How to distinguish ordinary silicone and food-grade silicone products?

I have been engaged in the production and processing of silicone products for nearly 26 years.With the improvement of consumers’ health awareness, more and more brands and end users have asked when they buy the silicone products: “Is this product food-grade silicone?”, “How to verify that it is safe and non-toxic?”, “What is the difference between food-grade and ordinary silicone?”

This is not only a product quality issue, but also related to user health, product compliance, brand image and even export customs clearance.

This article will answer the key methods of how to identify ordinary silicone and food-grade silicone, helping brands, procurement and R&D personnel make wise decisions.

The silicone can be divided into ordinary silicone and food-Grade silicone. Usually, ordinary silicone was widely in accessories for machinery, electronics, automobiles and agro-industrial industries.

What is Ordinary silicone?

Ordinary silicone usually refers to solid silicone gel, whose main components are silicon dioxide, water and surfactants, made of silicon oxide, usually made through a silicon-oxygen chain structure, and belongs to an inorganic polymer material. It is characterized by moderate cost and a wide temperature range (-40℃ to 280℃), but it may contain additives or fillers, and long-term use may cause problems such as yellowing and residual odor. It Mainly used in non-food contact fields such as industrial products, electronic components, and automotive accessories and other industries.

The physical properties of ordinary silica gel include good hygroscopicity and moisture absorption, but its surface is opaque and easy to stick to dust.

Main features Temperature resistance : Ordinary silica gel can remain stable in an environment of -40℃ to 280℃, but may release harmful substances at high temperatures

Physical properties : The surface is easy to stick to dust, the transparency is low, and whitening may occur when stretched

In addition, ordinary silica gel may volatilize harmful substances at high temperatures, so it is not suitable for applications that require high temperature environments. It should be noted that if ordinary silica gel is used in a high-temperature environment, it is necessary to carefully select qualified products that meet national standards.

What is Food Grade silicone?

Food-grade silicone refers to silicone materials that can come into direct contact with food, and are mainly used to make food-related products, such as baby pacifiers, food molds, water dispensers, kettles, etc.

Food-grade silicone rubber is an inorganic polymer colloidal material formed by the polycondensation of silica, the main component of which is silicon dioxide (SiO₂·nH₂O), with a content of more than 98%. This material is non-toxic and tasteless, has strong chemical stability, and only reacts with caustic alkali and hydrofluoric acid under normal conditions.

Non-toxic and tasteless and Safety: Food-grade silicone rubber has been refined and sterilized, and can be directly in contact with food without toxic side effects.

High chemical stability: Under normal conditions, it does not react with any acid, alkali, or salt except caustic alkali and hydrofluoric acid

Good physical properties: It has many micropores and a large specific surface area, and its surface is highly hydrophilic, and can absorb more than 80%-100% of its own weight of water.

- Food-grade silicone is a kind of environmentally friendly silicone, non-toxic, odorless and degradable;

- Soft, elastic, resistant to kinking and deformation;

- No cracking, long service life, cold and high temperature resistance;

- Has higher tear strength and superior electrical properties;

- No yellowing, no frost, no whitening, no fading at room temperature, no scale and no odor when placed in water for a long time It is non-toxic; does not stain food, dishes, or cookware; is easily removed from cast objects, and is safe for use on various plastic objects.

The main purpose of Food-grade silicone is used for the manufacturing of food-contact products. Food-grade silicone is a type of silicone that is safe for use with foods. Silicone is used frequently in making molds to use for food that begins as liquids and solidifies. Application range: Widely used in food molds, mainly for food molds, chocolate molds, candy molds, precision casting, as well as carbon fiber composite materials, food cake molds, craft ceramics, printing, human organ cloning, household appliances, lighting products, silicone ice trays, silicone nipples. Medical catheters, body fluid diversion tubes and other products, as well as daily use such as baby pacifiers and silicone gifts.

Food-grade silicone is widely used in silicone kitchen utensils, baby pacifiers, drinking cups, baby sippy cups, and other places. Since food-grade silicone is higher in quality and price than ordinary silicone, the cost of producing regular qualified silicone products will be much higher. It is for this reason that some unscrupulous manufacturers use ordinary silicone to produce water cups, kitchen utensils, baby pacifiers, etc., which are in contact with our diet in order to reduce production costs and are shoddy.

Such products not only fail to meet the requirements of quality but also endanger the health of our human body. So how do we tell which ones are ordinary silicone and which ones are food-grade silicone?

The best way is to test on the lab by Intertek or Bureau Veritas or SGS, TUV. So most of the brands for the food contact brand products have certification about their goods.

More About Food Grade Silicone

Why do we distinguish between ordinary silicone and food grade silicone?

We need to distinguish between ordinary silicone and food-grade silicone, mainly because of their different safety and application scenarios. Food-grade silicone meets food safety standards and is suitable for direct contact with food or medical scenarios; ordinary silicone is mainly used in industries, homes and other fields and cannot be directly in contact with food. If we do not distinguish them, in case of misuse, for consumers, “food grade” is an endorsement of the health and safety of the product, which will directly affect our brand trust.

Who care the difference of ordinary silicone or food grade silicone?

Brands and traders of silicone maternal and infant products, kitchen products, and medical products need to provide compliance endorsements to avoid after-sales disputes due to material issues.

Silicone products, cross-border e-commerce sellers: involving exports to Europe, America, Japan, Australia and other markets, with high material requirements.

Designers, product managers, and product development engineers of maternal and infant and kitchen products: because these types of silicone are directly related to whether the products can safely contact food or children’s skin.

End consumers who care about safety and health, especially mothers and health experts, are extremely sensitive to the word “food grade”.

When and where you will use ordinary silicone or food grade silicone?

Baby products, such as baby pacifiers, baby food spoons, all scenes that come into direct contact with food (such as pacifiers, silicone bowls, straws, lunch boxes, baking mats), tableware, kitchen utensils, sealing covers, female care products, medical consumables, and detachable wearable devices (such as silicone straps and body sensing instrument covers) need to use food-grade silicone

Industrial pipelines, mechanical seals, outdoor sports equipment dust plugs, and other areas that do not need to contact food, ordinary silicone can be used.

More FAQ about ordinary silicone or food grade silicone?

1: Does food-grade silicone have any smell?

High-quality food-grade silicone has no odor. If there is a plastic smell or greasy feeling during use, it may be low-quality ordinary silicone or incomplete vulcanization.

2: Are all silicones resistant to high temperatures?

Food-grade silicone is generally resistant to temperatures between -40°C and 230°C. Some ordinary industrial silicones are also resistant to temperatures, but are not suitable for contact with food.

3: How to tell whether silicone is food-grade?

A: Check whether there is an FDA/LFGB logo and report

Soft touch, delicate surface, non-greasy

No odor, no obvious acidic smell

As a Manufacturing company, we would like to share some easy ways to distinguish them.

Odor identification: Food-grade silicone is non-toxic and odorless, while ordinary silicone has a pungent odor

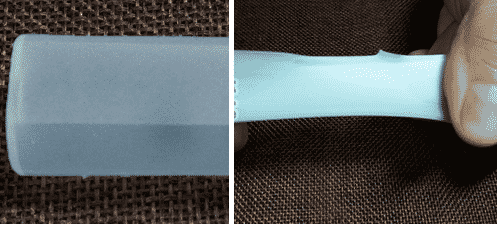

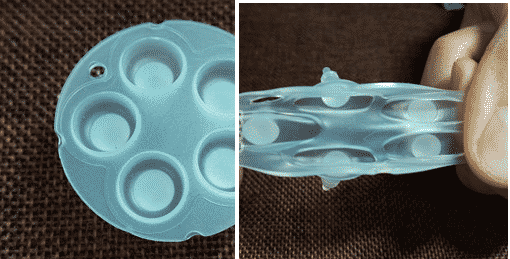

Pull test: Pull the silicone product hard. If white marks appear with a pungent odor, it is ordinary silicone; if there is no white mark but a slight odor, it may be food-grade silicone

Baking test: The upper temperature limit of ordinary silicone is 150℃, while food-grade silicone can withstand high temperatures up to 250℃, and even up to 350℃ in a short time

Certification mark: Choose silicone products with FDA food-grade certification to ensure that they are non-toxic and odorless, resistant to high temperatures, chemically stable, and highly transparent, and will not turn yellow or darken over time.

Smell Difference

Ordinary silicone products have a big smell.

The Food Grade Silicone also has a little odor, which is because the production process does not affect the quality, safety, and other issues, and the odor will be automatically eliminated after a period of time

The LSR silicone rubber smell is better than solid silicone rubber.

Learn More About Silicone Molding Method And Process

Touching Difference

Food-grade silicone has very good toughness and elasticity. It is not easy to be permanently deformed by the action of external force, and the hand feel will be smoother, while ordinary silicone products are easily deformed and rough to the touch.

Pinch or Twist test

When you pull hard, pinch or twist the products. The FDA products and ordinary silicone products will change colors.

The LFGB standard products will not change color. If you want to make sure your product is Food Grade Silicone(LFGB). You can use it this way, only at a little higher cost.

Certification mark: Choose silicone products with FDA food-grade certification to ensure that they are non-toxic and odorless, resistant to high temperatures, chemically stable, and highly transparent, and will not turn yellow or darken over time.

For our consumers, buy food-grade silicone products, try to go to a large supermarket to choose Brand Products produced by regular manufacturers are not only responsible for the protection of our consumers’ rights, but also for the health of our consumers.

Food-grade silicone and ordinary silicone are significantly different in terms of raw materials, safety, processing flow, and application areas. Choosing the right material is not only a guarantee of product quality, but also related to brand reputation and user health. If you are a maternal and child/kitchenware brand or a cross-border e-commerce seller, it is recommended to intervene in material classification control in the early stages of design and production. We recommend choosing a silicone manufacturer with integrated raw materials, molds, injection molding, and testing capabilities to ensure professionalism and compliance in every link.

If you are hesitant in the product material selection process, please contact the experts of Z.S.R Group, and we will provide material selection suggestions for the corresponding project.

In Z.S.R Group, We offer any molded Silicone products or Silicone project that needs technical support to the brand and retails, you could buy custom-molded Silicone products at ZSR Group. ZSR Group has rich experience in producing Silicone products with FDA or LFGB approved standards. We have the FDA register list number is 3011147430.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.