Silicone Leather for Ball

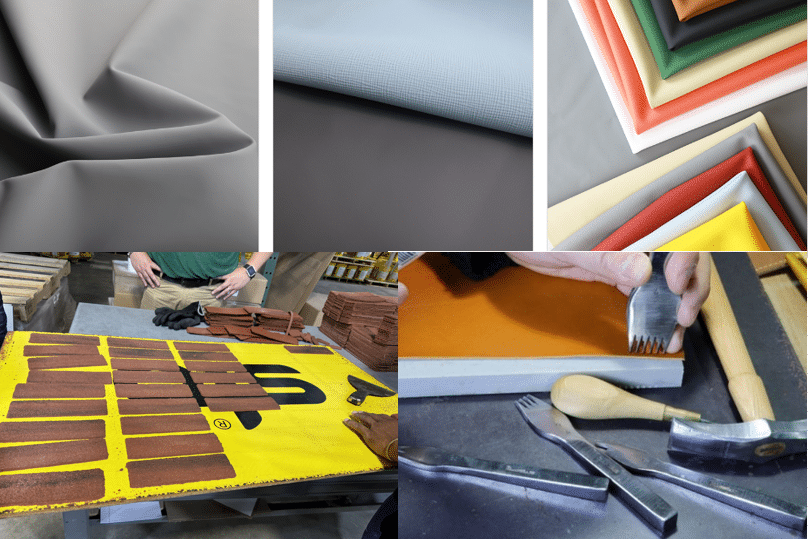

The Ball silicone leather including all kinds of artificial leather or synthetic leather for making balls for sports. Z.S.R ball leather is made of high-quality silicone vegan leather, using backing fabric layer Polyester, cotton, linen + silicone coating process to ensure its excellent durability, Wear-resistant, supportive and stain-resistant easy cleaning, environmental friendliness, and good touch and visual effects, Anti-slip performance.

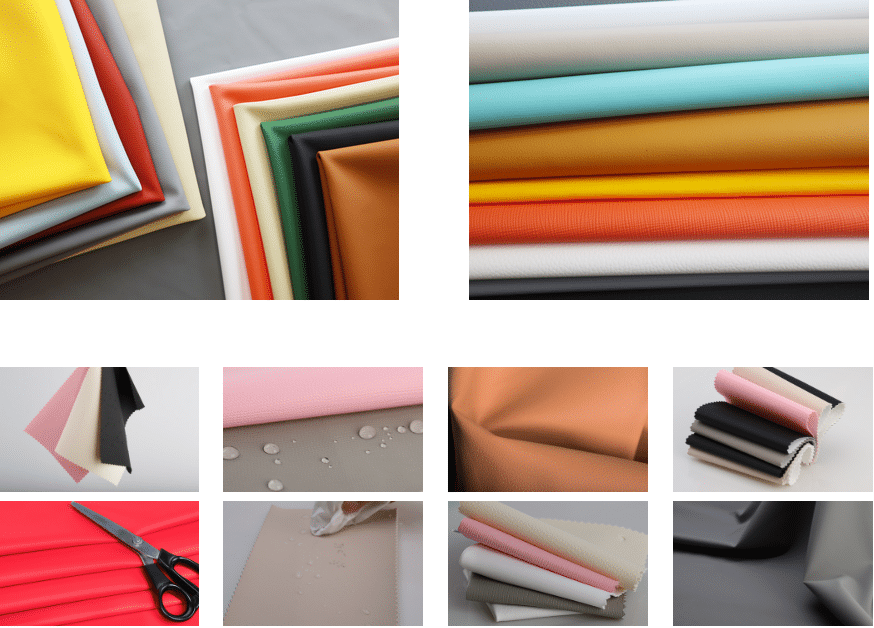

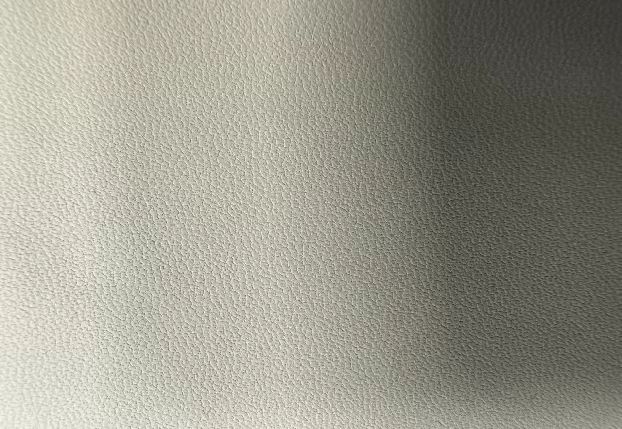

Z.S.R provide them ball silicone leather of different thickness and colors, and can cut it as required. Basketball leather: Thickness is 2.0~3.5 mm, usually dyed Brown and Red. Volleyball leather: Thickness is 1.2~1.8 mm, usually dyed white. It is recommended to use silicone leather with Lychee /Classic smooth leather/ Napa pattern according to the different types and styles of balls, the specific parameters are as follows:

|

Material |

Polyester, cotton, linen + 100% Platinum Silicone |

|

Width |

1.37-1.40 M, 54” |

|

Thickness |

1.2-1.8MM 2.0-3.5MM |

|

Texture |

Lychee /Classic smooth leather / Napa pattern or customization |

|

Color |

Brown, Black, Red, White or Customization color as the customer request |

|

Application |

Ball, Basketball, Volleyball Football |

|

MOQ |

300 m |

About this Product

Specifications & Properties

| Item | Specification / Description |

|---|---|

| Product Name | Ball silicone leather material |

| Material Composition | 100% Silicone + Polyester, cotton, linen |

| Backing Fabric Technics | Blended fabrics |

| Texture | Lychee, Classic smooth leather, Napa pattern or Customization |

| Width | 54/55” |

| Thickness | 1.2 MM – 3.5 MM |

| Weight | 900 – 1200 gsm |

| Color | Brown, black, white or Customized per request |

| Finish | Matte, glossy, textured finishes |

| Origin | China |

| MOQ | 300 Meters |

| Customization | Texture, color, backing customization available |

Performance Metrics

| Item | Specification / Description |

|---|---|

| Tensile Strength | Warp >400 N/200mm, Weft >400 N/200mm (ISO 3376) |

| Elongation at Break | Warp >15%, Weft >20% (ISO 3376) |

| Tear Strength | >60 N (ISO 3377-2) |

| Peeling Strength | >30 N/30mm (ISO 11644) |

| Bursting Strength | ≥ 1 MPa (Müller Bursting Tester) |

| Abrasion Resistance | >200,000 cycles (Martindale Wear ISO 12947) |

| Flex Resistance | RT: 700,000 cycles no crack; -10°C: 200,000 cycles no crack |

| Rub Fastness | Dry: 5,000 cycles, Wet: 500 cycles, Ethanol ≥10x, Soap ≥100x (Grade 4/5, AATCC-8) |

| Color Migration | 50±2°C, 5kg pressure × 18h: No migration |

| Blocking Resistance | 80±2°C, 10N load × 3h: Peelable by hand |

| Stain Resistance | ≥ Level 4 (Italian dressing, Lipstick, Mustard, Suntan oil, Coffee, Ketchup, Ballpoint ink, Cola, Soy sauce, etc.) |

| Heat Aging Resistance | 80±2°C, <10% RH × 24h + cooling: No degradation (Grade 4) |

| High Temp Resistance | 120°C × 168h: No surface cracks |

| Low Temp Resistance | -30°C × 24h: No surface cracks |

| Hydrolysis Resistance | 70°C, 95% RH × 10 weeks/15k cycles: No crack/discoloration (ASTM D3690) |

| Light Fastness | ≥ Grade 4 (ISO 105-B02) |

| Mildew Resistance | Excellent (ASTM G21) or Add per request |

| Anti-Yellowing | Grade 4 (QUV 200h, HG/T 3689) |

Safety & Eco Compliance

| Item | Specification / Description |

|---|---|

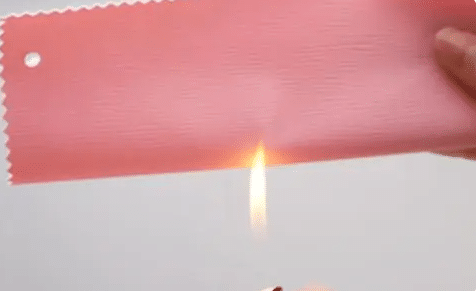

| Flame Resistance | ≤100 mm/min (FMVSS 302, CA 117) |

| Chemical Resistance | High resistance to chemicals, stains, UV |

| Odor | None |

| Waterproof | Excellent |

| Eco-Friendly | Non-toxic, PVC-free, phthalate-free, recyclable |

| Certifications | REACH, RoHS, OEKO-TEX Standard 100 compliant |

Application & Care

| Item | Specification / Description |

|---|---|

| Application | Ball leather |

| Use Case | Ball, Basketball, Volleyball, Football manufacturing |

| Storage | Cool, dry place, avoid direct sunlight |

| Cleaning | Mild soap + water; stain-resistant |

| Features | Durable, waterproof, antifouling, easy-clean, eco-friendly, premium tactile/visual |

Related information download

Benefits of Silicone Leather for Balls

Excellent durability and wear resistance: Silicone leather has extremely high wear resistance. After Martindale testing, the wear resistance is up to 50,000 times, which is excellent. This feature allows silicone leather to maintain a long service life in frequently used ball sports and reduce the frequency of replacement.

Excellent anti-slip performance: The surface of silicone leather has been specially treated to have good anti-slip performance. In slippery or greasy environments, it can still provide stable grip, ensuring that athletes can complete movements accurately and safely

Foul-proof and waterproof: This material has anti-fouling and waterproof properties, ordinary stains can be removed with a light wipe, keep clean

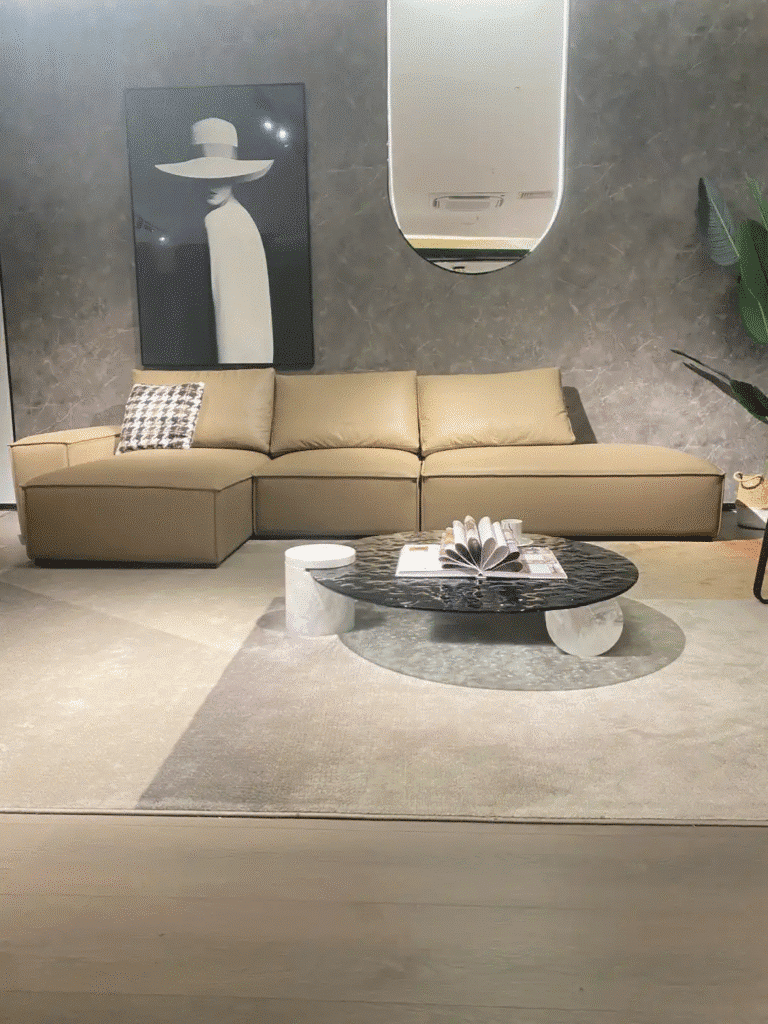

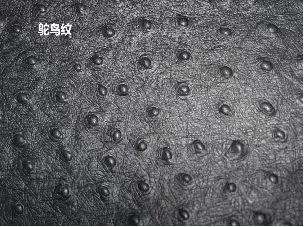

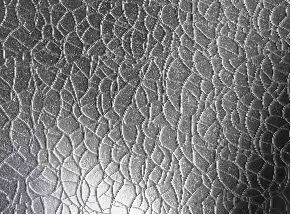

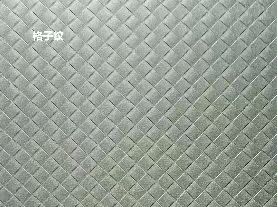

Silicone leather can imitate a variety of leather textures, including genuine leather and other imitation leather textures, so the silicone leather can adapt to different styles ball manufacturing.

Silicone leather customization details

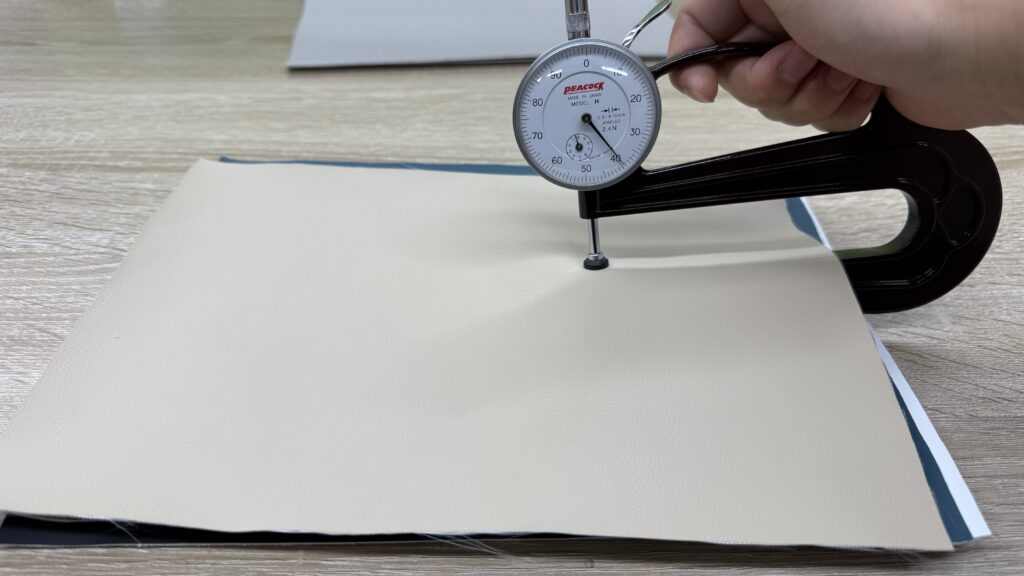

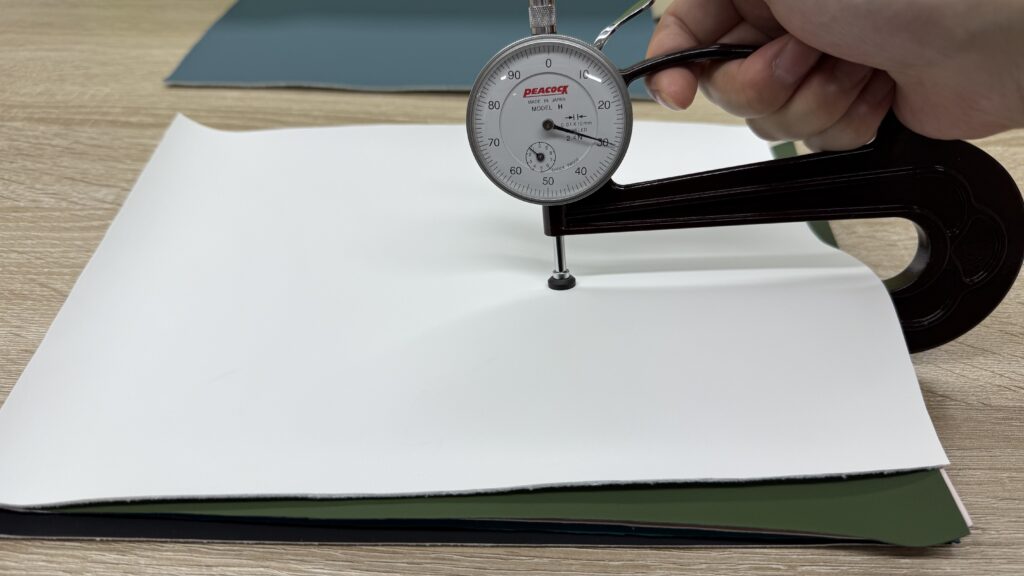

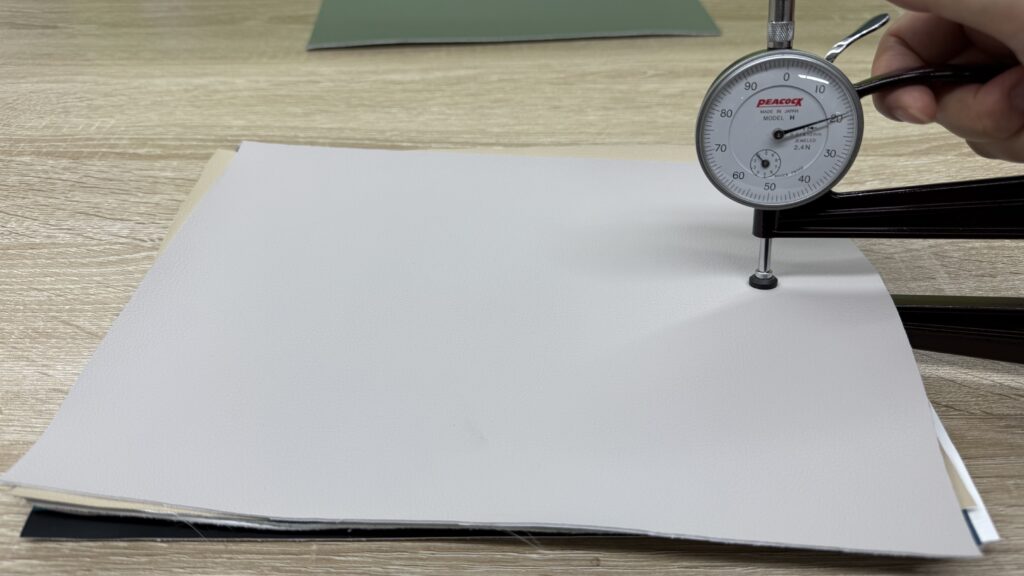

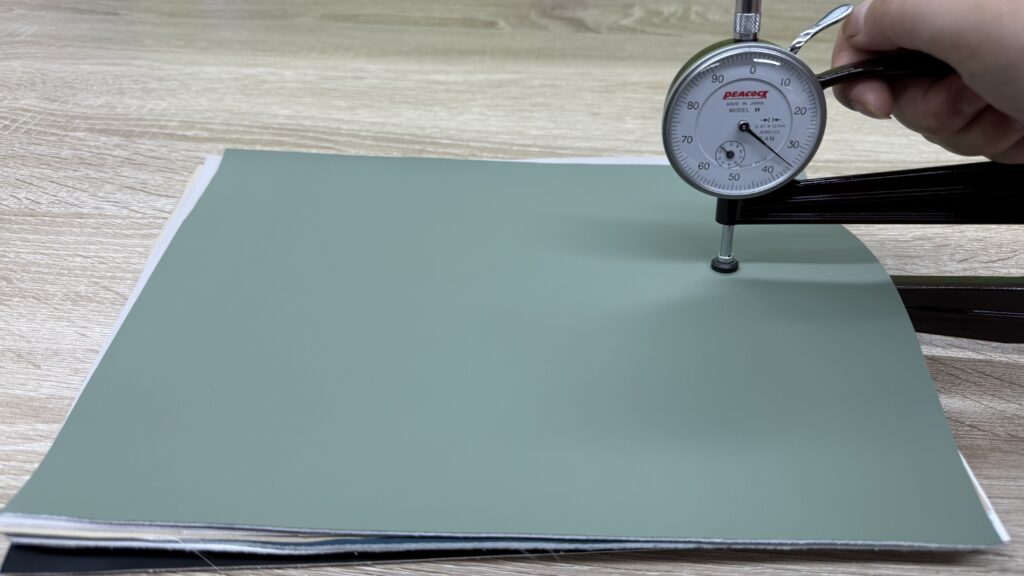

silicone leathers thickness

You can custom the silicone leathers thickness and embossed and debossed logo, texture by use the different tooling. The custom silicone leathers texture :Grains – smooth, leather,or other styles ,Textures – smooth or tacky (grip) texture . You can make is Lychee/plain/carbon fiber/crocodile/star/kid skin etc.

All the silicone leathers that your custom is Food Grade Silicone, BPA-free, Eco-friendly, and Heat-resistant.

The custom silicone leathers width can design from 1370MM-1470MM, the thickness that we can make is from 0.4-4.2 mm.

thickness 1.65MM

thickness 1.65MM thickness 0.39MM

thickness 0.39MM thickness 0.44MM

thickness 0.44MM thickness 0.54MM

thickness 0.54MM thickness 1.3MM

thickness 1.3MM thickness 1.19MM

thickness 1.19MM thickness 1.35MM

thickness 1.35MM

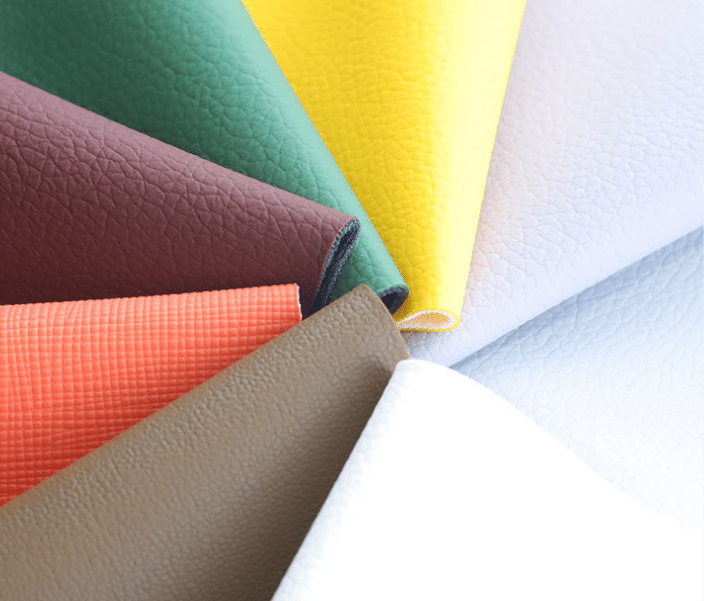

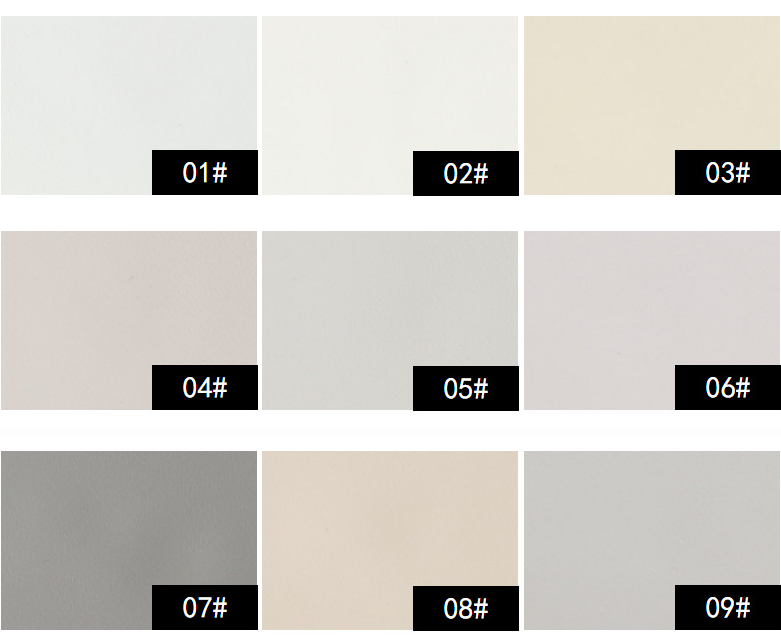

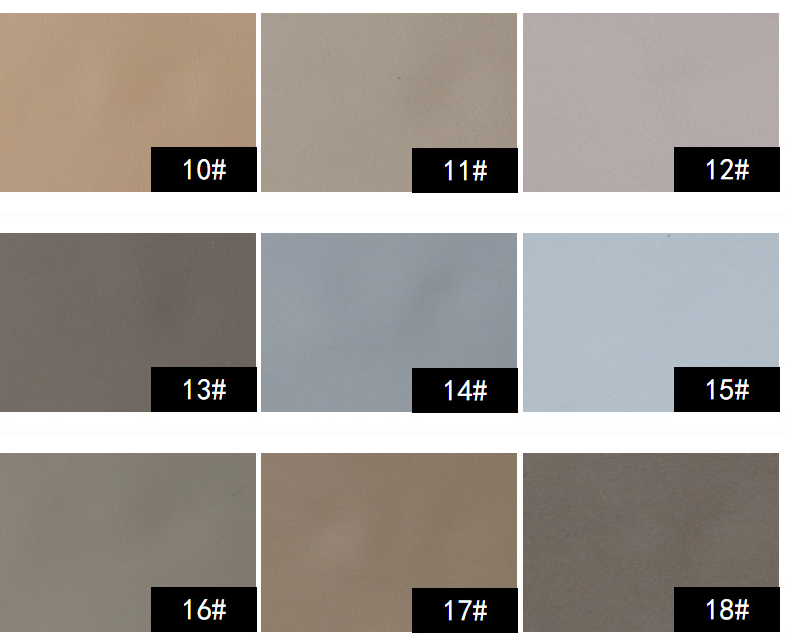

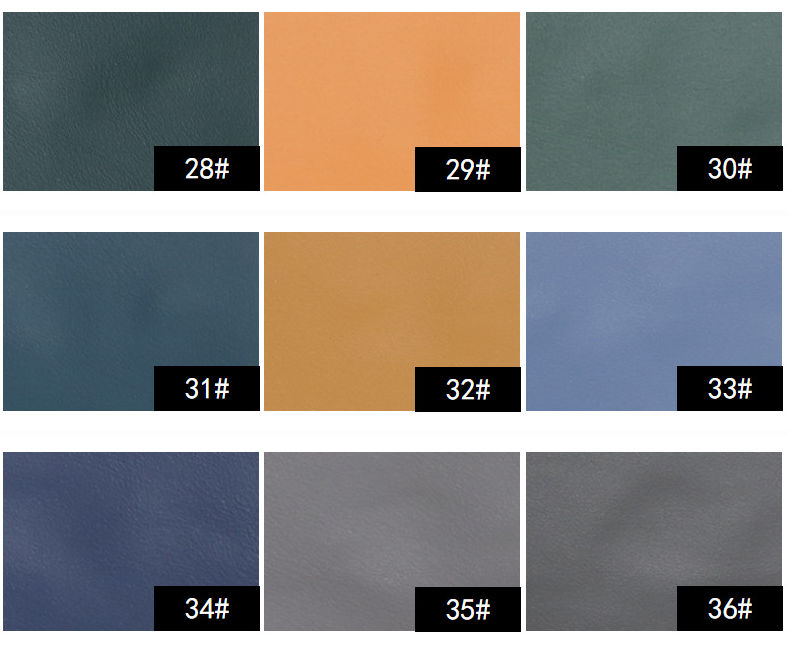

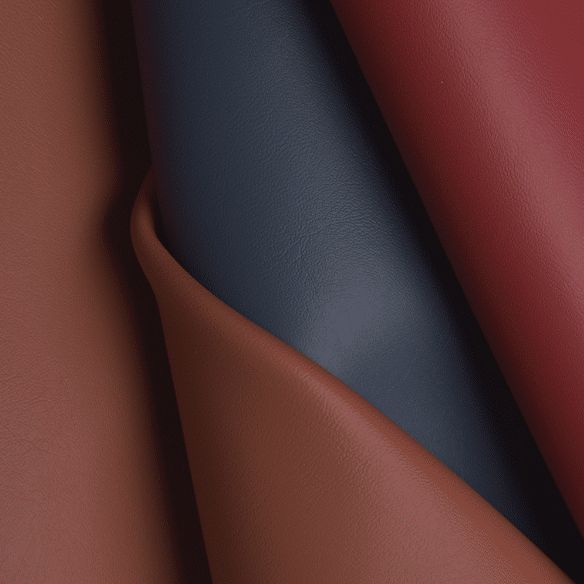

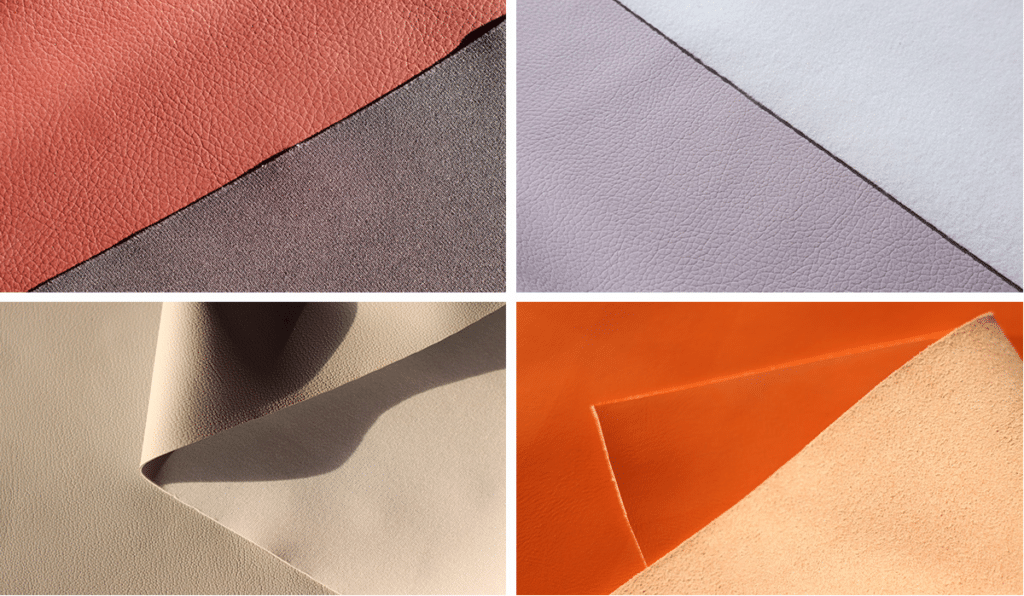

Custom silicone leathers Color

You can customize the size color according to the Pantone book. Our usual colors are white, green, orange, grey and milk white ect.

ZSR own the printing workshop for printing your pattern,design and logo by Laser Engraving, Silk Screen printing, UV printing with flexibility design for your artwork printing.

See the blog to know more about it: Silicone Printing Guide

Custom silicone leathers brands, labels and package

Z.S.R also provide customized packaging solutions for manufactured silicone leathers. We offer one-stop services such as helping customers to design, develop, assemble and inspect the packaging, ensuring the appearance of finished products and the safety of transportation.

Our packaging team is committed to ensuring that each of our finished products can delivery to the clients with the highest quality.

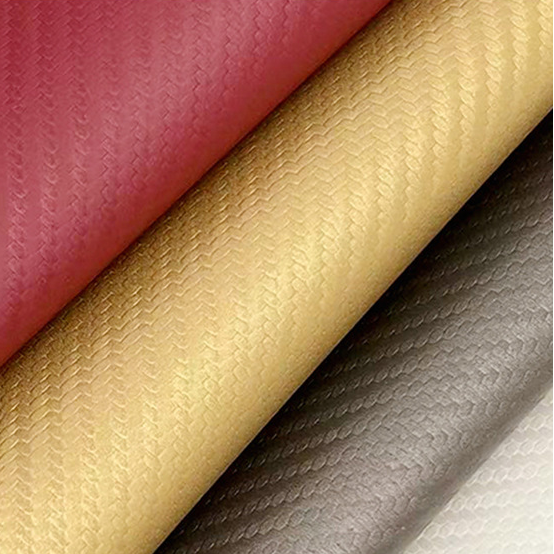

Custom silicone leathers texture

Z.S.R produce and supply wide range of customized options, including color and surface textures. You can choose the following texture silicone leathers to fit your projects.

Bark Texture silicone leather

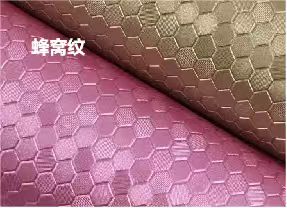

Bark Texture silicone leather Honeycomb pattern silicone leather

Honeycomb pattern silicone leather Crocodile pattern silicone leather

Crocodile pattern silicone leather Carbon fiber pattern silicone leather

Carbon fiber pattern silicone leather Weaving pattern silicone leather

Weaving pattern silicone leather Pinhole Grain Pattern silicone leather

Pinhole Grain Pattern silicone leather Snake texture silicone leather

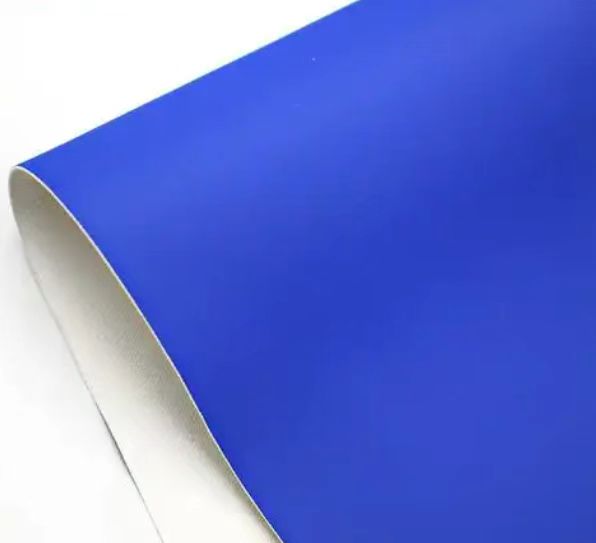

Snake texture silicone leather Plain silicone leather

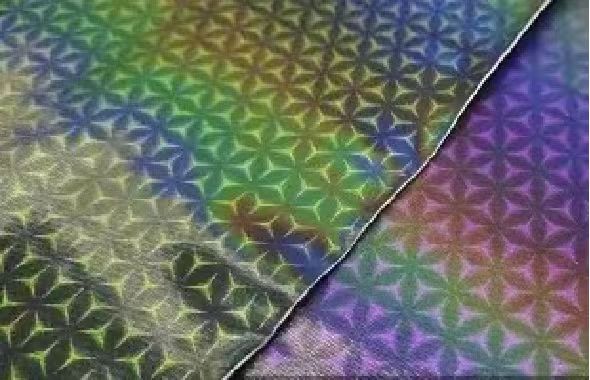

Plain silicone leather Optical iridescent texture

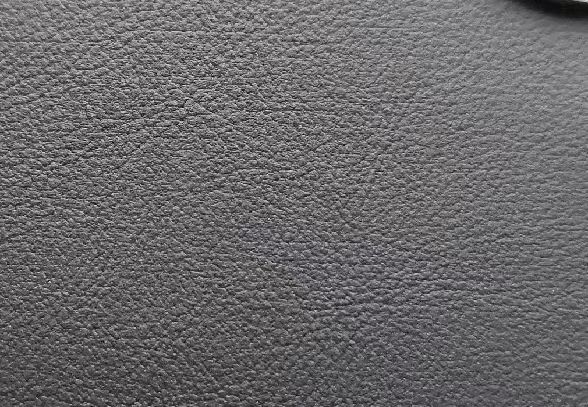

Optical iridescent texture Gravel Texture silicone leather

Gravel Texture silicone leather lamb pattern silicone leather (2)

lamb pattern silicone leather (2) Cloth pattern silicone leather

Cloth pattern silicone leather Diamond pattern silicone leather

Diamond pattern silicone leather Nappa silicone leather

Nappa silicone leather Lychee texture silicone leather

Lychee texture silicone leather Oil wax pattern silicone leather

Oil wax pattern silicone leather kidskin silicone leather

kidskin silicone leather Ostrich pattern silicone leather

Ostrich pattern silicone leather Napa silicone leather

Napa silicone leather Hami Melon pattern silicone leather

Hami Melon pattern silicone leather Plaid silicone leather

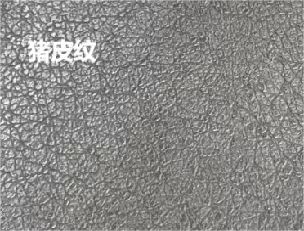

Plaid silicone leather Pigskin silicone leather

Pigskin silicone leather

silicone material and base backing fabric layer

Z.S.R offer Custom silicone leather service from Custom the silicone raw Material and base backing fabric layer:

Our expert Engineer will recommend the most suitable raw materials according to your requirements (e.g. Platinum Liquid silicone rubber and base fabric layer, tensile strength, tearing strength, etc.; different standards such as FDA and LFGB or medical grade or different Brands. Different base baking fabric layer such as Microfiber cloth/imitation lint cloth/flannelette cloth according to your application). The fabric can directional stretching or no elasticity. Flame resistance standards,Durability other specific characteristics. Also it is feasible to add an antimicrobial agent to the raw materials for the product to reach the sterility standard.

Silicone leather vs traditional leather

|

Item |

Silicone Leather |

Nature Leather |

pvc |

PU |

Microfiber |

|---|---|---|---|---|---|

|

Breathability |

Excellent |

Good |

Bad |

Medium |

Good |

|

Fire Resistance |

Excellent |

Good |

Good |

Bad |

Medium |

|

Solvent/chemical resistance |

Excellent |

Bad |

Good |

Medium |

Medium |

|

Acid resistant |

Excellent |

Bad |

Good |

Medium |

Good |

|

Alkali resistance |

Excellent |

Bad |

Good |

Medium |

Good |

|

Hydrolysis resistance |

Excellent |

Medium |

Good |

Medium |

Good |

|

Durability |

Excellent |

Good |

Medium |

Bad |

Good |

|

Color fastness |

Excellent |

Bad |

Medium |

Better than PVC |

Medium |

|

Antibacterial and mildew resistance |

Excellent |

Bad |

Medium |

Medium |

Medium |

The silicone leather not contain DMF, phthalates, lead. The silicone leather can pass Reach, ROHS (Phthalate Free), EN-71-3 Free, Azo Dyes Free, Formaldehyde Free, DMFU&DFMA Free.

Artificial leathers such as polyurethane rubber (PU) synthetic leather and polyvinyl chloride (PVC) commonly found in the finished leather market are not resistant to aging, high temperature, easy to hydrolyze, easy to stain, and have a short lifespan. They will cause certain pollution to the environment during the manufacturing and use process.

File Download: Silicone leather

custom silicone leather

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

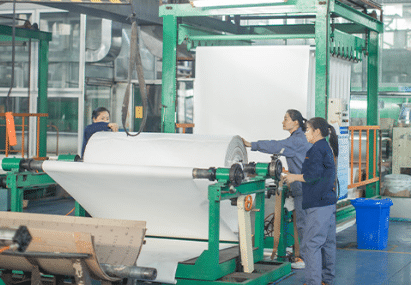

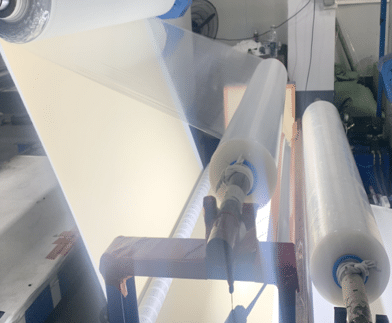

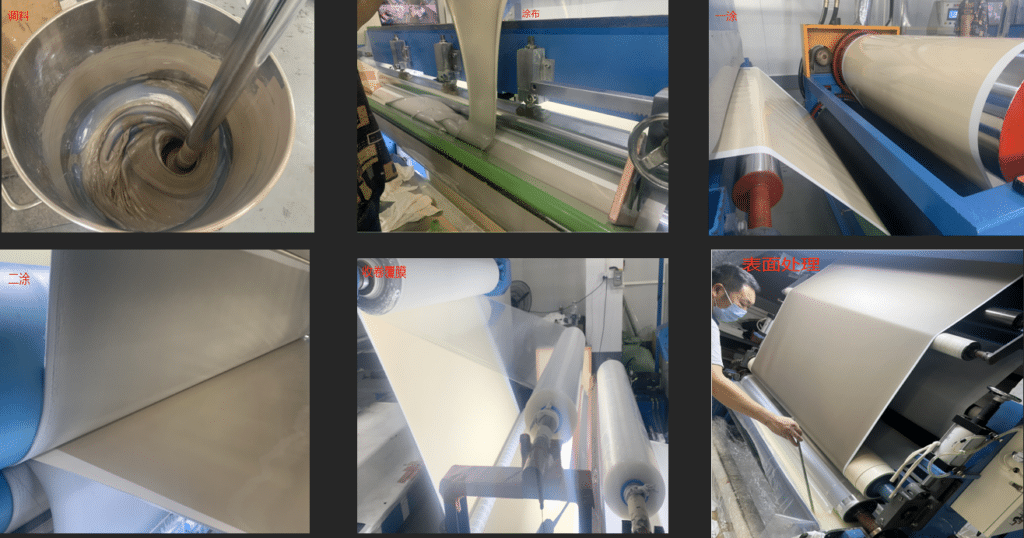

Silicone leathers Making Process

1. Prepared Material: Mixed the Liquid silicone rubber material color according to the confirmed samples ‘color. Prepare the confirmed base fabric layer.

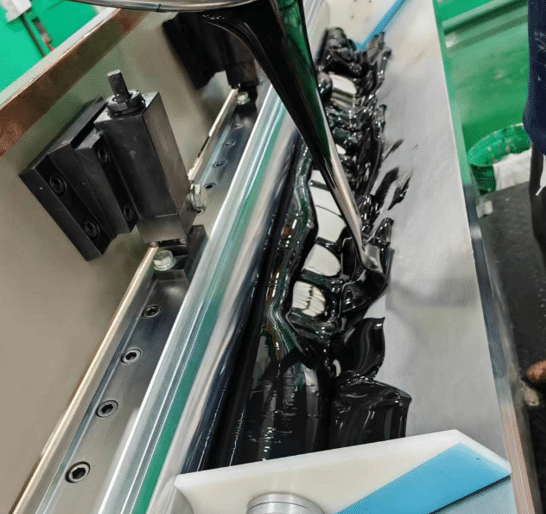

2. Set up and coating:Put mixed LSR on the machine, then coating the liquid silicone rubber. lt is the First coating with the liquid silicone rubber on the surface. Embossed for the silicone leather texture in this process.

3. Heat the first coating silicone leather in the oven to dry.

4. Second coating: Second coating the liquid silicone rubber in bottom and then sticker with the base fabric layer

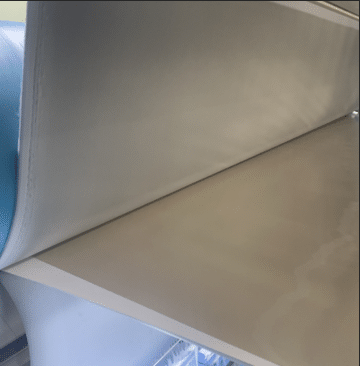

5. Lamination: Collection the half-finished silicone leather with plastic film in order to keep the surface clean

6. Painting Dusty Free oil: Painting the different oil to get different surface (gloss or matt) and different touch feeling silicone leather. (Skin, dry, smooth) and let the silicone leather keep dusty free and easy to clean.