How to Make Silicone Bags: A Comprehensive Guide from Material Selection to Finishing Touches

Silicone bag is made of environmentally friendly silicone as raw material and is formed by high-temperature vulcanization. It is a fashionable silicone bag used to store food, change, keys, bank cards and other items. It feels soft and feels closer to the skin. It has good elasticity, wear resistance, environmental protection, high temperature resistance, etc., and is anti-fall, anti-scratch and anti-abrasions.

The reusable silicone food storage bags have a secure closure to keep food fresh and prevent leaks, so you can feel confident toting your juicy pineapple, watermelon or a brothy pasta to work or marinating kabobs in the fridge without worry. Store cereal, snacks, grains, nuts and other non-perishables in these 36 oz reusable silicone storage bags. The reusable silicone bag is Premium, food-grade silicone: free of BPAs, phthalates, PVC, lead, and latex.

Z.S.R one of the leading manufacturers of different silicone bags for cosmetics, milk, and more silicone storage bags and shopping bags for small objects. We can supply custom logo packages and various models which can be added through silkscreen printing, full-color printing.

What are the advantages of silicone bag?

When you need the silicone bag?

Food preservation: Silicone bags have excellent air permeability, moisture resistance and waterproofness, and are suitable for preserving various foods. For example, silicone bags can be used to package cakes, desserts and other foods that need to be moisture-proof and preserved, and can also be used to store dry goods such as rice and mung beans to maintain their freshness.

Cosmetics and daily necessities storage: Silicone bags can be used to store cosmetics such as eyebrow pencils, lipsticks, face creams, etc. to prevent them from getting damp or deteriorating. Due to its high temperature resistance, silicone bags can also be used in microwave ovens or ovens, which is very suitable for preserving food that needs to be heated.

Environmental protection and reuse: Silicone bags are made of food-grade silicone, non-toxic and odorless, meet US FDA standards, can be recycled, and help reduce the generation of plastic waste. They are resistant to high and low temperatures and are suitable for various cooking and preservation needs.

Kitchen cleanliness: Silicone bags are soft, tear-resistant, easy to carry, and can be easily washed and reused, saving money.

When you buy the silicone bag, should pay attention to:

Material and Certification

The silicone bag should meet your needs and is non-toxic and environmentally friendly to ensure safe use. lead, PVC-, and phthalates-free. Check whether the silicone bag product has a safety test certificate to ensure that it meets the relevant food safety standards. In China, silicone bag products can be checked for compliance with the limit requirements of GB 4806.11-2016 “National Food Safety Standard Food Contact Rubber Silicone material and Products”, while foreign products should be checked for US FDA certification, CPSIA certification or EU LFGB certification, etc.

Food-grade silicone is preferred, IN USA -FDA Approved -silicone bag. The silicone bag should be 100% food-grade silicone raw silicone material to ensure safety. Ensuring that it complies with FDA and LFGB standards. Avoid choosing silicone bag made of ordinary plastics because they may release harmful substances.

Brands and channels

Prefer well-known brands to ensure quality, purchase through formal channels, and avoid buying counterfeit and shoddy products.

When you would like to buy the silicone bag, you should comprehensively consider factors such as material, safety, brand, Function, and size to ensure a safe.

How Much of the silicone bags?

From 0.69USD -15.99USD/pcs depend on the design, structure, package, etc. The smaller bags may be 0.69 USD. But the biggest size can be 15.9 USD.

In Z.S.R, we custom the silicone bags shape, size, color, pattern, brands, logo by silkscreen printing, full-color printing, or laser engraving for your needed bags, if you would like to custom your brands silicone bags contact Z.S.R.

Silicone Bags

How to make the silicone bag?

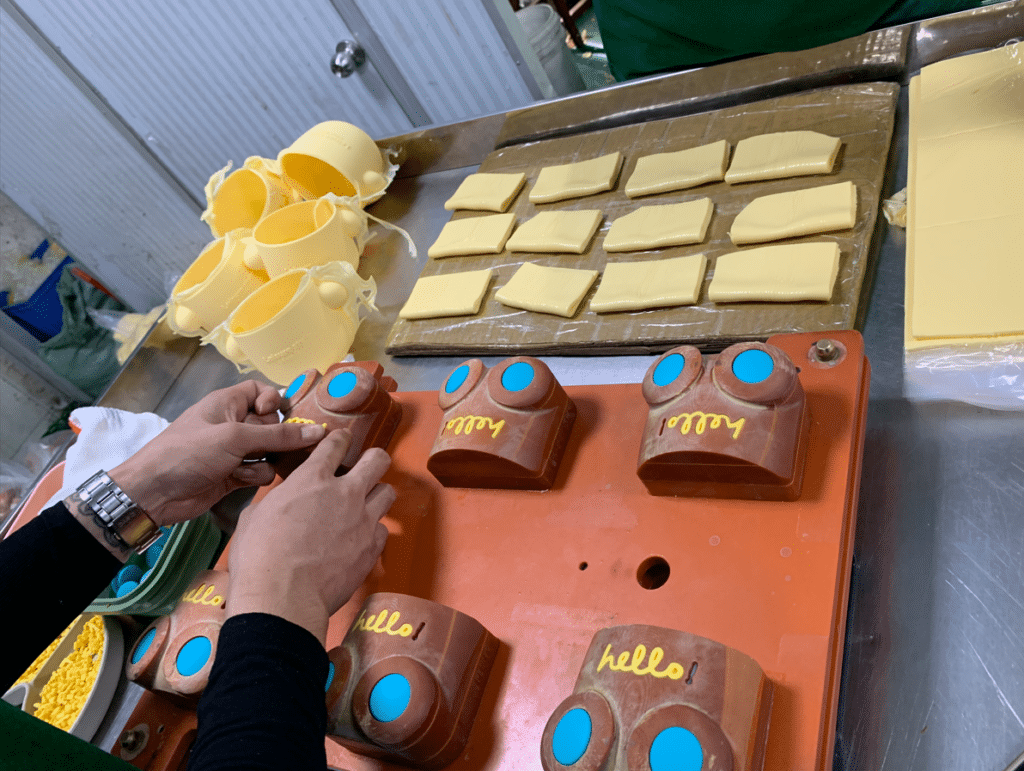

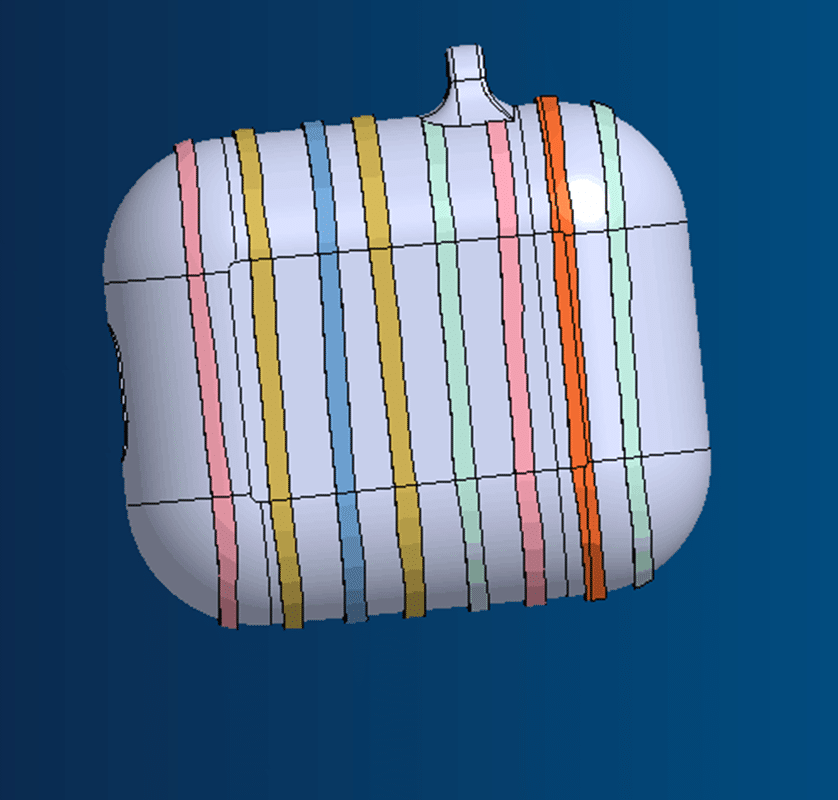

1. Design 3D structure of the silicone bag according to your idea

2. Make the silicone bag tooling according to the silicone bag design requirements (Signal color or multi color) use different metals, such as steel, copper or AL to ensure the accuracy and durability of the tooling.

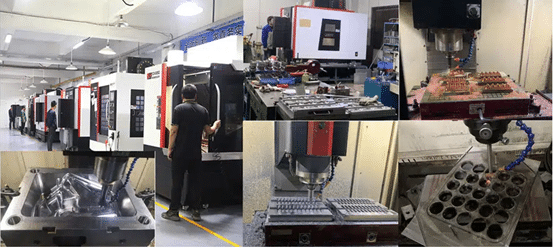

Z.S.R International Group (HONG KONG) CO., LIMITED in-house tool shop consists 6 sets of advanced CNC machining centers and 3 sets of EDM spark machines for tooling; So, we can make most of the silicone tooling and repair the silicone tooling in our factory to catch up your time needed.

3. Prepare the silicone bag raw material: Raw silicone material are the key to silicone bag’s products. Usually, silicone bags meet certain environmental protection standards, so silicone bag material are no exception.

Normally, environmentally friendly Fumed silicone rubber is selected for customized processing, while many manufacturers use Precipitated silicone rubber for processing.

Although the product is not greatly affected, it is still different Fumed silicone rubber from in quality after a long time. Mix the silicone color according to your silicone bag needed. Cutting the silicone bag material in the correct weight.

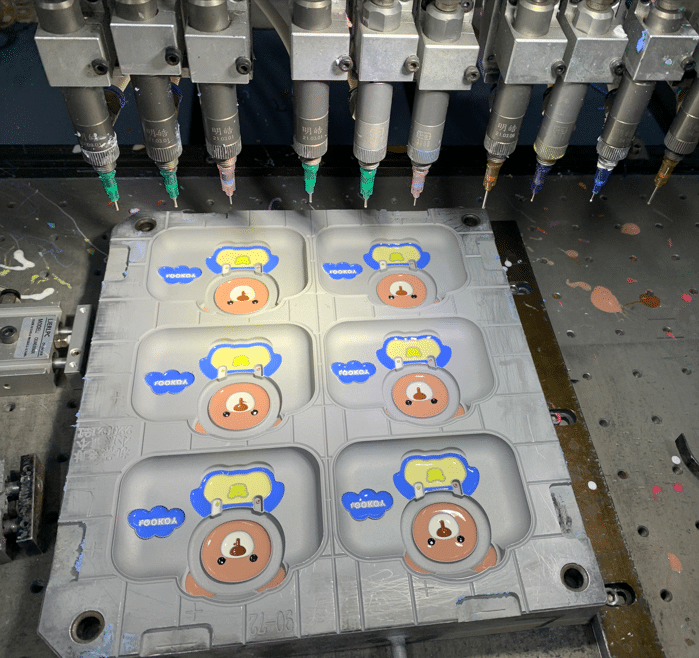

4. Feeding the prepared silicone bags mixed material on-Feeding the silicone bag material no matter the Liquid silicone rubber or solid silicone rubber in to the mold.

5. Curing the silicone bag: The silicone bag material is feeding into the mold after mixing, and the silicone bags material is filled into the entire space of the mold through heating and pressure. The temperature, pressure and time control of the molding process directly affect the size, shape and quality of the silicone bags.

No matter the silicone bag was made by: Compression molding, silicone dripping molding or LSR molding.

6.Demolding: After the curing is completed, take the silicone bag product out of the mold.

7.QC the silicone bag: Quality inspection: Visually inspect the molded silicone bag to see if there is lack of silicone bag material, uncooked Ness, or impurities

8. Post-processing: Carry out the silicone bag and then do the post processing and treatment, such as trimming, grinding, polishing, spraying, inspection, etc.

9. Secondary vulcanization: Secondary vulcanization is a process that must be handled for any product that has passed the inspection. The main reason why infant silicone bags have a certain smell is that they have not been subjected to Secondary vulcanization baking, and the catalyst of the raw silicone bags material of the products has not been emitted.

At present, many silicone product manufacturers basically handle it, but the time and temperature of the Secondary vulcanization treatment are different. Bake in oven 2-4 hours to meet FDA or LFGB Standard. LSR silicone bag may do not need this process.

10.LOGO or Pattern printing on the silicone bags if needed: screen printing or laser engraving. Most of time, we put the silicone bag logo on the silicone tooling directly. Check the products branding service to know more.

11.Final Quality control and testing: After all the silicone bag making process finished, we will arrange the final QC for the silicone bag before the delivery.

12.Package and Warehouse: Z. S. R offer custom packaging solutions you need for all your silicone bag packaging. Our custom packaging includes paper boxes, PE/PVC boxes, printed labels, hangtags, barcode stickers, etc to protect the safety of the product during transportation and storage, while ensuring the safety and aesthetics of the product.

In Z.S.R, we manufacture the silicone bag according to the client’s design and idea. We try our best to deliver the quality silicone bag to our customer

Final Conclusion:

In Z.S.R, all the steps from raw silicone bags material selection to molding, curing, and quality control, each step plays a vital role in creating your silicone bag that meet safety standards and perform well in their intended applications.

Understanding the silicone bag manufacturing process is essential for sellers, allowing them to offer high-quality, safe products to their customers.

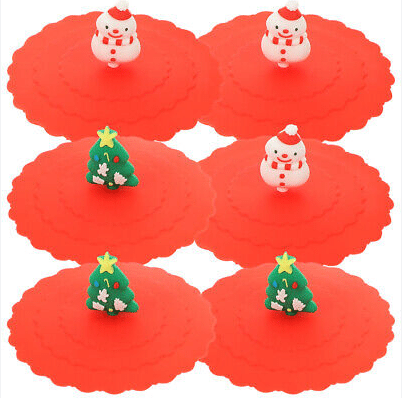

The silicone bags what we made include silicone Reusable bags, silicone food bags, silicone cosmetic bags, silicone purse bags, silicone key bags, silicone package bags etc. We can make any silicone bag with different size, shape model to fit your needs.

Related Article

How to create your molded silicone products?

How to create private silicone protector?

How to create private silicone trays?

How to create private silicone sleeves?

How to create private silicone shower scrubber or body scrubber?

How to create private silicone plate?

How to create private silicone placemats?

How to create private silicone molds?

How to create private silicone mats?

How To Create Your Silicone Cups?

How To Create Your Silicone Cases?

How To Make silicone boots?

How To Make Silicone Lids?

How To Make Silicone Bowls?

How To Make Silicone Earbud/Earphone Cases?

How to Make Your Silicone Brushes/Scrubbers?

How to Make Silicone Caps: Materials, Tools, Equipment

How to make air fryer silicone pots or silicone air fryer liner?

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.