FDA regulations on silicone products:A Comprehensive Analysis

FDA certification is a requirement for almost all companies exporting silicone products to the US market. Whether it’s silicone pacifiers, silicone kitchenware, or silicone medical devices, without FDA compliance, customers won’t be able to gain trust and access mainstream US distribution channels. So, what exactly are the FDA’s regulations for silicone products? How can companies pass their audits? What precautions should be taken during product development, production, testing, and cleaning? This article, combining regulatory text, user feedback, and authoritative analysis, systematically analyzes FDA requirements and provides practical advice to help you design and promote silicone products legally, compliantly, and safely.

What is FDA certification?

FDA testing for silicone primarily includes:

- Chemical composition analysis

- Chemical composition analysis examines the silicone for harmful substances, such as heavy metals, plasticizers, or other chemicals that could be harmful to the human body.

- Migration testing

- Migration testing simulates the liquids or foods that the silicone might come into contact with during actual use, detecting any release of harmful substances.

- Physical property testing

- Physical property testing includes tests for high temperature resistance and aging resistance to ensure the silicone’s safety over long-term use is not affected by environmental changes.

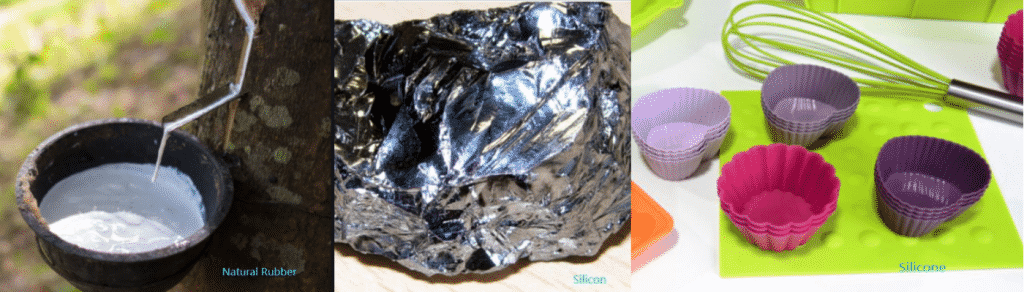

The FDA (U.S. Food and Drug Administration) is a U.S. government agency responsible for ensuring the safety of food, drugs, medical devices, cosmetics, and related materials. For silicone products, the FDA primarily regulates the following categories:

Food contact silicone products (FDA 21 CFR 177.2600), infant and toddler contact products (pacifiers, teethers, and baby bottle accessories).

The FDA has specific regulations for silicone products labeled “rubber articles intended for repeated use,” which apply to food contact applications such as kitchenware, baby bottle parts, and seals. These materials must meet the following requirements:

The material must be regulated under CFR Title 21 §177.2600. Raw material requirements: FDA-certified masterbatches and platinum vulcanizers must be used, and vulcanizers containing heavy metals (lead, cadmium, mercury) must be avoided.

Materials must not release hazardous substances under specified conditions.

Required testing typically includes:

- Overall migration

- Potassium permanganate consumption (KMnO₄)

- Heavy metals (lead, cadmium, etc.)

- Volatile substances

- Residual catalysts or additives

Common test media:

- Distilled water

- 3% acetic acid

- 10% ethanol

- N-hexane (fatty simulant)

Total migration levels must not exceed the following limits in the extraction test:

- Water extraction: ≤20 mg/in² (first 7 hours), ≤1 mg/in² (secondary 2 hours);

- Lipid extraction: ≤175 mg/in² (first 7 hours), ≤4 mg/in² (secondary 2 hours).

- EU: Complies with EU 10/2011 + EU 1935/2004 + EU 2023/2006

Applicable regulations:

- EU Regulation 10/2011: Food contact plastics, including silicone (organic polymers);

- EU Regulation 1935/2004: General Regulation for food contact materials;

- EU Regulation 2023/2006: Good Manufacturing Practice (GMP) regulations. Key Requirements:

Material safety and no excessive migration during normal use;

Overall Migration Limit (OML) ≤ 10 mg/dm²;

Specific Migration Limit (SML): Some substances have migration limits, such as:

Lead (Pb) ≤ 0.01 mg/kg

Cadmium (Cd) ≤ 0.002 mg/kg

A Declaration of Compliance (DoC) is required;

Three migration tests are required (the average or maximum value of the three tests is taken);

Testing with food simulants (A, B, C, D1, D2, etc., depending on the food type);

Recommended Documents (US/EU Common)

Document Name Description:

- Ingredients and Formula: Includes the ingredients and proportions of all raw materials and additives;

- Material Safety Data Sheet (MSDS): Chemical Safety Information;

- Test Report (Third-Party Laboratory): Includes overall migration, SML, heavy metal, and volatility testing;

- Declaration of Compliance (DoC): Mandatory in the EU and recommended in the US, stating that the product complies with relevant regulations;

- GMP documentation or quality control procedures: In particular, the EU requires good manufacturing practices.

Overview of Common Test Items

Test Items: US FDA, EU 10/2011, Total Migration Level, Specific Migration Level (SML), Heavy Metals (Pb/Cd), Volatile Substances, Sensory Tests (Odor/Flavor),

Additives must be GRAS (Generally Recognized as Safe) or otherwise approved.

Medical device silicone components (catheters, seals, prostheses, etc.)

FDA certification is not a single “certificate.” Instead, companies must provide a declaration of compliance and test reports to demonstrate that their materials and products comply with relevant regulations.

Z.S.R have help more than 100 brand clients with 30.00 silicone project get the FDA or LFGB certification for their products.

Why do silicone products need to comply with FDA regulations?

- To ensure health and safety, FDA-certified products ensure food contact safety and the absence of harmful chemical migration.

- Without an FDA Declaration of Conformity, US importers will not purchase, and e-commerce platforms (such as Amazon) will remove the product from their shelves.

- To enhance brand trust, FDA certification endorsements increase consumer confidence and willingness to purchase. FDA compliance means that product materials are safe, non-toxic, and harmless, preventing consumer complaints and claims.

- Non-compliant products may be seized by US Customs or even recalled, resulting in significant losses for the company.

- FDA certification allows entry into high-barrier markets such as food and medical.

Contact Z.S.R to create durable, compliant, brand-ready high-temperature resistance silicone solutions.

Who needs FDA certification?

Manufacturers: Silicone product factories, OEM/ODM manufacturers.

Z.S.R. closely monitors FDA certification standards. We select FDA-certified materials for silicone raw materials, curing agents, colorants, and other materials, ensuring that the products we help our clients produce pass FDA testing.

Z.S.R. partners with brands from over 40 countries, exporting baby products, pacifiers, teethers, kitchen supplies like baking mats and seals, and medical device manufacturers like tubing, catheters, and seals to the United States. These brands prioritize FDA certification.

Z.S.R.’s export companies are involved in regulatory requirements for exports to the United States. Z.S.R.’s distributors/e-commerce sellers include sellers on platforms like Amazon and Walmart.

End customers: Consumers who are particularly concerned about health and safety, such as mothers and medical institutions in the United States, Europe, China, and Japan.

Z.S.R custom silicone products are made with FDA-approved material. ZSR Group has rich experience in producing Custom silicone products with FDA or LFGB approved standards. We have the FDA register list number.

When is FDA certification required?

Where is the scope of FDA certification?

US market: All food-contact silicone products and medical-related silicone products entering the US.

Kitchen silicone products: Baking, storage, and cooking utensils;

Baby products: Pacifiers and soothers;

Medical seals: Catheters and medical seals;

Food equipment parts: Pipes and gaskets involved in the food distribution process.

Indirectly impacted markets: Canada, Mexico, and some South American countries will reference FDA standards.

Globalization of e-commerce platforms: Amazon Europe also requires reference to FDA standards for some categories.

Z.S.R’s team work with the different industries brand’s Owners, products development managers,products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure 10,600 silicone projects success.

Custom Silicone Products | OEM/ODM Service

How can products comply with FDA regulations?

Material Selection: Choose medical-grade materials that meet FDA 177.2600, USP Class VI, or USP Class V standards (such as those from Dow Corning, Shin-Etsu, and Wacker).

Testing: Migration testing should be performed by third-party laboratories such as SGS, Intertek, TUV Rheinland, and BV to ensure compliance with water and fat extraction standards.

Verification: Raw material traceability records and batch reports must be maintained during the production of silicone products.

Record-filing: Before exporting to the US, a Food Contact Substance notification must be submitted to the FDA or an exemption must be obtained.

Z.S.R help the brands and customer send our finished samples or Pre-production samples to SGS or Intertek to get the FDA certification.

How can FDA-compliant silicone products be produced?

First, choose materials: Choose FDA food-grade/medical-grade silicone materials, especially those certified by the FDA and LFGB.

Silicone Molds: Ensure that the steel molds produced are free of heavy metal contamination to avoid secondary contamination.

Production Process: Use high-temperature compression molding or liquid injection molding, and control the amount of vulcanizing agent used.

Testing: After silicone products are produced, they should be sent to a reputable laboratory (such as SGS or TÜV) for testing and an FDA CFR 21 compliance report.

Z.S.R molded silicone products Quality Control Inspection is from supplier selection, production specification, In-process Inspection, Before shipment inspection (OQC). We also accept the customer hire the 3rd party to pre-shipment QC include Full inspection if needed.

How much does it cost to get FDA certification for your product?

Food-grade silicone testing: Approximately $1,500–2,500 per material. You also can add CP65, CPSIA, TSCA test with SGS if you need sales in USA Market. If EU market, you can use 1935/2004/EC. In Germany,

Medical-grade silicone testing: More stringent, ranging from approximately $5,000–10,000.

Turnaround: 2–6 weeks.

How to choose FDA-compliant silicone and silicone products?

- Choose a raw material supplier with a COA (Declaration of Conformity) and an FDA-certified manufacturing facility.

- Confirm that the supplier’s materials have an FDA CFR 21 testing report.

- Perform migration testing on finished products to ensure safety in actual use.

How to control the quality of silicone products?

- Establish an IQC incoming material inspection system to ensure that each batch of silicone meets specifications.

- Avoid the use of recycled materials, inferior masterbatches, and vulcanizing agents during production.

- Perform random inspections of finished products for odor, tensile strength, and high-temperature resistance testing.

How to clean FDA-approved silicone products?

For individuals: You can clean with warm water and a baby-safe detergent.

Manufacturers: Products should be sterilized at high temperatures before leaving the factory to prevent contamination.

More FAQs

1.Is FDA certification a certificate?

No, the FDA does not issue certificates. Instead, it requires companies to provide test reports and a declaration of compliance.

2.What are the standards for migration testing required by the FDA?

According to 21 CFR 177.2600, products contacting “aqueous foods” and “fat-soluble foods” are extracted using reflux with water and n-hexane, respectively. The compliance values are detailed in the regulatory section.

3.Do all silicone products require FDA registration?

All products intended for contact with food or drugs must comply with FDA requirements, but non-food contact applications do not. Food contact and medical products entering the US market do.

4.Which standard is more stringent, the FDA or the LFGB?

LFGB involves more migration testing, but the FDA’s regulations are more international, making compliance with both more authoritative.

5.How can ordinary home users identify qualified silicone?

Look for the FDA logo, platinum curing, and non-toxic material declaration. Avoid cheap products with bright, opaque colors or unclear markings. If necessary, consult the manufacturer’s report.

6.Are pacifiers and kitchenware subject to the same regulatory standards?

Children’s pacifiers must also meet medical safety standards such as USP Class VI and ISO 10993, which are higher than those for ordinary kitchenware.

7.What is the difference between food-grade silicone and medical-grade silicone?

Food-grade silicone is primarily used in kitchenware and baby products, while medical-grade silicone has higher requirements and must meet safety requirements for implants or long-term contact.

8.Is FDA certification valid once and for all?

No. Retesting is required after any changes to raw materials or processes.

Summary

FDA regulation of silicone products extends beyond a single certificate; it encompasses a comprehensive process encompassing raw material selection, production processes, testing and certification, and market access. FDA regulation of silicone products is centered around 21 CFR 177.2600, encompassing multiple dimensions, including migration limits, production processes, and safe material screening. Compliance not only ensures health and safety but also serves as a brand’s gateway to the food and medical sectors. For clients focused on certification, cleanliness, safety, and longevity, companies should create transparent labeling, educational content, and comprehensive service packages to enhance trust and market influence. Companies seeking a long-term presence in the US market must ensure that silicone materials comply with FDA regulations from the source and continuously reinforce compliance throughout production and marketing.

In ZSR Group, We have rich experience in producing Custom silicone products with FDA or LFGB Approved standard products. If you need a compliance assessment or project plan tailored to your brand, please feel free to contact Z.S.R. Group. Our dedicated team can provide expert consultation!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.