What is silicone over-molding

What is silicone over-molding?

Silicone Over-molding, also known as silicone Rubber compression over-molding, liquid silicone rubber (LSR)over-molding.

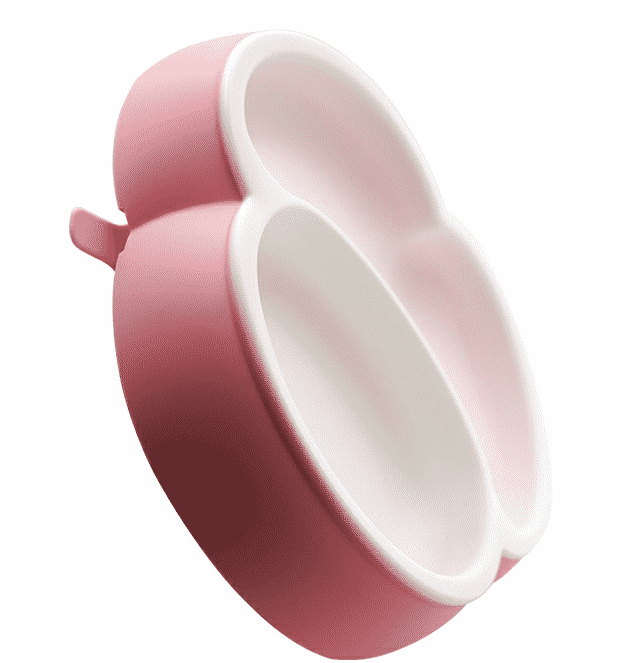

Silicone over-molding is a molding process that molds silicone over, under, or through a substrate material to complete the final part. Silicone Over-molding is a process of over-mold silicone rubber onto a wide variety of thermoplastics, metals, electronics and other substrates. By allowing product designers to combine the best of two materials, this manufacturing process supports variations in durometers and rigidity.

How many kinds of silicone over-molding?

Silicone overmolding with other substrates (Silicone, Metal, Plastic, etc)

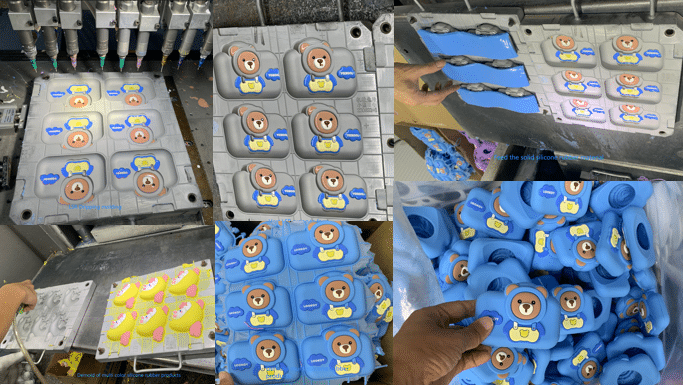

Silicone Over Silicone-First a silicone substrate is molded. Then another silicone is molded onto or around the substrate. The silicone could differ in color and/or hardness. This picture show silicone rubber compression overmolding.

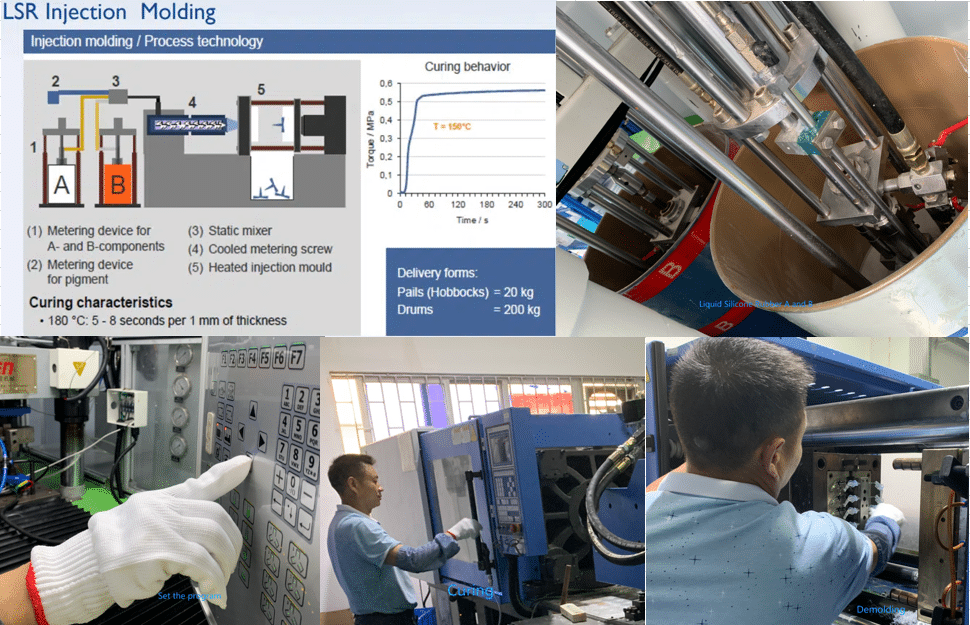

Silicone Over Plastic – First a rigid plastic substrate is molded. Then a soft Silicone is molded onto or around the substrate. This is often used to give a soft grip area to a rigid part. The picture show Liquid Silicone Rubber (LSR) overmolding.

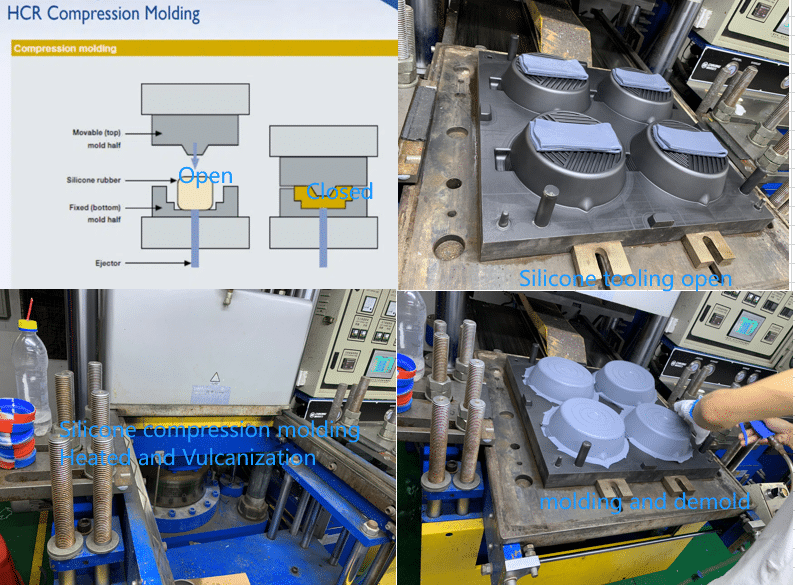

Silicone Over Metal-First a metal substrate is machined, cast or formed. Then, the substrate is inserted into a silicone compression molding tool and the silicone is molded onto or around the metal. This is often used to capture metal components in a silicone part.

Benefits of Silicone Overmolding

Cost-effective and time savings-By molding silicone directly onto a metal or other substrate, you’ll save the expense and time required to assemble a complex part manually. This can dramatically reduce your manufacturing costs and turnaround time. allowing you to get your product to market more economically.

The ability to mold complex designs and geometries which could never be done using a separate assembly step.

High-quality surface finish with the best bonding properties.

Clean surfaces and consistent thicknesses throughout the parts.

What is silicone Overmolding used for?

- Multi Component – Overmolded

- Multi colored – Overmolded

- wearable devices

- mechanical reinforcement

- gaskets

- seals

- fluidic components

- medical catheters

- medical implants

- Baby products

- Promotional products

Conclusion

In Z.S.R Group, we have the Silicone overmolding capability. If any over-molded Silicone products or over-molded Silicone projects need technical support, please contact us, We will support your Silicone products from idea to life.

If you like the article or you need more information from us, please leave a message or contact us by info@consumersiliconeproducts.com, Any inquiry from you is welcome.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.