Are Silicone Cake Molds Safe?

Is this colorful soft mold really food grade? “, “Will it be toxic after heating?”, “There is a strange smell after using it a few times. Did I buy low-quality silicone?” As the home baking craze continues to heat up, silicone cake molds are favored by more and more users due to their softness, high temperature resistance, non-stick and easy demoulding. However, doubts have also increased. Today, from the perspective of a professional manufacturer, we will fully answer the high-frequency question of “Is silicone cake mold safe?”

What is silicone cake molds?

Silicone cake mold is a high-temperature baked silicone mold made of food-grade silicone raw materials. It belongs to the category of silicone kitchen utensils among silicone products. It can be used to make cakes, pizza, bread, mousse, jelly, prepared food, chocolate, pudding, fruit pie, etc.

100% Food Grade Silicone Material Cake Molds. Made FDA Approved, They are perfect to use and safe.

Silicone cake molds are microwave-safe, freezer-safe, and oven-safe. From 1979, the FDA deemed silicone safe to be used for cooking and everyday usage. Temperature changes will not cause food-grade silicone to leach into foods, despite common consumer concerns.

- High temperature resistance: Applicable temperature range -40 to 230 degrees Celsius, can be used in microwave ovens and ovens.

- Easy to clean: Silicone cake molds can be cleaned by rinsing with clean water after use, and can also be cleaned in a dishwasher.

- Long life: Silicone materials are very stable, and cake molds made from them have a longer life than other materials.

- Soft and comfortable: Thanks to the softness of silicone materials, cake molds are comfortable to the touch, very flexible, and do not deform.

- Various colors: Different beautiful colors can be formulated according to customer needs.

- Environmentally friendly and non-toxic: No toxic or harmful substances are produced from the entry of raw materials into the factory to the shipment of finished products

1. What is Silicone?

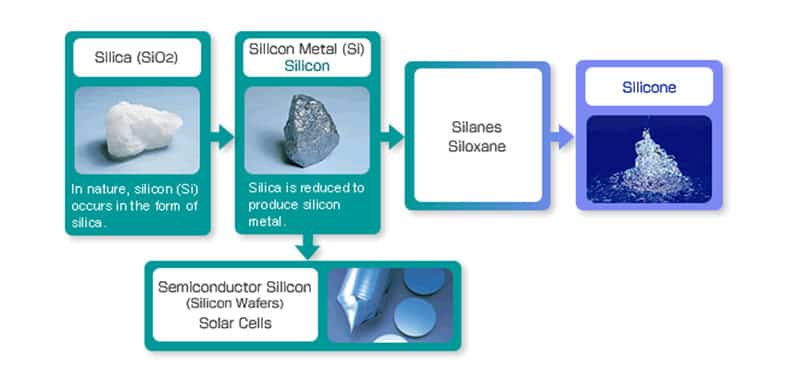

Silicone rubber is a polymer elastomer whose main chain is composed of alternating silicon (Si) and oxygen (O) atoms, and two organic groups (such as methyl, vinyl, etc.) are usually connected to the silicon atom. This unique structure gives it excellent temperature resistance, flexibility and chemical stability.Silicone rubber is categorized as a synthetic elastomer because silicone polymer is both man-made and displays elastic properties. Silicones are compounds made up of repeating units of siloxane. Siloxane is an alternating chain of silicon-oxygen atoms, which are combined with hydrogen and carbon.

Silicone has low toxicity and high heat resistance. This makes it a wonderful compound for use in sealants for watertight containers like fish tanks as well as plumbing pipes. The food Grade Silicone material meets FDA and EU requirements for food contact and safety.

Temperature resistance: Conventional silicone rubber can work for a long time at -55℃ to 180℃. After the introduction of phenyl, the low temperature resistance can reach -73℃, and the instantaneous high temperature resistance exceeds 300℃. Outstanding thermal stability, it can still maintain elasticity for several weeks at 200℃.

Physiological inertness: Non-toxic and odorless, non-coagulating, widely used in the medical field (such as implant materials, catheters, etc.).

Breathability: The oxygen permeability is the highest among synthetic polymers, suitable for special sealing needs.

Chemical stability: Resistant to most chemicals except strong alkali and hydrofluoric acid

2. Is silicone cake mold-safe?

Silicone rubber is inert. It does not emit fumes of any sort, leach into food, or pose any health risks according to the FDA. Experts consider it non-reactive and a good choice when looking for low-risk cookware. If you are concerned about the possibilities of long-term use of silicone bakeware, consider confining your use to spatulas, trivets and other items that are not exposed to heat on a consistent basis. If you do use silicone pans, you should also keep in mind that they should be placed on a firm surface, like a cookie sheet, when baking. Lifting a flexible pan from the oven can leave you with burns and a cake on the floor rather than your table.

Silicone products are resistant to high and low temperatures and can be used over a wide range of temperatures. The conventional temperature range of -40 ~ 230 degrees within the long-term use. They are also soft and comfortable, environmentally friendly, non-toxic, and degradable. The food-grade silicone material is soft and comfortable, environmentally friendly, non-toxic, and degradable. They are also, Lead, Reach, BPA, PVC Free.

The silicone cake mold was made by FDA of LFGB Silicone. Should be safe for food and microwave-safe, freezer-safe, and oven-safe.

Why do people worry about the safety of silicone cake molds?

There are a large number of low-priced and low-quality silicone products on the market that have not been tested for food grade.

Some products use industrial silicone or oil-containing silicone, which may release toxic substances after heating.

Consumers have a unclear understanding of “food grade”, “LFGB” and “FDA”, which leads to concerns.

3. Advantage of Silicone cake mold?

The silicone cake mold made by ZSR Group with the smooth surface inside made it easy to pull out. It is safe for use in the oven, freezer, microwave and dishwasher.

Flexible and durable silicone molds, are easy to fill, easy to use, easy to clean, and easy to pop out without cracking.

CHEMICAL AND BPA FREE: Made from food-grade silicone, BPA free, the heat-resistant temperature is (-40℃ to 230℃), odorless, non-toxic, environmentally friendly and reusable

Reuseable-Good for the environment.Durable and long-lasting, Flexible material, Can withstand high temperatures, Offered in a wide variety of color options

Offers options for fun shapes, you can use the different silicone cake molds according to your like.

Who care the safty of silicone cake molds?

Home baking enthusiasts and cooking content creators or KOLs need to ensure that the baking products they use are safe and do not harm their own and others’ health

Bakery equipment buyers, distributors, and brand owners need to ensure product safety, ensure brand credibility, and enhance brand influence

Bakery equipment cross-border e-commerce sellers need to ensure that the products they sell are safe and reduce legal risks.

When should you pay special attention to the safety of silicone?

As a brand owner, distributor, importer, or manufacturer, you need to provide testing and certification before exporting or putting silicone baking mold products on the platform.

Household cake molds, dessert molds, and commercial baking molds need to be cleaned and disinfected before first use.

When silicone cake molds are heated at high temperatures for a long time or used frequently, you need to check whether they are aged or discolored.

How to make a safe silicone cake mold?

- Raw material preparation (also called silicone rubber refining, material preparation, etc.):

Including the mixing of raw rubber, color matching, weight calculation of raw materials, etc. - Vulcanization molding (also called hydraulic molding):

Use high-pressure vulcanization equipment to vulcanize at high temperature to make the silicone raw materials into solid molding - Peaking (also called processing, deburring, etc.):

The silicone cake molds products removed from the mold will be accompanied by some useless burrs and holes, which need to be removed; currently, in the industry, this process is completely completed by hand, and some factories also use punching machines to complete it. - logo printing:

This process is only used for some products with patterns on the surface of silicone cake molds, such as printing customer logos, etc.

5.Secondary vulcanization:

When the silicone cake mold reaches a certain degree of vulcanization, remove the heat source, in order to further promote the cross-linking reaction, increase the cross-linking density, thereby enhancing the hardness, tensile strength and resilience of the product, reduce, and continue to heat the vulcanization process for 2-4 hours.

This is the comprssion molding ways for produce the silicone cake molds. You also can choose the LSR injection molding to produce the silicone cake molds.

How to Control the silicone cake molds quality?

Material and mold process control

High-purity, high-elasticity and heat-resistant silicone materials are preferred to ensure mold durability. The mixing ratio of silicone and curing agent must be precisely controlled during production, and high-efficiency mixing equipment must be used to improve uniformity. Mold design must consider silicone fluidity, and cold runner technology must be used to reduce bubbles and uneven filling.

Process control during product molding:

A temperature control system must be installed during the molding process to ensure accurate vulcanization temperature (usually 150-200°C) to avoid over- or under-sulfurization. The pressure must be moderate to avoid mold deformation or silicone overflow.

Quality testing and certification:

During the production process, the product must be tested for IPQC, and tensile strength and tear strength must be checked at the same time. Before shipment, the product’s temperature resistance, tensile strength, and migration residue indicators must be regularly tested. At the same time, the goods are sampled and sent to a third party for FDA and LFGB testing.

4. How to Choose and clean Silicone cake mold?

Choose some well-known brands and check whether they are marked with FDA and LFGB certification

Check whether the silicone mold products on sale have a test report QR code or BPA-Free logo

Safe silicone baking molds should be odorless, non-greasy, soft and flexible. Food-grade silicone generally uses food-grade masterbatch, which has a gentle and natural color and is not dazzling. You can choose a safe silicone cake mold by checking the color of the appearance, smelling the odor, and touching the feel.

Cleaning silicone bakeware is easier than you might think! Check your products to make sure they are dishwasher safe if you would like to throw them in for automatic cleaning.

Dishwashers the non-stick silicone mold ensures the coaster tray is very easy to clean and dry quickly,

Hand washes Simply rinse them in warm soapy water or place them in a dishwasher after use.

More FAQ :

Can all silicone molds be used in the oven?

A: No. Only products marked as food-grade, high-temperature resistant silicone (-40~230℃) can enter the oven. Some inferior products may soften or release harmful substances.

2: What should I do if there is a smell after heating?

A: Stop using it. The smell may come from an incompletely vulcanized catalyst or the use of inferior silicone. It is safer to choose products from regular manufacturers with a secondary vulcanization process.

3: How to determine whether it is food-grade silicone?

A: Look at three points:

Is there a third-party test report (FDA/LFGB)

Is there a pungent smell

Is there oil or discoloration after rubbing vigorously

5. Conclusion

From the above information, The premise that silicone cake molds are safe is that you choose qualified food-grade materials and reliable manufacturers.

From raw materials, testing, use, cleaning to brand marketing, every link determines whether your product can withstand the dual test of consumers and the market.

we can answer that: Are silicone cake mold-safe? Yes, They are when they are made with FDA-approved material. ZSR Group has rich experience in producing Custom silicone products with FDA or LFGB approved standards. We have the FDA register list number 3011147430.

Any Silicone products or Silicone projects need technical support, you also can custom Silicone products at ZSR Group.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.