Nylon VS silicone cooking utensils

In everyday kitchens, nylon and silicone are two common materials for cooking tools. Nylon cooking tools is durable and suitable for stir-frying heavy objects, while the silicone tools is resistant to high temperatures, mild and non-stick, and easy to clean. In this regard, clients and purchasers often struggle with which one is more suitable for their cooking style and usage scenarios. This article deeply analyzes the advantages and disadvantages of the two, provides selection suggestions and marketing strategies, and helps you make accurate decisions.

What is Nylon Cooking?

Nylon cooking tools are made of polyamide (PA) and have the characteristics of high temperature resistance and wear resistance, but there are health risks.

Nylon kitchen utensils mainly include spatulas, spoons, funnels, clips, etc., which are mostly used in cooking scenes such as stir-frying and serving food.

Performance characteristics High temperature resistance: can withstand high temperatures above 200℃, suitable for daily frying.

Wear resistance: smooth surface and low friction coefficient, long service life.

Lightweight: lighter than metal tools, but moderate hardness.

What is silicone cooking utensils?

Silicone cooking tools are kitchen utensils made of food-grade silicone through molding or encapsulation technology. They are mainly used for kitchen operations such as baking, cooking, mixing, and mixing ingredients.

Silicone cooking tools are mainly divided into two categories:

Pure silicone tools: Made entirely of silicone materials, such as silicone scrapers, silicone shovels, silicone egg beaters, etc. Silicone shovels are suitable for stir-frying, and oil brushes are used to apply oil. The high temperature resistance, softness, and non-stick characteristics of silicone are used for direct cooking operations. Baking category: Silicone rolling pins and molds assist in dough processing.

Encapsulated tools: Silicone encapsulates hardware or plastic materials, such as encapsulated silicone spatulas, which protect hardware parts through the silicone layer and assist in cooking operations.

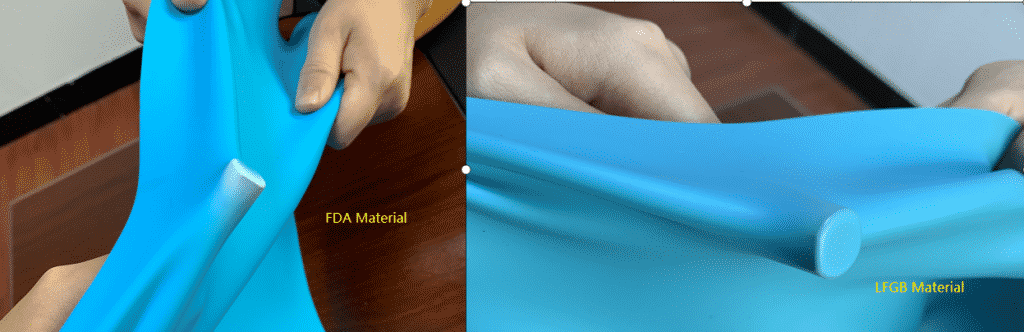

Silicone cooking tools have the characteristics of high temperature resistance (up to 200°C), environmental protection and non-toxicity (compliant with FDA/LFGB standards), anti-fouling and dirt-resistant, and easy to clean, and are gradually becoming mainstream kitchen tools.

Z.S.R is a professional custom silicone kitchen products manufacturer, specializing in food-grade, heat-resistant kitchenware such as spatulas, baking mats, lids, molds, oven mitts, and more. Perfect for private labels, promotional brands, and bulk wholesalers with full OEM/ODM customization service.

Custom Silicone Products | OEM/ODM Service

Why You Should Know the Difference Between Nylon and Silicone cooking utensils?

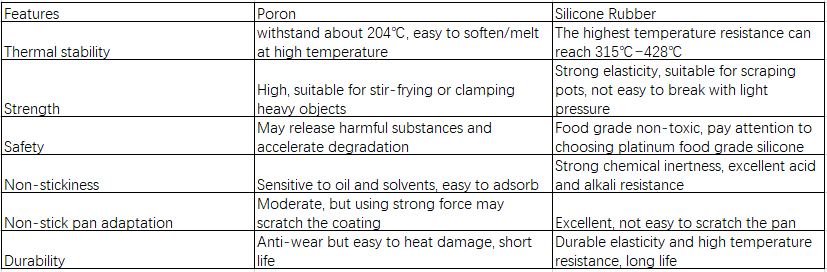

Nylon and silicone cooking utensils have significant differences in material properties, safety, and usage scenarios. Understanding these differences can help you choose more suitable utensils and avoid health risks:

Material properties

Nylon utensils (such as spatulas and spoons) are resistant to high temperatures (around 200°C), but long-term high temperatures may release carcinogens such as diaminodiphenylmethane (DDM).

Silicone utensils are more heat-resistant (300-400°C), but they must be made of food-grade silicone and have good edge sealing to prevent gas from seeping into the oil pan during frying.

Safety

Nylon utensils have a carcinogenic risk, especially black nylon products may contain benzene ring structures, which may decompose harmful substances at high temperatures.

Silicone utensils must be made of regular brand food-grade materials to avoid gas leakage or chemical seepage caused by inferior silicone.

Prioritize unpainted wood/bamboo or food-grade silicone cooking utensils to avoid metal or inferior plastic tools from damaging the pot or releasing harmful substances.

Silicone tools are preferred for high-temperature cooking (such as frying), while wooden/bamboo tools can be used for ordinary cooking.

All the silicone kitchenware in Z.S.R was Made from BPA-free, FDA/LFGB-approved silicone, heat resistant (up to 230°C/446°F) & non-stick, no toxic, Dishwasher, microwave, and freezer safe, Eco-friendly, reusable, and easy to clean. They are wide range: spatulas, baking tools, oven mitts, molds, etc.

Why Nylon VS silicone cooking utensils?

When and Where Will You Choice Nylon VS silicone cooking utensils?

For non-stick pans, baking/scraping pans, high-temperature deep-frying, pan-frying, or stir-frying meat, silicone is preferred.

For stir-frying heavy ingredients and long-handled operations, mechanical stability is stronger and nylon tools are stronger.

How to Choose the Nylon vs Silicone Cooking utensils?

- Temperature resistance requirement ≥250℃, choose silicone kitchenware, consider safety and non-stick pans, choose silicone kitchenware

- Choose kitchenware with food-grade platinum silicone or BPA-free nylon logo

- Silicone is soft and suitable for scraping, nylon is firm, judge whether the grip is suitable

- Choose dishwasher-safe kitchenware.

How much of Nylon vs Silicone Cooking utensils?

Set price: Nylon about ¥30–60, silicone about ¥60–150.

How to use nylon cooking utensils and silicone cooking utensils correctly to extend their lifespan?

Nylon cooking utensils:

Avoid high temperature environment

Nylon material has limited heat resistance (usually no more than 150℃), avoid long-term high-temperature frying or dry burning. It is recommended to use medium or low heat when cooking, and make sure the pot is preheated before putting the ingredients.

Handle with care to prevent impact

Avoid strong knocks or drops during use to prevent external impact from causing structural damage. It is recommended to stand upright or lay flat when storing to reduce stacking friction.

Timely cleaning and maintenance

Wash and dry immediately after use to avoid residual food or oil stains corroding the material. Use neutral detergent (such as detergent) for regular maintenance, and avoid using hard objects such as steel wool to scratch the surface.

Avoid extreme chemical corrosion

Avoid long-term contact with strong acids (such as vinegar), strong alkalis (such as alkaline water) or high-temperature grease, which may accelerate material aging. Thoroughly clean and dry after handling acidic ingredients.

Silicone cooking utensils:

Proper use of silicone cookware primarily involves material selection, operating procedures, and daily maintenance:

Material and Usage Environment

Avoid direct contact with open flames: Silicone cookware should not be heated directly on gas or electric stoves, as this may cause deformation or damage.

Choose food-grade silicone: High-quality silicone offers excellent elasticity and abrasion resistance, while inferior materials are prone to aging. We recommend purchasing products marked “food grade.”

Operating Instructions

Handle with care: Avoid scratching the surface with sharp objects. Handle knives and other tools with care when cooking.

Temperature Control: For frying and stir-frying, the recommended temperature should not exceed 230°C (the upper temperature limit for silicone). For stewing, the temperature can be raised slightly, but avoid drying out.

Cleaning and Maintenance

Wash promptly: Wash immediately with warm water and neutral detergent after use to prevent food residue from corroding the material.

Store dry: After washing, store in a cool, well-ventilated area to dry naturally. Avoid direct sunlight or high temperatures.

Avoid stacking: Keep the cookware flat during storage to prevent it from bending or deforming due to heavy objects.

If discoloration, deformation, or cracks occur, it is recommended to replace it promptly to ensure safety.

How to clean Nylon vs Silicone Cooking utensils?

Clean Nylon Cooking utensils

To clean cooking utensils, you need to choose the appropriate method according to the characteristics of the material. Avoid using metal utensils or strong acid and alkali cleaners. The specific steps are as follows:

- Manual cleaning: Use a neutral detergent (such as dishwashing liquid) and a soft sponge/nylon brush to scrub, and avoid excessive force that may cause material wear.

- Avoid soaking in hot water: No need to soak for a long time before cleaning, just rinse with cold water to prevent hot water from softening the material and affecting the structure.

- Treatment of stubborn stains Baking soda decontamination: Sprinkle baking soda on the stain, let it stand for 5 minutes, wipe with a soft cloth, and finally rinse with clean water.

- Boiling method: When it is severely scorched, add water and boil it, then pour it out, and repeat the operation until the stain falls off.

Contact Z.S.R to safe, stylish, and your branded custom silicone kitchen products.

Clean Silicone Nylon Cooking utensils

Silicone cookware cleaning needs to choose the appropriate method according to the type of stains. It is preferred to use mild detergent or white vinegar solution to soak and scrub. Stubborn stains can be treated with baking soda or alcohol.

- Daily cleaning method Warm water + detergent: Soak and scrub with warm water of about 40℃ and mild detergent, then rinse with clean water.

- White vinegar solution: Mix white vinegar and water in a ratio of 1:20, soak for 15-20 minutes and rinse. It is suitable for removing odors or light stains.

- Treatment of stubborn stains Baking soda paste: Mix into a paste and apply to stubborn stains, scrub with a soft brush and rinse.

- Alcohol wiping: 75% concentration of alcohol can remove oil stains, but safety needs to be tested on a small area first.

- Maintenance after cleaning Put it in a ventilated place to dry naturally after cleaning, avoid direct sunlight or high temperature baking.

Regularly boil it in boiling water or high temperature disinfection in a dishwasher can deeply remove oil.

More FAQs

1: Will nylon melt?

It starts to soften when it exceeds about 204℃, and it may deform or release substances such as BPA under long-term high temperature.

2: Does silicone have an odor?

Low-quality silicone may have residual additives. It is recommended to choose Grade A food platinum silicone.

3: Can the two be used together?

Yes. Nylon is used for stir-frying, and silicone is used for scraping the pot/non-stick protection. The two complement each other.

4: Which is more environmentally friendly?

Silicone has a long service life and is not easy to discard; nylon can be recycled, but it has a short service life and is often discarded.

5: How to avoid scratching the pot?

Soft silicone tools are preferred, and nylon is only used for stir-frying on the edge of the pot.

Summary

Nylon Cooking utensils has strong rigidity, suitable for stir-frying heavy ingredients and efficient cooking.

Silicone cooking utensils good at High temperature resistant, non-stick, easy to clean, best for stir-frying to protect pots and scrapers.

Z.S.R is One-Stop food-grade silicone utensils Supplier For Consumer Silicone Products And Silicone Molding Solution From Idea To Market. We work with the product development manager, product manager, product designer in Kitchen industry offers the Custom silicone kitchen products service with the custom silicone kitchen products shape, sizes structure, functionality, custom color, printing, Printed/engraved logos, pattern printing, label and packaging and other silicone products technical support.

Z.S.R offer silicone Kitchen products technical support to the home-ware, house-ware, DTC and e-commerce brands, private label sellers, Kitchen gadget gift sets, Cooking schools & food companies and promotional industry.

Contact Z.S.R to safe, stylish, and branded custom silicone kitchen products trusted by chefs and families alike.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.