Can silicone rubber be injection molded

If you would like to know Can silicone rubber be injection molded? Do you need to know what kind of object form silicone material has?

There are two kinds of object forms for silicone material. One is HTV Solid silicone. Another one is LSR Silicone Rubber. Then, There are two types of moldable silicone raw materials:

- High Consistency Rubber (HCR/HTV) and Liquid Silicone Rubber (LSR).

- HTV /HCR has the consistency of solid silicone. The catalyst can be platinum or peroxide and is compounded with the base via a two-roll mill.

HTV/HCR can be molded via compression molding or transfer molding. With compression molding, the material is placed between two plates. The heated plates are compressed, and the excess seeps out along the parting line. This is an older technology but can still be a cost-effective method for low-volume parts.

Further Reading: Silicone Material

Transfer molding differs from compression molding in that the press transfers the material through a runner, sprue and gate system into the cavity of the mold. Transfer molding can be a preferred processing method for silicone parts requiring unique material properties or low to mid-range annual volumes.

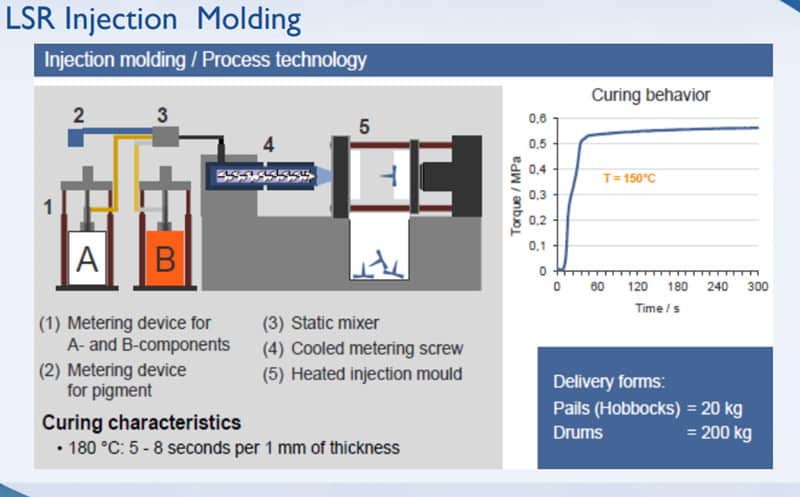

Liquid silicone rubber (LSR) molding is a thermoset process that mixes a two-component compound together, which is then heat cured in the mold with a platinum catalyst to produce a final part.

Liquid Silicon Rubber parts are formed through an injection-molding process similar to that of conventional plastic injection molding with one major difference — the material delivery system is cooled and the mold is heated. Liquid silicone rubber possesses thermal, chemical and electrical resistance, plus biocompatibility.

Also, Liquid Silicone Rubber parts can withstand sterilization while maintaining physical properties at extreme temperatures.

The most recent processing technology in silicone molding is liquid injection molding (LIM), which uses LSR material. LSR is the consistency of corn syrup, is supplied in drums, and uses a platinum catalyst. Within LIM molding, there are a variety of sub-categorizations and associated technologies including Silicone injection molding, silicone over-molding, two-shot molding and micro molding.

Silicone Over Silicone-First a silicone substrate is molded. Then another silicone is molded onto or around the substrate. The silicone could differ in color and/or hardness.

Silicone Over Plastic – First a rigid plastic substrate is molded. Then a soft Silicone is molded onto or around the substrate. This is often used to give a soft grip area to a rigid part.

Silicone Over Metal-First a metal substrate is machined, cast or formed. Then, the substrate is inserted into a liquid silicone molding tool and the silicone is molded onto or around the metal. This is often used to capture metal components in a silicone part.

So, Then answer is silicone rubber be injection molded. But only the Liquid Silicone Rubber can be injection molded.

Z.S.R Group works closely for achieving high-quality custom LSR injection molded silicone products for your company. Get in touch to discuss how their liquid silicone rubber injection molding services can be utilized in your next design. Visit their website for more information.

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.