Silicone Leather vs. Traditional Leather

1. What is silicone leather?

Silicone leather is a new composite material which combines the characteristics of silica gel and leather. It forms a protective film by coating the surface of the leather with a layer of silicone, thereby retaining the natural texture and beauty of the leather, while enhancing its durability and water resistance.

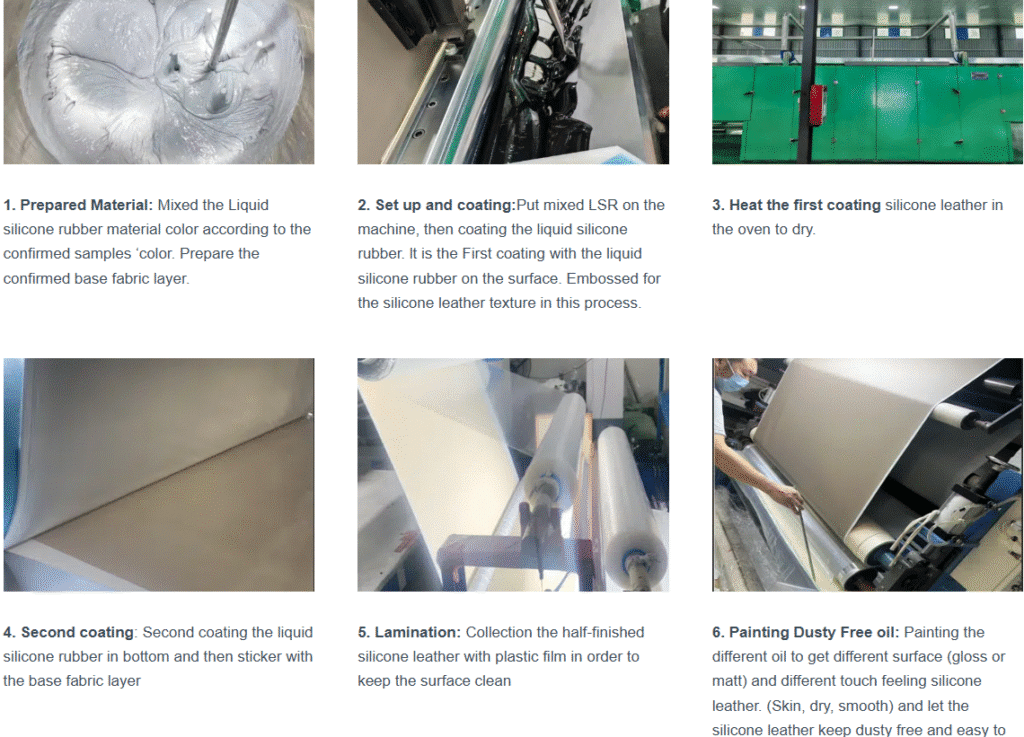

The production process of silicone leather includes two steps of leather treatment and silicone coating. First, the leather is cleaned and softened, and then a layer of silicone is evenly applied on the surface of the leather to form a tough protective film through a special process.

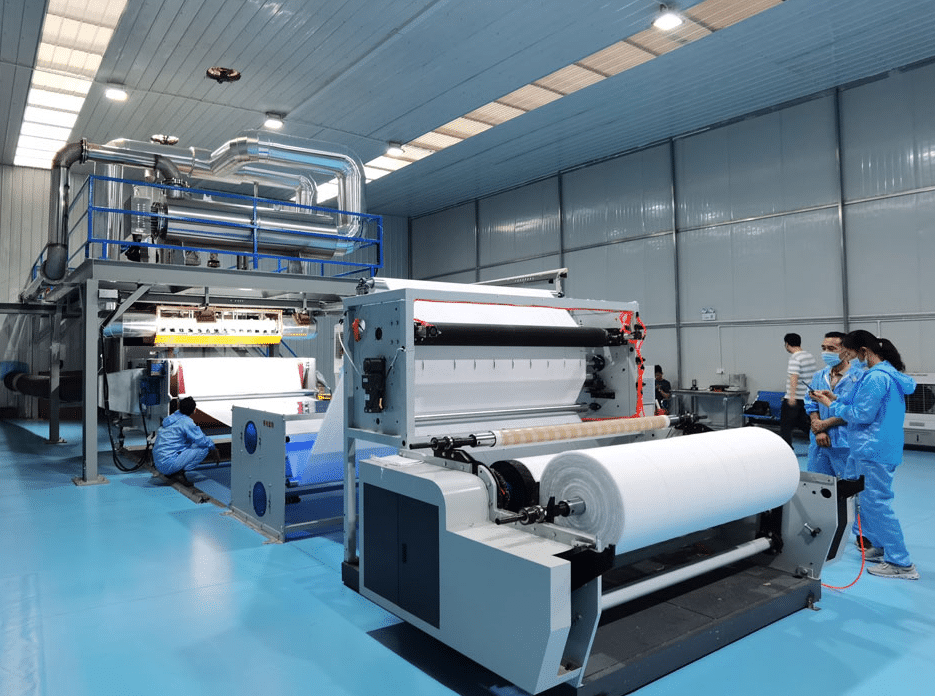

The silicone leather was made by liquid silicone rubber (LSR) raw material and fabric (knitted fabric, nonwoven fabric or the like, and natural fiber, synthetic fiber, or regenerated fiber may be used as the fiber type). The making process is silicone with fabric Coating and curing – a method of manufacturing a silicone synthetic leather superior in abrasion resistance.

Uncured silicon is made into a film of a certain thickness with a roller. coated on the fabric, and then completely hardened by pressing the silicon surface with a heat roller having a specific pattern, And a step of coating with a surface treating agent after the above-mentioned process. ZSR Silicone leather is made of organic silicone coated and bonded to various substrates utilizing a solvent free technology.

Mixed liquid silicone rubber, color paste, and platinum vulcanizer evenly and coated once. The uncured silicone is made into a film of a certain thickness by a roller, and then the surface of the silicone is completely cured by a hot roller with a specific pattern to obtain a silicone sheet with a textured film; The silicone sheet with a textured film is pressed with the base layer, initially vulcanized, and the textured film is peeled off to obtain a silicone leather semi-finished product with a texture; Hand-feel oil is applied on the texture surface of the silicone leather semi-finished product with a texture, and finally vulcanized.

The creation of our Silicone Synthetic Leather is environmentally responsible by using less water than traditional vinyl’s and incorporates a solvent-free production process and has no off gases. It contains no flame retardants, polyvinyl chloride (PVC), plasticizers, phthalates, heavy metals, BPA, or formaldehyde are used or added. Quartz contains ultra-low VOC emissions, creates no indoor air pollution, and is in compliance with RoHS and REACH making it a perfect choice for customers with skin sensitivity or allergies.

Silicone Leather Fabric Material Manufacturer

2. What is the traditional leather?

Traditional leather refers to a kind of biological material with good physical and mechanical properties, wearing comfort and degradation stability, which is made from raw materials with the original structure of roughly complete rawhide through a series of physical and chemical processing. Specifically, the process of making traditional leather includes steps such as hair removal, tanning, etc., to make it soft, durable, and retain the skin’s natural texture and pores.

3. How is silicone leather made?

- Raw material preparation: Prepare the required base fabric layer and silicone.

- Silicone coating: Apply the prepared silicone evenly on the leather surface.

- Lamination: Laminate another piece of leather with the silicone-coated leather.

- Curing: Place the laminated leather into the curing equipment for curing.

- Package and ship: After surface treatment, the silicone leather is packaged and shipped to ensure the quality and integrity of the product.

Learn More: Silicone Leather Guide

4. How is traditional leather made?

From the beginning of the fur acquisition, the hair removal process must first be carried out to remove the hair on the skin to form a blue wet skin. The blue skin is then sorted and divided into different layers as needed. After that, the skin is re-tanned and dried on a plate to form a skin embryo.

In this process, tanning is a very critical step, which determines the softness, wear resistance and stability of the leather. After the skin embryo is formed, it is also coated and processed, and through various processes, it finally becomes the finished leather we see. After finishing, the leather should also be inspected and controlled to ensure that the quality meets the requirements.

5. What is the property of silicone leather?

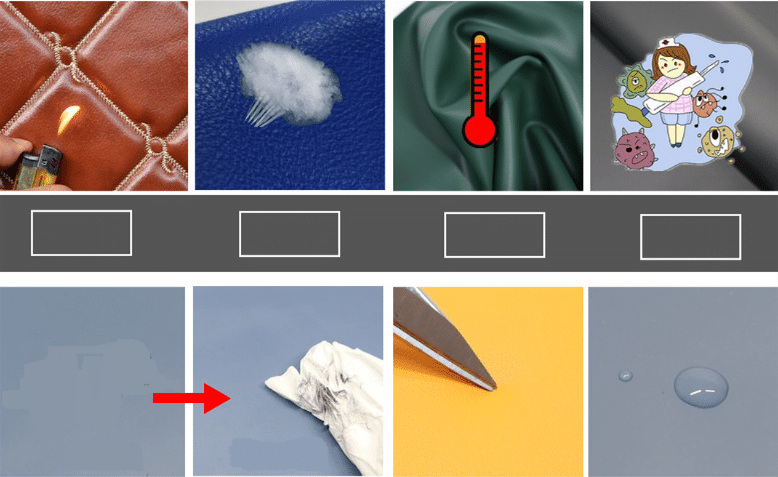

- Hydrolysis resistance: Silicone leather has a strong hydrolysis resistance, after more than 10 weeks of testing (temperature 70±2℃, humidity 95±5%), the leather surface has no sticky, shiny or brittle degradation phenomenon.

- Waterproof: Silicone leather has excellent waterproof properties, water molecules can not pass through the surface, the surface of the water will not penetrate under the bottom cloth.

- Antifouling: Silicone leather waterproof and antifouling, wipe directly with water to remove surface stains, such as ball-bead handwriting, iodophor, oil stains.

- Abrasion resistant: Silicone leather appearance scratch resistant, strong, no skin, wear resistance.

- Thermostability: Silicone leather can not be deformed in a high temperature environment of up to 280 °C, and still maintain the original feel.

- Antibacterial and mildew proof: Silicone leather is insoluble in water and any solvent, non-toxic and tasteless, can inhibit mold growth.

- Environmental protection: The production process and use of silicone leather are green environmental protection products, using solvo-free technology, in line with environmental protection standards.

6. What is the property of traditional leather?

Durability and toughness: Leather materials are known for their excellent wear resistance and toughness, which can withstand long periods of use without losing their texture and beauty, and are suitable for design products requiring high durability.

Texture and aesthetics: Leather has a natural texture and tone, and each piece of leather is unique. This unique texture and visual effect make leather the perfect choice to give products a sense of luxury and premium.

Air permeability and comfort: The natural breathability of leather makes it possible to adjust the temperature and humidity during use, bringing a comfortable use experience. This property has made leather popular in clothing and furniture design.

Plasticity and machinability: Leather has good plasticity, through embossing, dyeing, engraving and other processing technology, to achieve a variety of design effects to meet different design needs.

Water is not easy to deform, dry is not easy to shrink, chemical agents and anti-aging: These characteristics allow leather to maintain good physical properties in a variety of environments.

High tensile strength, good wear resistance: For example, cowhide has small pores, fine grain surface, thin surface, large tensile strength, uniform thickness in each part, small difference in parts, and high utilization rate.

7. What is the appearance and texture of silicone leather?

Appearance: Silicone leather usually presents a smooth, delicate appearance, bright colors and does not fade easily. Its surface is easy to clean, not easy to absorb dust and stains.

Texture: The silicone leather feels soft and smooth, has a certain elasticity, can bounce back quickly after pressing, and will not leave obvious marks. High quality silica gel skin color uniform natural, full and pure color, smooth and delicate surface, no obvious color difference, color spots or fading phenomenon.

8. What does traditional leather look like and feel like?

Appearance: The surface of real leather has clear pores and patterns, which is one of the key features that distinguish it from other materials.

Texture: The surface of real leather is smooth, soft, full and elastic, while artificial leather feels astringent, rigid and poor softness. For example, cowhide is firm and elastic, while sheepskin is softer and comfortable to wear. The surface of real leather is smooth, soft, full and elastic, while artificial leather feels astringent, rigid and poor softness. For example, cowhide is firm and elastic, while sheepskin is softer and comfortable to wear.

9. What is the cost effectiveness of silicone leather?

Cost: The raw material cost of silicone leather is high, which directly leads to its high market price, especially high-quality silicone leather, the price may be much higher than ordinary leather.

Benefit aspect: Silicone leather has the characteristics of safety and environmental protection, strong weather resistance, good waterproof performance, soft feel, etc., the application field is extremely wide, can meet the needs of different industries, and promote the development of silicone leather industry.

10. What is the cost effectiveness of traditional leather?

Cost aspect: The raw material animal fur itself is more expensive and is affected by animal protection and environmental protection policies. In the processing process, it is necessary to go through multiple processes, the production efficiency is relatively low, and skilled technical workers are required to operate, which increases the cost. In addition, equipment acquisition and maintenance, environmental protection investment is also a cost item that cannot be ignored.

Benefit aspect: Traditional leather has a high added value in the market due to its excellent physical properties and unique natural texture. At the same time, leather products are also a symbol of culture, identity and taste, which can meet the diverse needs of consumers.

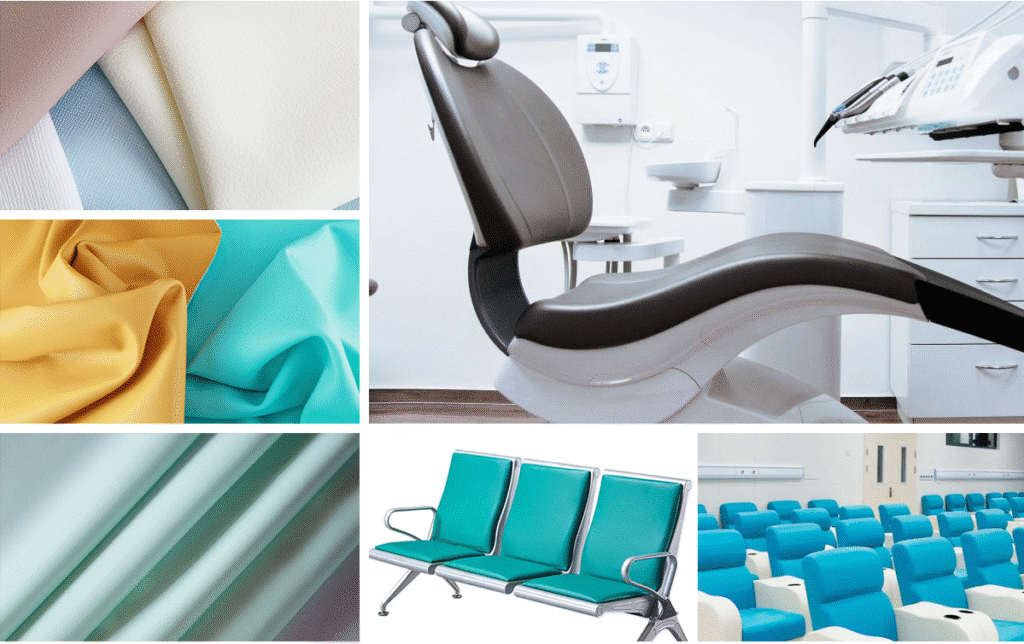

11. When to use silicone leather?

Children product: Silicone leather has reached the United States Food and Drug Inspection Administration food grade standards, suitable for children’s toys, children’s furniture and child seats and other products, because of its safety and non-toxic, you can rest assured to use.

Medical products: Silicone leather has the characteristics of anti-mold, anti-bacterial, wear and stain resistance, suitable for medical beds, seats, ward interiors and other medical equipment, can meet the high standard of medical environment requirements.

Outdoor furniture and yachts: Silicone leather has the properties of salt spray resistance, anti-fouling, weather resistance, hydrolysis resistance and UV resistance, and is widely used in outdoor furniture such as yachts, open-air sofas and tables and chairs.

Residential and office furniture: Silicone leather wear-resistant, anti-UV, anti-acid and anti-mildew, suitable for bed, sofa, chair and indoor soft clothing series, to provide a comfortable home environment.

Automobile: Silicone leather with hydrolysis resistance, anti-fouling, environmental protection, odorless and flame retardant characteristics, widely used in automotive cockpit, to meet the needs of high-end customers.

Shoes, bags and clothing: Silicone leather has the characteristics of easy adhesion, wear-resistant, light, breathable and anti-fouling, suitable for shoes, bags and clothing, fashion, beautiful and practical.

More About silicone leather

12. When to use traditional leather?

- Clothing: Traditional leather is often used to make high-end clothing, such as leather jackets, leather pants, etc., and is popular for its durability and fashion sense.

- Footwear: Leather footwear is one of the main application areas of traditional leather and is popular for its comfort and durability.

- Furniture: Leather furniture, such as sofas and chairs, is widely used because of its luxury and easy to clean characteristics.

- Automotive trim: Commonly used leather materials such as car seats and interior panels provide a comfortable ride experience and a sense of luxury.

- Sports goods: Such as saddles, riding crop and other equestrian supplies, as well as some high-end sports equipment.

- Other: It also includes bags, gloves, purses and other everyday items.

Conclusion

In the field of fashion and furniture, leather materials are widely used. Among them, silicone leather and ordinary leather are two common leather types. They differ in appearance, performance, and purpose. If you need a leather material that is durable, easy to clean and beautiful, silicone leather is a good choice. Ordinary leather is also an affordable option for those on a limited budget or with low performance requirements. At the same time, understanding the characteristics and application scenarios of different types of leather helps to better play their advantages and bring more convenience and comfort to our life and work.

Silicone leather performs well in terms of safety, weather resistance, waterproof performance and environmental protection.

Z.S.R silicone leather series provides high design freedom with a wide variety of tailored options in colors, textures, and fabric. We work with the waterproof product development manager, product designer, product manager together designs and make the custom synetics silicone leather to fit the waterproof product’s needs.

Contact Z.S.R silicone to get your own needed silicone leather for your products now.

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.