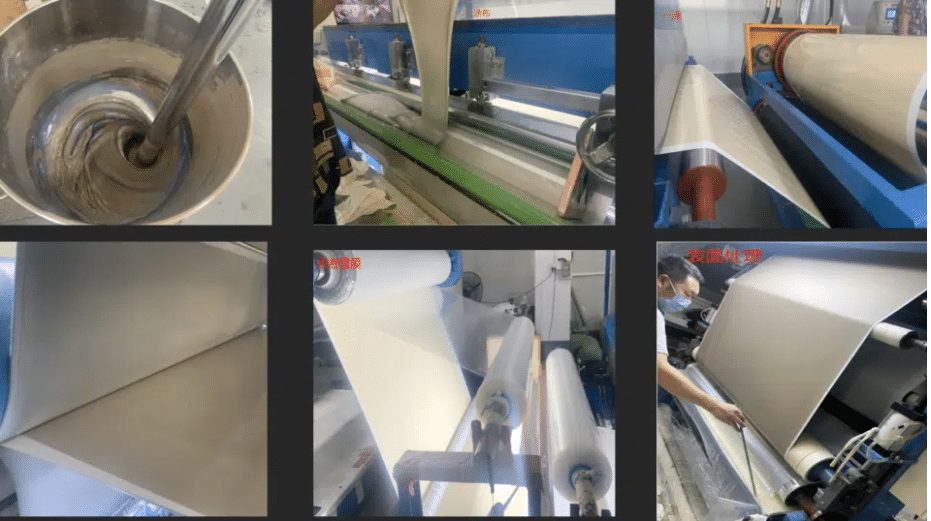

Silicone leather production steps

1. Z.S, R worker will mix liquid silicone rubber, color paste, and platinum vulcanizer evenly and coated once. The uncured silicone is made into a film of a certain thickness by a roller, and then the surface of the silicone is completely cured by a hot roller with a specific pattern to obtain a silicone sheet with a textured film;

2.The silicone sheet with a textured film is pressed with the base layer, initially vulcanized, and the textured film is peeled off to obtain a silicone leather semi-finished product with a texture;

3. Hand-feel oil is applied on the texture surface of the silicone leather semi-finished product with a texture, and finally vulcanized.

What is the appearance and texture of PU leather

Appearance: PU leather can imitate the texture and luster of real leather in appearance, showing a similar texture and luster to real leather, giving people a noble and elegant feeling. However, compared to real leather, the texture and gloss of PU leather often appear more artificial, lacking the natural feel and depth of genuine leather .

Texture: Although the texture of PU leather can imitate real leather, its feel is slightly astringent and lacks the soft and elastic characteristics of real leather. When touched, PU leather will give a more blunt feeling, the lack of smooth and natural leather . In addition, PU leather does not have the natural lines and pores of real leather, and the surface is smoother .

Environmental protection metal pearl litchi pu leather clothing furniture fabric

Environmental protection metal pearl litchi pu leather clothing furniture fabric

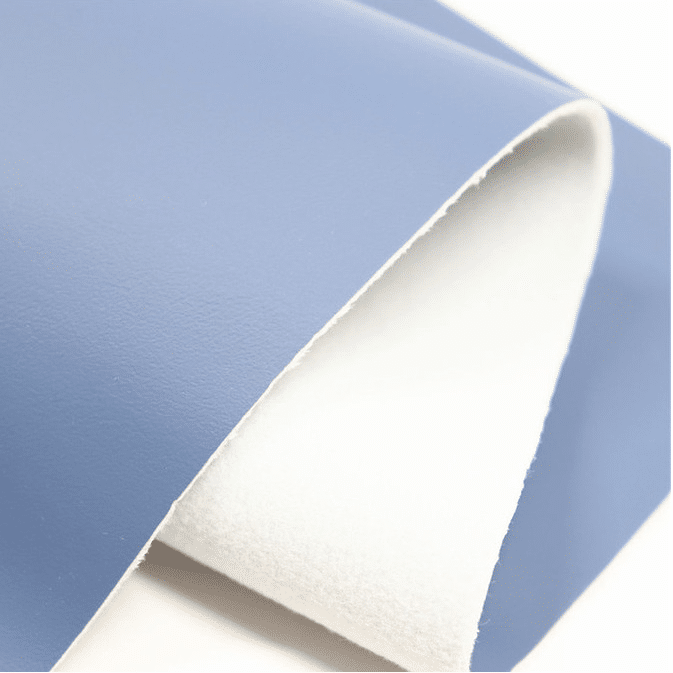

What is the appearance and texture of silicone leather

Appearance: The appearance of silicone leather usually presents a smooth, delicate quality, bright colors and is not easy to fade. Its surface is easy to clean, not easy to absorb dust and stains.

Texture: Silicone leather feels soft and smooth, with good elasticity, can bounce back quickly after pressing, without leaving obvious marks. In addition, the texture of silicone leather is strong plasticity, providing designers with rich creative inspiration.

What are the properties of PU leather

Wear resistance and softness: PU leather has excellent wear resistance and softness, which can resist wear and scratching in daily use, while being very comfortable to sit and touch.

Waterproofness: PU leather has a certain waterproof, can resist rain and wet environment, keep dry and comfortable.

Breathability: Although the air permeability of PU leather is relatively poor, in some types, its air permeability can reach 8000-14000g/24h/cm², which is suitable for making waterproof and breathable clothing.

Environmental protection property: PU leather non-toxic, no smell, no pollution, in line with the modern concept of environmental protection.

Workability and appearance: PU leather is easy to process and shape, suitable for a variety of cutting and sewing, smooth surface and high gloss, good appearance .

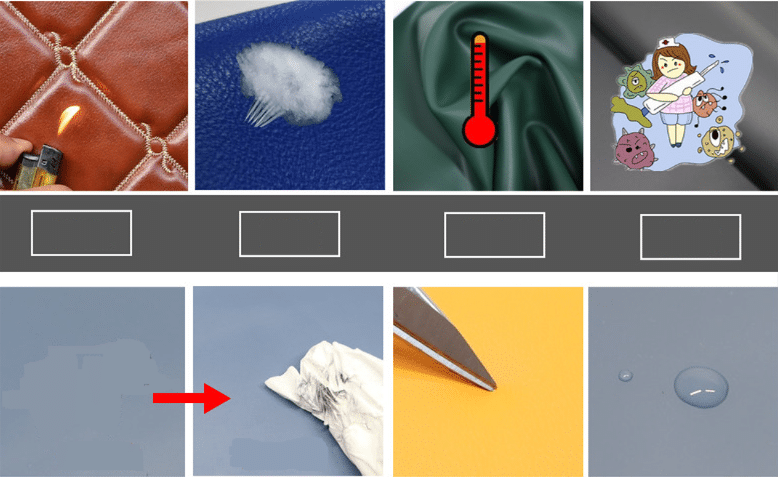

What are the properties of silicone leather

Environmental protection property: Silicone leather is a new type of environmental protection material, the use of solvent-free technology, non-toxic and tasteless, production and use process are green products. It is mainly made of baby pacifier grade silicone and is environmentally friendly.

Serviceableness: Silicone leather has extremely high wear resistance and scratch resistance, and has been tested by Martindale for up to 50,000 times of wear. In addition, it also has good yellowing resistance and corrosion resistance, can keep the color unchanged within 24 hours, and corrosion resistance is strong. Silicone leather at 100℃ after 72 hours no change, showing excellent aging resistance.

Security: Silicone leather has good biocompatibility, low cytotoxicity, meets the standards in the medical field, and is non-carcinogenic. It has good biocompatibility to the human body, physiological inertia and anticoagulant, will not cause cancer, so it has a wide range of applications in medicine, such as artificial joints and artificial skin.

Waterproof and antifouling: Silicone leather has excellent waterproof performance, the surface is clean after a wipe, and can be dribbled into beads, water molecules can not pass through the surface. It has natural anti-fouling and waterproofing for common stains and can be removed with a wipe.

Weather fastness: Silicone leather exhibits excellent resistance to hydrolysis and light. After more than 10 weeks of testing in a high temperature and humidity environment (such as 70℃ and 95% humidity), the leather surface does not appear sticky, shiny or brittle. In addition, silicone leather is excellent in resistance to sunlight fading, and can still maintain stability and color unchanged after ten years of exposure.

More About silicone leather

What areas will PU leather be used in

Leatherware: PU materials are widely used in the field of leather products, such as bags, shoes, belts, seats, etc. Due to its good wear resistance, tear resistance and strong plasticity, PU leather products can simulate natural leather in appearance and texture, and the price is more affordable.

Architecture and decoration: PU materials also play an important role in the field of architecture and decoration. It is used as thermal insulation material, sound insulation material and wall decoration. The good thermal insulation performance and environmental protection characteristics of PU materials make it an ideal choice in modern architecture.

PU stone background wall

PU stone background wall

Atomobile industry: In the automotive industry, PU materials are widely used in the manufacture of seats, steering wheels, dashboards and other components. Its excellent wear resistance and anti-aging properties make the interior parts of the car more durable, while the comfort of PU material also enhances the driving experience.

Medical equipment and sports equipment: Because PU material has good elasticity and fatigue resistance, it is also widely used in medical devices and sports equipment. For example, the production of some sports protective gear, rehabilitation equipment and medical mattresses. In addition, PU material is often used to make some waterproof breathable sportswear.

In addition to the above fields, PU materials are also widely used in furniture, electronics, aerospace and other fields. For example, in furniture manufacturing, PU material is used to make soft bags, cushions, etc.In the aerospace field, PU material is used to manufacture some key components due to its good performance and stability.

Fall bodyfitting PU leather women’s workout wear

Fall bodyfitting PU leather women’s workout wear

What areas will silicone leather be used in

Fashion product: Silicone leather has a soft feel and colorful color choice, suitable for the manufacture of handbags, belts, gloves, wallets, watch bands, mobile phone cases and other fashion products.

Furniture life: The waterproof, anti-fouling and oil-proof properties of silicone leather make it suitable for the manufacture of household articles, such as placemats, coasters, tablecloths, throw pillows, mattresses and so on.

Silicone mattress

Silicone mattress

Medical equipment: Silicone leather is non-toxic, tasteless, not easy to produce dust and bacterial growth, suitable for medical equipment accessories, gloves, protective pads and other manufacturing.

Food packaging: Silicone leather with corrosion resistance, waterproof, anti-fouling and other characteristics, suitable for food packaging bags, tableware packaging bags and other manufacturing.

Auto spare parts: Silicone leather has wear resistance, high temperature resistance and other characteristics, suitable for the manufacture of auto parts, such as steering wheel cover, seat cushion, visor and so on.

Children product: Silicone leather has reached the food and Drug Inspection Administration food grade standards, can be used for children’s toys, children’s furniture, child seats and other products.

Personalized silicone authentic leather luggage tag

Personalized silicone authentic leather luggage tag

What is the price difference between PU leather and silicone leather

PU leather: PU leather is a kind of artificial leather, the price usually ranges from 10-60 USD, the specific price depends on the quality and use of the product. The price of ordinary PU leather is roughly 3-6 USD/code, while the price of microfiber leather is generally 5-15 USD/code.

Silicone leather: The price of silicone leather is relatively high. On the market, the price of silicone is about 4 USD to 7 USD per kilogram. The specific price of silicone leather will also be affected by its excellent physical properties and environmental performance.

silicone leather VS other leather

| subject | Polymer silicon material Finished leather | natural leather | PVC artificial leather | PU synthetic leather | Microfiber PU Finished leather | |

| principal raw material | non-woven fabric, etc. | Pigskin, cowhide, sheepskin, etc. | PVC resin, non-woven | Knitted fabrics, woven fabrics | PU resin microfiber non-woven fabrics, etc. | |

| dermatosis | fine | fine | range | fair | fine | |

| Feel, elasticity | fine | fine | poor | poor | fine | |

| Color, pattern | more | fair | fair | More | fair | |

| preparation technology | dry process | Tanning and nitrificati | dry process | Wet and dry process | Microfiber weaving, wet, reduction, dry process | |

| working life | 5-15 years | 5-10 years | 2-5 years | 2-5 years | 2-10years | |

| price | 80-300 | 150-300 yuan per Square meter | 6-15 yuan per square meter | 7-25 yuan per square meter | 50-100 yuan per square meter | |

| Ecological and environmental protection | Environmental protection of raw | pollution-free | serious pollution of auxiliary materials | Have some pollution | Better than pre-artificial leather | fair |

| Environment all pollution during production | pollution-free | more | fair | fair | There is a benzene reduction process Fixed pollution | |

| Health and safety of products | safe | relatively safe | In danger harm | relatively safe | There is a benzene reduction process Fixed pollution | |

| Environment all protection of products sex | recyclable | degradable | degradation-resistant | degradation-resistant | degradable | |

| Waste disposal method | large | large | fair | fair | ||

Conclusion

PU and silicone leather may be can some application, but they are significant differences between silica gel leather and PU leather in terms of composition, production process, performance and environmental protection characteristics. Silicone leather with its non-toxic and harmless, environmental protection and durable, flame retardant performance and other characteristics, in many fields to show a strong competitiveness and broad market prospects. PU leather, with its moderate price and wide range of applications, continues to meet the diversified needs of the market. When choosing these two materials, users should make comprehensive consideration according to the specific application scenarios and needs to choose the most suitable for their own products.

The silicone leather provides an innovative, durable, and sustainable coated fabric option for Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronics, Handbags, Baby products, upholstery etc.

Z.S.R work with the different industry product fabric selection designers, product developer, R&D engineer, product manager, Material Specialists, Fabric Specialist, Material Consultant together to customized the silicone leather according to the needs of customers, with fabric layer base, textures, thicknesses and colors to fit their project needs and ensure their project success. Our engineers provide sample analysis, which can quickly match customer needs and 100% match sample to meet the customized of different customers’ request.

Contact Z.S.R silicone to get your own needed silicone leather to ensure your project success!

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.