Silicone material properties: Why is it the first choice in many industries?

Silicone has become the material of choice in many industries, including kitchenware, medical, maternal and child care, automotive, electronics, and seals, due to its non-toxic, high temperature and aging resistance and good biocompatibility. This article starts from the essence of performance and comprehensively analyzes the advantages and limitations of silicone to guide design material selection and enhance product competitiveness.

What are Silicone Rubber?

Silicone rubber refers to a rubber whose main chain is composed of alternating silicon and oxygen atoms, and the silicon atom is usually connected to two organic groups. Ordinary silicone rubber is mainly composed of siloxane chains containing methyl and a small amount of vinyl. The introduction of phenyl can improve the high and low temperature resistance of silicone rubber, while the introduction of trifluoropropyl and cyano can improve the heat and oil resistance of silicone rubber. Silicone rubber has good low temperature resistance and can generally work at -55℃. After the introduction of phenyl, it can reach -73℃. The heat resistance of silicone rubber is also outstanding. It can work for a long time at 180℃, and can withstand several weeks or more at a temperature slightly higher than 200℃ and still be elastic. It can instantly withstand high temperatures of 300℃-418℃. Silicone rubber has good air permeability and the oxygen permeability is the highest among synthetic polymers. In addition, silicone rubber also has the outstanding characteristics of physiological inertness and does not cause coagulation, so it is widely used in the medical field. Combining the advantages of thermoplasticity and rubber elasticity, it has toughness and transparency, and can be processed into various forms to meet delicate needs.

Silicone rubber is divided into heat-cured type (high temperature vulcanized silicone HTV) and room temperature vulcanized type (RTV). Among them, the room temperature vulcanized type is further divided into polycondensation reaction type and addition reaction type. High temperature silicone rubber is mainly used to manufacture various silicone rubber products, while room temperature silicone rubber is mainly used as adhesive, potting material or mold. The heat-cured type has the largest usage. The heat-cured type is further divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, with the largest usage and product brand), methyl vinyl phenyl silicone rubber PVMQ (low temperature resistance, radiation resistance), and others include nitrile silicone rubber, fluorosilicone rubber, etc.

As a silicone molding factory in China with 16 years, Z.S.R’s Precision Silicone mold /tooling ,Silicone Compression molding(48sets), Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any type silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations etc. Custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality silicone products for different industry application from industrial, consumer, commercial to medical.

Silicone material properties:

1. Extreme temperature adaptability

Silicone rubber has a very wide temperature resistance range and can maintain elasticity and stability within -100℃ to 350℃ (some documents are marked as -73℃ to 300℃ or -50℃ to 250℃). Its glass transition temperature is as low as -100℃, and it can still maintain flexibility and mechanical properties at high temperatures, making it suitable for harsh environments such as aerospace and power equipment.

2. Excellent electrical insulation performance

Silicone rubber has high resistivity (about 10^15-10^17 Ω·cm), and remains stable over a wide temperature and frequency range, with outstanding corona and arc resistance. This feature makes it an ideal insulating material for high-voltage cable accessories.

3. Chemical and weathering stability

It has strong resistance to acids, alkalis, salt solutions and organic solvents. At the same time, the Si-O bond structure can resist ozone, ultraviolet rays and oxidative degradation, and the physical properties change little after long-term outdoor exposure. For example, it can still maintain functional integrity under high-pressure steam (0.64 MPa).

4. Mechanical and interface properties

It has high elastic recovery rate (hardness is only 15 Shore A at 15% elongation), low compression permanent deformation, and excellent hydrophobicity and breathability. Its hydrophobicity can automatically migrate surface dirt and reduce the risk of wet flash.

5. Biocompatibility and safety

It is non-toxic, odorless, and meets medical-grade standards, but the core value of this feature in the power field lies in its material stability, which can avoid the release of harmful substances.

Why will you choice silicone material?

Who cares about silicone rubber properties?

- Engineers/product designers in production factories: need to accurately match functional parameters and processes;

- Brands/purchasers of kitchen supplies, maternal and child supplies, and medical supplies need to measure costs, safety, and market demands based on the performance of silicone materials;

- Users of kitchenware, maternal and child products, and medical products: care about safety, feel, and cleanliness;

- Users of factories that use silicone accessories for industrial/electronic applications: focus on weather resistance, electrical insulation, and protective performance.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Custom Silicone Products | OEM/ODM Service

When and where will you choose silicone rubber material?

How to use, design and choose suitable silicone rubber materials?

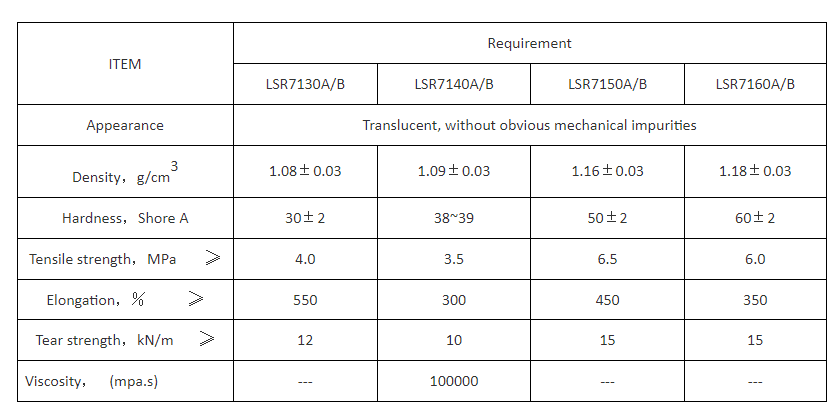

Clarify the use temperature, corrosion resistance, and elasticity requirements, and select HCR/LSR materials according to the temperature, chemical environment, and elastic durability requirements; determine whether high transparency or color customization is required; choose whether solid silicone rubber or liquid silicone

If high tear strength or oil resistance is required, reinforcing fibers or coatings can be added;

Process control should be accurately matched: such as temperature control for injection molding LSR and vulcanization time control for compression molding HCR;

For surface powder adhesion problems, dust-proof coatings or mixed preparations can be selected.

Check relevant certifications: FDA, LFGB, ISO, USP VI, RoHS

Select the appropriate material based on the actual quantity of customer product requirements. Generally, solid silicone rubber is selected for small-scale trial production, and liquid silicone rubber is selected for large-scale production exceeding 5W.

How to control silicone products quality?

First: we start to control from the design of the product. After the customer sends the product, our engineering will evaluate the design of the silicone product for DFM and give suggestions that meet mass production and meet customer requirements.

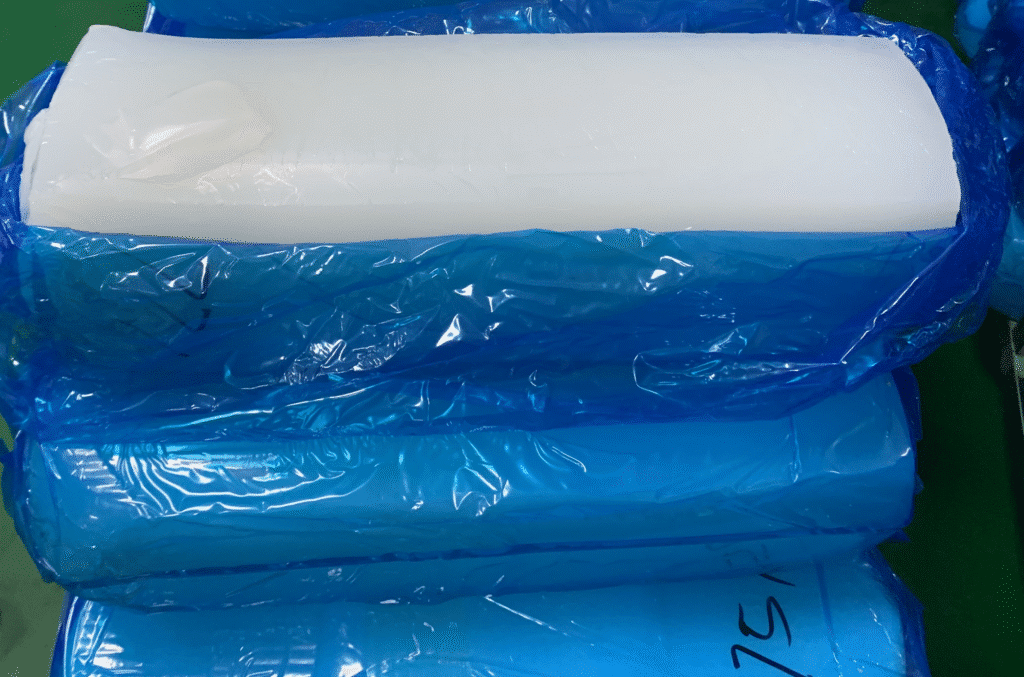

Second: We control from the feed of raw materials, purchase FDA/LFGB certified silicone raw materials, and conduct feed inspection at the same time, inspect the hardness, purity, color, etc. of the silicone raw materials, and mark them to ensure that the raw materials used for production are qualified.

Third: Mold design and mold making: According to the customer’s product requirements, we rationally design the silicone molds used in production, and control the dimensional accuracy of silicone products by vacuum exhaust + controlling the injection volume, reducing the appearance of bubbles, controlling the mold gap, and reasonable degumming. Use fluorine treatment/spraying release agent to improve the sticking problem.

Fourth: Control during the product production process, add anti-yellowing agent or choose a high-transparency formula to increase the aging resistance of silicone products. Add reinforcing agent/cross-linking treatment to obtain the ideal product tensile strength effect. The molding process control points (vulcanization time/temperature/pressure) reduce the problems of immature products, raw rubber, bubbles, etc. In addition, through visual inspection, patrol inspection, and 100% full inspection, ensure that the finished silicone products shipped are of qualified dimensional stability, resilience, and hardness consistency.

Z.S.R Group’s quality ratings are sustained through the implementation of a rigorous quality control system. All the products quality is carefully verified through in-process inspection plans where products are constantly monitored for defects, damage, or any other inconsistencies. Every product package can then be traced back to the date the part was produced, the processes performed, and the materials employed.

How to clean and maintain silicone rubber products?

General stains Soak in warm water (40-50℃) and wipe with a soft cloth, using neutral detergent.

Stubborn stains Wipe with alcohol or white vinegar (be careful to avoid direct contact with the skin), or use a professional cleaning agent.

Special materials Silicone that requires high temperature disinfection (such as medical grade) can be wiped with 70%-75% alcohol to avoid prolonged contact.

More FAQs

1: Can silicone really withstand temperatures from -70 to 250°C?

Yes, it has been tested by ASTM and is widely used in high-temperature baking and low-temperature freezing appliances.

2: Can it be used for baby products for a long time?

Medical-grade platinum silicone does not contain plasticizer residues and is one of the safest materials currently available. It can be used for baby products.

3: Can silicone materials resist oil and solvents?

Conventional silicone is more sensitive to motor oil and alcohols, so it is recommended to choose a special fluorosilicone formula.

4: Will it stick to powder?

A: Standard silicone may slightly absorb dust, so it is recommended to select a dust-proof coating or design packaging.

5: Can it be recycled?

A: Thermosetting materials cannot be melted and recycled, so it is recommended to replace them according to the service life to save resources.

Summary

Silicone materials are widely used in many fields due to their unique high and low temperature adaptability, biological inertness, insulation performance, formability and user safety characteristics. Recommended selection process: Definition: temperature requirements, elastic properties, tear resistance → Material selection: HCR/LSR/reinforced or aerogel → Process: injection molding/compression/extrusion → Use and maintenance: cleaning, disinfection, testing. Our company has professional engineers who can help you choose product materials according to the different needs of your products. Please contact our experts to customize your exclusive silicone project.

Z.S.R consists of a strong engineering design team 12 experts with more than 20 years’ experience. We offer personalized services and supports for projects through all steps of products development. From conceptual design, silicone material selection, engineering, prototyping and testing, to final volume production and assembly.

Contact Z.S.R to choose the correct silicone material for your projects. We have help more than 1000 clients/year to analyze their material needs and empower their silicone project success.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.