The Difference Between Full Silicone Leather and Semi Silicone Leather

1. What Is Full Silicone Leather

Full silicone leather is a synthetic material consisting of silicone rubber and coating material, made primarily of 100% silicone polymer, usually with a fabric base. It has a variety of excellent properties, including wear resistance and scratch resistance, anti-fouling and waterproof, yellowing resistance, corrosion resistance, aging resistance, high and low temperature resistance.

The raw material of the whole silicone leather is food-grade liquid silicone rubber, which meets the standards for infants and children, has good biocompatibility and low cytotoxicity, and is suitable for the medical field.

More than 10 years, Z.S.R Group offer the Custom silicone leather service with the custom silicone leather Base fabric layer, color, texture, application, sizes, thickness, custom silicone leather logo, printing, pattern, brand, package and other silicone products technical support to the baby, Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronic, Upholstery industry.

2. What Is Semi-Silicone Leather

Semi-silicone leather is a kind of leather which is coated with a thin silicone coating on the surface of solvent-free PU leather. This leather does not belong to silicone leather in a strict sense, but belongs to a kind of PU leather.

Semi-silicone leather is coated with silicone layer on the surface of PU leather, so that it has the characteristics of scratch resistance, flame retardant, easy to clean, but after a period of use may appear powder, color change and other problems.

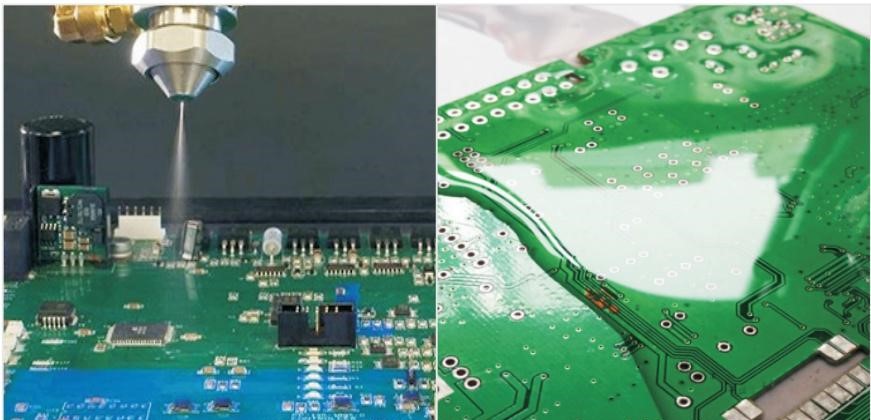

3. How Is Full Silicone Leather Processed

The processing process of full silicone leather mainly includes the following steps:

Material preparation: Select the appropriate substrate and silicone material. Commonly used substrates include polyester fiber, polyurethane foam, artificial leather, etc. These substrates should have good softness and breathability. Silicone materials can choose polydimethylsiloxane, polymethyl siloxane, etc., they have excellent heat resistance, cold resistance, aging resistance.

Mix and stir: The silicone resin and solvent are mixed to form a uniform solution. This step requires strict control of the mixing ratio and stirring time to ensure the stability and uniformity of the solution. The choice of solvent is also crucial, it should have good solubility and volatility, in order to quickly volatilize in the subsequent drying and curing process.

Molding: The mixed silicone solution is uniformly poured onto the prepared substrate to form a uniform film. This step requires precise control of the pouring volume and uniformity to ensure the thickness and appearance quality of the leather. After pouring, the substrate is sent to the curing chamber for curing reaction.

Curing reaction: During the curing process, the solvent in the silicon solution gradually volatilizes, and the silicone resin cross-links to form a strong and soft leather. Curing temperature and time have an important effect on the properties of leather, so the curing conditions need to be precisely controlled.

Surface treatment: Steps such as sanding, finishing and cleaning are included to improve the appearance quality and feel of the leather. Sanding removes imperfections and unevenness from the leather surface, trimming makes the leather flatter and smoother, and cleaning steps remove stains and dust from the leather surface in preparation for subsequent finishing and finishing.

Finish and finish: Finishing can give the leather rich color and luster, while increasing the waterproof and anti-fouling properties of the leather. Finishing includes softening, stretching, styling and other steps to make the leather softer, more comfortable and durable.

Finished leather cutting: The finished and finished leather is cut according to the requirements, and the finished product meets the requirements of size and shape.

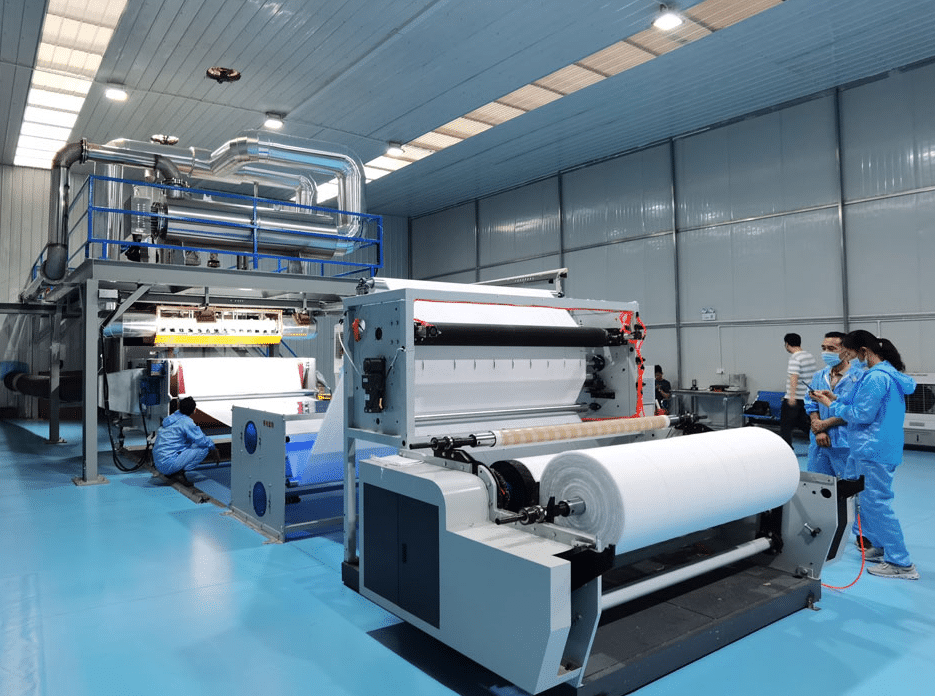

Silicone Fabric Coating And Curing

4. How Is Semi-Silicone Leather Processed

Semi-silicone leather is formed by coating an organic silicon layer on a synthetic leather base. The specific processing process is as follows:

Basic material preparation: First of all, it is necessary to prepare the Base of synthetic leather, which is generally composed of a surface layer, foaming layer and bonding layer, and is a semi-finished product formed by coating the polyurethane foaming layer and bonding layer on the base cloth.

Coated with silicone layer: On the basis of synthetic leather base, a layer of organosilicon is coated to form semi-silicon leather. This layer of silicone surface layer and the interface bonding layer constitute A semi-silicon coating, and the layer resin contains two components A and B, which need to be mixed evenly according to measurement before use.

Process technology: Due to the difference in surface tension, it is difficult to bond silicone layer and polyurethane foam layer, so it is necessary to use interface adhesives to achieve high strength bonding between silicon layer and polyurethane layer. This step has certain requirements for processing technology and technology.

Subsequent processing: After the silicone layer is coated, a series of subsequent treatments, such as foaming and embossing, may also be required to give the coating good foaming and embossing effects, and meet the specific needs of use.

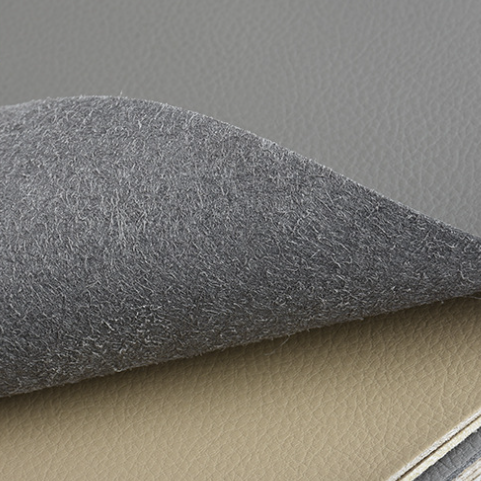

5. What Is the Appearance and Texture of All Silicone Leather

Appearance: The appearance of all silicone leather is usually more uniform, the texture is better, the surface is smooth and there is no obvious uneven feeling. Its color is uniform and natural, full and pure color, smooth and delicate surface, no obvious color difference, color spots or fading.

Texture:

- Touch: Full silicone leather texture is soft, comfortable to feel, with a certain degree of elasticity and stretch, feel similar to “meat”.

- Waterproofness: Full silicone leather has a high waterproof performance and feels smooth and tender.

- Smell: Real full-silicone leather does not emit a pungent odor, but has a slight silicone smell.

6. What Is the Appearance and Texture of Semi-Silicone Leather

Appearance: The surface of semi-silicone leather usually has a certain gloss, and the color is more bright. Its appearance may not be as uniform as full silicone leather, and the texture is relatively poor.

Texture: Semi-silicone leather feels hard, has good elasticity and can bounce back. However, after a period of use, its easy to clean characteristics may disappear, and even appear powder, color change and other phenomena.

7. What Are the Properties of All Silicone Leather

Wear and scratch resistance: After Martindale testing, the full-silicone leather has a wear resistance of up to 50,000 times, showing strong wear resistance and scratch resistance.

Antifouling and waterproof: It has natural anti-fouling and waterproof properties for common stains, and can be removed with a wipe, making it very easy to clean.

Resistant to yellowing and corrosion: No color change within 24 hours, strong corrosion resistance, can maintain long-term beauty and stability.

Ageing resistant: After 72 hours at 100 °C, there is no change, excellent aging resistance, and can resist the damage of high temperature environment.

Anti-high and low temperature: No surface rupture at temperature difference of 300° to -30°, strong adaptability, can be used in extreme temperature conditions.

Biocompatibility: It has good biocompatibility, low cytotoxicity, meets the standards in the medical field, and is safe and non-toxic.

Hand feel and drape: The surface texture of all silicone leather is soft, comfortable to feel, good elasticity and strong plasticity, which provides designers with rich creative inspiration.

Environmental protection property: The production process and use are green environmental protection products, and harmful gases will not be released when burned.

In addition, the full silicone leather also has the advantages of skin-friendly antibacterial, mildew proof, acid, alkali and salt resistance, light resistance, heat aging, bending resistance, toxicity elimination, color fastness and so on. These excellent properties make full silicone leather have a wide range of application prospects in many fields.

|

Comparison Item |

Silicone Leather |

Genuine Leather |

PVC Artificial Leather |

PU Synthetic Leather |

Microfiber PU Leather |

|---|---|---|---|---|---|

|

Primary Raw Material |

Non-woven fabric, etc. |

Pigskin, cowhide, sheepskin, etc. |

PVC resin, non-woven fabric |

Knitted/woven fabrics |

PU resin, microfiber non-woven, etc. |

|

Surface Texture |

Fine |

Fine |

Average |

Good |

Fine |

|

Feel & Elasticity |

Good |

Good |

Poor |

Poor |

Good |

|

Color/Pattern Options |

Extensive |

Limited |

Limited |

Extensive |

Limited |

|

Manufacturing Process |

Dry process |

Tanning & Nitrification |

Dry process |

Wet + Dry process |

Microfiber weaving + Wet + Reduction + Dry process |

|

Lifespan |

5-15 years |

5-10 years |

2-5 years |

2-5 years |

2-10 years |

|

Price (m2) |

80-300 |

150-300 |

6-15 |

7-25 |

50-100 |

|

Eco-Friendliness – Production |

Eco-friendly materials, zero pollution |

Pollution-free |

Severe auxiliary material pollution |

Moderate pollution |

Better than traditional artificial leather |

|

Eco-Friendliness – Safety |

Safe |

Relatively safe |

Hazardous |

Relatively safe |

Fixed pollution (benzene reduction) |

|

Eco-Friendliness – Properties |

Recyclable |

Biodegradable |

Degradation-resistant |

Degradation-resistant |

Biodegradable |

|

Eco-Friendliness – Disposal |

Easy |

Easy |

Moderate difficulty |

Moderate difficulty |

Moderate difficulty |

More About silicone leather

8. What Are the Properties of Semi-Silicone Leather

Material and construction: Semi-silicone leather is made of PU leather as a base cloth, on which a thin layer of silicone coating is applied. This structure allows it to temporarily possess some of the characteristics of silicone leather.

Scratch resistance, flame retardant, easy to clean: Thanks to the silicone coating on the surface, semi-silicone leather is scratch-resistant, flame retardant and easy to clean. However, these properties may disappear after a period of use due to powder dropping.

Limitations of wear resistance, weather resistance and environmental protection: Because its base material is PU leather, semi-silica gel leather may have certain shortcomings in terms of wear resistance, weather resistance and environmental protection. After a long time of use, there may be problems such as color change and loss of easy cleaning properties.

High-temperature resistance: Semi-silica gel can generally only withstand high temperatures of about 150 °C, compared to full silica gel skin (usually can be used at high temperatures of 300 °C), its high temperature resistance is low.

Chemical stability: Semi-silica gel is relatively easy to react with external chemicals, and the chemical stability is not as good as that of full silica gel skin.

In general, the performance of semi-silicone leather combines the characteristics of silicone and PU leather to a certain extent, but its performance may change in long-term use and under specific environments.

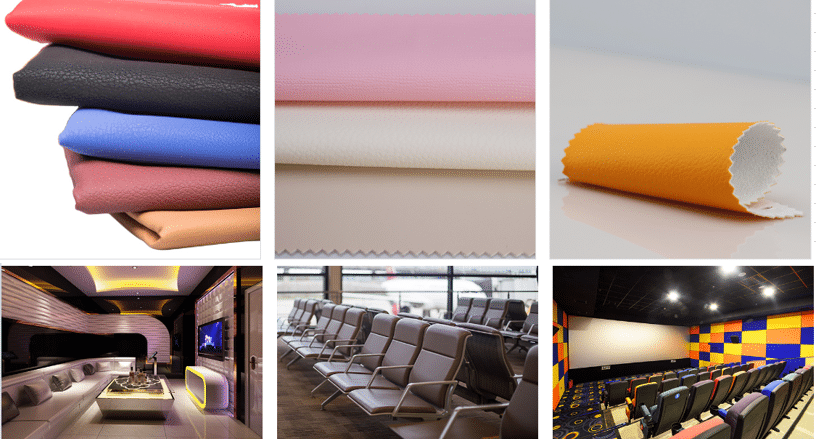

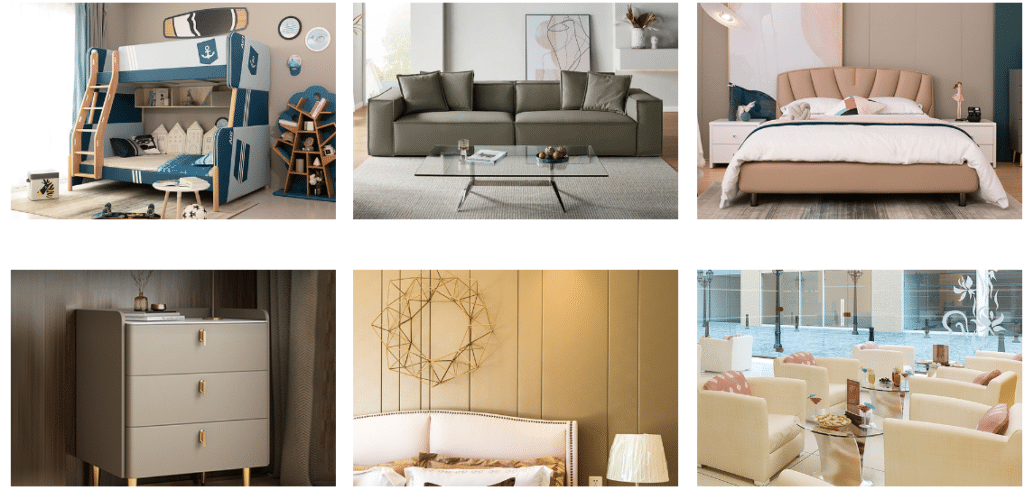

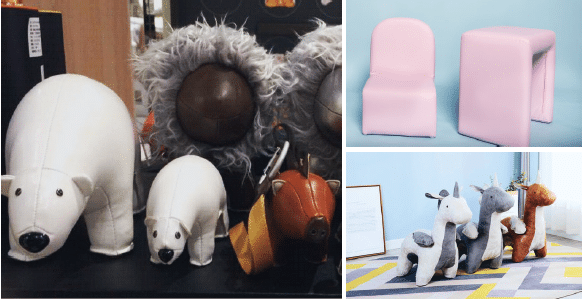

9. What Are the Application Areas of All Silicone Leather

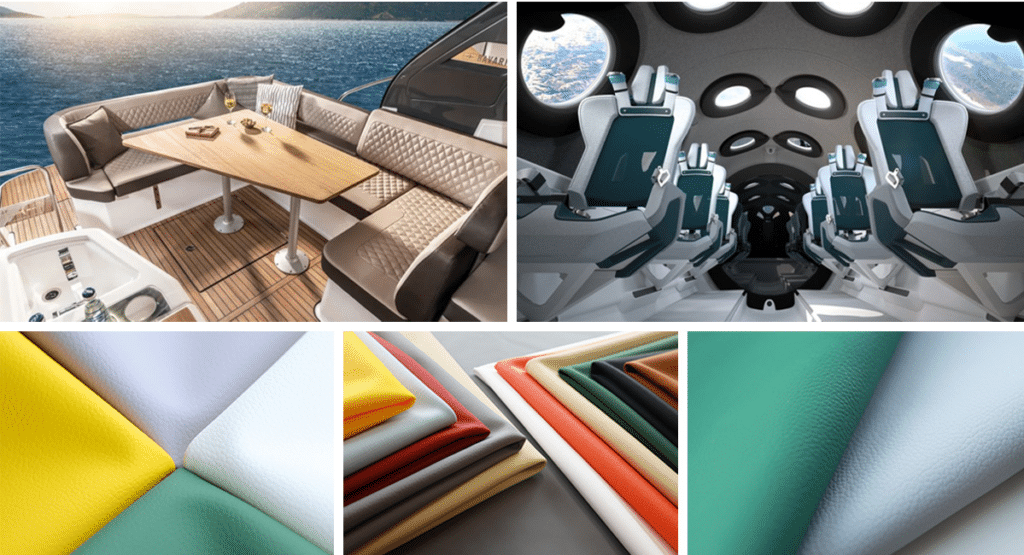

Automotive Upholstery: Because of its waterproof, wear-resistant, anti-fouling and easy to clean characteristics, silica gel leather is widely used in automotive interior, such as seat, door panel, steering wheel and other parts, not only improve the interior grade sense, but also improve the comfort of the driver.

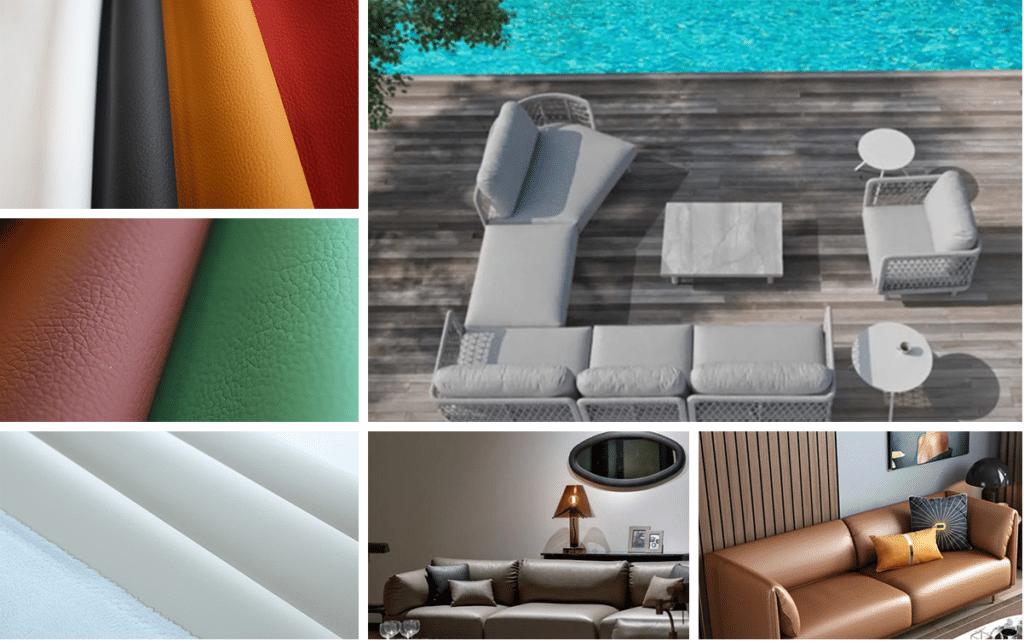

Home decoration: In the field of home, all silicone leather is used to make sofas, chairs, bedding, etc., because of its waterproof, easy to clean and beautiful characteristics, it can effectively protect furniture and extend the service life.

Fashion Industry: The softness and texture of all-silicone leather has made it a popular material in the fashion industry and can be used to make fashion accessories such as clothing, footwear and handbags. Its water resistance and wear resistance are particularly suitable for outdoor sports clothing and footwear.

Medical and heather care: Full silicone leather with low sensitivity and cleanability, widely used in medical devices and medical auxiliary equipment, such as gloves, infusion tubes, etc., to ensure the safety and comfort of patients.

Industrial use: Due to its high temperature resistance, weather resistance and chemical resistance, full silicone leather is used in the industry to make seals, pipes, conveyor belts, etc., which can play an excellent performance in harsh industrial environments.

Other application areas: Full silicone leather is also used in luggage, yacht decoration, architectural decoration, flexible packaging and other fields. Its environmental protection, ease of processing and high functional characteristics make it excellent in these fields.

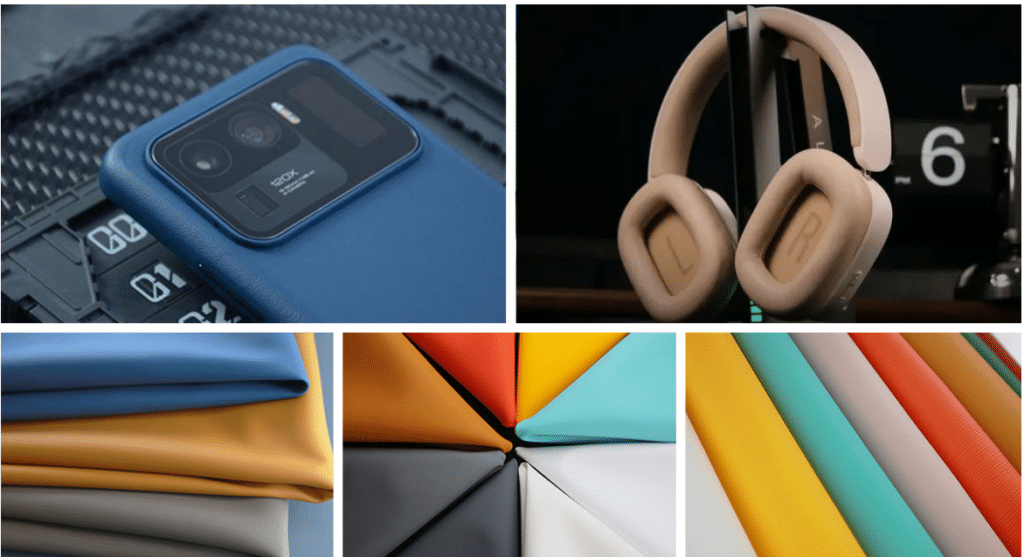

Z.S.R Group use the silicone fabric coating and curing process make the silicone leather. Z.S.R Silicone leather is becoming popular n Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronics, Handbags, Baby products, etc.

10. What Are the Application Areas of Semi-Silicone Leather

Furniture industry: Semi-silicone leather is widely used in furniture industry. Because of its wear-resistant, easy to clean and other characteristics, it can be used to make sofa, chair and other furniture packaging. In addition, the environmental performance of semi-silicone leather also meets the requirements of modern furniture environmental protection and is favored by consumers.

Automotive trim: In terms of automotive interior, semi-silicone leather is often used for car seats, instrument panels, door panels and other parts of the package due to its realistic appearance, comfortable feel, wear resistance, dirt resistance and other characteristics, to improve the grade and quality of automotive interior.

Footwear industry: Semi-silicone leather also has great application potential in the footwear industry. It has better air permeability and comfort, suitable for the production of sports shoes, casual shoes and other types of shoes. At the same time, its appearance and feel also make it an ideal material for high-end shoes.

Bags and Accessories: The texture and realistic appearance of semi-silicone leather make it an ideal material for making bags and accessories. Whether it is handbags, backpacks, wallets, watch bands and other accessories, semi-silicone leather can provide high-quality touch and visual effects.

Household supplies: Semi-silicone leather can be used to make all kinds of household goods, such as table cloth, bed products, curtains and so on. Its wear resistance, dirt resistance and other properties make household items more durable, while rich color and texture can also add fashion and comfort to the home environment.

Clothing industry: Semi-silicone leather can also be used in the design and production of clothing industry, such as coats, skirts and other clothing, to bring comfortable texture and fashion appearance.

Medical supplies: Semi-silicone leather has the characteristics of wear-resistant and easy to clean, so it is also widely used in medical supplies. For example, it can be used for medical mattresses, operating tables, etc., to provide a better use experience and health environment.

Appliance: Semi-silicone leather can be used to make office supplies, such as folders, pen cases, etc. Its refined appearance and comfortable feel add a professional and high-quality feel to the office scene.

Travel accessories: The wear and stain resistance of semi-silicone leather make it an ideal material for travel supplies. For example, it can be used to make suitcases, travel bags, etc., to provide better use experience and lasting performance.

Household appliance industry: Semi-silicone leather can also be applied to the home appliance industry, such as television, audio and other peripheral equipment packaging. Its realistic appearance and texture add upscale feel to home appliances.

Conclusion

The difference between semi-silicone skin and full silicone skin is the composition and scope of use of silicone. Semi-silicone skin is a mixture of silicone and other materials, usually used to make mobile phone cases, computer protective cases and so on. The full-silicone skin is made of 100% silicone and is often used to make kitchen utensils, baby products and so on. In general, full silicone leather and semi-silicone leather have their own characteristics and advantages, which material to choose depends on the specific application needs and scenarios. In the future development, with the continuous progress of science and technology and the diversification of application needs, the application field of silicone leather will be more extensive and in-depth.

Z.S.R team work with the different industry product fabric selection designers, product developer, R&D engineer, product manager together designs and make the Silicone leather fabric in an assortment of tear strength, hydrolysis resistance, waterproof and stain resistant ,Wear resistant and scratch resistant ,Heat/Cold temperature resistance, base layer, colors and texture to empower them automotive interior, furniture, luggage ,fashion, medical device, Upholstery and other industry product’s project success in design and functional requirements.

Contact Z.S.R to custom the different silicone leather to fit your projects.

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.