How safe is using food-grade silicone in baking and high temperatures?

Silicone baking molds are microwave-safe, freezer-safe, and oven-safe. In 1979, the FDA deemed silicone safe to be used for cooking and everyday usage. Temperature changes will not cause food-grade silicone to leach into foods, a common consumer concern.

So,you can put silicone in the oven. And the silicone will not melt in the oven, addressing concerns about whether silicone can melt in the oven. The silicone cookware is safe. The silicone is also microwave safe, safe at high temperatures, and can withstand a wide oven temperature range.

What is Food-Grade Silicone?

The food-grade silicone means meets FDA and EU(LFGB)requirements for food contact and safety. FDA & LFGB-approved silicone is considered food safe, and silicone that has passed LFGB testing is higher quality silicone. Silicone is made from alternating silica and oxygen molecules. Food grade silicone will no toxic when heated.

The silicone that makes up ZSR silicone products is made from these foundational elements and combined with carbon to create a raw silicone product. This material is then cured under heat and pressure to create silicone parts that are sturdy, inert and versatile.

More About Food Grade Silicone

Properties of Food-Grade Silicone

Food-grade silicone is a type of silicone that is safe for use with foods. non-toxic type of silicone that doesn’t contain any chemical fillers or by-products, making it safe for use with food. Silicon, the naturally occurring chemical element that makes up silicone, is a metalloid, which means it has properties of both metals and non-metals and is the second most abundant element in the earth’s crust, after oxygen.

Silicone is used frequently in making molds used for food that begin as liquids and solidify. It is non-toxic; does not stain food, dishes, or cookware; is easily removed from cast objects; and is safe for use on various plastic objects.

- Temperature resistance: Highly resistant to degradation from extreme temperatures and can withstand heating and freezing without leaching off hazardous chemicals. The conventional temperature range of -40 ~ 230 degrees within the long-term use.Sometimes, the Instantaneous temperature can stand 350 C.

- Easy to clean: Silicone products produced from silicone can be cleaned by rinsing with water after use, and can also be cleaned in the dishwasher. Easy to clean with its smooth and soft surface.

- BPA-free, therefore, is safe for food.

- Stable, Durable, and Flexible.

- Hypoallergenic, odor and stain-resistant.

- Does not break, peel, or rot, making it the perfect material for eco-friendly products.

- Lightweight, easy and space-saving, therefore, can be taken everywhere.

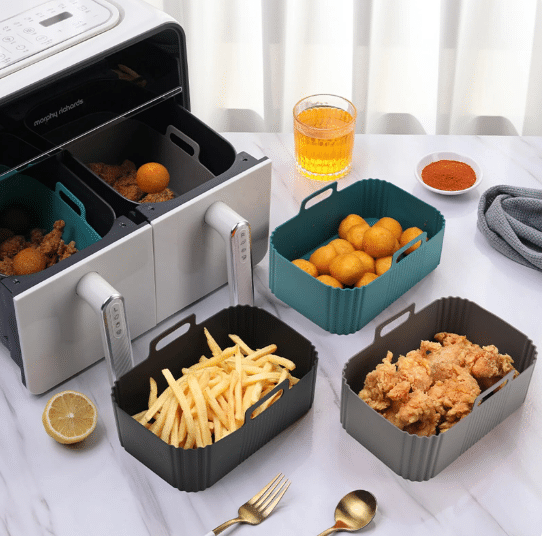

- Different beautiful colors can be blended according to customer needs.

- More durable than plastic and better for the environment.

Food Silicone in High-Temperature Cooking

High heat food grade silicone’s high-temperature resistance is generally 250 degrees., and its short-term high-temperature resistance can reach about 350 degrees. So, the silicone is heat safe. Normally, if you cook Food Silicone products with the food less than 230 degrees. It is safe and can be worked.

silicone safety concerns

FAQ

Tips for safely using silicone in baking and cooking

Recommendations on choosing high-quality silicone products

conclusion

In conclusion, silicone products are notable for their wide food grade silicone temperature range tolerance (-40 to 230 degrees Celsius), making them suitable for diverse applications.

They are valued for their softness, comfort, environmental friendliness, non-toxicity, and degradability, especially as food grade heat resistant silicone. Additionally, high-quality silicone products are free from harmful substances like lead, BPA, and PVC.

From the above information, we can answer that: Is food-grade silicone in high temperatures and bake safe? Yes, it is when it is made with FDA-approved material. ZSR Group has rich experience in producing Custom silicone products with FDA or LFGB-approved standards. We have the FDA register list number 3011147430.

For now, you may need to know: How to choose a good silicone products manufacturer?

The custom silicone products industry belt is the first choice.

Currently, silicone manufacturers are mainly concentrated in the three major cities of Shenzhen, Dongguan, and Huizhou in Guangdong. ZSR Group is in Dongguan area.

Secondly, professional technology and rich experience can make you take a lot of detours when customizing silicone products. Facing the custom category Silicone products test whether a silicone product factory can take on this role and whether it can independently manufacture silicone mass production tooling becomes one of the audit criteria.

The quality of a silicone tooling’s determines the dimensional accuracy of the silicone product and the efficiency of manual edge removal.

Thirdly, for the silicone products price, don’t blindly choose suppliers based on price. It is recommended to choose based on the customization experience of silicone manufacturers. You must know that you pay for a penny. The cheap price brings you not a discount, but low-quality silicone products and Poor after-sale service; of course, the smaller the quantity of customized silicone products, the higher the price, the higher the price.

The customized silicone products mainly account for the bulk of labor costs.

Finally, the company’s size, personnel, equipment, and supporting silk screen spraying oil drops Surface technology such as glue is also one of the exquisite items.

Any custom-molded Silicone products or Silicone projects that need technical support, please contact ZSR Group. We have the 4 types silicone molding process and the silicone tooling making in our one factory roof to support your silicone products success.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.