How Can You Glue Silicone Together?

Silicone rubber is one of the most challenging substrates to bond, and there are only a few adhesives that can make a strong bond?However, the low energy and high hydrophobicity of the silicone surface make it difficult for ordinary glues such as white latex and epoxy resin to adhere firmly and easy to fall off. Understanding the principles and methods of bonding can not only help expand product functions, but also improve user experience and product value.Can we glue silicone rubber together?

The answer is yes, but it requires specialized formulas and processes:

Silicone surface properties: highly hydrophobic, extremely low surface energy (~22 mN/m), chemical coupling agents are required to improve adhesion.

Optional adhesive systems:

Specialized silicone glue (silane coupling agent + methyl hydrogen silicone oil)

Platinum cross-linked silicone gel adhesive (such as RTV or LSR adhesive formula)

UV/heat-cured specialty adhesives

From our mass production experience, I see there are 4 ways to gule the silicone together. Please get the below details to see it:

- Silicone Co-injection molding

- Silicone Over-molding

- Bonding – Use the gule by hand

- Bonding- Use the LSR by hand

Why is it difficult to glue silicone together?

The surface is chemically inert and cannot be directly cross-linked with ordinary glue.

Epoxy, polyurethane and other glues are very weak in bonding silicone and are prone to delamination.

If the bond is not strong, it will cause seal failure, toy shedding, and unqualified repair operations.

1. Silicone Co-Injection molding

Co-injection is a polymer injection technology in which different polymers are injected into the same mold. This specialized process can be used to improve part performance and cost while minimizing cycle time and production volume. Co-injection can be used to extend shelf life, improve production efficiencies, and allow for greater design flexibility depending on the materials used and the application.

Co-injection molding involves the injection of two dissimilar materials. Because of this, co-injection has some special advantages, as well as some potential molding problems. The Co-injection analysis helps you overcome the potential problems and leverage the advantages, by helping to optimize process control strategies and enhance part quality.

Silicone Co-Injection molding :

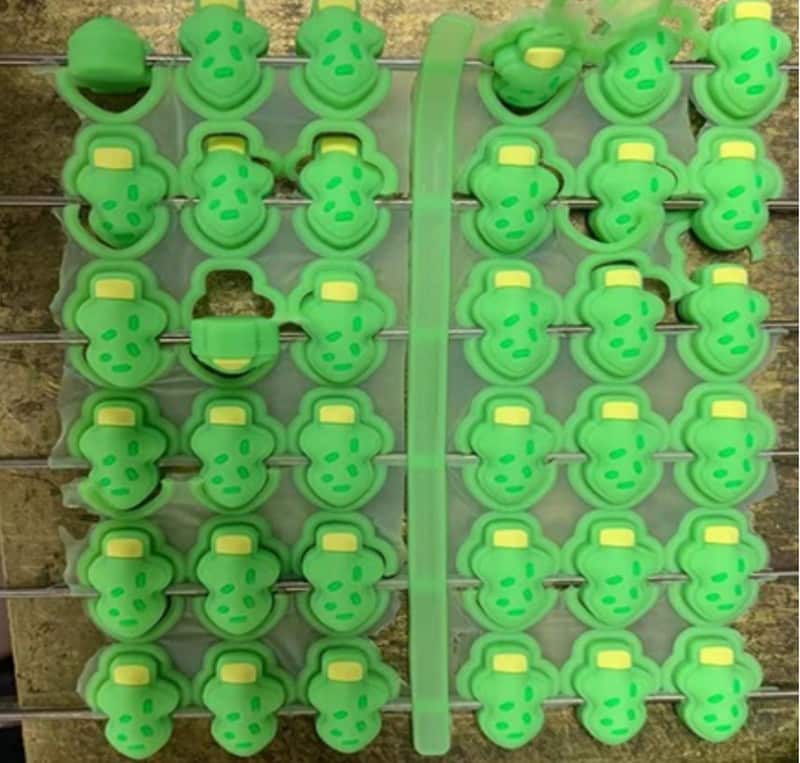

Co-injection Silicone molding allows two different silicone materials (solid silicone rubber and liquid silicone rubber) to be combined into a single products stream. This specialized process can be used to enhance products’ color performance and reduce cost without any penalty to cycle time or production volume. Depending on the materials selected and the application, Co-injection can be used to improve production efficiencies and allow for greater design flexibility. Co-injection dripping molding can be used for a wide range of applications across any industry including Consumer Electronic(Cute phone case, iPod case, Ipad case), and baby products(baby toy, baby feeding).Promotional gifts(Colorful products include: keychains, fashion accessories and gifts)

The Co-injection Silicone molding process:

Dispensing Dripping the liquid silicone rubber to the pattern of the mold with the Dispensing Dripping machine:

Heat the liquid silicone rubber and let them mold first.

Put the solid silicone rubber in the silicone mold and then molding.

You can get a colorful co-injection silicone molding products with many colors without any glue.

2. Silicone Over-molding:

Silicone Overmolding is a process where a single part is created using two or more different materials in combination. Typically the first material, sometimes referred to as the substrate, is partially or fully covered by subsequent materials (overmold materials) during the manufacturing process.

- Silicone Over Silicone-First a silicone substrate is molded. Then another silicone is molded onto or around the substrate. The silicone could differ in color and/or hardness.

- Silicone Over Plastic – First a rigid plastic substrate is molded. Then a soft Silicone is molded onto or around the substrate. This is often used to give a soft grip area to a rigid part.

- Silicone Over Metal-First a metal substrate is machined, cast or formed. Then, the substrate is inserted into a silicone compression molding tool and the silicone is molded onto or around the metal. This is often used to capture metal components in a silicone part. That is today’s process that we would like to show.

2.1: Liquid silicone rubber over injection molding:

Make the green leaf first. Then over-molding the purple grape outside.

2.2: Solid silicone rubber over-molding

The white plate should be compression molding first, Then over-molded the pink color.

3. Bonding – Use the Gule by hand

Sometimes, because the structure of the silicone goods. When we hope to get the function of the goods. We may need to use glue. Check the below silicone 3D cartoon on the silicone bottle sleeve.

As we all know: Silicone rubber is one of the most challenging substrates to bond, and there are only a few adhesives that can make a strong bond. One option that has been successful in other silicone rubber applications is 3M™ Scotch-Weld™ Plastic & Rubber Instant Adhesive PR100 with 3M™ Scotch-Weld™ Instant Adhesive Primer AC79.

The basic steps are

Surface pretreatment – activation is the key

Mechanical roughening: light grinding increases surface roughness.

Solvent cleaning: use ethanol to wipe along the grain to remove oil.

Plasma treatment or flame treatment (optional): generate temporary polar functional groups to enhance bonding strength.

Coating coupling agent (Silane): representative such as GPTMS, can form a silicone-coupling agent-adhesive layer bridge.

- apply the primer to both parts,

- let it dry completely,

- apply the instant adhesive as soon as the primer is dry.

4. Bonding- Use the LSR by hand

When we make the silicone bag, especially the bag for shortage the food. We may not use glue for bonding. We use the Liquid silicone rubber to do the bonding.

Adhesive glue system

Platinum cross-linked silicone gel RTV/LSR: Mix A/B two-component, level the bonding surface, and form a whole after vulcanization.

Silane coupling glue: Contains low amount of silicone oil + coupling agent, suitable for splicing thin sheets.

UV/heat curing glue: Suitable for low tension surface bonding applications.

Gap control and clamping

After applying the glue, fix it with silicone strips and clamps to ensure that the border fits smoothly.

Control the thickness of the glue layer: 0.2–0.5 mm is recommended to ensure structural stability.

According to the product instructions, wait for the full curing time (24h at room temperature or accelerated curing).

4.1:Two pieces of silicone bag before the LSR bonding:

4.2: The Silicone shortage reuseable bag after the liquid silicone rubber bonding:

Post-processing inspection

Check whether there is edge warping or breakage.

Test whether the tensile shear force, water resistance, oil resistance, and heat resistance meet the standards.

Who need glue the silicone together?

Product designer: Secondary assembly link, such as injection molding followed by manual bonding, functional splicing, module combination requires reliable bonding.

After-sales repairer: Repair damaged silicone products, such as seals, pacifier cracks, and quick repair of silicone products requires safe bonding solutions. Use silicone dispensing + thermosetting/platinum cross-linking silicone glue. Creative assembly toys, hooks, kitchen storage collage projects can use Platinum cross-linking glue + matching primer/surface treatment agent.

Creative DIY silicone decorations ,Handmade instructors and DIY experts: Splicing creative products, do not want to use mechanical buckles.UV light curing glue + surface activation treatment

Kitchenware and maternal and child products merchants: require non-toxic, washable, high and low temperature resistant splicing solutions such as Medical-grade RTV silicone gel set.

How much and how to choose of glue the silicone together?

Safety and certification: Platinum RTV/LSR processing formula is recommended for maternal and infant/medical use to ensure no silicone oil residue and no toxic odor. Platinum RTV/LSR processing is selected for high-strength structural parts; the process complexity is high and the price is high.

If it is a simple splicing, choose coupling agent formula glue, which has a medium price and medium process complexity.

Price sensitivity: For DIY use, low-cost UV spot bonding solutions can be selected; the brand recommends batch formula glue customization.

Process requirements: whether pretreatment is required, accelerated curing, etc.

How to control and clean the silicone bonding?

Test the bonding strength, curling and tensile test ≥5 N/cm.

Cross water test, hot and cold cycle test (-20℃~+100℃ cycle ≥100 times).

Oil and alkali resistance is required for media contact scenes; home use is recommended to have no delamination after ≥95°C high temperature.

Use low-residue alcohol to wipe the bonding surface.

Avoid using strong solvents containing ethanol to clean the whole.

Ensure that the product is fully cured before handing over, otherwise it is easy to leave fingerprints or oil stains.

More FAQ for silicone glue together

1: Can ordinary white latex be used to bond silicone?

No. Ordinary latex has very weak adhesion and is easy to loosen.

2: Can UV glue be used to bond silicone?

It is suitable for light bonding, but it requires surface treatment and sufficient UV light to be effective.

3: How to remove the glue after bonding?

It cannot be easily removed after curing. Professional silicone remover can be used with mechanical cleaning.

4: Can RTV adhesive be mixed manually?

It is recommended to use a double-barrel pre-mixed ratio package. Manual mixing has errors and affects curing and strength.

Conclusion

From the above 4 information, The difficulty of silicone bonding lies in its low surface energy and chemical inertness, and a special glue system is required;

Main available solutions include: platinum RTV/LSR silicone glue, coupling agent glue, UV curing glue;

Four steps need to be controlled for bonding: surface treatment → glue application method → clamp pressure → curing detection

you will see, only the Third way, we may use in our daily life. Others, all need the Professional equipment. If you have professional project needs, or need technical support.Contact Z.S.R Group.

ZSR Group has rich experience in producing Custom silicone products with FDA or LFGB Approved standards with bonding or glue. We have the FDA register list number 3011147430.

Any Silicone products or Silicone projects need technical support, you also can custom Silicone products at ZSR Group. We will support your Silicone products from idea to life.

The silicone overmolding bowl making video

Make the orange collar first, then with the blue body overmolding the orange collar.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.