21 Misconceptions About Liquid Silicone Rubber

The silicone family consists of a wide variety of compounds and is probably the most widely used family of materials in the world. Liquid silicone rubber materials can be used in consumer products such as electrical and electronics, astronomy, biotechnology, as well as in the automotive, aviation, beverage, construction, paint, plumbing, textile and toy industries.

There are some myths and misconceptions about silicone materials as a whole, including liquid silicone rubber, which prevent some practitioners from using these materials with complete confidence. Below are the most common myths about the silicone material family, with a specific focus on liquid silicone rubber, and simple explanations of why each material is inaccurate.

What is Liquid Silicone Rubber?

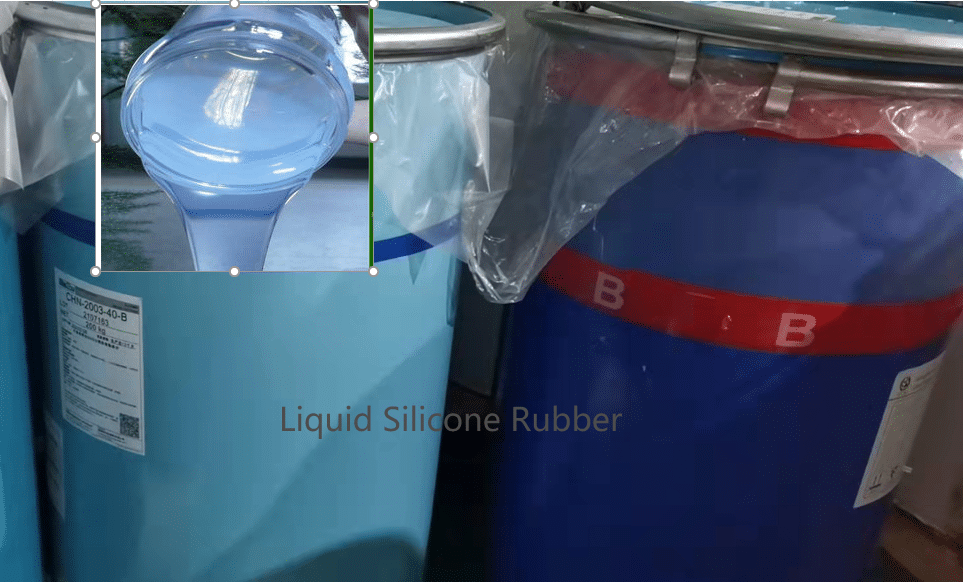

LSR is the abbreviation of Liquid Silicone Rubber, which means liquid silicone rubber (potting glue). In fact, all silicone products that are liquid before curing and elastomer after curing can be called LSR (liquid silicone rubber). However, LSR is usually referred to as liquid silicone rubber in a narrow sense.

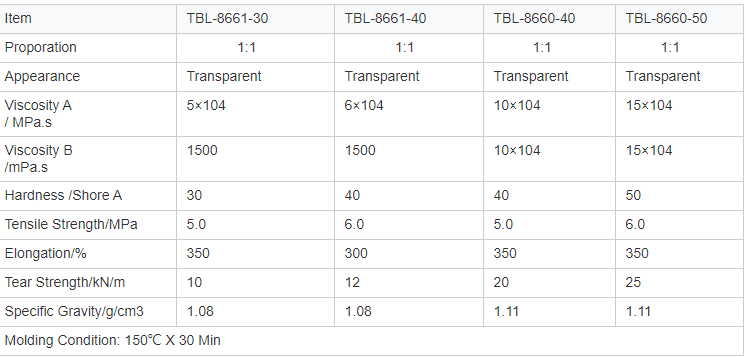

GE defines it as follows: LSR refers to a two-component addition silicone rubber that produces elastomers by injection molding in a 1:1 weight or volume ratio, which is LIM (Liquid Injection Molding) in the SHINETSU product classification. It refers to silicone rubber specifically used for injection molding and is often used to make large-scale standard parts.

The LSR in DOWCORNING’s product classification includes not only injection molding products but also colorless and transparent two-component addition silicone rubber mixed in a 1:1 ratio such as conformal coatings. According to DOW CORNING, LSR refers to a colorless, transparent or translucent, high viscosity (generally greater than 10Pa”S), two-component addition-molded rubber in a 1:1 weight or volume ratio. It can be used to make transparent and translucent silicone rubber products, and can also be used with pigments, primers, etc.

Misconceptions 1: Silicone is a chemical element or ingredient

The first silicone products that come to mind are usually breast implants, lubricants, an ingredient in certain cosmetics, and can even be confused with silicone. The reality is that silicones are a family of chemicals that come in different states (liquid, gel, solid). Specifically, silicone rubbers, which are long molecules formed from silicon (Si) and oxygen (O), can have different properties and be used in different applications depending on how they are arranged.

Misconceptions 2: Silicone rubber is a synthetic material

Silicone rubber, including liquid silicone rubber, is synthetic in the sense that its synthesis is created by humans. However, the raw materials are completely natural: sand or “silicon dioxide” is formed from silicon and oxygen. In fact, humans have been using natural silicon materials in arrowheads and bowls for many years. Although silicon, silicon dioxide, and silicone are different, the confusion is understandable. To clarify: Silicon is a chemical element; silicon dioxide is a type of silicon dioxide (sand) used to produce the silicone family of materials.

Misconceptions 3: Silicone rubber can only be processed and applied at high temperatures

There are different types of silicones, such as room temperature vulcanizing (RTV) silicone rubber that can be processed and applied at room temperature. If the application requires the use of liquid silicone rubber (LSR), it can be modified so that it can be molded and vulcanized at low temperatures. This is mainly used in electrical and electronic applications and the production of silicone molds.

Misconceptions 4: LSR materials can be used at any temperature

Although the temperature range is wide, different types of LSR have different maximum temperature resistances, and the appropriate variety must be selected according to the use environment.

Misconceptions 5: Silicone rubber is sticky

This myth is related to the touch of silicone rubber. Generally, people tend to think that all silicone rubber is sticky, but this depends on the processing and application requirements. For example, in cable insulation or medical applications using liquid silicone rubber, the surface of the part must be as smooth as possible without a sticky feeling. The silicone rubber formula can be modified to add mica or change the processing conditions.

Misconceptions 6: Silicone rubber is soft and elastic

The Shore hardness is a scale used to measure the hardness of silicone. For example, a rubber band has a Shore hardness of 25, while rollers or skates have a Shore hardness of 100. It is generally believed that all silicones have a hardness of less than 40 Shore hardness, so they are considered to have low mechanical properties. However, this is not the case. There are many ways to increase the hardness of silicone rubber, such as creating more cross-links or adding fillers. For example, the Shore hardness of optical liquid silicone rubber is 70, which is almost non-elastic.

Misconceptions 7: The lower the hardness of the LSR material, the better the elasticity

Hardness and elasticity are not simply proportional, and the design needs to take into account the application requirements.

Misconceptions 8: Silicone rubber produces a lot of smoke when burning

It is believed that burning silicone rubber produces smoke and gas, which is unfavorable for some applications. In fact, silicone rubber is inherently self-extinguishing. Depending on the matching of silicone rubber, adding flame retardants can completely eliminate the generation of gas and smoke and meet standard requirements.

Misconceptions 9: Silicone rubber will cause atmospheric pollution

Chemicals that cause environmental pollution are volatile organic compounds (VOCs), such as acetone, alcohol, methacrylate, acetate, etc. Chlorofluorocarbon compounds (CFCs) have been determined to have an impact on the ozone layer. Due to their inorganic nature, organosilicon compounds or mixtures do not contain these chemicals that cause pollution.

Misconceptions 10: Silicone rubber takes thousands of years to degrade

By the literal definition of biodegradability, silicone rubber is non-biodegradable. However, under certain environmental conditions, the silicon-oxygen backbone can break down into water, silicic acid, and carbon dioxide. Sunlight and atmospheric oxygen produce low molecular weight silicone chains (cyclopentasiloxane). When they are buried, soil minerals act as catalysts, accelerating chain breakage and degrading silicone rubber in just a few days.

Misconceptions 11: LSR can be recycled like thermoplastics

In fact, LSR is a thermosetting rubber that cannot be melt-recycled after curing and requires physical or chemical recycling techniques.

Misconceptions 12: Silicone can cause allergies and irritation

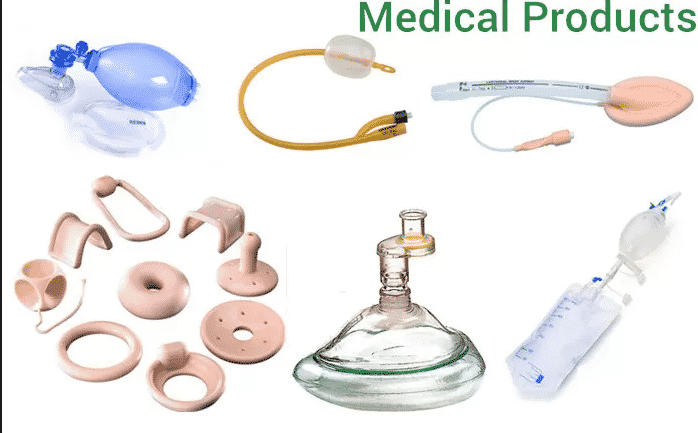

Many studies have been conducted on this topic, and unlike other types of rubber (i.e. natural latex rubber), silicone rubber does not irritate the skin or produce allergic reactions. In fact, the inherent biological inertness of silicones (including liquid silicone rubber) is an advantage.

Misconceptions 13: Silicone rubber is bioaccumulative in the human body

Bioaccumulation is “the accumulation of toxic substances in the tissues of living organisms. This occurs when the rate of ingestion of a substance is greater than the rate of excretion or metabolic transformation of the substance”. In extensive testing, silicone rubber has excellent compatibility with human tissues and fluids compared to other elastomers, and has extremely low tissue reactions when implanted. Odorless and tasteless, silicone does not support bacterial growth and will not stain or corrode other materials. Their formulations generally comply with FDA, ISO and third-party medical product biocompatibility guidelines.

Misconceptions 14: LSR products are absolutely safe and do not pose any allergic risk

Most LSRs are non-toxic, but may still cause allergic reactions in a very small number of sensitive people.

Misconceptions 15: All LSR materials are suitable for food-grade and medical-grade applications

The performance and certification of LSRs with different formulations vary significantly and need to be selected according to specific regulations (FDA, USP Class VI, etc.).

Misconceptions 16: Silicone rubber can cause disease

Since many applications of silicone rubber come into contact with the human body or food, there is a concern that the material can cause disease. In terms of the release of molecules during application, they are too large to penetrate tissue. The U.S. Food and Drug Administration (FDA) is very strict about materials that come into contact with humans and has approved them for use with consumables such as food and beverages. Food-safe silicone can also be used in the cosmetics and pharmaceutical industries.

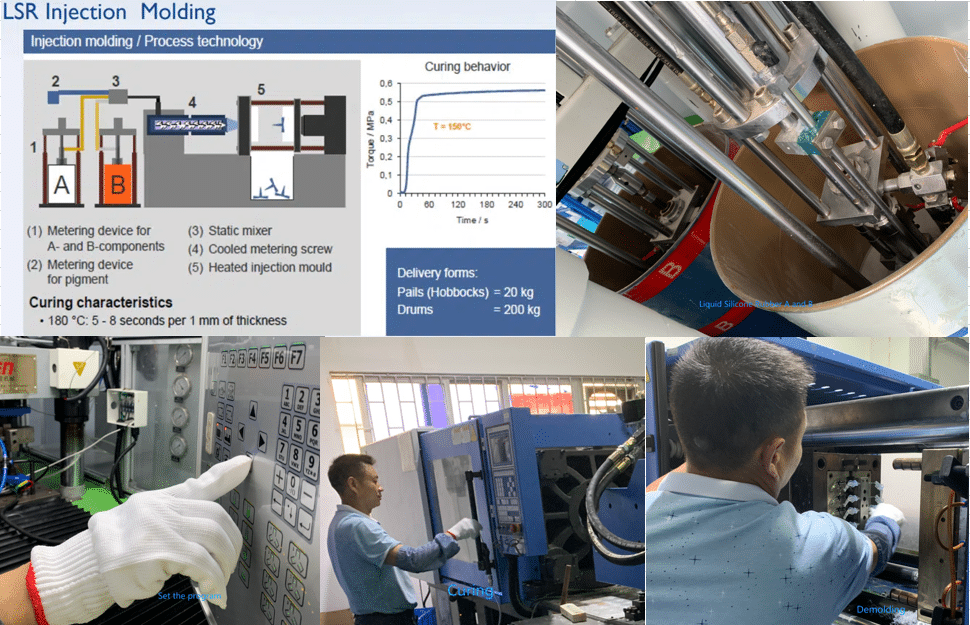

Misconceptions 17: LSR injection molding is simple and requires few processes adjustments

The LSR molding process is complex and requires strict control of temperature, pressure, mixing ratio and vulcanization time.

Misconceptions 18: LSR products do not require post-processing

Some LSR products require mold release cleaning, secondary vulcanization or surface treatment to ensure stable performance.

Misconceptions 19: LSR can replace all rubber materials

Other rubbers may be more suitable in certain high-wear or extreme mechanical load environments.

Misconceptions 20: LSR products are inevitably expensive and not suitable for the mass market

Large-scale production and process optimization can effectively reduce costs and are suitable for a wide range of applications.

Misconceptions 21: LSR has unlimited color and transparency

Due to material properties, the transparency and color range are limited.

Why we choose the LSR?

LSR Application areas

L.S.R Production process

The production of liquid silicone rubber mainly includes raw material preparation, mixing, injection molding or extrusion molding, post-processing and inspection. During the mixing process, the ratio of base polymer to cross-linking agent and the amount of catalyst must be precisely controlled to ensure the stability of product performance. During the molding process, complex shapes and high-precision products can be manufactured through precise mold design and temperature control. Post-processing includes curing, deburring, cleaning, inspection, etc. to ensure the final quality of the product.

With Z.S.R Unlimited custom silicone molding service, Z.S.R custom silicone products manufacturing for diverse needs of worldwide—from sketch to final delivery, ensuring quality products for different industry application from industrial, residential, commercial to medical.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from LSR molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Liquid Silicone Rubber (LSR) Injection Molding

More FAQ about LSR

Q1: What is the difference between liquid silicone and ordinary silicone?

A1: Liquid silicone is a two-component injection moldable material, while ordinary silicone is mostly solid or sheet-like, and the molding method is different.

Q2: Can LSR products be sterilized at high temperatures?

A2: Most LSRs can withstand high-temperature sterilization, but the specific temperature limit needs to be confirmed based on the material grade.

Q3: Can LSR products be dyed?

A3: Yes, special color pastes must be used, and the color stability is related to the material formula.

Summary

As a high-performance elastomer material, liquid silicone rubber has a wide range of application prospects. However, there are many misunderstandings about its performance and application. In-depth understanding and scientific selection are the key to ensuring product quality and reducing risks. Silicone product application and sales companies should combine their own needs, with the help of professional supplier technical support, reasonably design and control processes, to maximize the value of LSR materials. Through correct understanding and effective application, LSR will help more industries achieve innovative breakthroughs.

If you need LSR material selection and process guidance for specific industry applications, please contact Z.S.R’s material and injection molding experts. We will recommend suitable materials based on the application scenarios and needs of your silicone project to help your silicone project succeed.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.