Silicone-sustainable And Recyclable

Silicone products is popular in these days with the banning of the plastic and the awareness about the environmental protection? but what about with environmentalists?

1.What is Silicone?

Silicone is normally described as belonging to the rubber family pure, natural rubber is more commonly recognized as latex which naturally is derived from the rubber tree. These trees were first discovered in South America. With this natural material as a starting point, anything which is not formed from this rubber is a synthetic aka man-made and not naturally occurring. Silicone is a synthetic polymer made of the chemical element silicon.

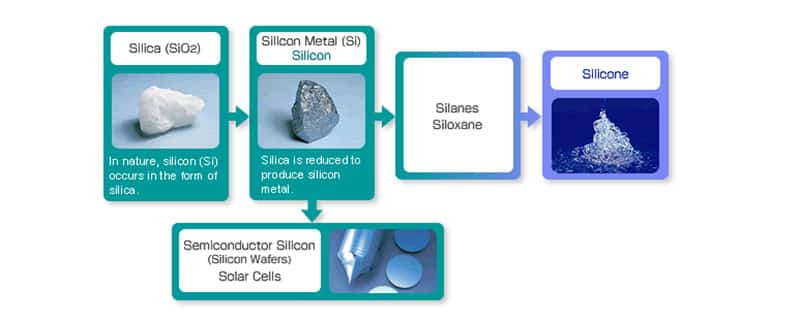

To clarify the difference between silicon and silicone, silicon is the raw chemical element and silicone is a rubber primarily derived from it. In its pure form, silicon is very brittle and hard. It forms as a crystalline solid with a grey/blue metallic sheen. Despite being the eighth most common element in the universe, it very rarely forms as a solid in the earth’s crust. Silicon is most often found as silica, an oxide of silicon and also the main constituent part of sand.

What is silicone made of ?

Silicone is primarily made of silicon but also includes oxygen, hydrogen and carbon. It is a man-made material and has viscoelasticity, meaning that it is both viscous and elastic. Materials that display viscoelasticity are known generally as rubbers. Silicone rubber is categorised as a synthetic elastomer because silicone polymer is both man-made and displays elastic properties. Silicones are compounds made up of repeating units of siloxane. Siloxane is an alternating chain of silicon-oxygen atoms, which are combined with hydrogen and carbon.

How is the silicone made?

To make silicone, the silicon atoms must be isolated from the silicon dioxide compound silica. This is done by heating large volumes of quartz sand to extremely high temperatures, up to 1800°C. From here, there are several processes where silicon is combined with methyl chloride and heated. It is then distilled into a polymerised siloxane known as polydimethylsiloxane. The polydimethylsiloxane can then be polymerised. This is done using a variety of techniques depending on the use of the final product.

The production of silicone rubber base compounds can be done on a mass scale at relatively low costs. As a result, silicone has become one of the most popular elastomers for both commercial and industrial usage.

2.Is Silicone Sustainable?

Silicone Properties

Silicone, due to its polysiloxane, provide several advantages:

Thermal stability (from -80°C to 250°C)

Resistance to natural ageing (oxidation, UV)

Resistance to fire, low emission of smoke and toxic fumes, self-protection, ceramization of ashes

Low surface energy

Good wetting on many substrates

Hydrophobia (beading effect)

Release or adhesion properties, according to need

Exceptional harmlessness for a wide range of applications

Biocompatibility, well-suited for food contact and medical applications

Safe and comfortable skin contact

Flexible chain of up to -100°C for enhanced lubrication and gas permeability performance

Easy processing, excellent spread and coating capabilities

Available in a variety of forms – fluids, liquid silicone elastomers (LSR) and high-consistency rubbers (HCR)

Silicone has some great features and there are a few products that are definitely considered as sustainable alternatives. If you cannot use other more sustainable materials. High grade silicone is the less bad alternative to plastic because:

It is safer for the earth and for human life: as it does not give off dangerous toxins into the environment. In fact, the Canadian Health Department states on its website that there are no known health hazards associated with the use of silicone cookware, unlike those made of plastic.

It avoids the use of tonnes of disposable products: one single menstrual cup can save the environment from the disposal of kilos of sanitary pads and tampons during its lifetime.

It is more durable and much stronger than plastic: it can endure radiation, salinity and extreme temperatures, therefore when it ends up exposed to the elements in nature it doesn’t break up as easily as plastic.

It doesn’t give off toxic gases when incinerated: if incinerated in waste treatment plants, silicone only gives off silicon, carbon dioxide and water vapour, in comparison with the toxic gases generated by burning plastics.

Therefore silicone, if it is high grade, is the less bad solution. But you can also find even greener options for certain products.

3.Is Silicone eco-friendly?

Silicone is more environmentally friendly than plastic. It is made from silica, which is derived from sand, and manufacturing silicone does not involve mining for crude oil, which most plastics are made from. It is also more durable than plastic so it lasts longer. Silicone is recyclable but not biodegradable, however it does not break down into micro-plastics either, which makes it ocean-friendly and less harmful than plastic.

4.Is Silicone Biodegradable?

Silicone is more environmentally friendly than plastic. It is made from silica, which is derived from sand, and manufacturing silicone does not involve mining for crude oil, which most plastics are made from. It is also more durable than plastic so it lasts longer. Silicone is recyclable but not biodegradable, however it does not break down into micro-plastics either, which makes it ocean-friendly and less harmful than plastic.

5.Is Silicone Recyclable?

Silicone products can be recycled.it is not often included in the list of items that municipalities will pick up. Neither is silicon as it is used in solar panels, but environmentally compliant solar recyclers can handle the element at utility-scale levels. Silicone needs to be sent to a specialized recycling company in order to get recycled correctly, as Earth Hero reports. From there, silicone can be downcycled into various products, such as an industrial lubricant or mulch.

6.How to recycle silicone products?

STEP 1: Collect Silicone Rubber Worldwide.

STEP 2: Grind Into Small Pieces.

STEP 3: High Temperature Heating.

STEP 4: Fine filtration.

STEP 5: Redistribution.

STEP 6: Polymerization.

STEP 7: Collect Silicone Oil.

See the picture:

7. Conclusion.

All in All, Silicone products is sustainable and recyclable. Before you can find more greener material products to use. You can choose the silicone material products. And please chosse the FDA Approved food grade silicone material made products. They are safe and health.

Any Silicone products or Silicone project need technical support, you could contact ZSR Group. ZSR Group has rich experience in producing Silicone products with FDA or LFGB Approved standard.We have the FDA register list number is 3011147430.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.