Pros and Cons of Silicone Elastomers

Silicone elastomers have excellent heat resistance, anti-aging and safety, and are widely used in medical, maternal and child, baking, industrial seals and other fields. This article will combine industry data to comprehensively analyze the advantages and disadvantages of silicone elastomers to help designers, purchasers and brands accurately locate material selection and improve market competitiveness.

Z.S.R’s team work with the different industries brand’s Owners, products development managers, products managers, products designers together and offer them OEM ODM solution from molded silicone products design, prototyping to silicone products contract manufacturing, printing, package to ensure their silicone projects success.

Custom Silicone Products | OEM/ODM Service

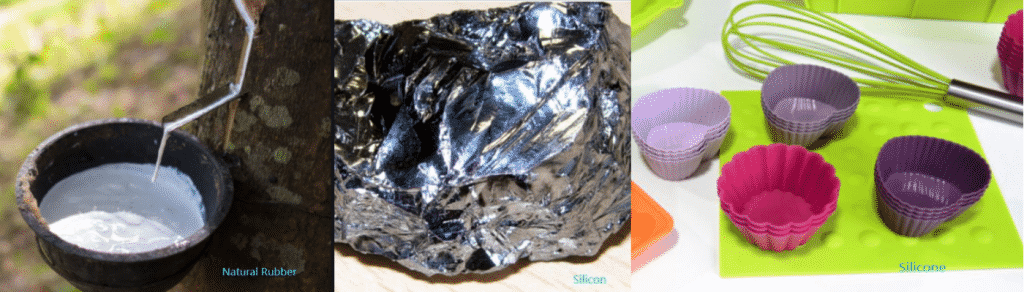

What are Silicone Elastomers?

Silicone Elastomers is an organic silicon compound, which refers to a compound containing Si-C bonds and at least one organic group directly connected to the silicon atom. It is customary to regard compounds that connect organic groups to silicon atoms through oxygen, sulfur, nitrogen, etc. as organic silicon compounds. Among them, polysiloxanes composed of silicon-oxygen bonds (-Si-O-Si-) as the skeleton are the most numerous among organic silicon compounds. They have the characteristics of high elasticity, wide temperature resistance, weather stability, and chemical inertness. They can be made into a variety of products through different formulations and molding processes such as HCR, LSR, and RTV.

The basic structural unit of organic silica gel products is composed of silicon-oxygen chain links, and the side chains are connected to various other organic groups through silicon atoms. Therefore, the structure of organic silicone products contains both “organic groups” and “inorganic structures”. This special composition and molecular structure make it a combination of the characteristics of organic matter and the functions of inorganic matter. Compared with other polymer materials, silicone products have good biocompatibility, are non-irritating, non-toxic, non-allergic to human tissues, and have very few body rejection reactions; they have good physical and chemical properties, can maintain their original elasticity and softness during contact with body fluids and tissues, and are not degraded. They are a fairly stable inert substance. They are resistant to high temperatures and can be sterilized. They are easy to process and shape, and easy to carve and use.

Why will you use the Silicone Elastomers?

Who is concerned the performance of silicone elastomers?

- Engineers/designers in silicone molding factories: They pay attention to the thermal stability, strength, and molding difficulty of silicone materials, so as to select the right materials for the right projects.

- Purchasers/brands in the silicone brand industry: Purchasers pay attention to the cost and certification of materials to ensure the reliability of silicone products;

- End consumers of silicone products (kitchenware, maternal and child products, outdoor products): They care about the safety, feel, and ease of cleaning of silicone products.

- Industrial/medical application silicone fields: They require silicone elastomer materials to comply with industry standards (FDA/LFGB/ISO/UL).

Z.S.R is the partner of choice for leading silicone products brands and retailers. The silicone products what we made suitable for various industries, including consumer, Commercial, industrial, medical. Recognized for delivering innovative custom-molded silicone products, manufacturing expertise, and technical solutions to them.

When to Use Silicone Elastomers?

When extreme temperature resistance or frequent disinfection and sterilization are required, silicone elastomers can maintain good elasticity in the range of -60℃ to 250℃, which is especially suitable for high-frequency disinfection scenarios (such as surgical instruments, orthopedic implants), and can withstand repeated high-temperature sterilization (such as 121℃ steam sterilization).

Long-term stability requirements

Silicone exhibits stronger anti-aging properties in long-term use. It is exposed to outdoor environments during application and needs anti-aging and UV resistance. It is suitable for scenarios that require long-term implantation or repeated deformation (such as orthopedic implants and seals), and its cross-linked structure gives it excellent deformation recovery. When high safety, non-toxicity and hygiene are required, the scene has requirements for material flexibility and fit: silicone pads, medical catheters.

Biocompatibility requirements

Medical-grade silicone is widely certified by ISO 10993 and has better compatibility with human tissues. It is especially suitable for sensitive skin or implantable medical devices (such as earmuffs and syringes).

When high pressure resistance or sealing performance is required, when contact with chemicals is required, silicone is oil-resistant, acid-resistant and alkali-resistant (except hydrofluoric acid and strong alkali), and is suitable for contact with disinfectants (such as alcohol and sodium hypochlorite).

Where is the silicone elastomers application?

All the silicone products what Z.S.R made are stable and highly durable, resistant to heat or cold (- 40 °C – 230 °C), chemicals, and UV damage. Easy cleaning, molded wide variety of shapes and sizes, colors, soft, flexibly, comfortable, PVC and BPA-free, no phthalate and lead, safe with Non-toxic and harmless, environmentally friendly, food touch safe, good biocompatibility. Sustainable & Recyclable.

How to use and design silicone elastomers?

Choose the appropriate formula according to the scene setting temperature and chemical resistance requirements.

If it is used in a pressure cooker, you need to choose a high-temperature resistant silicone elastomer.

If it is used on outdoor sports equipment, if tear resistance is required, use high-strength fillers or high-tensile formulas.

If the product is a consumer product or a gift, then do a good job of surface treatment or coating to reduce dust absorption.

For infant products or medical products, choose platinum vulcanization technology to improve the purity and performance of the final product.

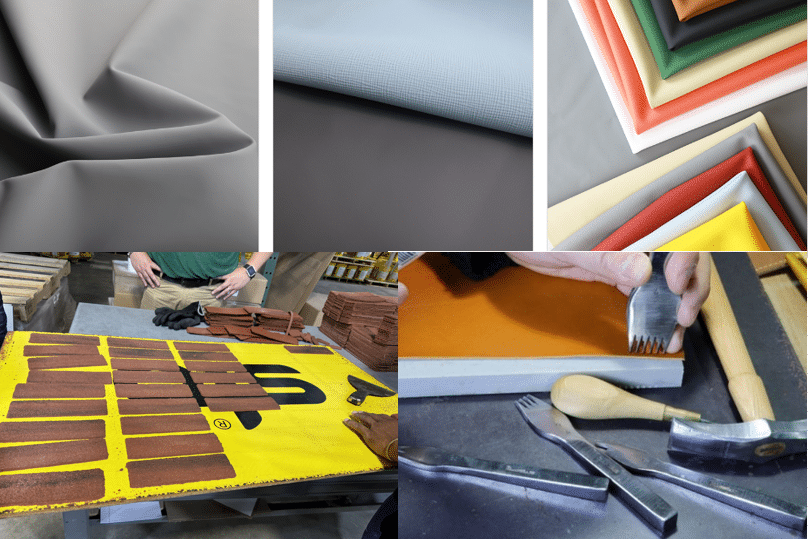

At the same time, you can consider combining other materials such as fabrics and glass fiber materials to add layers to enhance strength.

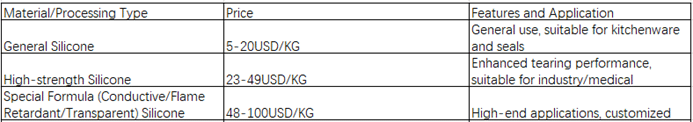

How much of the silicone elastomers?

The different type and grade silicone rubber will have the different price, you can choose the silicone elastomers according to your application and budgets to fit your projects.

Z.S.R Group have the expert team will help you to recommend the fitted silicone elastomers for your silicone projects to empower your silicone products success. Contact Z.S.R expert now.

At the same time, injection molding and extrusion molding have significant cost-effectiveness advantages in large quantities;

Small batches of high-end customization require rare costs; if possible, please choose HTV compression molding or transfer molding.

How to choose silicone elastomers?

The selection of silicone rubber materials should be determined according to the specific application scenarios and needs, and can be mainly divided into the following categories:

1. Classification by vulcanization method

Hot vulcanization type (HTV): It needs high temperature heating and molding, which is suitable for complex structural products. It has low cost but requires professional equipment.

Room temperature vulcanization type (RTV): It is divided into polycondensation reaction type and addition reaction type, which is suitable for non-structural scenarios such as bonding and potting.

2. Classification by the material form of silicone

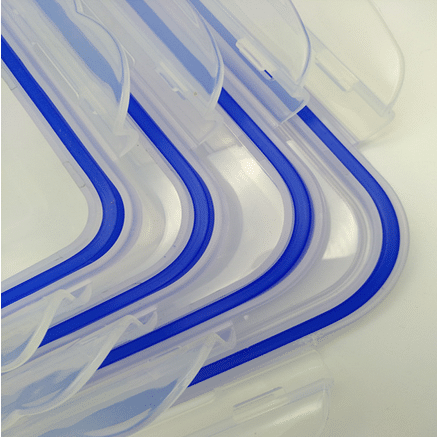

Solid silicone: It is solid, non-fluid, and has low transparency of raw materials. It usually presents milky white and translucent color. In the finished product, the burrs at the mold joint are more obvious, and the product has no injection port.

Liquid silicone: It remains liquid before curing, has fluidity, and has high transparency of raw materials. In the finished product, its mold joint line is almost invisible, the burrs are so fine that they are difficult to detect with the naked eye, and there will be injection ports on the product.

3. Choose according to different processing techniques

Hot pressing molding, pressurized vulcanization molding in the mold, suitable for products with complex shapes

Injection molding: injection molding machine injects into the mold, suitable for products with high flexibility requirements and high precision requirements

4. Classification by the final use of the product

General type: Suitable for conventional products such as industrial seals and buttons, with low cost but not suitable for food/medical scenarios.

Food grade: Meets FDA/LFGB standards and can be used for products that directly contact food such as tableware and kitchen utensils.

Medical grade: Passed ISO10993 certification, suitable for medical devices, human implants and other scenarios that are in direct contact with the human body.

Special performance type: Including conductive silicone (electronic seals), flame retardant silicone (fire safety), etc., selected according to specific needs.

5. Selection points

Temperature range: Select according to the ambient temperature of use, for example, silicone rubber that needs to withstand more than 250°C in high temperature environments. Judge the use temperature and contact substances (organic solvents, oils, water); food grade/medical grade silicone should be selected for direct contact with food or the human body.

Physical properties: Select the formula according to parameters such as hardness and tensile strength.

Processing method: Hot vulcanization is suitable for complex structures, and room temperature vulcanization is suitable for rapid prototyping.

Environmental protection and safety: Medical-grade silicone needs to pass biocompatibility testing, and food-grade silicone needs non-toxic certification

Determine the hygiene requirements (food/medical certification);

Whether the sensitive surface needs to be dustproof;

Whether special functions are required (flame retardant, conductive, transparent)

When choosing the right silicone material, you need to consider the above 5 factors and combine them with the characteristics of your silicone project to choose the right material. We have professional engineers who can help you choose materials, please contact us.

Pros and Cons of Silicone Elastomers?

Pros of silicone rubber

1. Strong high temperature resistance

Silicone rubber is a rubber material with excellent high temperature resistance. Silicone rubber will not decompose, age, or lose its special properties at high temperatures. Therefore, silicone rubber is widely used in the automotive, electronics, medical, food and other industries.

2. Corrosion resistance

Silicone rubber can withstand the corrosion of acids, alkalis and other chemicals, so it can work stably for a long time in some harsh environments such as strong acids and alkalis, and has a wide range of application value.

3. Good softness

Silicone rubber has good softness and can fit tightly with objects to avoid leakage and breakage. It is widely used in seals, pipes and valves and other fields.

4. Good wear resistance

Silicone rubber has excellent wear resistance. After long-term use, its surface is still smooth and not affected by wear. Therefore, it has been widely used in liquid transportation pipelines, food operations and medical treatment.

Cons of silicone rubber

1. High price

Compared with other rubber materials, silicone rubber is relatively expensive, so the cost needs to be considered when using silicone rubber. Silicone rubber has poor machinability, high processing difficulty and high processing cost.

2. Difficulty in manufacturing

Silicone rubber is more difficult to manufacture than other rubbers, and requires highly advanced technology and production processes, which increases production costs.

3. Poor elasticity

Silicone rubber is not as elastic as other rubbers, so it is not suitable for some high elasticity applications and needs to be replaced by other materials.

4. Low tear strength

Compared to rubber, silicone rubber products have low tear strength and are easily damaged by sharp edges or impacts. To solve this problem, fabric or rubber can be added.

5. Generally, silicone rubber has poor oil-solvent compatibility and is not suitable for fuel or alcohol environments; at the same time, the surface of silicone rubber products is easy to stick to dust and retain dust: untreated surfaces will absorb dust. Therefore, it is necessary to spray hand oil for post-processing.

6. Limited chemical compatibility

Sensitive to some catalysts and sulfides.

In short, although silicone rubber has many advantages, it also has many disadvantages. It is necessary to select materials according to the specific use environment and requirements, and apply them in combination with actual conditions.

More FAQs

Summary

Silicone elastomer is a high-performance, multi-purpose material with excellent thermal stability, weather resistance, safety and electrical properties. It is the first choice for many high-end applications. However, its cost, tear resistance and chemical compatibility issues cannot be ignored. Therefore, when we choose materials, we must accurately select the formula and process according to the ambient temperature, strength requirements, material budget and cleaning requirements, so that your products can better fit your target market.

Contact Z.S.R to create your own business line of silicone products.

Further Reading

Technical Related

About Author: Z.S.R International Group

Z.S.R International Group(Hong Kong) co., Limited, is a one-stop supplier for molded silicone products and silicone products molding solution provider in the consumer products field. We offer OEM services from silicone product design to Silicone products contract manufacturing. We have the capability for custom silicone tooling, LSR(Liquid silicone Rubber) molded silicone products, solid silicone molded products, molded silicone multi-colored products. We also can custom molded silicone, custom molded LSR, custom molded dripping injection dispensing(co-injection) silicone multi-colored products.