How Put Logo Or Pattern On Silicone Rubber Products?

A great way to personalize and advertise your business is to put your logo, text, and pattern on silicone rubber products. To print a logo on silicone rubber items. Putting logos or patterns on silicone rubber products is a fantastic way to enhance brand visibility and create customized silicone items.

Whether you’re looking to personalize promotional merchandise, create unique silicone corporate gifts, or brand your silicone products, understanding the logo, text, and pattern-putting process is essential.

With this article, you’ll have a clear understanding of the requirements and considerations for successfully printing logos or patterns on silicone rubber products.

Debossed or Embossed Logo on Silicone Tooling Mold:

If you can accept open a new tooling to customize the shapes of your silicone products. The popular and Economical way of putting logos or patterns on silicone rubber products is by using debossed or embossed logos on silicone tooling molds. Here’s an overview of the process:

Firstly, Design the silicone tool mold: Work with a skilled tooling engineer to create a mold that incorporates your logo, pattern, and text design in a raised (embossed) or recessed (debossed) format.

Then, you need to make the silicone mold tooling production: The tooling mold is fabricated using precision techniques (EDM or CNC) to ensure accurate reproduction of the logo pattern and text.

Thirdly, You need to Check finished products for logo, text or pattern accuracy, texture and overall quality.

Direct Printing on Silicone Rubber Products Surface:

Direct printing is also a good method for putting your logo, text, and pattern on silicone rubber product surfaces. Printed logos or pattern on silicone rubber products is a fantastic way to enhance brand visibility and create customized silicone items without developing new silicone tooling.

As we all know printing your company’s logo on silicone rubber products is a fantastic way to personalize and promote your brand. Please use the following straightforward procedures to print a logo, text, or pattern on silicone rubber products:

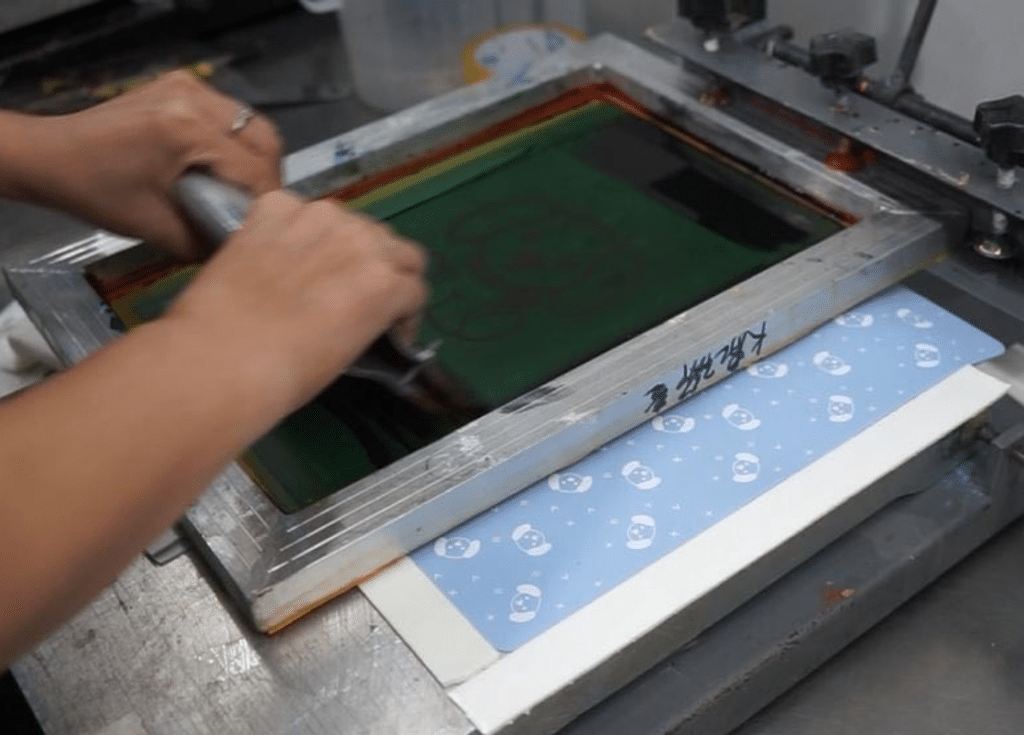

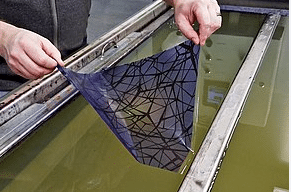

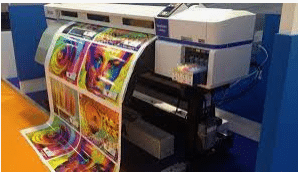

Select a Printing Technique Printing Method: When it comes to printing silicone rubber products, there are several options available, including Laser engraving, screen printing, pad printing, heat transfer printing, water transfer printing, In-Mold Decoration, and digital color printing.

There are several techniques you can use to print silicone rubber products, Choose the approach that best meets your needs among them because each has positive effects. Since they all have advantageous impacts, pick the one that best fits your demands.

Create the Artwork: Before manufacturing your logo, you must have artwork that is the correct size and resolution. The artwork can be created using any design program; just be sure to save it in a file format that is compatible with the printing process you intend to use.

Clean the Silicone Rubber Surface: Clean the silicone rubber products with a treatment agent. Make sure the silicone rubber product surface is clean, dry, and free from any contaminants.

Printing the logo, text, or pattern: You can start printing promptly as long as your ink, design, and surface have been prepared. You must use the printing equipment according to the directions provided by the method you select.

Curing or Drying: After printing the logo, the ink needs enough time to dry or be cured to ensure that it doesn’t smear, crock, or rub off. You can leave the silicone rubber product in a controlled environment or use a curing oven that dries the ink quickly.

Lastly, Check finished products for logo, text or pattern color, accuracy, texture, and overall quality.

Conclusion:

Putting the logo, text, or pattern on silicone rubber products is a great way to give your brand a professional look and feel. With the right tools and techniques, you can easily put your logo, text, or pattern onto silicone products with high-quality results.

We hope that our guide has helped you understand how to put a logo or pattern on silicone rubber products so that you can create stunning products for your business.

Related Blog

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.