What Are All The Catalysts Of Silicone rubber?

The molded silicone products performance quality lies in the cross-linking mechanism. The catalyst not only determines the vulcanization efficiency, but also determines the safety, reliability, cost and regulatory compliance of the material. Choosing the right catalytic system is the prerequisite for achieving high-quality silicone products and is also the core competitiveness of production and marketing.

What is catalysts?

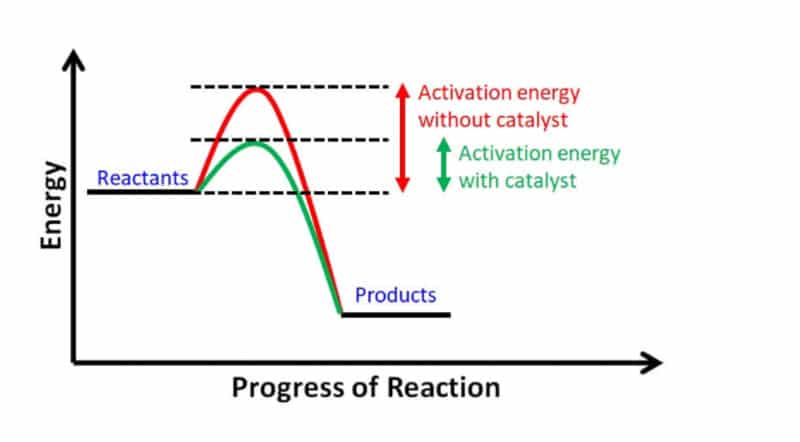

Catalysts can effectively change the reaction rate of reactants in chemical reactions without changing the mass and chemical properties of the substances themselves. Catalysts play a vital role in chemical reactions. They can effectively change the chemical reaction rate of reactants, Catalysis is the increase in the rate of a chemical reaction due to the participation of an additional substance called a catalyst. With a catalyst, reactions occur faster or less and require less activation energy, and the mass and chemical properties of the catalyst remain unchanged throughout the process.

Because catalysts are not consumed in the catalyzed reaction, they can continue to catalyze the reaction of further quantities of reactant. Often only tiny amounts are required.

Why we need to use the catalysts?

Catalysts speed up the rate of reactio, which saves money because the plant doesn’t have to operate for as long to produce the same amount of product.

Catalysts allow the reaction to work at a much lower temperature. This reduces the energy used up in a reaction which is good for sustainable development.

They save industries money.

They never get used up in a reaction so once you’ve got them you can use them over and over again.

In silicone area, the normal catalysts is Vulcanizing agent.

The Vulcanizing agent is a material, usually sulfur, that is used in the chemical process of vulcanization. Vulcanization Agent gives natural rubber or other polymers( like silicone) more strength, elasticity and durability by the addition of sulfur or other accelerators such as zinc oxide and peroxide. These additives add cross-links (bridges) to individual polymer chains to make them stronger and more durable.

What are all the catalysts of silicone?

Silicone vulcanizing agents currently include: 2,4-Dichlorobenzoyl peroxide (C14H6Cl4O4) , 2,5-Dimethyl(C32H66O2), The 2,5-Dimethyl(C32H66O2) have the odor and odorless vulcanizing agent, Platinum Catalysts(Heterogeneous catalyst) ,Tin/bismuth/rhodium and other catalytic systems,Bimetallic oxide or particle-type catalysts. Most of the vulcanizing agent what we used in our mass production are :

1. 2,4-Dichlorobenzoyl peroxide (C14H6Cl4O4): 2,4-Dichlorobenzoyl peroxide (C14H6Cl4O4) is used for cross-linking of silicone extrusion and calendering process products. It is suitable for the production of mid-range silicone rubber products and the production of extruded products with slightly higher transparency requirements. The product has high transparency, anti-yellowing, low odor, no bubbles, excellent electrical properties and heat resistance. The decomposition temperature is low and the decomposition speed is fast, so it is a common vulcanizing agent for rubber compounds with slightly higher requirements for extrusion molding.

The advantages of 2,4-Dichlorobenzoyl peroxide are low decomposition temperature and fast decomposition speed, so it is a common vulcanizing agent for rubber compounds for extrusion molding. However, due to the low decomposition temperature, the scorch performance is not good, so the amount should be as small as possible. The decomposition products are 2.4-dichlorobenzoic acid and 2.4-dichlorobenzene, which are toxic and affect the heat resistance of rubber compounds. Because carbon black interferes with the vulcanization of 2,4-Dichlorobenzoyl peroxide, it cannot be used in rubber compounds containing carbon black. When the amount of peroxide exceeds the appropriate amount, the elongation, tear resistance and other properties of the vulcanized rubber will decrease, and the influence of 2,4-Dichlorobenzoyl peroxide will be greater. 2,4-Dichlorobenzoyl peroxide is a general-purpose vulcanizing agent, generally used in extrusion, the vulcanization temperature is 90 degrees

2. 2,5-Dimethyl(C32H66O2) has a small amount of sulfur, fast vulcanization speed, no volatilization, no fire, suitable for crosslinking of vinyl silicone rubber, polyethylene, and ethylene-propylene rubber. It is applied to environmental protection standards of molded products made of various silicone materials: such as silicone buttons, bracelets, mobile phone cases, watch straps, silicone gifts and other fields.

2,5-Dimethyl has high decomposition temperature and good scorch performance. Since it does not produce products with carboxyl groups during decomposition, it does not affect the thermal stability of the rubber compound. 2,5-Dimethyl can be used in rubber compounds containing carbon black and has a wide range of applications. When using 2,5-Dimethyl, the vulcanized rubber has lower compression deformation and higher elongation.2,5-Dimethyl is a special vulcanizing agent for vinyl. It is used for molding and the vulcanization temperature is 175 degrees.

3. The fast and odorless vulcanizing agent 2,5-Dimethyl(C32H66O2) has excellent dispersibility, fast vulcanization speed, and odorless vulcanized silicon products. It is suitable for cross-linking vinyl silicone rubber, polyethylene, and ethylene-propylene rubber. It is applied to food-grade standards of molded products made of various silicone materials: such as silicone mobile phone cases, silicone sheets, silicone gifts, silicone kitchen supplies and other fields.

Organic peroxide catalyst: suitable for HTV compression molding silicone, the reaction produces carboxyl byproducts, and post-vulcanization is required

4. Platinum Catalysts(Heterogeneous catalyst)is a two-component platinum addition molding silicone vulcanizing agent, mainly used for low-temperature vulcanization and odorless silicone products. Such as: extruded silicone tube, shaped strip, LED light bar, silicone calendered coil, silicone wire, etc. Products vulcanized with platinum vulcanizing agent can pass FDA and ROHS certification for primary vulcanization, and LFGB certification for secondary vulcanization.Platinum (precious metal) addition catalyst: suitable for liquid silicone (LSR) and platinum hardness silicone, pure reaction, suitable for maternal and infant and medical

Why choose different catalyst?

Platinum-catalyzed silica gel has high temperature resistance, no volatility, and few by-products; peroxide requires post-baking treatment.

Platinum catalysts are expensive and need to be protected from light and poison; peroxides are low-cost but require high-temperature vulcanization.

Medical/maternal and infant/food grade mandatory platinum catalysis; industrial/construction choose tin or peroxy system for better cost performance.

Who care the choice of different catalyst?

Catalyst research engineers focus on the impact of different catalytic systems on product properties.

Silicone product manufacturers: They need to consider costs and process complexity and choose different catalyst types to meet the project requirements at the time.

Silicone product brands and their marketing teams: All catalysts in the products need to be legal and compliant to meet consumer safety needs.

Third-party quality inspection and compliance teams: They need to ensure that products made with these catalysts are free of toxic residues and meet regulatory standards.

When and where do you need to know the different catalysts?

Product planning and design period: Early decision on the catalyst system can avoid the significant costs caused by subsequent changes. For maternal and infant products and e-commerce exports, it is recommended to choose a platinum addition catalyst. For industrial seals and large structural parts, it is recommended to choose a peroxide vulcanization system. For room temperature sealing and dispensing, choose a tin-based RTV catalyst. For high-temperature oxidation production scenarios, choose a bimetallic oxide catalyst.

Before submitting the product certification that needs to be done, it is necessary to submit and confirm with the certification agency, because different catalytic systems require different test items.

During the production stage of the product, if the catalyst needs to be switched: the process parameters and quality inspection standards should be adjusted simultaneously.

How to use the different catalysts?

Platinum catalytic system: Karstedt catalyst (Pt-vinyl complex) is commonly used, with 20-100ppm platinum added. When using platinum catalysis, nitrogen, sulfur, and tin poisoning must be strictly prevented.

Peroxide system: Add TBPB, DCP, etc., and vulcanize at 150-200℃. When using this vulcanizing agent, it needs to be post-baked to remove the odor.

Tin/bismuth RTV system: Room temperature vulcanization, not suitable for food grade; suitable for rapid sealing.

Bimetallic oxide catalytic system: used in laboratory-specific scenarios, not common in daily silicone products

How much of different catalysts?

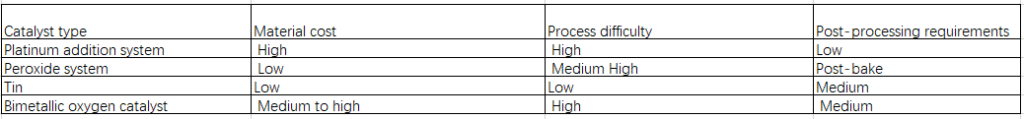

The different Catalyst have the different price and process diffcullty. See the picture below:

How to control different catalysts and clean equipment and product cleaning?

When using platinum system catalysts, ensure that there is no platinum poisoning, accurate mixing and metering, and control the ambient temperature. At the same time, avoid pollution, use special cleaning solvents, and clean the platinum system equipment.

When using peroxide system catalysts, the vulcanization temperature and time must be strictly set, and the post-treatment must be thoroughly baked for 2-4 hours to avoid pungent odors. It is necessary to clean the furnace residue in time and ventilate the exhaust gas.

When using tin RTV catalysts, control humidity and environmental hygiene to prevent structural weakness and maturation. RTV system: anti-sticking treatment of the mold surface, anti-static.

Bimetallic catalytic system: strict material ratio and reaction temperature control. At the same time, the residual liquid needs to be handled according to the chemical waste specification.

More FAQ of different catalysts?

1: Will platinum catalysts be poisonous?

Yes. Sulfur, nitrogen, tin and other substances will passivate the platinum system, requiring a clean environment and strict inspection of raw materials.

2: Is peroxide vulcanization environmentally friendly?

It needs to be baked at high temperature to remove odors, contains volatiles, and pay attention to ventilation and waste gas treatment

3: Can the tin system be used in food grade applications?

Not recommended. Tin/bismuth catalysts are often used in industrial sealing and are not suitable for food or medical use.

4: Is the bimetallic oxidation system common?

Rare, limited to special industries or research applications at high temperature and high pressure

Conclusion

Silicone catalysts include four major catalytic systems: Platinum addition catalysis: high purity, strong safety, the first choice for modern high-end silicone products. Peroxide vulcanization: economical high-temperature process, suitable for industrial mass production. Tin RTV catalysis: low-cost ready-to-use system, suitable for additional uses such as bonding and sealing. Bimetallic oxidation system: high-end tool for special applications.

Practitioners in the silicone products industry can ensure product quality and market competitiveness by combining process requirements, compliance requirements and cost structure and scientifically selecting the catalytic system.Z.S.R expert can help you choice the correct catalysts according to your projects needs to empower your silicone project success!

In Z.S.R Group,We has rich experience in producing Custom silicone products with FDA or LFGB Approved standard products. That means the catalysts of silicone what we used is odorless vulcanizing agent and Platinum Catalysts(Heterogeneous catalyst). We have the FDA register list number is 3011147430.

Any Silicone products or Silicone project need technical support, Contact us.

You also can custom Silicone products at ZSR Group.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.