How to Change the Color of Silicone

If you’re looking for ways to change the color of your silicone, you’ve come to the right place. In this blog post, we’ll explore how to change the color of silicone using three different methods.

Although pure-color silicone is practical, there are more and more demands for customization, such as baby products, decorative pieces, industrial signs or handicrafts, which often require specific colors or gradient effects. Compared with plastic post-spraying, silicone has its own unique challenges: it is insoluble in water, resistant to high temperatures, and requires a suitable color fixing method and pigment formula.

First, we’ll look at how to change the color of silicone by adding dye to it.

Next, we’ll discuss how to change the color of silicone by adding pigment to it.

Finally, we’ll talk about how to change the color of silicone by using a heat gun. So if you’re ready to learn how to change the color of your silicone, read on!

What is silicone coloring?

Silicone coloring requires adding special pigments to liquid silicone before curing, including silicone pigment powder, color paste (color paste), and liquid dye. After addition, it is fully mixed with the main agent and has a uniform color after curing. Different coloring methods (internal dyeing vs. surface dyeing) have a significant impact on performance and cost.

Silicone coloring is a process of changing the color of silicone products by adding colorants, mainly using the mixing method to evenly mix the colorants into the silicone.

Common coloring methods

Mixing method is the current mainstream process, including dry powder coloring, color paste coloring, granular coloring and masterbatch coloring:

Dry powder coloring: Mix the powdered colorant with the small material and add it to the rubber compound, and mix it through a rubber mixer. It is low in cost but easy to cause dust pollution and uneven dispersion.

Color paste coloring: Mix the colorant with a liquid compounding agent (such as a plasticizer) to make a paste and add it to the rubber compound, which can reduce dust pollution and improve dispersibility.

Pellet coloring: The colorant is made into granules and then added to the rubber material, which is evenly dispersed and avoids pollution, but the process is complicated and the cost is high.

Masterbatch coloring: Use special silicone masterbatch or master paste to add directly to the rubber material, which is easy to operate and has stable color.Masterbatch/color paste addition : Add special masterbatch or color paste during the refining (activating the activity of silica gel) stage, and mix a variety of colors through the three primary colors (red, green, and blue).

Color paste method: Mix the color paste with liquid compounding agent and add silica gel, grind it into a paste with a three-roller machine, and then mix it to avoid dust pollution.The color uniformity is good, but the transportation loss is large.

Granular carbon powder treated with surfactants is evenly dispersed and dust-free, suitable for high-precision color matching.

Special process: Use non-contact inkjet technology to directly spray patterns on the surface of silica gel, which is suitable for personalized coloring needs of high-temperature treated products.

Spray painting: Spray special paint directly on the surface of the finished product, suitable for large products

Silicone Basics

Silicone itself has a relatively single color, but it can be mixed into a variety of colors (such as transparent, milky white, light yellow, gray, etc.) by adding masterbatch or dye. Common colors of ordinary silicone include translucent, milky white, light yellow and gray, among which translucent and milky white are common base colors.

Why color silicone?

Enhance visual performance: brand recognition, distinguish product types or brands through different colors, enhance market competitiveness, emotional expression, functional prompts.

Functional coating: specific colors can enhance product functionality, such as electronic accessories need to use specific color identification to distinguish interfaces, such as fire protection signs, dental hue simulation, toy colors;

Increase added value: customized products are more popular with users.

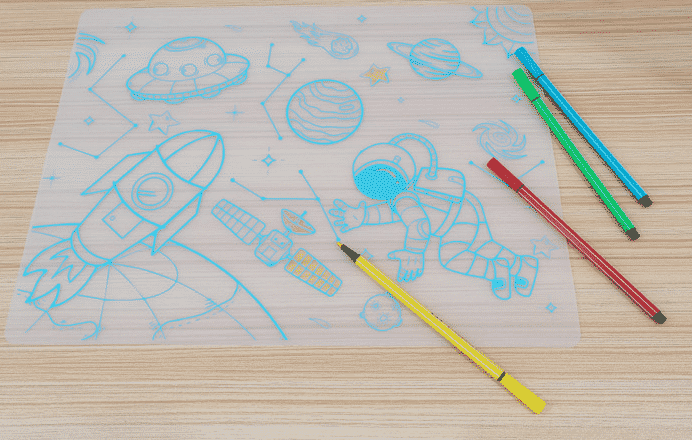

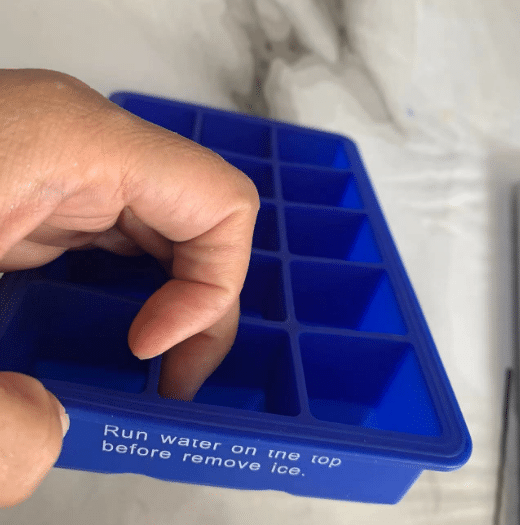

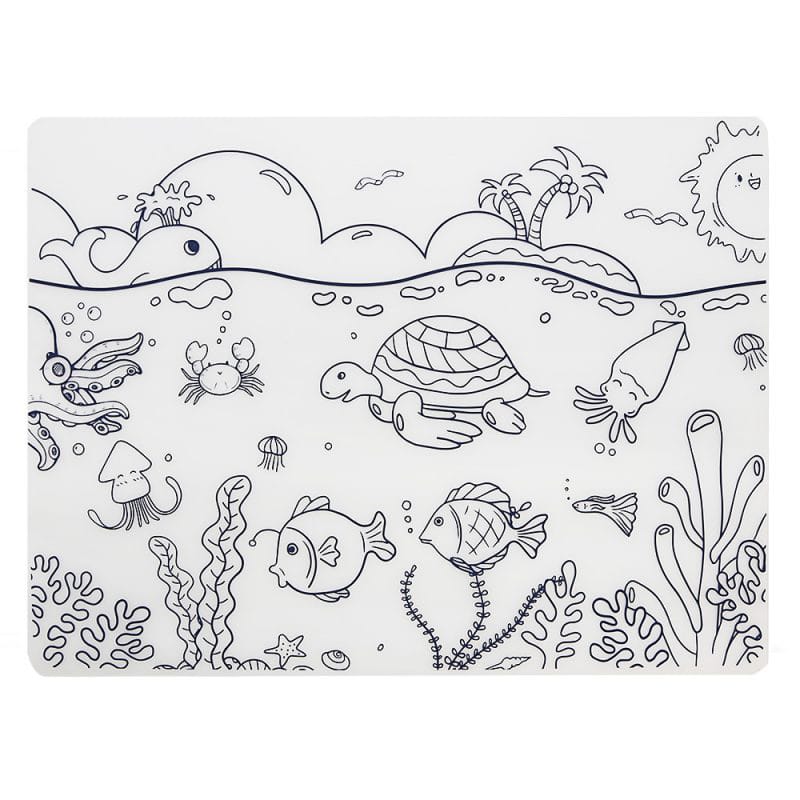

Silicone coloring is mainly used to enhance the appearance of products and meet diverse market needs. Daily necessities (such as kitchenware, daily necessities, gifts) enhance visual appeal through colorful designs .

When it comes to choosing the right silicone for your project, one of the most important factors to consider is its color. While some silicones are available in a variety of colors, others are only available in clear or white. Luckily, there are a few ways you can change the color of silicone, depending on your needs.

The mixing method is the most commonly used method for coloring silicone products. The coloring agent is directly added or mixed with the carrier before adding it to the rubber material, and then mixed evenly through a rubber mixer to color the silicone rubber.

Dry powder coloring is to directly add the powdered coloring agent together with the small material into the silicone rubber and mix it on an open mixer. This method is simple to operate and low in cost, but it produces a lot of dust during mixing, pollutes the environment, and is not easy to disperse evenly. There is a color difference. If the particles are too hard and too coarse, it will also cause quality problems such as color spots, stripes or color spectrum contamination.

Color paste coloring is to first mix the coloring agent with the liquid compounding agent, grind it into a paste or slurry with a three-roll mill, and then add it to the silicone rubber in a certain proportion for mixing.

One way to change the color of silicone is to add a pigment or dye to it. This is typically done during the manufacturing process, but can also be done at home with some special supplies. Adding pigment or dye will give the silicone a permanent color change that will not wash away or fade over time. See this blog to know more information:

How To Get The Colorful Silicone Products?

You can get multi color and double color silicone products by mixed silicone rubber material or co-injection molding.

Another way to change the color of silicone is by painting it. This method is ideal for small projects where you want to add a pop of color, or for changing the color of an existing piece of silicone.

When painting silicone, it’s important to use a paint that is specifically designed for use on rubber and plastics – regular paint will not adhere well and may even damage the surface.

Spray printing: You also can use a spray paint designed for rubber and silicone. Regular spray paint may not adhere well to silicone surfaces and may even damage the surface. You can use screen printing, pad printing, heat transfer printing, water transfer printing to change the color of the silicone products. See the silicone phone case pattern printing way to get more about the printing ways.

Who would like to change the color of silicone?

DIY handmade enthusiasts, handicraft players;

SFX & film and television props makers;

Industrial designers, medical equipment engineers;

Intellectual property brands (such as baby, kitchen and bathroom appliances);

OEM/ODM manufacturers hope to provide color customization services.

Finally, if you need to change the color of large areas of silicone, you can always opt for vinyl wraps. Vinyl wraps come in a variety of colors and patterns and can be applied directly over top of existing silicone surfaces. This is an easy and relatively inexpensive way to completely transform the look of your project – just make sure you choose a wrap that is compatible with silicone!

Where would you like to change the color of silicone?

Baby silicone products and toys (pacifiers, teethers).With the different color and cute color to interest the babies.

Medical equipment :simulated skin color, classification color, etc.

Crafts mobile phone cases, candle molds to get mor colorful to Decorate your life.

Industrial use :red flag identification, sealing ring coloring to let you assembly the parts easily.

The Different Colors of Silicone

Have you ever wondered why silicone comes in so many different colors? The truth is, the different colors of silicone serve a variety of purposes. Here are the most common colors of silicone and what they’re used for.

Clear Silicone: Clear silicone is the most versatile type of silicone. It can be used for a variety of applications, including seals, gaskets, and adhesives.

White Silicone: White silicone is commonly used for food-grade applications. It’s also often used as an electrical insulator.

Red Silicone: Red silicone is often used in medical applications due to its ability to resist blood and bodily fluids.

Black Silicone: Black silicone is often used in industrial applications where high temperatures are a concern. It’s also UV resistant, making it ideal for outdoor use.

How to Change the Color of Silicone ?

Color powder/pigment: such as dry powder mica, color fast, need to be evenly ground, suitable for light colors

Special color paste for silicone: high concentration, suitable for industry and precise color matching

Oil paint/acrylic: community recommended oil painting, small amount is suitable for soft colors; acrylic needs to be added with caution

Liquid dye: evenly dispersed, transparency can be adjusted.

Operation steps

Prepare a safe environment: ventilation, wear gloves, goggles, etc.

Add pigment in proportion: 0.5%–3% is a general recommendation

Thorough mixing: stir the pigment with silicone A and B components until uniform;

Degassing: first pour a small amount into the mold, tap/vacuum degassing to reduce bubbles;

Observe curing: color powder may affect leveling or surface gloss, need to be tested.

How to change the color of silicone products?

If you want to change the color of silicone, you need to do a few things. First, you need to clean the silicone with soap and water. Next, you need to apply a thin layer of silicone primer on the surface. Once the primer is dry, you can apply a thin coat of silicone paint.

Tips for Changing the Color of Silicone

Choose the right type of silicone for your project. There are many different types of silicone, so make sure to select the one that is best suited for your needs.

Pick a color that you want to change to. You can find special dyes or pigments at most craft stores.

Follow the instructions on the dye or pigment package to mix it with the silicone. Make sure to mix it thoroughly so that the color is evenly distributed.

Apply the mixture to the silicone item that you want to change the color of. Use a brush or other applicator to ensure that it is evenly coated.

Allow the mixture to dry completely before using or wearing the silicone item.

FAQ about change the color of silicone

Q1: Can I use acrylic paint at home?

A1: A small amount of light color is OK, but too much may interfere with curing; color-proof color paste or Mica is recommended.

Q2: Can food-grade silicone be added with pigment?

A2: Yes, but make sure the pigment is food-grade and the ratio is controlled at <1%.

Q3: Will the mica glitter fall off?

A3: Use white primer to cover the glitter, which is basically stable after curing.

Q4: Can water-based color essence be used for coloring?

A4: Not recommended, water-based is not soluble in the silicone system, and the effect is unstable.

Q5: How to make gradient/two-color?

A5: Gradient effect can be achieved by batch injection, side pouring or partial mixing and then casting.

Conclusion

As long as you master some skills, changing the color of silicone is actually very simple. Color powder, color paste and oil paint/liquid dye meet different needs. There are many colors. As long as you focus on the proportion of addition, mixing uniformity, and degassing process, you can give full play to your creativity and enjoy the fun. Whether you want to show your brand fashion or just want to add a touch of bright color to your life style, changing the color of silicone is an excellent choice.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.