How to test silicone quality?

Silicone rubber is a commonly used industrial material, widely used in mats, medical, food, kitchen supplies, baby products, industrial seals and other fields. Good quality silicone not only has stable performance, but also provides users with a safe, environmentally friendly and long-lasting experience. However, there are a large number of low-quality products on the market that contain fillers, have strong odors, poor elasticity, and are poorly vulcanized. In order to ensure that the quality and performance of silicone products meet the requirements, various tests are required. This article will introduce several commonly used silicone product testing methods to provide practical strategies for brands and consumers.

Z.S.R offer stable and highly durable, resistant to heat or cold (- 40 °C – 230 °C), chemicals, and UV damage Silicone products. They are easy cleaning, molded wide variety of shapes and sizes, colors, soft, flexibly, comfortable and BPA-free, no phthalate and lead, safe with Non-toxic and harmless, environmentally friendly, food touch safe, good biocompatibility. Sustainable & Recyclable.

What is Silicone Quality Testing?

Silicone product quality testing is a process of comprehensively evaluating the safety, performance and quality of silicone products through a series of scientific methods, mainly including the following tests:

1. Appearance inspection: Appearance inspection is one of the most basic test methods. The quality of silicone products is judged by observing with the naked eye whether the surface is flat, smooth, free of bubbles and impurities. Appearance inspection mainly includes whether there is color difference, transparency, surface flatness, whether the edges are neat, etc.

2. Hand feel test: Silicone products usually have a soft and smooth texture and good elasticity due to the use of high-quality silicone raw materials, and can easily restore to their original state. In contrast, counterfeit and inferior silicone products often have a hard texture, rough feel, poor elasticity, and are easy to stretch or deform. Therefore, by touching and observing the texture and elasticity of the product, the authenticity of the silicone can be preliminarily judged, and gently pinching to observe whether it turns white and whether it restores its shape.

3. Odor identification: Whether there is no odor or chemical smell, real silicone products usually have light or odorless characteristics. Counterfeit and inferior silicone products often have pungent chemical odors or odors due to the addition of a large number of industrial raw materials and additives. Therefore, by getting close to your nose and smelling the smell of silicone products, you can also effectively distinguish their authenticity.

Functional verification, sealing: evaluate the sealing effect of the sealing strip/seal ring through water pressure and air pressure tests. Aging resistance: simulate ultraviolet rays, high temperature and other environments to observe changes in material properties.

4.Combustion test: Combustion test is an effective way to identify the authenticity of silicone. Genuine silicone products will produce white smoke when burning, and the remaining residue is white powder. Counterfeit and inferior silicone products will produce black smoke when burning, and the remaining residue is black powder. By conducting a simple combustion test, you can visually observe the performance of silicone products when burning, so as to judge their authenticity.

5.Physical properties: Hardness test: use a hardness tester to measure the compression hardness of silicone and evaluate the elasticity of the material. Temperature resistance: verify the anti-aging ability of the material through high temperature (280℃) or low temperature (-40℃) tests. Dimensional accuracy: measure whether the product size meets the design requirements (the error is controlled within 0.1mm), and at the same time, the tensile strength, elongation at break and other indicators of silicone products can be measured by the tensile testing machine. These indicators can evaluate the tensile properties and durability of silicone products. Tensile, rebound, and tear resistance.

6.Chemical safety: Detect whether there are harmful chemicals (such as heavy metals, plasticizers, etc.) in silicone to ensure compliance with food grade, medical grade and other safety standards, and volatile organic compounds (VOC) and heavy metal migration tests in food grade testing.

7.Biocompatibility: Ensure that there is no adverse reaction when silicone comes into contact with the human body (applicable to the medical field).

Why test the silicone quality?

The quality testing of silicone products is mainly used to ensure the safety, durability and compliance of silicone products with the standards of specific application scenarios. Improve customer trust, enhance brand image, and reduce the risk of legal disputes and returns:

Ensure safe use

Biocompatibility testingEvaluate the compatibility of silicone with human cells to avoid allergic or toxic reactions (such as cytotoxicity tests, sensitization tests).

Chemical stability testingDetects oil resistance, acid and alkali resistance and other properties to ensure reliability in extreme environments (such as when medical implants come into contact with body fluids or drugs).

Evaluate physical properties

Physical properties testingIncludes tensile strength, tear strength, etc. to ensure that the material can withstand the expected stress without failure (such as medical equipment that needs to withstand repeated disinfection or deformation).

Cleanliness testingDetects surface residues (such as release agents, metal debris) to prevent contamination of food, medical parts or electronic components.

Comply with industry standards

VOC testingTargets volatile substances in high temperature environments to avoid the release of harmful substances in specific scenarios (such as high-temperature medical equipment).

UV light test Evaluate outdoor weather resistance and ensure that the physical/chemical properties of materials are stable under ultraviolet light (such as automotive seals, outdoor electronic components)

Who care the test of silicone quality?

The manufacturer is concerned about the quality testing of silicone products. The manufacturer needs to ensure the quality through raw material control and process optimization. For example, some companies use medical-grade liquid silicone and establish a raw material traceability system. They use blockchain technology to track raw material batches and production processes to ensure that there is no mixing of industrial-grade silicone and doping of recycled materials. Vacuum mixing and high-temperature vulcanization are used in the process to reduce the residual volatile substances.

Brand manufacturers of silicone products and silicone mold design and sales companies must ensure that the products they produce meet the testing standards and enhance brand awareness.

E-commerce buyers and importers of silicone products, as sellers, must ensure that the products they sell meet the quality requirements and reduce the risk of silicone product returns.

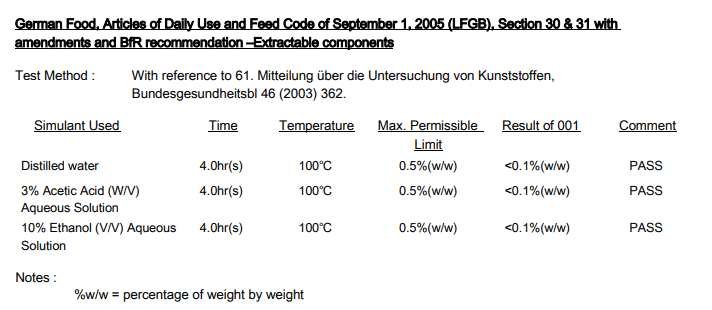

Regulatory agencies, testing agencies, and R&D, quality inspection, and compliance personnel in the industry. FDA certification requires that silicone products do not contain harmful substances such as phthalates, and LFGB certification focuses on the migration of heavy metals. The domestic GB4806 series of standards stipulate that food contact silicone must pass migration tests and light aging tests. The testing agency conducts a 220°C aging test on the silicone spatula to test indicators such as potassium permanganate consumption and heavy metals. Professional testing agencies use instrumental analysis (such as gas chromatography) to identify SVHC substances and make up for sensory testing loopholes.

What we care most about is that the buyers and users are families or parents who are sensitive to health and safety. We care about the safety of the products we buy. We can filter products by appearance identification and certification marks. For example, check the FDA, LFGB logo and quality inspection QR code on the package, choose silicone products with uniform color and no pungent smell, and avoid low-price traps.

Z.S.R’s team work with the different industries brand’s Owners, products development managers , products managers, products designers together and offer them OEM ODM solution from molded silicone products design ,prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Custom Silicone Products | OEM/ODM Service

When and where need the test of silicone quality?

As a brand or manufacturer of silicone products, we need to select laboratories and quality inspection centers during the sample acceptance stage to conduct certification tests on our products.

Batch testing before production, our company’s factory entry inspection point conducts material testing to ensure that the materials are consistent with the sample materials, and at the same time conducts other appearance, odor, physical and chemical performance tests in the factory laboratory.

Third, when silicone products need to be iterated, or our raw material suppliers change; we need to conduct a new round of testing on our products. Ensure that the alternative materials and iterative products can pass the quality test.

Fourth, when we receive market complaints or need to recall products, we need to test our bulk products and confirm again whether our products meet the quality standards.

How to test of silicone quality?

a. Appearance and hand-pinch test

During the inspection, attention should be paid to the color uniformity, transparency, surface finish, and the presence of defects such as bubbles, cracks, burrs, particles, stripes, and impurities. For products with special textures or patterns, the clarity of the pattern, the accuracy of the position, and the conformity with the design should also be checked. In addition, dimensional accuracy is also an important part of appearance inspection. Precision measuring tools should be used to verify key dimensions to ensure that the product meets the design requirements. Gently pinch to determine whether white discoloration occurs. White marks indicate that fillers are present.

b. Odor identification

Children’s products should be “odorless”. Silicone products are close to the tip of the nose. If a pungent odor is smelled, it is not food grade; food-grade silicone should have no odor. If there is a plastic smell, it may contain PVC or unqualified materials.

c. Elasticity test

The elasticity test method for silicone is a tensile test. The tensile test can determine the elasticity of silicone by testing the degree of deformation of silicone under different tensile forces. Stretch and bend it many times to observe whether it rebounds to shape and whether there are cracks. The tensile fracture strength test verifies the physical properties.

d. Simple food grade test

Odor test: bring the silicone product close to the tip of your nose. If you smell a pungent odor, it is not food grade; food grade silicone should not have any peculiar smell.

Stretching test: stretch the edge of the silicone product and observe whether the stretched area turns white. Food grade silicone remains transparent after stretching, while industrial grade silicone tends to turn white when stretched.

High temperature test: put a small piece of silicone sample into the oven and bake it at 200℃ for 30 minutes. Food grade silicone does not deform or turn yellow, while industrial grade silicone may produce a burnt smell or surface coking.

Immersion test: soak the silicone sample in 60℃ edible oil for 24 hours to observe whether it swells, changes color or has peculiar smell. Food grade silicone should maintain physical and chemical stability.

Odor description: if it smells bitter or bleaching powder, harmful substances may be added.

Certification document verification: require merchants to provide third-party test reports, focusing on verifying migration test data (such as hexane and ethanol extract content) and heavy metal test results.

e. Advanced laboratory testing

Ask a third-party testing agency to conduct migration testing and heavy metal analysis according to LFGB/FDA standards

The agency can use GC-MS/ICP-OES to accurately analyze the formula ingredients

How to choose high-temperature-resistant silicone?

Based on the application temperature range (e.g., choose ordinary silicone for temperatures under 200°C, and fluoro silicone for temperatures above 250°C).

Based on industry standards (food grade, medical grade, industrial grade).

Based on service life (long-term vs. short-term high-temperature conditions).

Z.S.R is the partner choice of custom silicone products for leading silicone products brands and retailers. Recognized for delivering innovative molded silicone products, silicone products manufacturing expertise, and silicone technical solutions to meet your brand’s functional and design needs. We will recommend the suitable temperature silicone material for your silicone projects, just contact our expert.

How much the test of silicone quality?

DIY feel test takes < 5 minutes for each silicone products

Laboratory testing costs $500–$3000/batch, with a cycle of 2–6 weeks from SGS, Intertek, BV, etc.

How to choose the test of silicone quality?

If we are a brand owner or importer, our products involve food and baby products. When we sell them, we must have an official test report. We need to ask a third-party testing organization to conduct random inspections on our bulk products and get LFGB/FDA test reports.

If we are individual consumers, we can ask the seller to show the LFGB/FDA test report. And do DIY personal testing on the products we buy. Ensure that our products meet quality requirements.

How to control the test of silicone quality?

As a manufacturer, we need to conduct factory inspections on raw materials, conduct random inspections and patrol inspections during the production process of silicone products, and we can also conduct market return visits to our customers and retest products once a year;

As a brand, we need to establish a supplier evaluation system to ensure that the products produced by the selected suppliers meet the quality standards

At the same time, we can hire an ISO-certified third-party organization to conduct third-party inspections or tests to ensure the quality of our silicone products.

How to clean the silicone samples before testing?

Please clean and dry the silicone sample before test to avoid detergent residue affecting the test.

Rinse with odorless warm water and dry naturally for 24 hours;

For details of laboratory sampling, please refer to the SOP of the testing agency.

More FAQs

1: Does it mean that the material that turns white after being squeezed is of low quality?

White means that it contains fillers but it does not necessarily mean that it is harmful; but high-purity platinum silicone generally does not turn white.

2: Can DIY testing determine food grade?

It can only make a preliminary judgment, and the results of non-laboratory migration tests are invalid.

3: Are all platinum vulcanized silicones food grade?

No, it must pass FDA/LFGB testing and obtain a test report.

4: Is it normal for the material to harden after high-temperature boiling?

There is no problem with short-term boiling, but repeated high temperatures exceeding the specifications (such as 230°C) may accelerate aging.

5: Can users detect harmful substances?

It is impossible to test heavy metals or trace migration substances at home, so it is recommended to choose certified products.

Summary

To ensure the quality of silicone products, a combination of “appearance and feel + smell + physical test + laboratory chemical test” should be adopted. All the simple appearance, feel, and smell methods we provide can only be used for quick screening, and to obtain authoritative conclusions, third-party testing such as FDA/LFGB is required. Brands should focus on transparent strategies, report support, and user education to drive product differentiation and stickiness. Only after consumers understand the testing levels and methods can they make truly qualified and safe choices and realize the conversion of purchasing motivation.

In Z.S.R Group, all the steps from raw silicone products material selection to molding, curing, and quality control, each step plays a vital role in creating your silicone products that meet safety standards and perform well in their intended applications .Connect to work with Z.S.R Group.

From 3D CAD modeling to prototyping mold to Mass Silicone production molding, third parties testing for the silicone quality, we will help you along the way!

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.