How is Silicone Rubber molded?

The Silicone rubber is molded with Vulcanized and curred. A combination of heat and pressure applied to the liquid silicone rubber cures the material until it solidifies.

There are 3 forms of Silicone Rubber and then with the 5 types of silicone rubber molded:

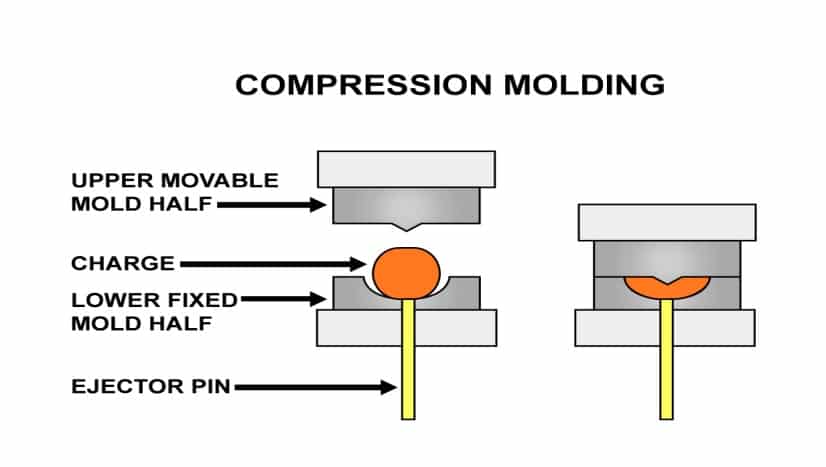

- Solid Silicone rubber Compression molded

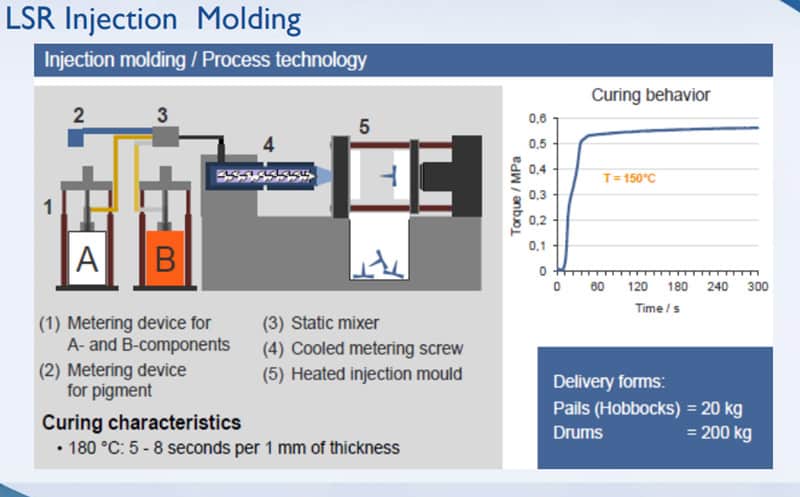

- Liquid Silicone Rubber Injection molded

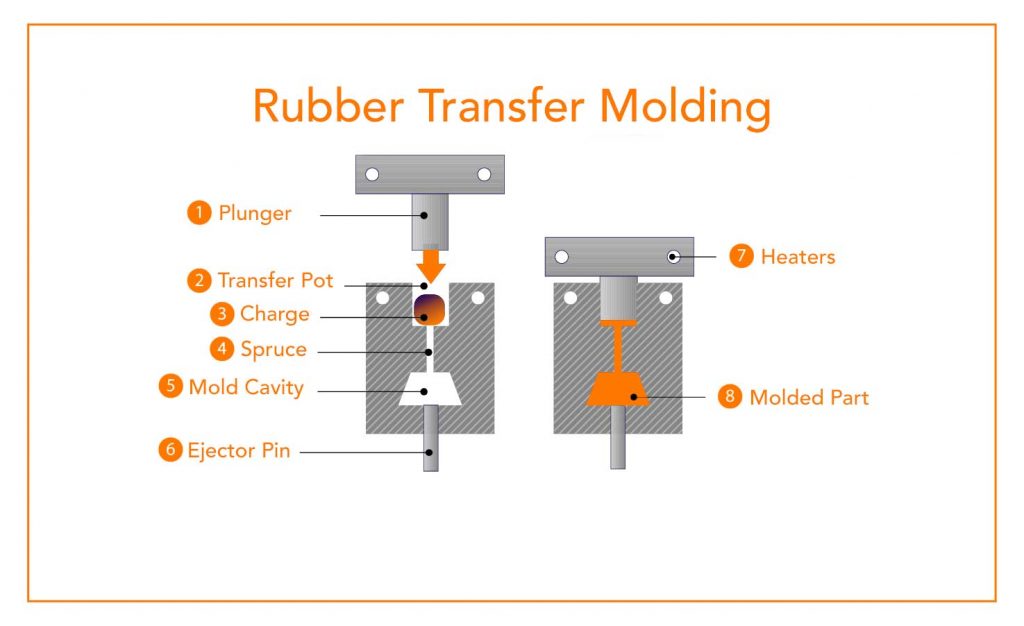

- Transfer molding

- RTV molding

- Dripping injection dispensing (co-injection)molding

Solid Silicone Rubber or High-Temperature Vulcanized, HTV – Solid silicone rubber contains polymers with a high molecular weight and relatively long polymer chains. They are available in uncured form and required traditional silicone rubber compression molding processing techniques.

Liquid Silicone Rubber, LSR – Liquid silicone rubber contains polymers of lower molecular weight and hence shorter chains. It has better flow properties. It is processed on specially designed injection molding and extrusion equipment.

Room Temperature Vulcanized, RTV – RTV silicone rubber is a type of silicone rubber made from one-part (RTV-1) or two-component (RTV-2) systems where their hardness range from very soft to medium. They are available for potting, encapsulations, sealants, etc.

Further Reading: Silicone Material

Transfer molding: Transfer molding is a manufacturing process in which casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact.

Compared to injection molding, transfer molding uses higher pressures to uniformly fill the mold cavity. This allows thicker reinforcing fiber matrices to be more completely saturated by resin. Furthermore, unlike injection molding, the transfer mold casting material may start the process as a solid. This can reduce equipment costs and time dependency. The transfer process may have a slower fill rate than an equivalent injection molding process.

Dripping injection dispensing (co-injection) molding: Dripping injection dispensing )Co-injection molding allows two different silicone materials (solid silicone rubber and liquid silicone rubber) to be combined into a single products stream. Liquid silicone’s colors can be adjusted according to different customers, and the colors will do nothing to the qualities of rockery liquid silicone.

When in use, we need to mix the two parts evenly according to a certain proportion first, and then carry on the vacuum processing. This specialized process can be used to enhance products color performance and reduce cost without any penalty to cycle time or production volume. It is the perfect customize solution for difficult complex multicolored silicone products.

How Strong is the silicone Rubber?

Silicone stays stable and keeps its physical properties up to 230°C (446°F) and high-temperature silicone grades can withstand up to 270°C. Not only is silicone excellent in extreme heat but it is also seen as a sterile elastomer, which is why you see it used in the food and beverage industry as dairy tubing, seals and gaskets on food machinery and also vending tubes in drinks machines.

The strong Si-O chemical structure and high bond energy give Si Elastomers their unique performance properties.

Several benefits of silicone rubbers include:

- Wide service temperature range – excellent thermal and thermoxidative resistance (-Si-O-Si- binding energy is higher than C-C bonds)

- Excellent resistance to attack by oxygen, ozone and sunlight

- Readily resistant to electromagnetic and particle radiation (UV, alpha, beta and gamma rays)

- Excellent non-stick and non-adhesive properties

- Low toxicity

- Flexible at low temperatures due to their low glass transition temperature (Tg).

- Optical transparency

- Good excellent insulation properties

- Low chemical reactivity

- High bio-compatibility: Excellent mechanical properties (high tear strength, high elongation)

- Excellent Flexibility: Solid Silicone rubber has excellent flexibility, it can be modified easily and responds well to a variety of circumstances.

- Noise Reduction: Solid silicone reduces high-volume noises passing through.

- Vibration Dampening: The rubber reduces vibration, suitable for mass transit applications.

- Sealing: Solid profiles are mainly used for precision sealing, this format of silicone responds well to sealing tight spaces due to its flexible nature.

- Insulation: Solid silicone rubber is designed to stop the process of heat and electricity from spreading.

- Thermal Insulation: The silicone material stops unwanted heat from entering through to the other side.

- Thermal Shielding: The silicone material acts as a shield from absorbing excessive heat from travelling to it’s centre.

- Gasket: Solid silicone gaskets sit between two surfaces, generally to prevent leakage into the joined objects while under compression.

Final

In Z.S.R Group, we can support you with silicone rubber compression molded silicone products, custom LSR molded silicone products and custom molded multi-color products. Get in touch to learn more and order your custom-molded silicone rubber products.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.