What Is Medical Grade Silicone

Medical grade silicone is medical grade polymer material, which is a polymer silicone material synthesized from silicone compounds refers to silicone materials used in the production of medical application products such as medical devices and medical consumables. It has high biocompatibility, chemical stability softness, non-toxicity, odorlessness and mechanical strength.

Medical-grade silicone

Silicone is a versatile material that can be used for a ton of stuff, including things like medical implants. ‘Medical-Grade’ means the silicone has been tested and approved by the FDA for biocompatibility – so it’s designed to be worn safely inside the body for long periods of time. Medical grade silicone is hypoallergenic, latex-free and contains no toxins, and is also nonporous and so resists bacterial growth.

Medical-grade silicones are silicones tested for biocompatibility and are appropriate to be used for medical applications. In the United States, the Food and Drug Administration (FDA) Center for Devices and Radiological Health (CDRH) regulates devices implanted into the body. It does not regulate materials other than certain dental materials. The FDA regulates silicones used in food contact under the auspices of the Center for Food Safety and Nutrition (CFSAN) and for use in pharmaceuticals under the auspices of the Center for Drug Evaluation and Research (CDER).

Medical-grade silicone is a class of clinically-tested products designed to interact safely with the human body in a medical setting. The many uses and forms of medical silicone make it difficult to define and classify. But before it can be applied medically, it must pass rigorous FDA standards. Because medical silicone is safe and durable, it can be engineered for short-term or long-term use. Such items like tubes, dental retainers, implants, respiratory masks, and gel sheets for scar therapy all contain medical-grade silicone.

The medical silicone grade: Medical grade silicone is usually divided into three grades and VI grades, namely ISO10993 and USP Class VI. Each grade corresponds to different test standards.

ISO 10993

ISO 10993 is an international standard that divides medical devices into three categories: surface, implant, and external communicating. Based on the time of exposure, these categories are further divided into three subcategories: limited, prolonged, and permanent.

Before selecting a molding material such as a medical silicone, it’s important to determine which category and subcategory describes your application. Otherwise, you won’t know which testing protocol applies. ISO 10993 is not a checklist, but it does provide a risk-based guide for evaluating different materials.

USP Class VI and Biocompatible silicone

USP Class VI refers to a set of biocompatibilities testing requirements from the U.S. Pharmacopeia (USP), a non-profit organization whose standards inform decision-making at the U.S. Food and Drug Administration (FDA).

Specifically, USP publishes test instructions for the plastics, polymers and elastomers that are used in medical devices and surgical equipment. These tests correspond to numbered classes and use different extracts, such sodium chloride and alcohol saline. Among USP classes, Class VI materials meet the toughest testing requirements.

Medical Grade Silicone is designed for health care applications that require a low volatile, non-toxic, FDA material with extremely high and low-temperature resistance. This material was formulated with a silicone base that has been tested and complies with UPS Class VI. Medical Grade Silicone Sheeting is platinum cured and is an excellent gasket material because it has exceptional resistance to ozone, oxidation, ultraviolet light and extreme temperatures.

What is medical grade material?

Medical-grade materials refer to specific materials used in the medical field. These materials must comply with regulatory requirements related to medical devices, medical equipment and medical consumables, as well as specific requirements of international standards and industry standards. Medical-grade materials usually have high biocompatibility, corrosion resistance, mechanical strength and chemical stability, and can meet the special requirements of the medical field for materials.

what are the different types of medical silicones?

Why is Silicone good for Medical Applications

- Silicone is a biocompatible material

- Silicone is easy to sterilize

- Silicone is an effective barrier against bio-materials within bio-medical devices and implantables

- Silicone is resistant to temperature, UV radiation, and X-rays

- Silicone doesn’t adhere to body tissue

- Silicone does not support microbial growth

- Silicone provides electrothermal insulation

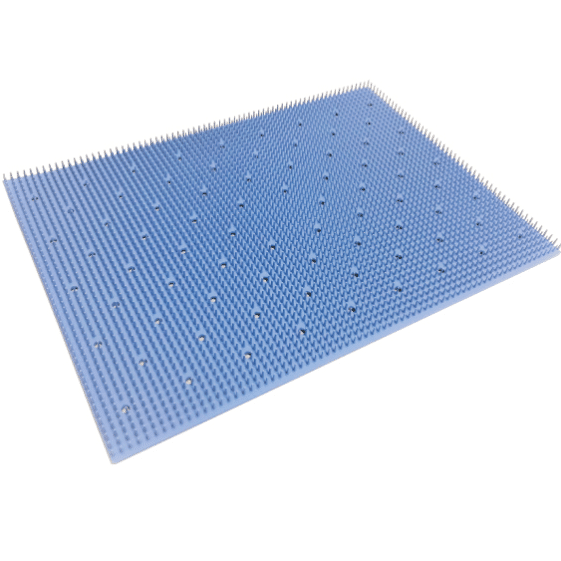

- Silicone can be used as a no-slip surface

- Silicone is soft and pliable and does not crack

- Medical grade silicone is safe/sterile alternative to latex

- Medical grade silicone FDA biocompatibility

- Medical-grade silicone resistance to chemical and bacteria

- Medical grade silicone has excellent transparency, which allows light Medical grade silicone transmittance and illumination

- Medical-grade silicone Gas permeability

- Medical grade silicone Clarity

- Medical grade silicone High elongation

- Medical grade silicone Superior dielectric strength

- Medical grade silicone Superior tensile strength, elongation, tear Medical grade silicone strength and compression at temperature extremes

- Medical grade silicone Ability to function in extreme temperatures

- Medical grade silicone Low compression set at wide temperature ranges

The use of Medical Grade Silicone Rubber

- Tubing

- Drains

- Feeding tubes

- Catheters

- Implants for long and short-term use

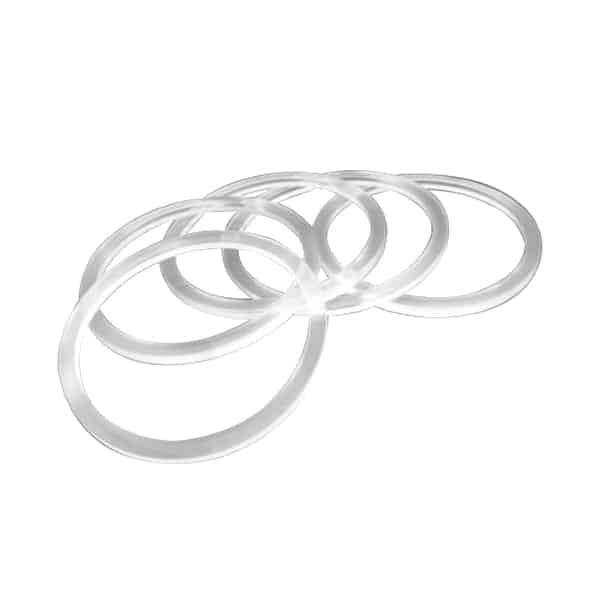

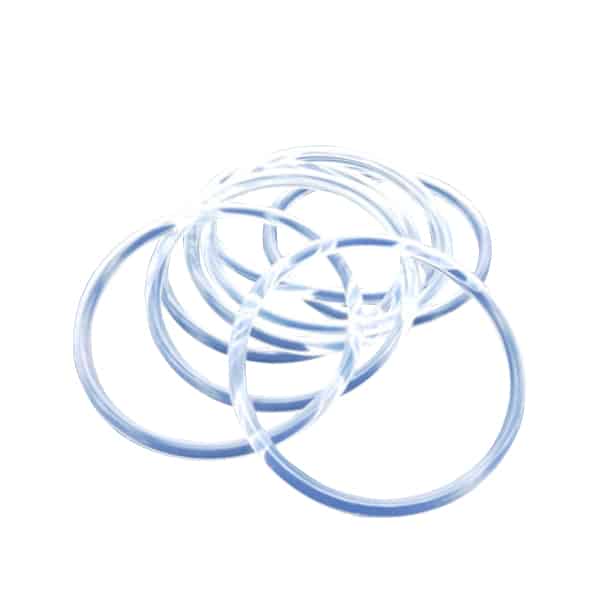

- Seals and gaskets

- Syringe pistons

- Scar Treatment Silicone Sheets (FDA Class 1 Medical Device) and gels.

- Condoms

- Menstrual cups

- Sex toys

- Non-Stick Containers

- Respiratory masks

Conclusion

To learn more about medical-grade Liquid Silicone Rubber or receive a free quote, contact Z.S.R Group representative today.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.