How Strong is the silicone Rubber?

Silicone is an inorganic polymer comprising carbon, hydrogen and oxygen (Silicone). Silicone is used extensively across many industries and applications from rail, aerospace, food/beverage and automotive plus many more. Silicone rubber has a number of advantages but it is most commonly known for and used due to its resistance to extreme temperatures.

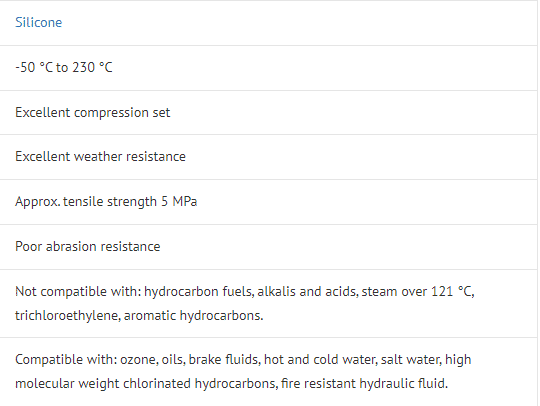

Silicone stays stable and keeps its physical properties up to 230°C (446°F) and high-temperature silicone grades can withstand up to 270°C. Not only is silicone excellent in extreme heat but it is also seen as a sterile elastomer, which is why you see it used in the food and beverage industry as dairy tubing, seals and gaskets on food machinery and also vending tubes in drinks machines.

The strong Si-O chemical structure and high bond energy give Si Elastomers their unique performance properties. Several benefits of silicone rubbers include:

- Wide service temperature range – excellent thermal and thermoxidative resistance (-Si-O-Si- binding energy is higher than C-C bonds)

- Excellent resistance to attack by oxygen, ozone and sunlight

- Readily resistant to electromagnetic and particle radiation (UV, alpha, beta and gamma rays)

- Excellent non-stick and non-adhesive properties

- Low toxicity

- Flexible at low temperatures due to their low glass transition temperature (Tg).

- Optical transparency

- Good excellent insulation properties

- Low chemical reactivity

- High bio-compatibility: Excellent mechanical properties (high tear strength, high elongation)

- Excellent Flexibility: Solid Silicone rubber has excellent flexibility, it can be modified easily and responds well to a variety of circumstances.

- Noise Reduction: Solid silicone reduces high-volume noises passing through.

- Vibration Dampening: The rubber reduces vibration, suitable for mass transit applications.

- Sealing: Solid profiles are mainly used for precision sealing, this format of silicone responds well to sealing tight spaces due to its flexible nature.

- Insulation: Solid silicone rubber is designed to stop the process of heat and electricity from spreading.

- Thermal Insulation: The silicone material stops unwanted heat from entering through to the other side.

- Thermal Shielding: The silicone material acts as a shield from absorbing excessive heat from travelling to it’s centre.

- Gasket: Solid silicone gaskets sit between two surfaces, generally to prevent leakage into the joined objects while under compression.

Further Reading: Silicone Material

In Z.S.R Group, we manufacture our products exclusively from pure silicone. Silicone is a type of polymer known as an “elastomer” – these polymers are stretchy or elastic. For any of your custom silicone rubber products, please contact us.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.