What kind of Silicone Products Used in hospitality-hotels and restaurants industry?

As the catering service industry continues to improve its requirements for hygiene, efficiency, and aesthetics, silicone products are gradually becoming an important substitute for kitchen and dining table equipment in catering and reception venues such as hotels, restaurants, and resorts due to their high temperature resistance, anti-slip, safety, and environmental protection. This report deeply explores the application and selection methods of silicone products in hotel catering scenarios, providing reference for procurement and construction, brand decision-making, and operation optimization.

Z.S.R team work with the hotel’s General Manager, product development Manager, Front Office Manager, branding manager, hotel supply together provides custom and standard silicone placemats, silicone door hanger, Silicone Bathroom Vanity Trays etc for the different hotels.

What kind of Silicone Products Used in hotels and restaurants?

Silicone is highly favored in hospitality for its non-slip, heat-resistant, food-grade, and easy-to-clean properties. Silicone products commonly used in hotels and restaurants, covering kitchen, tableware, cleaning, guest service, and operational use.

1. Kitchen & Food Preparation

Silicone spatulas, Silicone tongs, Silicone cooking spoons, Silicone whisks, Silicone baking mats, Silicone oven mitts, Silicone pot holders, Silicone pan liners, Silicone ladles, Silicone basting brushes, Silicone hot plate pads, Silicone food prep gloves, Silicone knife guards, Silicone cutting board feet/grips, Silicone measuring cups/spoons, baking tray mats, non-slip tray mat etc.

2.Tableware & Buffet Service

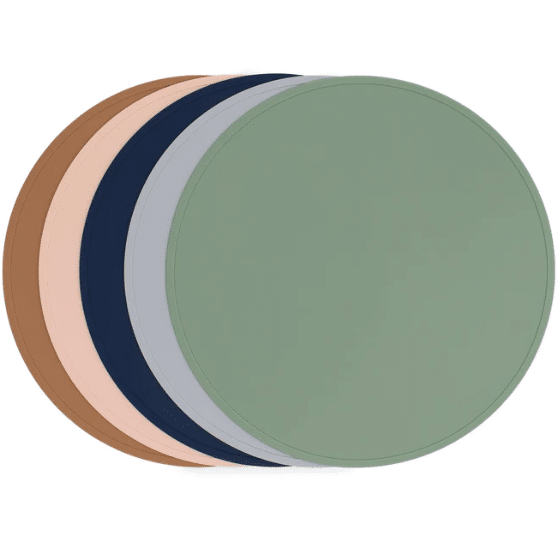

Silicone placemats (non-slip, stylish), Silicone coasters, Silicone trivets

Silicone bowl covers, Silicone reusable food wraps/lids, Silicone serving tray mats, Silicone condiment bottle grips, Silicone utensil rests, Silicone drink markers (e.g. wine glass tags), Silicone cup sleeves (hot drinks)

Silicone bread basket liners, Silicone buffet line food covers, Silicone tea bag holders, Silicone chopstick rests, Silicone plate stack dampers, Nozzle sleeve, sealing ring, pipe gasket, coffee machine auxiliary pad, sealing ring etc.

3.Cleaning & Maintenance

Silicone scrubbers (eco-friendly), Silicone dishwashing gloves with bristles, Silicone sink strainers, Silicone drain covers, Silicone grout brushes, Silicone squeegees (mirror/shower glass), Silicone mop handle grips, Silicone corner cleaning tools, Silicone anti-slip mats for cleaning carts, Silicone bottle brushes (bar, kitchen) etc.

4.Guest Room & Bathroom Amenities

Silicone soap holders, Silicone toothbrush holders, Silicone travel amenity kits (toothbrush cases, small pouches), Silicone tissue box covers, Silicone bathroom hooks, Silicone non-slip mats (bath or tray use), Silicone lotion/soap pump sleeves, Silicone minibar mat liners, Silicone water cup coasters, Silicone hair dryer grip pads, silicone Bathroom Vanity Trays.

5.Hotel Logistics & Utility

Silicone luggage tag bands (for housekeeping carts),

Silicone push cart wheels protectors,

Silicone elevator button covers,

Silicone do not disturb sign hanger,

Silicone bellboy cart liners,

Silicone housekeeping item holders,

Silicone remote control sleeves,

Silicone guest check tray grips,

Silicone sign holders (tabletop, room service) etc.

6. Gift, Promotion & Guest Use Items

Silicone luggage tags (custom logo), Silicone branded keychains, Silicone co-branded room card holders, Silicone eco gift pouches, Silicone sleep masks (with silicone seals), Silicone earplug cases, Silicone water bottles, Silicone travel snack containers, Silicone reusable straws (in pouch), Silicone bag tags

7. Safety & Hygiene

Silicone anti-slip door stoppers, Silicone temperature gloves (for staff), Silicone reusable face mask straps, Silicone hand sanitizer bottle holders, Silicone PPE storage trays, Silicone air-tight food covers, Silicone baby highchair placemats.

Z.S. R International Group (HONG KONG) CO., LIMITED,is a one-stop Custom-molded silicone products manufacturer and silicone molding solution provider in the silicone products field founded in 2007.It is certified by SA8000, ISO9001, ISO14001, BSCI, SEDEX 4P, BRC, FCCA, NBCU, and Disney FAC-020760. We support the hotels and restaurants custom the silicone products service from their idea to final used.

Contact Z.S.R the OEM silicone products factory to create durable, sustainable, and hospitality-ready silicone solutions.

Custom Silicone Products | OEM/ODM Service

Why are silicone products widely used in the hospitality-hotels and restaurants industry?

Silicone products are widely used in the hotel industry mainly because of their high temperature resistance, easy cleaning, environmental protection and other characteristics, suitable for a variety of scenarios. The following are the specific reasons:

High temperature resistance and safety

Silicone materials can withstand temperature changes from -80℃ to 320℃, suitable for baking, refrigeration, hot water disinfection and other needs, suitable for ovens, dishwashers and high temperature environment tableware and lamps that need insulation.

Non-stick, safe, food-grade silicone LFGB/FDA certified, no oil absorption, no odor, no toxic plasticizers, no damage to equipment, in line with hotel hygiene standards.

Environmental protection characteristics

Silicone products meet environmental protection requirements, are not easy to pollute the environment after disposal, replace disposable plastics and paper products, reduce waste, and are suitable for hotel scenarios that focus on sustainable development.

Durability and easy maintenance

Silicone products are soft, wear-resistant, and have a long lifespan. They can be repeatedly disinfected to reduce accidents and utensils slipping. The cost is lower than disposable plastic or metal products. They are easy to clean, can be microwaved and dishwasher-safe, and are not prone to breeding bacteria.

Functional expansion

Silicone lamps can achieve light transmission and USB charging, while wipers are silent and wear-resistant, which improves the practicality and comfort of hotel facilities. At the same time, the colors are identifiable, and different colors can be used for cross-contamination prevention and zoning management.

Disadvantages:

- The unit price is higher than that of plastic or paper;

- It is not easy to use in extreme open flames;

- If the quality is not good, it is easy to age and fade, and produce odor.

Who will pay attention to or use silicone products for hospitality Industry?

Z.S.R‘s Custom Silicone products Service with the Custom Silicone Products material, hardness, size, design, function, structure, shape, color, logo, pattern, package, label and other silicone products technical support to ensure their silicone projects success.

When will you use the silicone products in hospitality Industry?

- Cooking, baking, serving hot food, carrying hot pots, and placing tableware in the kitchen.

- In the sterilization process, including washing dishes, high-temperature steam, reuse, site cleaning, and regular disinfection cycles.

- Use non-stick silicone placemats to clean salmon sauce and other sticky materials, and pack the food with silicone tableware in advance and sort them for later use.

Where will you use the silicone products in hospitality Industry?

Z.S.R is a full-service custom silicone products manufacturer offering end-to-end customization, from mold development and prototyping to mass production and packaging. We already customized more than 500 silicone hotel product projects for our partner in the past years with much experience in silicone products technical.

Contact Z.S.R to make your private silicone hotel products.

How to Produce the hotels used silicone products?

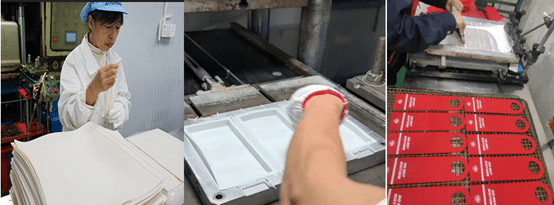

The production process of silicone products mainly includes core links such as raw material preparation, color matching and mixing, molding and vulcanization, post-processing and quality inspection. The specific operations of different process types (molding, extrusion, injection, etc.) are different.

Core production process

Raw material preparation and mixing

Select food grade, medical grade or industrial grade silicone raw materials, and screen and clean them to remove impurities.

Add auxiliary materials such as masterbatch and vulcanizer, and achieve uniform coloring and material fusion through mechanical mixing (about 20 minutes) or manual kneading.

Molding process

Compression molding: Cut the mixed rubber material and place it in the mold, and pressurize it (above 200℃) through the vulcanizer to cure it. It is suitable for complex-shaped products such as sealing rings and rubber sleeves.

Extrusion molding: Use an extruder to pass the rubber material through the mold to form a tubular or strip structure, which is suitable for long products such as sealing strips and silicone tubes. It is efficient but the process is single.

Injection molding: The injection molding machine injects high-temperature rubber into the mold for precision products such as pacifiers and medical catheters. It has a high degree of automation but the equipment cost is expensive.

Vulcanization and post-processing

Primary vulcanization: Complete the initial cross-linking reaction in the mold to form the basic structure of the product.

Secondary vulcanization: Remove residual low-molecular compounds through high-temperature baking (usually 180-200℃), improve mechanical properties and eliminate odors, and meet food grade standards.

Cape treatment: Manual trimming or mechanical removal of burrs, some of which use frozen deburring technology.

Quality control system

FQC full inspection: Test physical properties such as appearance, size, hardness, tensile rebound, etc.

Chemical testing: Including verification of indicators such as PH value and friction coefficient.

OQC sampling: Secondary sampling before shipment to ensure batch qualification rate.

Z.S.R is a silicone products fabrication factory. From initial silicone products design to final delivery, we provide comprehensive one stop services. You do not need deal with multiple suppliers or coordinate different aspects of the project yourself. Simplify the entire process and save your valuable time.

You can work with Z.S.R to create unique and competitive silicone products for your business.

How Much of the silicone products used in hotels?

How to Control the silicone products quality?

First: We start to control from the design of the product. After the customer sends the product, our engineering will evaluate the design of the silicone product for DFM and give suggestions that meet mass production and meet customer requirements.

Second: We control from the feed of raw materials, purchase FDA/LFGB certified silicone raw materials, and conduct feed inspection at the same time, inspect the hardness, purity, color, etc. of the silicone raw materials, and mark them to ensure that the raw materials used for production are qualified.

Third: Mold design and mold production: Secondly, according to the customer’s product requirements, we reasonably design the silicone molds used for production, and control the size accuracy of silicone products by vacuum exhaust + controlling the injection amount, reducing the appearance bubbles, controlling the mold gap, and reasonably removing the glue. Use fluorine treatment/spray release agent to improve the sticking problem.

Fourth: Control in product production, add anti-yellowing agent or choose a high-transparency formula to increase the aging resistance of silicone products.

Add reinforcing agent/cross-linking treatment to obtain the desired product tensile strength effect. In addition, through visual inspection, patrol inspection, and 100% full inspection, to ensure that the silicone products shipped are qualified.

How to Choose the silicone products used in hotels?

- Confirm food-grade safety certification; Material selection certification: Choose food-grade (FDA or LFGB) silicone products;

- Pay attention to the curing process: Support platinum curing to reduce residue;

- Determine thickness and hardness (Shore A) according to function, inspect material texture, surface process, no defects, distinguish between hanging holes and anti-slip texture functions, greatly improve use efficiency, standardize size, easy to replace, and can apply accessories;

- Supporting packaging promotion, such as “boiling and cleaning”, “resistant to 230℃”.

How to Clean silicone products used in hotels?

Silicone products can be cleaned with warm water and a neutral detergent, rubbing alcohol, or a white vinegar solution. Avoid using strong acids or alkalines, or sharp tools. Allow to air dry after cleaning to prevent deformation.

Recommended Cleaning Methods and Procedures

Warm water and a neutral detergent (suitable for daily cleaning).

Soak the silicone product in warm water at 40-50°C with a small amount of neutral detergent.

Gently rub the stained area with a soft cloth or sponge. For stubborn stains, allow to soak for 10-15 minutes.

Rinse thoroughly with clean water and dry in the shade, away from direct sunlight.

Alcohol wipes (suitable for grease or stubborn stains).

Soak a cotton cloth in 75% rubbing alcohol and gently rub the stained area.

Alcohol evaporates quickly, so a second rinse is not necessary. However, keep away from flames.

White vinegar solution (natural stain and odor removal).

Mix white vinegar and water in a 1:1 ratio and soak for 5-10 minutes or wipe directly.

Applying a baking soda paste (baking soda + water) and brushing gently can enhance the cleaning effect.

Professional Cleaner Selection

Neutral, environmentally friendly cleaning agent: Suitable for industrial-grade silicone oil residue. Dilute it in a 1:10 ratio and then ultrasonicate or soak.

Commercially available silicone cleaners: Verify the mildness of the ingredients and use according to the instructions.

Precautions

- Tools not permitted: Steel wool, hard-bristled brushes, and other items that can easily scratch the surface.

- Avoid cleaning agents: Preparations containing bleach, strong acids (such as hydrochloric acid), or strong bases (such as sodium hydroxide).

- Drying Method: Air dry in natural ventilation. High temperatures or direct sunlight may cause deformation and yellowing.

What is the hospitality Industry Clients like?

More FAQs

Summary

The advantages of silicone in the hotel and catering industry are reflected in high temperature resistance, food safety, color management and cleaning convenience. Therefore, silicone has a wide range of mature application value in the hotel and catering industry: non-toxic, safe, easy to clean, high temperature resistant, long life, it is an ideal upgrade solution for disposable products and ordinary plastics. Through the correct selection of materials (food grade platinum), structural design (hanging holes, anti-slip patterns), visual customization and standard certification combination, it can effectively meet the professional needs of hotel restaurants, improve kitchen quality control and user experience. High frequency of use and anti-wear also allow it to find a balance between cost and durability, and truly create a kitchen environment with both high-quality processes and efficient operations

If you are a hotel-related practitioner and want to develop silicone products for hotel use, then you have come to the right place. Z.S.R has a strong engineering design team and precision mold manufacturing workshop. All silicone product manufacturing processes, from product design, mold manufacturing to full production, are completed in the same factory. This will reduce your risk of working with multiple suppliers, shorten product time to market and reduce costs.

Contact Z.S.R Group now to get a design quote. From 3D CAD modeling to prototype mold making to production silicone molding, we are here to help you every step of the way!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.