Silicone vs PVC: The Differences You May want to know

PVC and silicone rubber are often used in similar fields, such as toys, gifts, wire sheaths, etc., but they differ greatly in performance, environmental friendliness, and safety. Therefore, during product design or market upgrades, many companies repeatedly weigh the pros and cons between the two. Silicone material belongs to elastomer material, while PVC belongs to plastic material.

In the early stages of product development or procurement, choosing the right material is critical to product cost and project success. Especially in the fields of baby products, kitchen appliances, wearable devices, industrial seals, etc., PVC and silicone are often compared.

“PVC is cheaper, but why do many brands use silicone?”

“Why is silicone better than PVC?”

“Do we need to upgrade the materials for our current products?”

This article deeply analyzes the advantages and disadvantages of the two materials from multiple aspects such as scientific performance, practical application, customer needs and cost control, and provides you with a reference for material selection.

Material characteristics

Silicone products are more cold-resistant and more heat-resistant than PVC products. Tableware made of silicone material can be heated in a microwave, while PVC can’t.

A: PVC is the world’s third-most widely produced

Polyvinyl chloride (PVC), referred to as PVC, is a polymer formed by free radical polymerization of vinyl chloride monomer in the presence of initiators such as peroxides and azo compounds, or under the action of light or heat. It is a white powder, non-toxic and odorless, with a relative molecular mass of 50,000 to 110,000 (industrial pure PVC), a relative density of 1.35 to 1.45, low water absorption and air permeability (pure PVC), insoluble in water, gasoline, alcohol, vinyl chloride, soluble in ketones, esters and chlorocarbon solvents. Polyvinyl chloride has good chemical corrosion resistance and good electrical insulation, but poor impact resistance, is unstable to oxygen and heat, and is easily degraded.

The production methods of polyvinyl chloride monomer vinyl chloride include calcium carbide method, ethylene method, etc., and the polymerization methods can be divided into emulsion method, suspension method, bulk method, etc. Among them, PVC produced by suspension method is the largest variety. Polyvinyl chloride is one of the earliest resin varieties to be industrialized. It was the largest resin variety before the 1960s, and retreated to second place in the late 1960s. General-purpose PVC resin was first industrialized in Germany in 1935 and was widely used during World War II to alleviate the shortage of steel at the time. Polyvinyl chloride can be processed into pipes, pipe fittings, rods, profiles, films, sheets, wire and cable insulation materials, artificial leather, floor tiles, toys, shoes, bottles, records, foaming materials, sealing materials, fibers and other products by extrusion, injection molding, calendering and blow molding. It is widely used in light industry, construction, agriculture, electricity, daily life and other aspects.

The Raw Material of PVC:

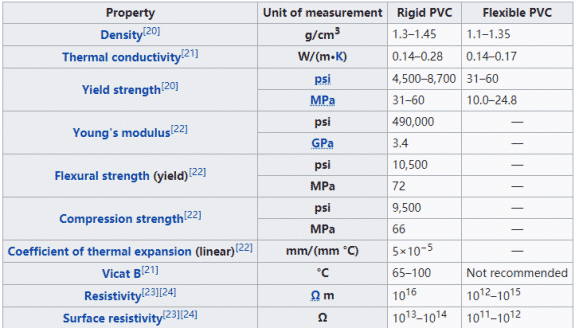

The property of PVC:

B: Silicone rubber is an elastomer (rubber-like material) composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubber refers to a rubber whose main chain is composed of alternating silicon and oxygen atoms, and the silicon atom is usually connected to two organic groups. Ordinary silicone rubber is mainly composed of siloxane chains containing methyl and a small amount of vinyl. The introduction of phenyl can improve the high and low temperature resistance of silicone rubber, while the introduction of trifluoropropyl and cyano can improve the heat and oil resistance of silicone rubber. Silicone rubber has good low temperature resistance and can generally work at -55°C. After the introduction of phenyl, it can reach -73°C. The heat resistance of silicone rubber is also outstanding. It can work for a long time at 180°C, and can withstand several weeks or more of elasticity at a temperature slightly higher than 200°C. It can instantly withstand high temperatures above 300°C. Silicone rubber has good air permeability and the oxygen permeability is the highest among synthetic polymers. In addition, silicone rubber also has the outstanding characteristics of physiological inertness and non-coagulation, so it is widely used in the medical field.

Silicone rubber is divided into heat vulcanization type (high temperature vulcanized silicone HTV) and room temperature vulcanization type (RTV), among which the room temperature vulcanization type is further divided into polycondensation reaction type and addition reaction type. High temperature silicone rubber is mainly used to manufacture various silicone rubber products, while room temperature silicone rubber is mainly used as adhesive, potting material or mold. The hot vulcanized type has the largest usage, and the hot vulcanized type is divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, the largest usage and product brand), methyl vinyl phenyl silicone rubber PVMQ (low temperature resistance, radiation resistance), and others include nitrile silicone rubber, fluorosilicone rubber, etc.

The Silicone products can pass the ROHS certification RoHS-certification.pdf and is environmentally friendly reach-certification.pdf.The Silicone products is BPA and Phthalate free phthalate-free.pdf and biodegradable, long-term use, and other characteristics.

There is two kind of silicone material. One is Solid silicone. One is Liquid Silicone Rubber.

The Raw Material of Solid Silicone.

The Raw Material of Liquid Silicone Rubber.

Further Reading: Silicone Material

Making Process

A: PVC-making process

PVC products are made of polyvinyl chloride and oil together with color paste, and its raw materials are made by heating and cooling microinjection epoxy process.

B: Silicone material only needs to use the silicone to add the color masterbatch to suppress and deploy in mixing machine, then put them in the mold by heating and cooling to take shape.

We usually use silicone compression molding when using solid silicone rubber.

We use Liquid silicone injection molding when using liquid silicone rubber.

Learn More About Silicone Molding Method And Process

Appearance difference

The Surface of PVC is Rough.

The surface of silicone products is smooth and shiny.

Touching difference

Hand touch feeling.

Silicone product is soft with good toughness and elasticity.

PVC is relatively hard.

The softness and hardness of both can be adjusted, but the PVC does not have tenacity.

Temperature difference

Silicone products have high thermal stability, and the chemical bonds of molecules do not break or decompose under high temperatures.

Silicone is resistant to high and low temperatures and can be used over a wide range of temperatures. The conventional temperature range of -40 ~ 230 degrees within the long-term use.

PVC material is a mainly white powdery amorphous material, density is 1.3-1.5, material vitrification temperature is within 90 degrees, the highest temperature resistance is 170 degrees.

With high temperatures, PVC will be automatically decomposed into hydrogen chloride, beyond the temperature range will automatically catalyze decomposition.

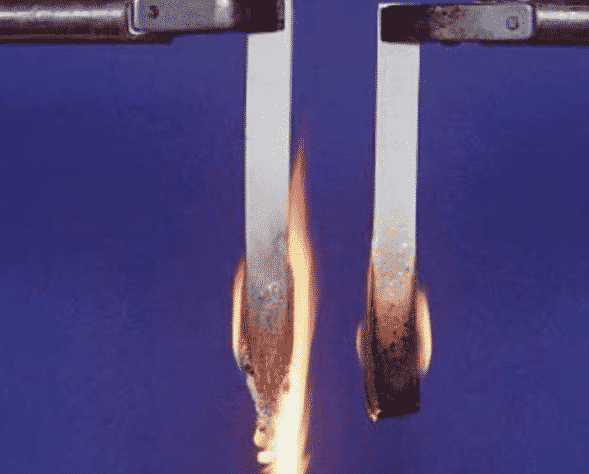

Burning Difference

Silicone products are generally transparent, with small burning smell and White powder.

PVC products will turn black after burning and smell bad when burning.

Rebound strength

Silicone material has a good silicon molecular connecting strength, the rebound strength will be much better.

PVC material products has poor rebound.

Cost difference

Silicone material is more expensive than PVC products in production and manufacturing.

The raw material price of PVC products is low, which is made of synthetic materials.

ZSR Group,all of our products include the Silicone baby products, Silicone Beauty&Health-care, Silicone Pets, Silicone Consumer Electronic Protective Cover, Silicone Housewares Products, Silicone Promotional Gifts all made by Food Grade Silicone material.

Who care the difference of Silicone VS PVC?

Product managers in brands that use silicone or PVC materials care about user experience, material upgrades, and environmental certification.

Purchasing managers who use PVC and silicone products care about product cost control and stable delivery.

Designers and engineers in manufacturers that use PVC or silicone materials care about the physical properties and processing methods of these two materials.

Cross-border e-commerce entrepreneurs: pay attention to the target market’s acceptance of materials (such as the US regulatory restrictions on PVC).

When and Where you should know the difference of Silicone VS PVC?

When developing new products for baby chews, pacifiers, medical-grade seals, and other products with high safety and high quality requirements, you need to choose silicone as the material to meet safety requirements and meet the market with higher material certification requirements, such as the United States, the European Union, Japan and other countries

If your product is a gift, as a brand owner, or at an event, if you want to increase the added value or environmental protection level of the product, silicone is the first choice as the raw material.

If you do not need high temperature resistance, wire sheaths, cables, household toys, and industrial products, you can choose PVC materials because the overall cost is low and can be mass-produced.

However, if it is used as kitchen supplies (shovels, gaskets) and video contacts, heat resistance, high temperature resistance, easy cleaning, and high safety are required, please choose silicone materials first.

How to produce PVC products?

The processing and manufacturing of PVC products mainly adopts the extrusion molding process, and the specific process is as follows:

Raw material preparation

Using polyvinyl chloride resin (PVC) as the main raw material, it is necessary to add additives such as stabilizers, plasticizers, lubricants, etc., and mix them evenly according to the formula ratio.

Mixing and plasticizing

The mixed raw materials are sent to the extruder, and the PVC resin is melted and plasticized by screw rotation and heating. The twin-shaft mixing extruder can initially plasticize the raw materials, and the single-screw extruder further heats to a suitable processing temperature (usually 145-175℃).

Mold molding

The molten PVC material is extruded and molded through a mold. For example, a specific mold is used to control the outer diameter and wall thickness of the pipe, or it is pressed into a sheet by a calender, and a film is blown to make a film.

Cooling and shaping

The molded product is cooled and solidified by a water tank or cooling roller to keep the shape stable. For example, the pipe needs to be sprayed with cooling water, and the film needs to be shaped on the cooling roller.

Post-processing

Cut into specified lengths, conduct quality inspections (such as appearance inspection, size measurement), and package and ship out after passing the inspection. Some products require surface treatment (such as UV coating) or slitting.

The process parameters of different PVC products (such as pipes, artificial leather, and films) are slightly different. The key lies in the coordination of temperature control, mold design, and extrusion speed.

How to produce the silicone products?

Silicone product processing and molding technology points, in today’s industrial manufacturing and daily life, silicone products have become an indispensable part with their unique properties and wide application fields. From medical supplies to electronic accessories, from household items to auto parts, silicone products are everywhere. The silicone product processing and molding technology is the key link to determine its quality and performance.

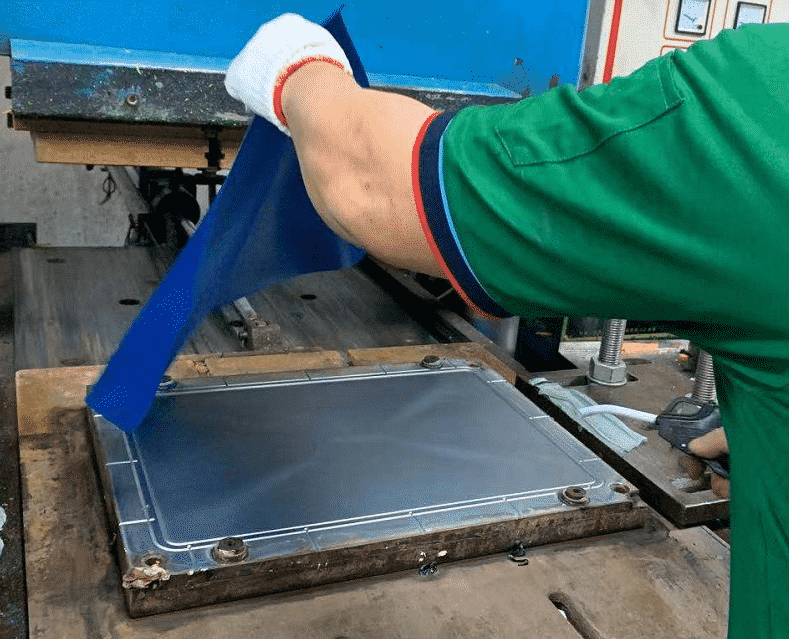

1.Compression molding process: Compression molding is a common silicone product molding process, which is mainly completed by mold cooperation. The shape of the mold determines the shape of the silicone product. Molded silicone products are usually formed by placing solid silicone raw materials with added vulcanizers in high-temperature molds, applying pressure through a vulcanizing machine, and solidifying them at high temperature. The hardness of molded silicone is usually 30°C-70°C. This production process is relatively simple and is suitable for all silicone products, especially products with complex shapes and high dimensional accuracy requirements, such as mobile phone keys, silicone tableware, etc. Its advantages are high dimensional accuracy, good surface finish, and high production efficiency; its disadvantages are high mold costs and are not suitable for small batch production. During the compression molding process, the accuracy and cleanliness of the mold must be ensured to avoid mold deformation or contamination affecting product quality. At the same time, parameters such as molding temperature and pressure should be reasonably controlled to ensure the molding accuracy and performance of the product.

2.Silicone Dripping molding: The glue dripping process is that the silicone raw material is in liquid state, the raw material is loaded in a syringe, and the glue is injected into the mold by injection molding and carving technology, and the raw material is dripped onto the mold manually, and then heated and vulcanized. Then put it into solid state and mold it with the main silicone at high temperature. This process is a manual process, which requires a lot of manual work, so the production capacity is not high. But it has a feature that a product can be dripped with multiple colors as required, so this process is mostly used to make handicrafts. In the process of drip molding, the speed and amount of dripping, as well as the time and temperature of heating and vulcanization, must be strictly controlled to ensure the quality and appearance of the product. In this process, manufacturers can produce two-color, three-color or multiple three-dimensional color products by adjusting the injection amount, stroke and color of the machine. However, due to the slow production efficiency, the process quality of the product is prone to problems, so the cost is relatively high. Therefore, if your silicone product requires more colors and needs a three-dimensional sense, you can choose the drip molding process.

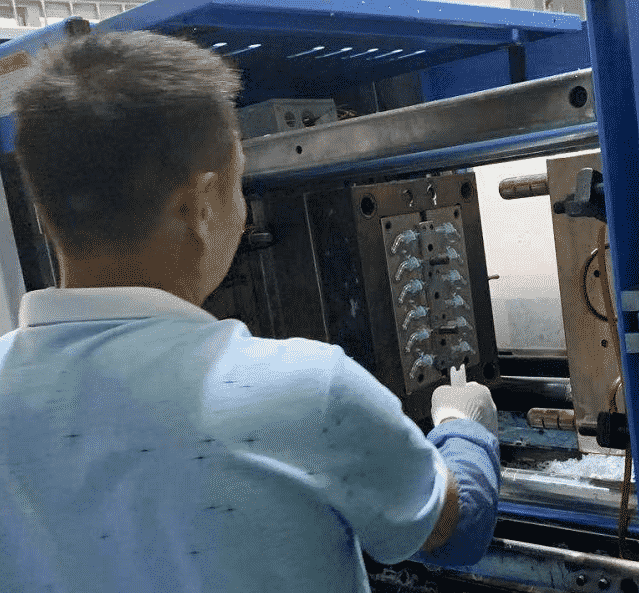

3.LSR Injection molding process: Injection molding is a process in which liquid silicone (LSR) is injected into the mold through an injection molding machine and solidified at high temperature. The quality requirements of injection molded products are high, and it is a combination of liquid silicone and plastic. Its products show good thermal stability, cold resistance, excellent electrical insulation performance, and no toxic substances are produced when burned. It has become an irreplaceable material in the production design of health products, automobiles, baby products, medical products, diving products, kitchen utensils and seals. Injection molding is to divide the silicone raw material into two components, add them to the injection machine and mix them thoroughly, and then put them in the mold to form through temperature changes. This process is suitable for the production of high-precision, thin-walled, complex structure products, and is widely used in medical, optical and other fields, such as contact lenses, medical silicone products, etc. In the injection molding process, the mixing ratio, temperature and pressure of the raw materials must be strictly controlled to ensure the quality and performance of the product.

4.Silicone Fabric Coating process: The coating process is a process of coating the silicone material on the surface of the substrate to form a film or coating.

5.Extrusion molding process: Extrusion molding is a process of continuously extruding the silicone material through an extruder to form a tubular, strip or profiled material. Extrusion molding is to continuously extrude the silicone raw material through a screw extruder, and pass through a die of a specific shape to form a continuous profile, such as a silicone tube, a sealing strip, etc. Extrusion molding has high production efficiency and is suitable for the production of long-sized products with fixed cross-sectional shapes. During the production process, the size and performance of the product can be controlled by adjusting parameters such as extrusion speed and temperature. Generally, the shape of extruded silicone is long and tubular and can be cut at will, but the shape of the product made by the extrusion process is relatively simple, mostly in the shape of strips. Silicone tubes are widely used in the fields of medical and mechanical equipment. During extrusion molding, it is necessary to ensure the normal operation of the extruder and regularly maintain and service the extruder to ensure the quality and production efficiency of the product.

6.Calendering molding process: Calendering molding is a process in which silicone material is pressed into sheets or films by a calender. Calendering molding is a process in which silicone rubber is kneaded and mixed with white carbon black, silicone oil, etc. to make a mixed rubber and then calendered into a sheet. The film obtained by calendering has obvious differences in its physical and mechanical properties in the longitudinal and transverse directions. This phenomenon is the calendering effect. Specifically, the longitudinal tensile strength of the film is greater than the transverse direction, the transverse tear elongation of the film is greater than the longitudinal direction, and the longitudinal shrinkage of the film is greater than the transverse direction. The size of the calendering effect is related to the composition of the rubber, calendering temperature, speed, speed ratio, etc. Calendering is used for larger products, such as silicone sheets and silicone plates. During the calendering process, the temperature, pressure, speed and other parameters of the calender must be strictly controlled to ensure the calendering effect and product quality.

7.Dipping molding process: Dipping molding is a process in which the mold is immersed in liquid silicone, the silicone adheres to the surface of the mold, and then solidifies.

The operation method of infusion or casting molding is to surround the product or model to be copied with a rubber plate or glass plate, pour the vacuumed silicone directly onto the product, wait for the silicone to dry and form, take out the product, and the mold is formed. Infusion molds generally use silicone with a relatively soft hardness to make molds, so that demolding is easier and will not damage the product in the silicone mold. It is a combination of solid and liquid. This process is often used for relatively smooth or simple products. There is no mold line to save manpower and time. Products such as mobile phone cases and luggage cases are used. During infusion molding, the vacuum degree and infusion volume of the silicone must be ensured to ensure the quality of the mold and the molding effect of the product.

8.3D printing process: 3D printing is an emerging silicone molding process that forms a complex three-dimensional structure by stacking liquid silicone materials layer by layer.

9.Transfer molding process (die casting: Transfer molding is a process in which silicone materials are injected into a closed mold under pressure and then cured.

10.Foaming molding process: Foaming molding is a process in which a foaming agent is added to silicone to form a porous structure during the curing process.

11.Vacuum forming process: Vacuum forming is a process in which silicone materials are attached to the mold surface by vacuum adsorption and then cured.

In Z.S.R group, we have the Silicone mold tooling ,Silicone Compression molding, Silicone over-molding, Liquid Silicone Rubber Injection molding: LSR molding, Liquid silicone rubber overmolding, LSR Multi-Shot (LSR/Thermoplastic/Metal), silicone Dripping molding, capabilities allow us to manufacture any silicone rubber products for your company’s needs in an infinite variety of design, function, material, structure, shape, sizes, color, logo, pattern, package, label configurations.

With Z.S.R Unlimited customized silicone products service, Z.S.R custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality products for different industry application from industrial,residetial,commercial to medical.

This creates a one-stop silicone solution to meet your scalability requirements for your Customized silicone products.Contact Z.S.R expert to choice the correct material for your projects.

More FAQ about silicone VS PVC

1: Is silicone better than PVC?

Not absolutely. Silicone is suitable for scenarios with high requirements for environmental protection, safety, and high temperature resistance, while PVC has more advantages in budget-sensitive, high-volume industrial products.

2: Is PVC environmentally friendly?

Traditional PVC may contain phthalate plasticizers and heavy metals, but there are also environmentally friendly non-toxic PVC on the market. You need to check whether it has passed RoHS, REACH and other certifications.

3: Will silicone age?

Under normal use conditions, silicone can remain unchanged and non-aging for more than several years; but it needs to avoid contact with motor oil, strong acids and alkalis.

Conclusion

From the above differences, we can see that silicone material is safer than PVC, which is more suitable for food and medicine materials.So even silicone and PVC each have their own characteristics and application scenarios. When selecting materials, it is necessary to consider functional requirements, target market regulations, cost budget, user experience and other factors. For high-end markets and high safety standards, silicone is the first choice; for low-cost, mass consumer areas, PVC is still competitive.

As a manufacturing expert with 26 years of experience in the silicone industry, we always insist on providing customers with customized solutions and professional technical advice. If you are facing challenges in material selection or product upgrades,Please contact Z.S.R to get our suggetion.

Any Silicone products or Silicone project need technical support, you could buy custom Silicone products at ZSR Group. ZSR Group has rich experience in producing Silicone products. Visit the ZSR Group website to get more details for the silicone products.

The buring video for Silicone or PVC

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.