What Are The Advantages Of Silicone Leather Compared To Traditional Leather?

The advantages of silicone leather over other leathers include safety, weather resistance, waterproof performance, environmental protection and durability.

What is leather?

According to the manufacturing method, the leather can be divided into Natural leather, recycled leather, artificial leather and synthetic leather.

Natural leather

which is what we often call genuine leather. It is made from animal (rawhide) tanned in a leather factory to produce leather goods with various characteristics, strengths, feel, colors and patterns.

The recycled leather

Waste skins and leather scraps from various animals are crushed and mixed with chemical raw materials for processing.

Artificial Leather

Artificial leather, also called imitation leather or rubber, is a general term for artificial materials such as PVC and PU. It is made of foamed or coated PVC and PU with different formulations on a textile or non-woven base. It can be processed according to different strength, wear resistance, cold resistance, color, gloss, pattern and other requirements. It has the characteristics of a wide variety of colors, good waterproof performance, neat edges, high utilization rate and relatively low price compared to genuine leather.

Synthetic Leather

Synthetic leather is a plastic product that simulates the composition and structure of natural leather and can be used as a substitute material. The surface is mainly polyurethane, and the base material is non-woven fabric made of synthetic fibers such as polyester, cotton, and polypropylene. Both the front and back sides are very similar to leather and have a certain degree of breathability. The characteristics are beautiful luster, not easy to mold and insects, and closer to natural leather than ordinary artificial leather. Silicone leather belongs to Synthetic Leather.

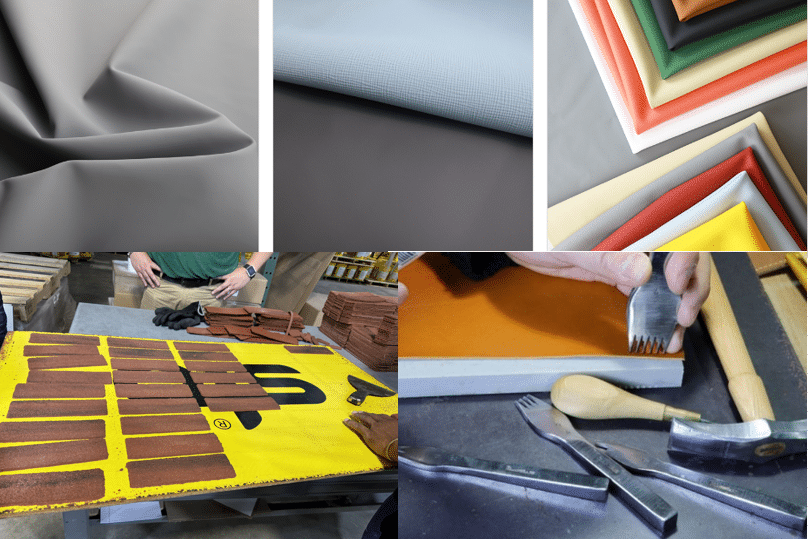

What is silicone leather?

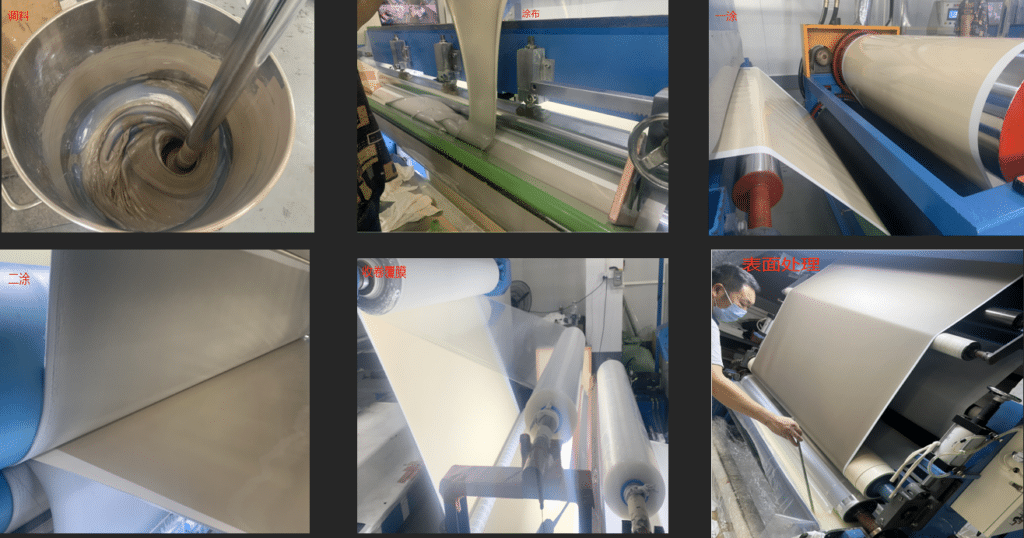

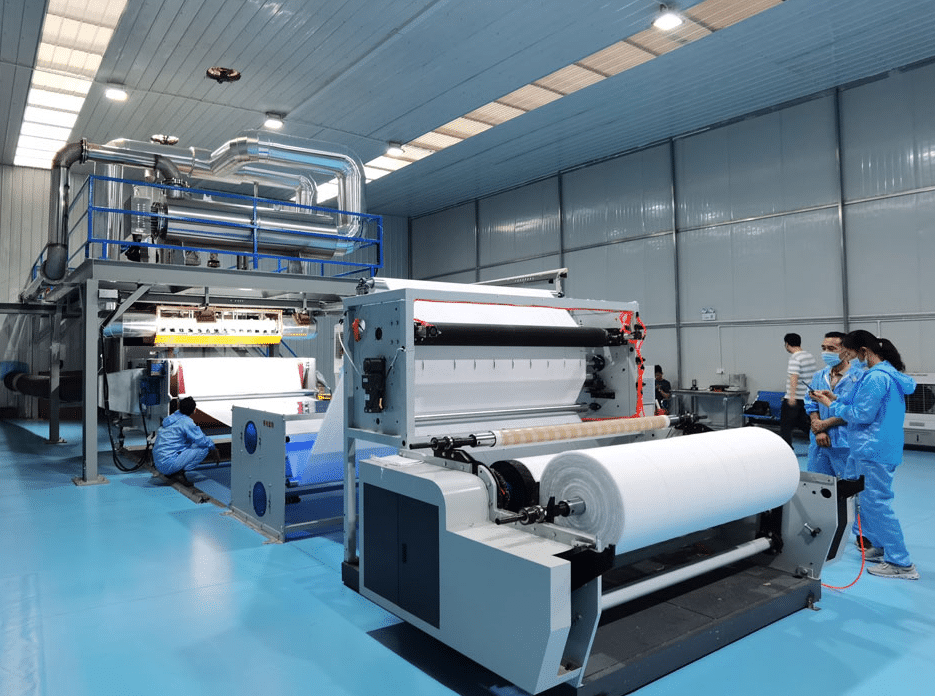

Silicone leather is a synthetic leather made of silicone material. The main component of this material is silicon dioxide, an inorganic polymer. In the preparation process of silicone leather, silicone is used as a raw material and processed by combining with various substrates. The surface of the substrate is coated with silicone using solvent-free technology to form a new type of environmentally friendly artificial leather.

Silicone leather has a variety of excellent physical properties, including wear and scratch resistance, natural anti-fouling and waterproof properties, yellowing resistance, corrosion resistance, aging resistance, excellent biocompatibility and low cytotoxicity. These properties make it recognized in the high-end market and used in environments such as the medical field that have high requirements for material performance.

In addition, silicone leather is also soft, durable, waterproof, and easy to clean and maintain. According to the different proportions of silicone components, it can be divided into full silicone leather and semi-silicone leather. The former refers to the entire leather product made of silicone material, and the latter refers to part of the material being silicone and the other part being other materials.

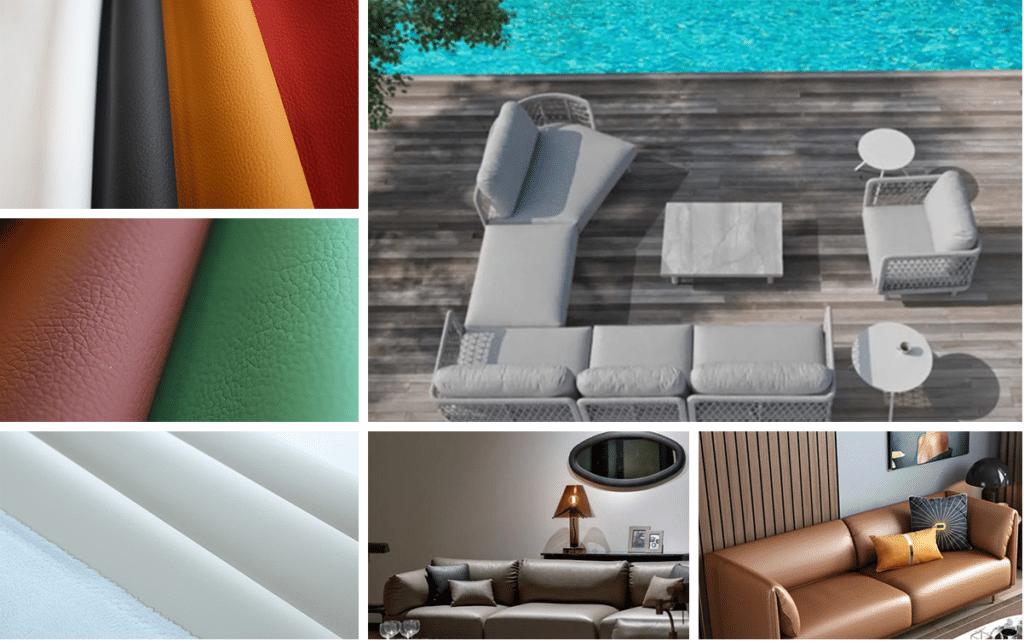

custom silicone leather

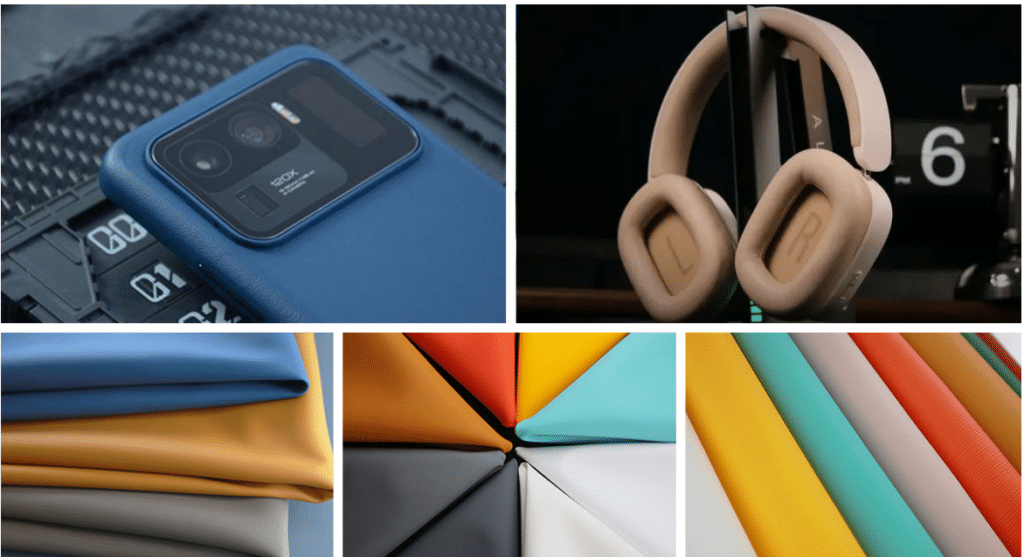

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone skin in an assortment of colors and patterns to fit their product’s needs.

| PROPERTIES | VALUES |

|---|---|

| Material | silicone vegan leather |

| Wide | 1370mm+100mm fabric margin |

| Thickness | fabric thickess+coating thickness |

| 0.4mm leather=0.2mm Silicone±0.02mm+fabric 0.2mm±0.05mm | |

| 0.6mm=leather=0.2mm Silicone±0.02mm+fabric 0.4mm±0.05mm | |

| 0.8mm leather=0.2mm Silicone±0.02mm+fabric 0.6mm±0.05mm | |

| 1.0mm leather=0.2mm Silicone±0.02mm+fabric 0.8mm±0.05mm | |

| 1.2mm leather=0.2mm Silicone±0.02mm+fabric 1.0mm±0.05mm | |

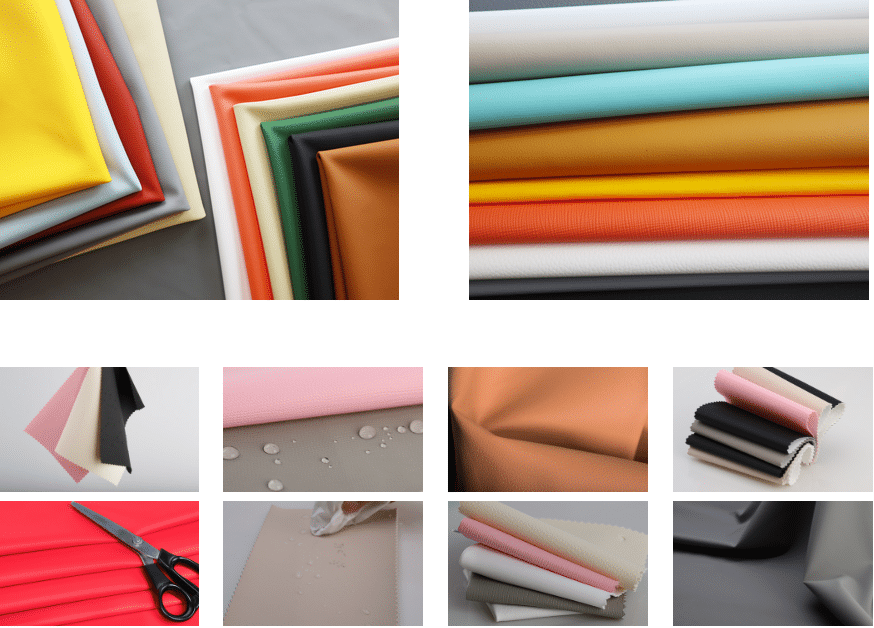

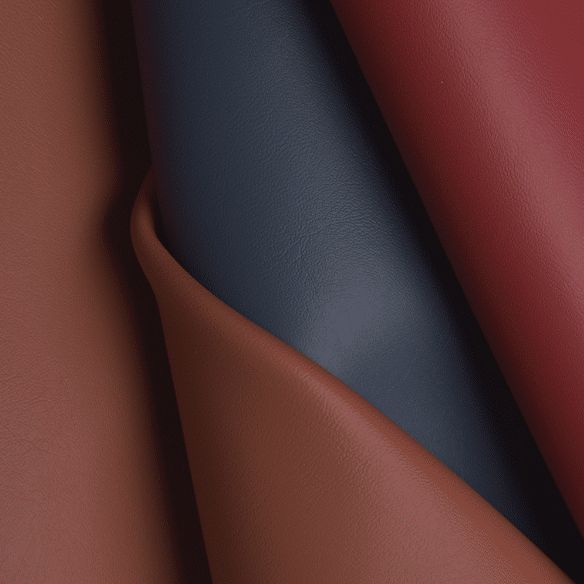

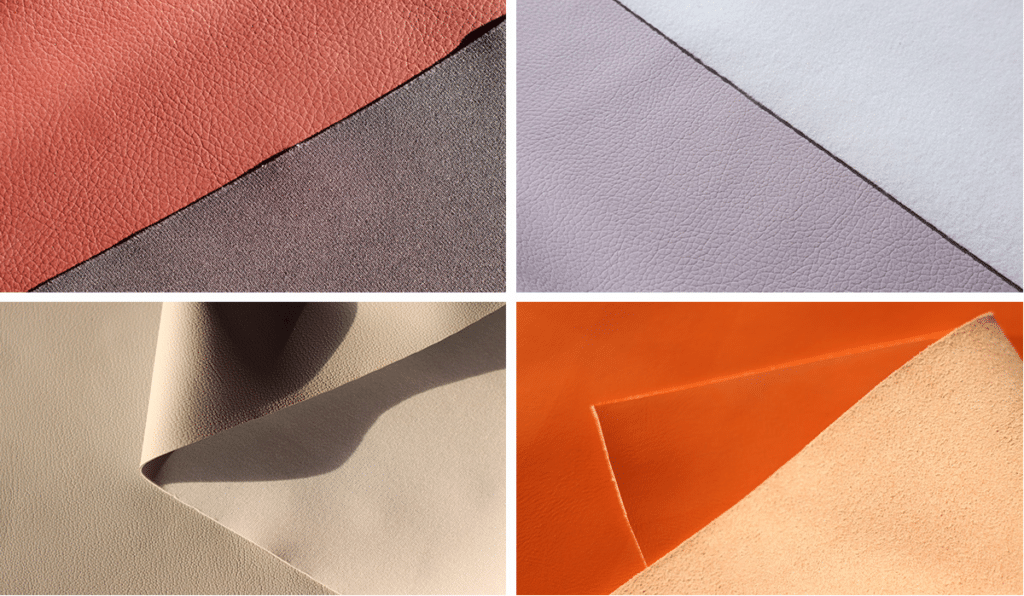

| Color | PMS color or follow sample color |

| Surface layer | 100% baby pacifier material |

| Texture | Lychee/plain/carbon fiber/crocodile/star/kid skin |

| Base fabric | Micro Fibric, Cotton, Lycra, Pique, micro suede, stretchy fabric, Knitted fabric, Non-woven fabric, flannelette, PET, PC, TPU, PI FILM 3M adhesive tape etc |

| Pattern | Lichi Grain, Plain grain, Lambskin Grain, Pigskin Grain, Pin Grain, Crocodile Grain, Giant Pebble, Hami melon Grain, Bark Grainetc |

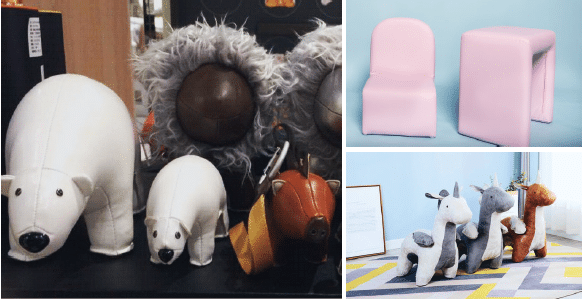

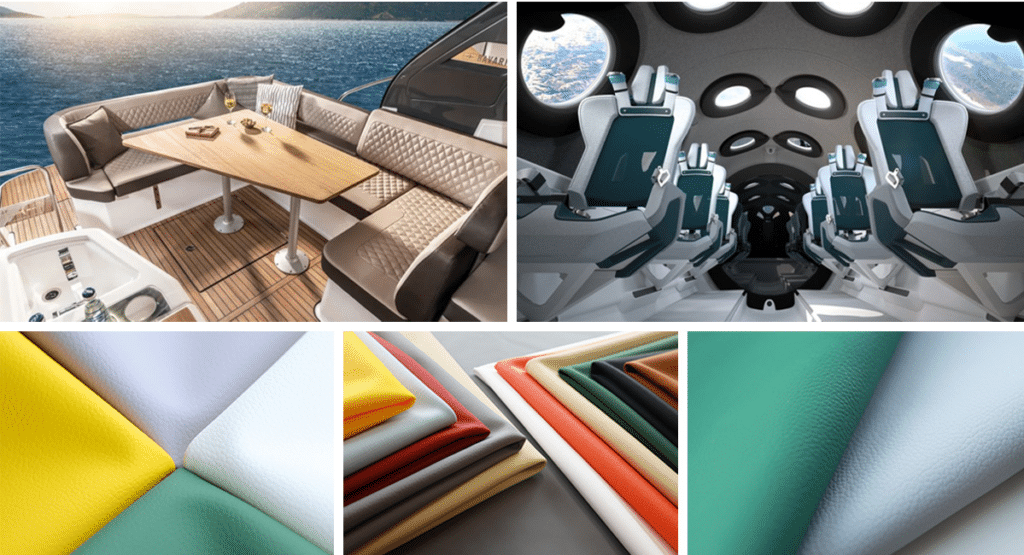

| Application | Marine, Furniture, Automotive, Healthcare, Sports, 3C Electronic, Baby product. |

| Production Capacity | 1000m-24000m |

What is Traditional leather?

The Traditional leather what we talk about here include: Natural leather, PVC and PU leather, and Microfiber leather.

The advantage of silicone leather

- Silicone leather is distinguished by its exceptional durability, making it more resistant to wear, tear, and environmental factors compared to traditional leathers.

- Additionally, silicone leather maintains its appearance over time, resisting fading and cracking, which is often a challenge with other synthetic leathers.

- Silicone Leather are safety, eco-friendly, sustainable, easy to clean, weatherproof, and highly durable performance fabrics that can be applied in various applications, even in extreme environments.

- The silicone leather possesses a unique texture that can closely imitate genuine leather, providing a similar tactile experience.

Low-temperature resistance

Leather maintains its original softness in the harsh climate of -40℃

Waterproof and anti-fouling

pen stains juice, sauce oil easy to clean

UV resistance

UV resistance fusion of excellent weather and light resistance

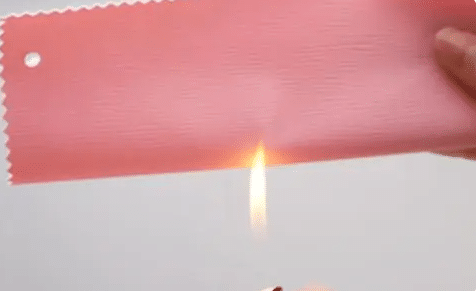

Anti-flaming

Silicone has strong flame-resistantgrade testing

High-temperature resistance

Not deformation, shrink, or burn athigh temperatures of +200℃

ECO-friendly

baby nipple material non-toxic no smell and anti-allergic

Get more details by “silicone leather guard”

The advantage of Natural leather

- Natural leather is a natural material with better texture, good breathability and long service life.

- Natural leather has a unique texture and luster, and looks more upscale.

- In addition, Natural leather has better elasticity and can adapt to different shapes.

The advantage of PU leather

Strong wear resistance, or polyurethane, is a polymer compound whose molecular structure gives it excellent elasticity and wear resistance. This allows PU products to maintain good appearance and performance after long-term use.

- Softness and comfort: PU material has good softness and elasticity, and feels comfortable. easy cleaning, the surface of PU material is smooth and flat, not easy to absorb dust and

- Stains, easy and quick to clean, just wipe with a damp cloth to restore the smoothness.

- Colorable, PU material can achieve a variety of colors and textures through dyeing, printing and other processes, providing designers with more creative space.

- Environmental protection, PU material does not require high temperature during the production process, which can save energy and resources, and its waste can be naturally degraded, which is environmentally friendly.

- Waterproof and moisture-proof: Pu material has excellent waterproof and moisture-proof properties, and can maintain good use even in humid environments.

- Good chemical resistance: PU material can resist the erosion of acids, alkalis, oils and other chemicals, and is not easily corroded or discolored.

The advantage of PVC leather

- Unique physical and chemical properties: PVC leather is rainproof, fireproof, antistatic, and easy to shape. These characteristics make PVC leather widely adaptable in application and can meet the needs of various use environments.

- Affordable price: Compared with natural leather, PVC leather is more affordable, which makes PVC leather highly competitive in the market, especially suitable for consumers with limited budgets.

- Easy to clean: PVC leather has a smooth surface and is not easy to adhere to dust and dirt. It is very convenient to clean. Usually, it only needs to be wiped with a damp cloth. This is undoubtedly a great advantage for places or products that need to be cleaned frequently.

- Environmental protection: During the production process of PVC leather, special refining technology can remove toxic substances, making it completely non-toxic and odorless, and there is no irritation to human skin or respiratory system. In addition, PVC leather meets national environmental protection standards and is more environmentally friendly than some natural leathers.

- Strong wear resistance: PVC leather has good wear resistance, can maintain its gloss for a long time, and is not easy to wear or age.

The advantage of Microfiber leather

The advantages of microfiber leather mainly include strong durability, good waterproof performance, strong wrinkle resistance, environmental sustainability, modern and elegant appearance and texture, excellent performance and durability, environmental protection, relatively low cost, wide application and sustainability.

- Strong durability: Microfiber leather has high wear resistance and tear resistance, and can withstand long-term use and wear, making the service life of microfiber leather products longer than traditional leather products.

- Good waterproof performance: Microfiber leather can effectively prevent water penetration and moisture erosion, and is suitable for making waterproof products such as shoes, bags, and raincoats.

- Strong wrinkle resistance: Microfiber leather will not show obvious wrinkles and marks even after repeated folding and use, and is easy to care for and maintain.

- Environmental sustainability: Microfiber leather is made of artificial fiber materials, which is more environmentally friendly than traditional leather. It can be produced by recycling and reusing discarded fiber materials.

- Modern and elegant appearance and texture: Microfiber leather has a smooth and delicate texture, which looks modern and elegant, similar to genuine leather.

- Excellent performance and durability: Microfiber leather adopt high-performance materials and high-tech processes, has high wear resistance, wrinkle resistance and tear resistance, and is easy to maintain.

- Relatively low cost: Although the price of microfiber leather is higher than that of ordinary leather, its performance and durability are correspondingly improved, and its service life is longer, and the cost is relatively low in the long run.

- Wide application: Microfiber leather has broad application prospects and development space in the leather industry, and is widely used in the production of shoe uppers, bags, clothing, furniture, car seats and other products.

- Sustainability: Microfiber leather can be recycled, reducing waste and energy consumption, reducing the impact on the environment, and its long life reduces waste and replacement frequency.

Silicone leather VS other Traditional leather

- Compared with other Traditional leather: The advantages of silicone leather mainly include safety, weather resistance, waterproof performance and environmental protection.

- Safety: Silicone leather has excellent biocompatibility, is harmless to the human body, is non-carcinogenic, and can effectively prevent bacteria from entering, protect the injured surface, and prevent infection. These characteristics make silicone leather widely used in the medical field, and can be made into artificial joints, artificial skin, etc.

- Weather resistance: Silicone leather has excellent hydrolysis resistance and light resistance. After rigorous testing, even in extreme environments, such as high temperature and high humidity conditions, silicone leather can maintain good physical properties, and will not become sticky, shiny, brittle, etc. In addition, its color stability is extremely high, and even if it is exposed to the sun for ten years, the color can remain unchanged.

- Waterproof performance: Silicone leather has excellent waterproof performance, excellent water repellency, water cannot penetrate its surface, and it is easy to clean. It can be restored to clean by simply wiping. This feature makes silicone leather perform well in various applications.

- Environmental protection: As a new type of environmentally friendly material, silicone leather not only has the high temperature resistance and corrosion resistance of silicone materials, but also has the appearance and texture of leather, and has good aging resistance and discoloration resistance. These characteristics make silicone leather an environmentally friendly and practical material choice.

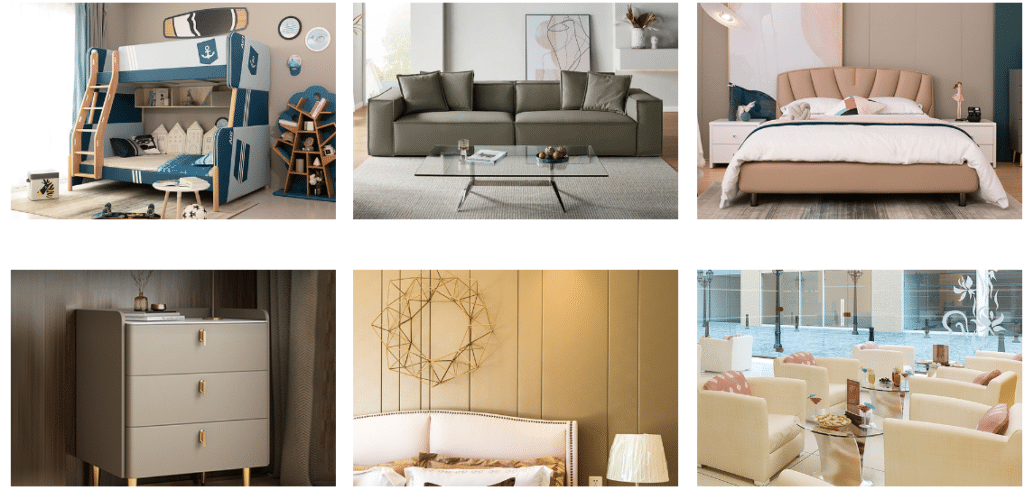

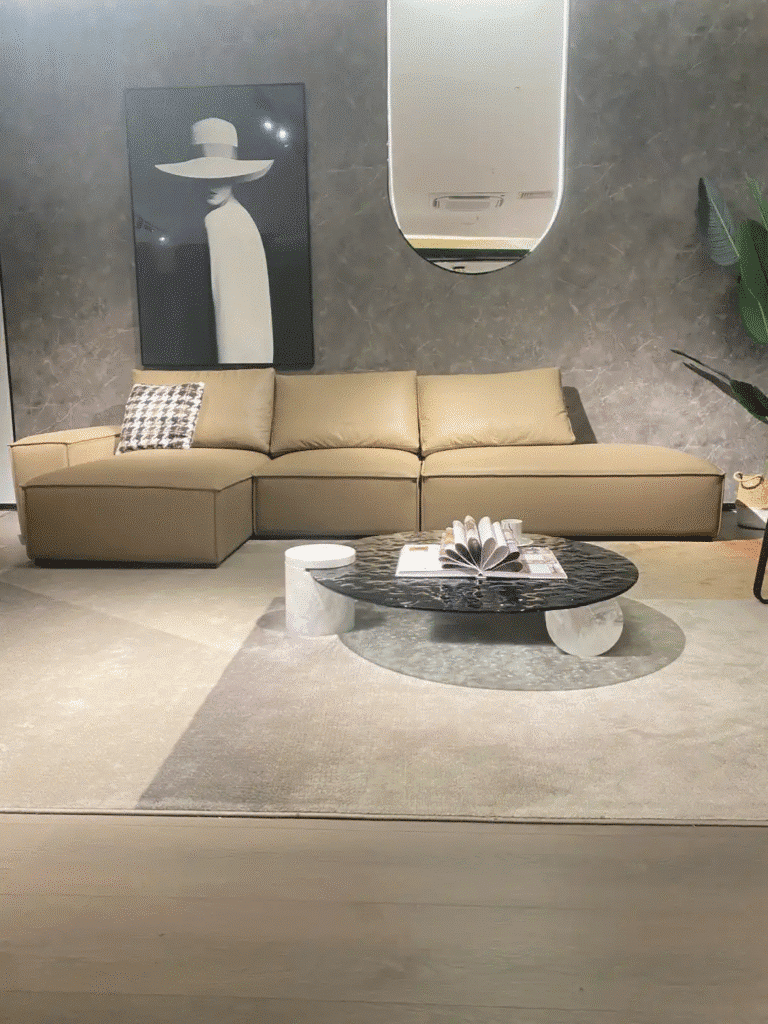

Silicone leather VS natural leather

Durability

- Silicone leather is highly durable, not prone to scratches and wrinkles, and has strong stain resistance, making it relatively easy to clean.

- Although leather sofas are durable, they are susceptible to scratches and wear, especially when there are pets or children at home, they are more likely to be damaged.

Comfort

- Silicone leather sofas are softer and more comfortable than leather sofas. Some people describe sitting on a silicone leather sofa as sitting on a cloud.

- Leather sofas are harder and may take some time to adapt, and the surface temperature will change with the ambient temperature, affecting comfort.

Price

- Silicone leather sofas are relatively cheap because they are cheap to produce and can imitate a variety of textures.

- Leather sofas are relatively expensive because of their high material costs.

Cleaning and maintenance

- Silicone leather sofas are easier to clean, and generally only need to be wiped with a damp cloth to keep them clean.

- Leather sofas require the use of special cleaners and maintenance products, and require regular cleaning and care.

Appearance

- Silicone leather sofas can imitate many different leather textures in appearance, and the price is relatively low.

- Leather sofas are loved for their noble, luxurious and natural appearance, and each leather sofa has a unique texture and texture.

Applicable people and scenarios

Silicone leather sofas are suitable for: families with limited budgets who want durable and easy-to-clean sofas; families with children or pets who need to clean the sofa frequently; consumers who pursue environmental protection and waterproof performance.

Leather sofas are suitable for: consumers who pursue high-quality life and high-quality texture; users who are willing to invest time and energy in daily maintenance and care; families with a relatively ample budget who want to buy durable and high-end furniture.

In summary, if you focus on durability, easy cleaning and budget control, silicone leather sofas may be a better choice. If you pursue high-end texture, natural appearance and don’t mind regular maintenance, leather sofas may be more suitable for you. The final choice should be based on your personal preferences and usage needs.

Silicone leather VS PU leather

There are significant differences between silicone leather and PU leather in many aspects, mainly reflected in material characteristics, environmental protection, durability, application fields and user experience.

Material properties

Silicone leather: Silicone leather is a new type of environmentally friendly material that is resistant to high temperatures and corrosion, while also having the appearance and texture of leather. It is made of silicone material, which has good elasticity and softness and feels comfortable.

PU leather: PU leather is a skin made of polyurethane and is widely used in the decoration of bags, clothing, shoes, vehicles and furniture. PU leather has good breathability, folding resistance, and water resistance, but its wear resistance is relatively poor.

Environmental protection

Silicone leather: Silicone leather does not use harmful chemicals during the production process, releases no harmful gases when burned, and easily passes the US FDA certification, SGS certification and European LFGB certification, fully complying with environmental protection requirements.

PU leather: PU leather may add some harmful substances during the production process. Although the amount is not large, it does not meet environmental protection requirements.

Durability

Silicone leather: Silicone leather has extremely high durability, resistance to wear, high temperature, chemical corrosion and oxidation, and is suitable for use in harsh environments.

PU leather: Although PU leather has good breathability and folding resistance, it has relatively poor wear resistance and hydrolysis resistance, and is especially prone to damage in extreme environments.

Application areas

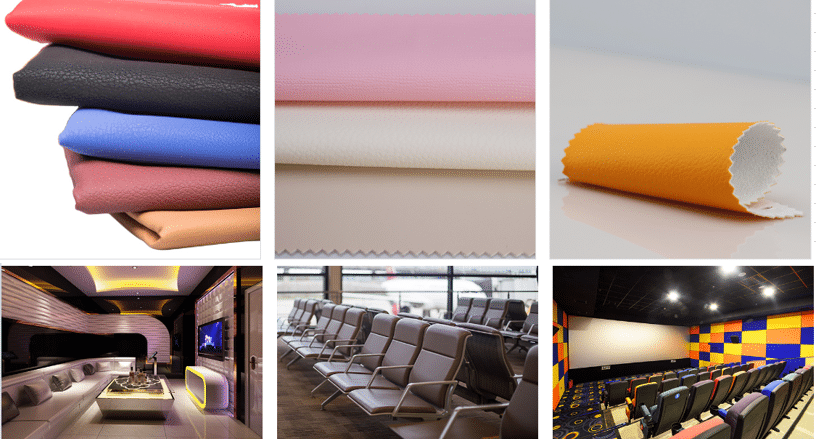

Silicone leather: Due to its environmentally friendly and durable properties, silicone leather is widely used in high-end automotive interiors, building materials and other fields.

PU leather: PU leather is widely used in clothing, shoes and hats and other fields because of its soft and delicate texture and good breathability.

User experience

Silicone leather: Silicone leather is soft to the touch, highly comfortable, and has good heat insulation. It is suitable for the production of high-end seats, sofas and other products.

PU leather: PU leather feels comfortable and close to real leather, but is slightly inferior to silicone leather in terms of durability and environmental protection.

To sum up, silicone leather has obvious advantages in environmental protection, durability and application fields, while PU leather performs better in terms of softness and breathability. The choice of material depends on the specific application needs and scenarios.

Silicone leather VS PVC leather

The main differences between silicone leather and PVC are in terms of material, performance, environmental protection, durability, appearance and maintenance.

Material and performance

Silicone leather is a new type of environmentally friendly material. It combines the high temperature resistance and corrosion resistance of silicone materials with the appearance and texture of leather, making it softer, more comfortable, and not easy to age or discolor. Silicone leather is easy to maintain, just wipe it with a damp cloth1.

PVC (polyvinyl chloride) is a plastic material that is widely used in various daily necessities. PVC has good wear resistance, folding resistance, and water resistance, but its environmental protection performance is relatively poor, and pollution may occur during the production process.

Environmental protection

Silicone leather is more environmentally friendly than PVC because its production process has less burden on the environment.

The production and processing of PVC may cause certain pollution to the environment.

Durability

Silicone leather is dirt-resistant, wear-resistant, easy to clean, and has a long service life.

Although PVC table mats are widely used in many fields, their durability is not as good as silicone leather.

Appearance and maintenance

Silicone leather has a simple and high-end appearance, is more popular with young people, and is easy to maintain.

The appearance and texture of PVC leather are very similar to genuine leather, but it may discolor and turn yellow after long-term use.

Hardness and temperature tolerance

Silicone material has a lower hardness, better rebound strength, and a wide temperature resistance range (-40 to 250 degrees).

PVC material has a higher hardness, poor rebound strength, and a lower softening or melting temperature range (75~90 degrees).

In summary, silicone leather has obvious advantages over PVC in terms of environmental protection, durability, appearance and maintenance, especially in application scenarios that focus on environmental protection and durability, silicone leather is a better choice

Silicone leather VS Microfiber leather?

There are significant differences between silicone leather and microfiber leather in terms of performance, environmental protection, and application fields.

In terms of performance, silicone leather exhibits excellent breathability, abrasion resistance, aging resistance and anti-pollution properties, has a soft feel and good flame retardant properties, meets environmental protection and safety requirements. In contrast, although microfiber leather also has high wear resistance and tear resistance, its aging resistance and flame retardant properties may be slightly inferior to silicone leather. In addition, silicone leather also has good decontamination properties, suitable for families with children or pets.

Environmental protection, Silicone leather is made of silica gel as raw material, no toxic substances are released during the production process, harmless to the environment, has good degradability, is conducive to the recycling of resources. The production process of microfiber leather may involve the use of some toxic substances, such as solvents and catalysts. Although many manufacturers are committed to developing environmentally friendly microfiber leather, there is still a risk of environmental pollution.

Application fields: Silicone leather is widely used in furniture, car interiors, shoe materials, clothing and other fields due to its excellent performance and environmental protection characteristics. Especially in the field of automotive interiors, it is favored for its good flame retardant properties and environmental protection. Microfiber leather is widely used in shoe materials, luggage, car interiors and other fields due to its good wear resistance and flexibility.

To sum up, silicone leather performs better in terms of performance and environmental protection, and is suitable for consumers who pursue high-quality life and pay attention to environmental protection. Microfiber leather has outstanding performance in wear resistance and flexibility, suitable for general daily use

How to choose the correct Leather for your project?

When you choose the material that depends on the specific application requirements and scenarios. Especially in application scenarios that focus on environmental protection and durability, silicone leather is a better choice.

Summary:

In summary, silicone leather performs well in terms of safety, weather resistance, waterproof performance and environmental protection.

Z.S.R silicone leather series provides high design freedom with a wide variety of tailored options in colors, textures, and fabric. We work with the waterproof product development manager, product designer, product manager together designs and make the custom silicone skin to fit the waterproof product’s needs. Contact Z.S.R silicone to get your own needed silicone leather for your waterproof products now.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R work with product development manager, product designer, product manager together designs and make the custom silicone leather in an assortment of performance,colors and patterns to empower their product’s success.

Z.S.R Group offers customized silicone leather services, including customization of silicone leather base fabric layer, color, texture, application, size, logo, printing, pattern, brand, packaging, and technical support related silicone products. These silicone leather are suitable for industries such as baby products, marine, furniture, automotive, medical and healthcare, sports, 3C electronics, interior decoration, industrial manufacturing, and vegan fashion.